Method For Monitoring A Temperature Control Media Supply

A temperature-regulating medium and supply device technology, which is applied in the field of temperature-regulating medium supply devices, can solve problems such as pressure fluctuations that cannot be considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

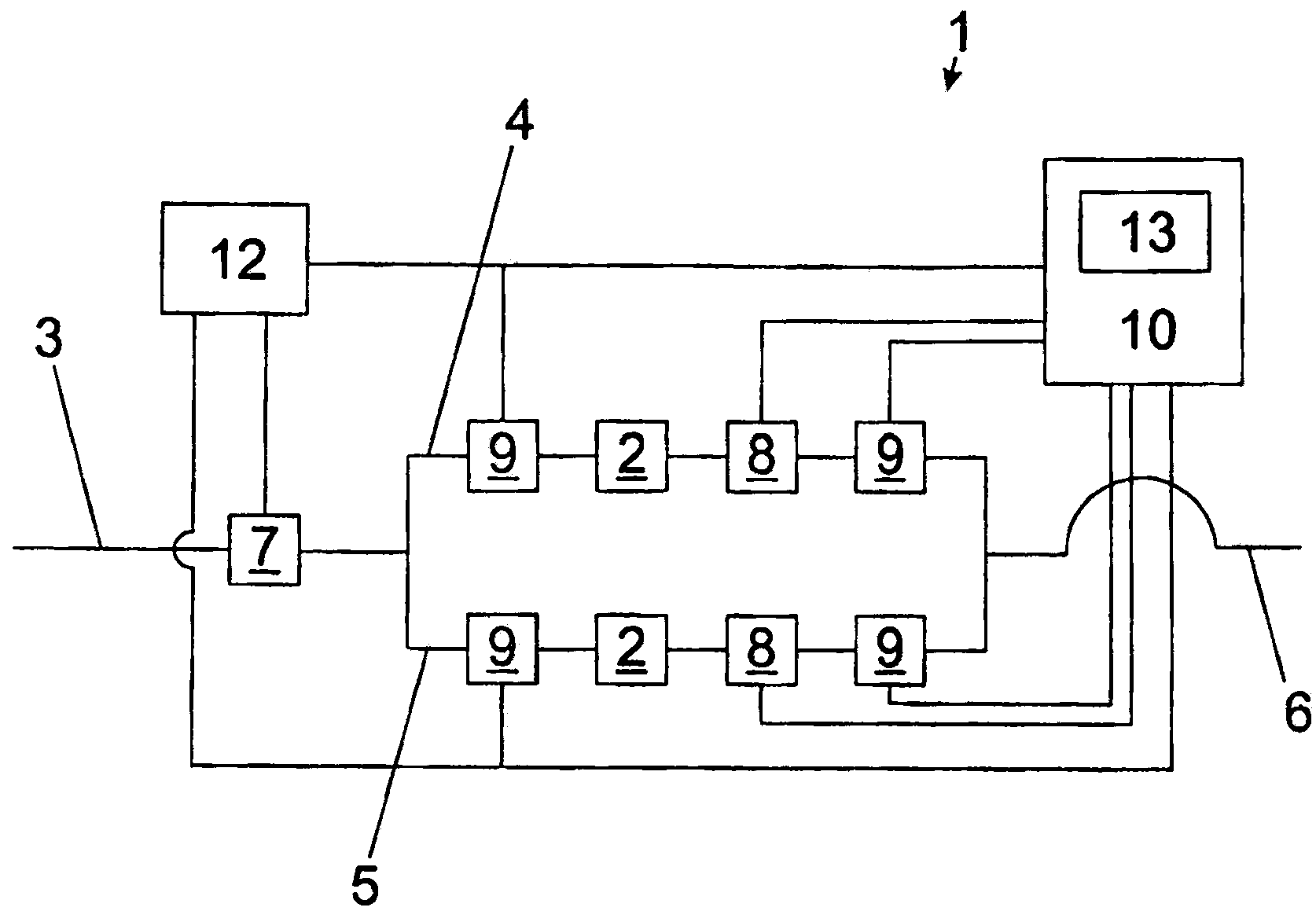

[0032] figure 1 In the figure, the inflow end 3 of the temperature control device 1 , the temperature control lines 4 and 5 and the return end 6 can be seen first. Tempering lines 4 and 5 pass through mold 2 , which is thereby tempered. Furthermore, two pressure sensors 9 and one flow sensor 8 are arranged in each of the temperature control lines 4 and 5 , which are respectively connected to an analysis device 10 . Analysis device 10 has screen 13, alarm signal or by means of formula The calculated hydraulic resistance can be displayed on this screen. In addition, an alarm signal can be displayed on the screen 13 when one of the hydraulic resistances R leaves an allowable range.

