Emergency load rejection mechanism of deep-sea manned submersible

A manned submersible and deep-sea technology, applied in the field of manned submersibles and emergency dumping mechanisms, can solve problems such as unloading and floating, and achieve the effect of safe return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

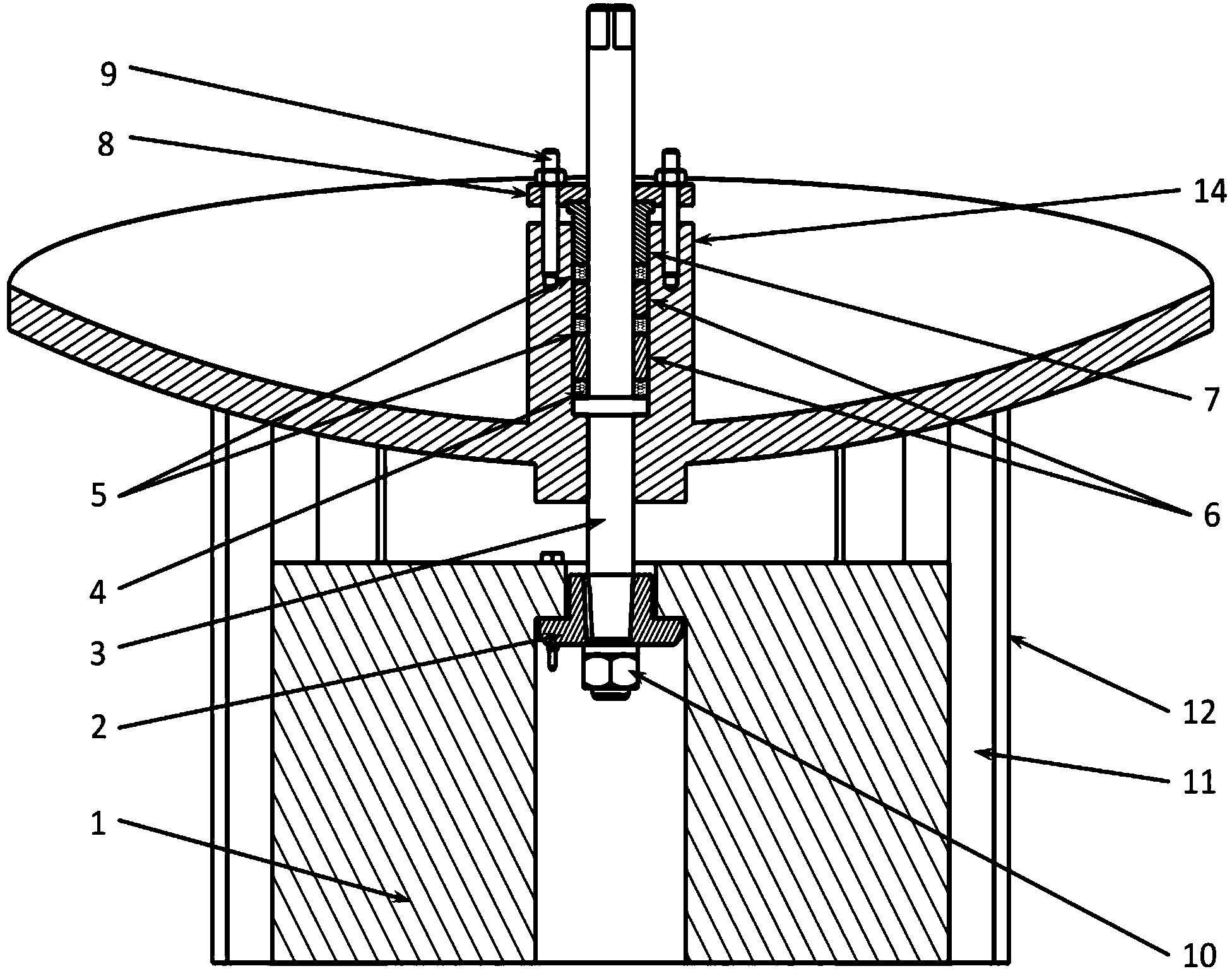

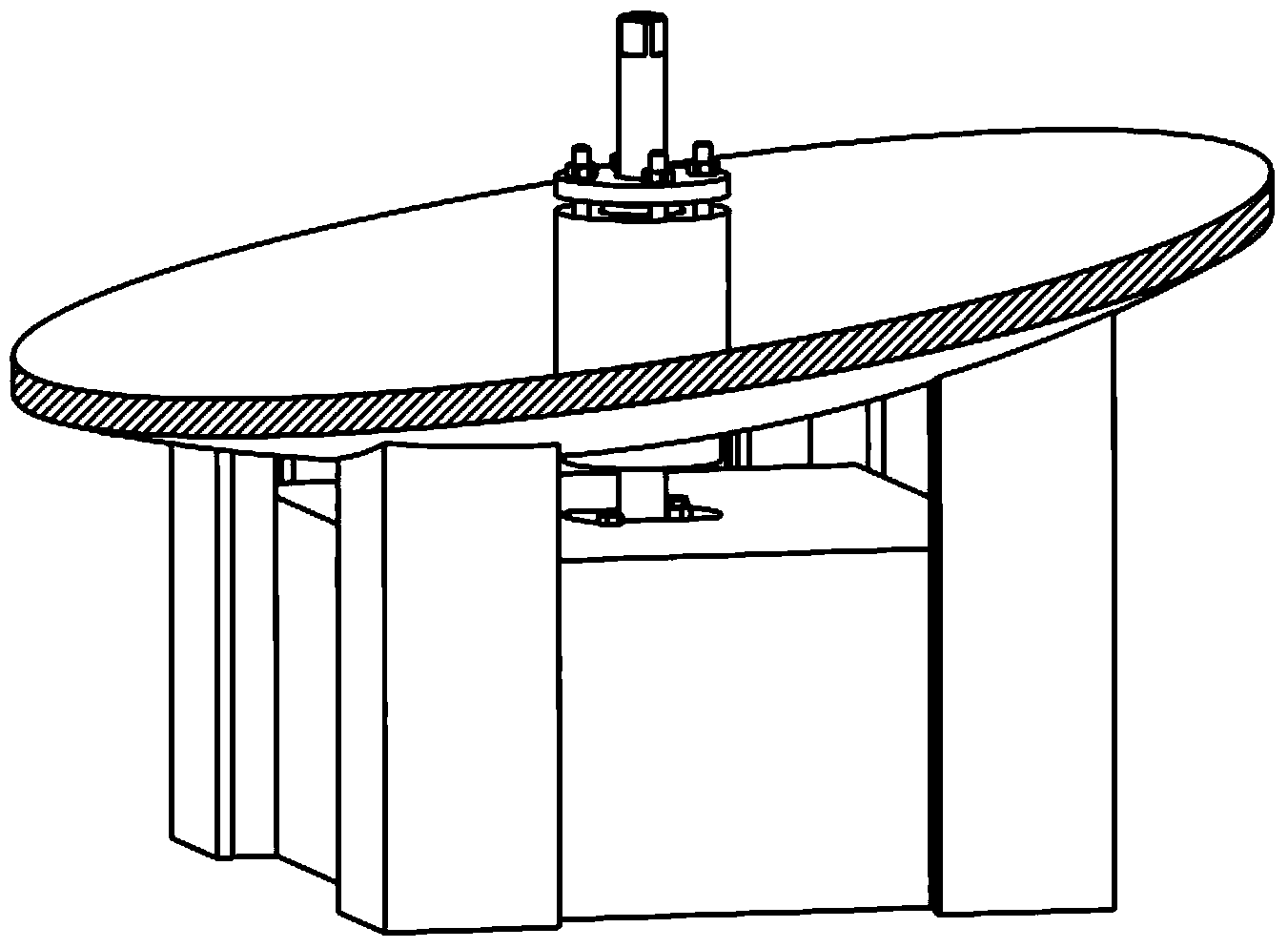

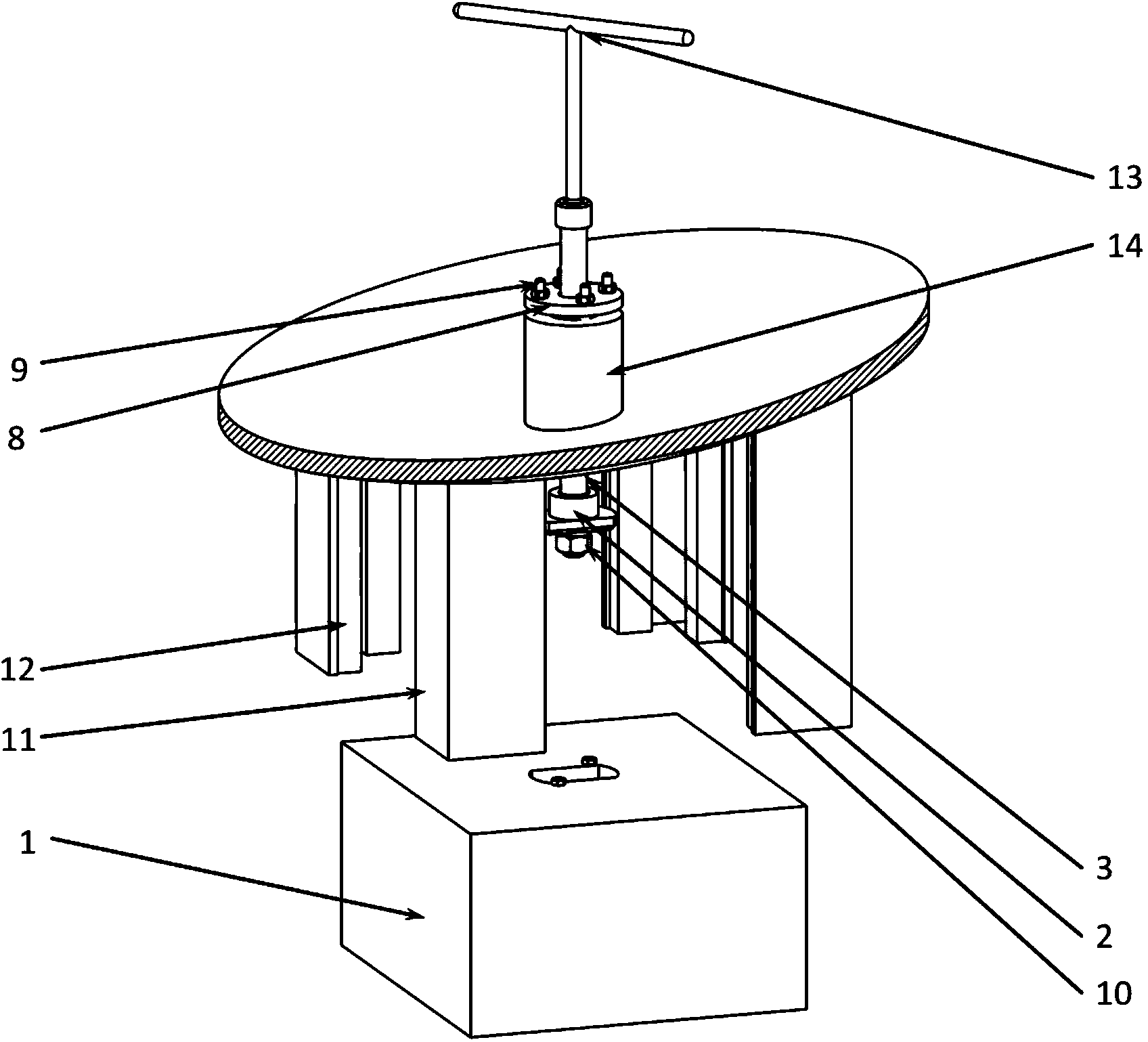

[0017] like figure 1 — image 3 As shown, the present invention includes: a rotating shaft 3 that runs through the pressure-resistant spherical shell cabin, and the upper end of the rotating shaft 3 is inserted into a T-shaped hand lever 13; the middle part of the rotating shaft 3 is installed under the spherical shell of the pressure-resistant spherical shell cabin In the shaft sleeve 14, the lower end of the rotating shaft 3 is installed with a ballast hanging dog wheel 2 through the shaft key and the cam nut 10, and the ballast hanging dog wheel 2 is inserted into the long hole on the top surface of the ballast block 1. When the claw of the hanging claw wheel 2 is horizontally placed in the long hole of the ballast block 1, the suspension is realized. The vertical surfaces of the four sides of the ballast block 1 are respectively provided with two guide slides 12, and the guide slides 12 are installed on the guide bracket 11 to ensure that the ballast block 1 can move smoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com