[0033] In this exemplary embodiment, the flow through the temperature control lines 4 , 5 is regulated by means of a flow control valve 7 . For this purpose, the control device 12 is connected not only to the flow regulating valve 7 but also to the two pressure sensors 9 .

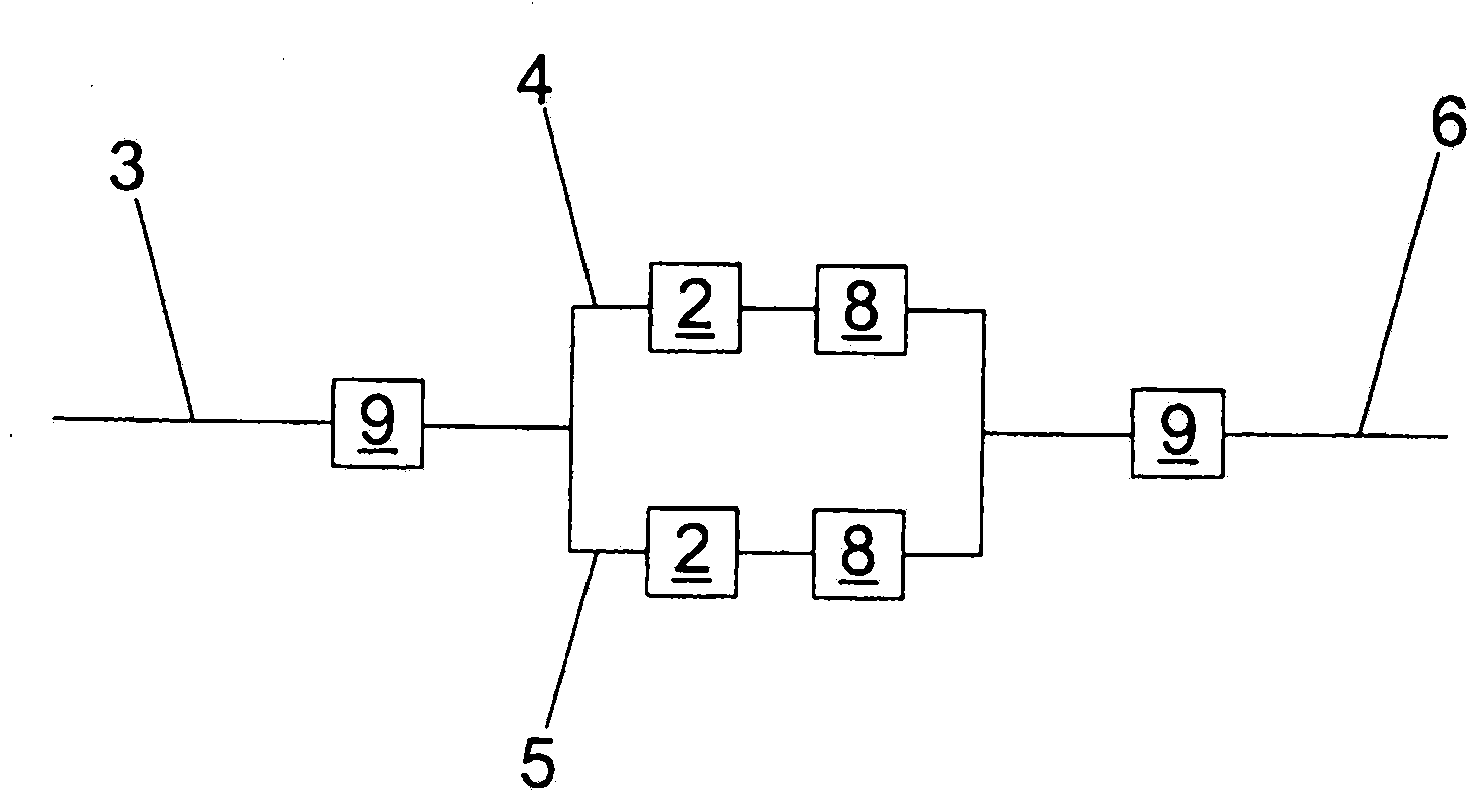

[0034] figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com