Concrete aggregate regeneration apparatus

A concrete aggregate and regeneration device technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of low added value, low added value, physical strength damage of aggregate, etc., and achieve high utilization rate The effect of improving and adding value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

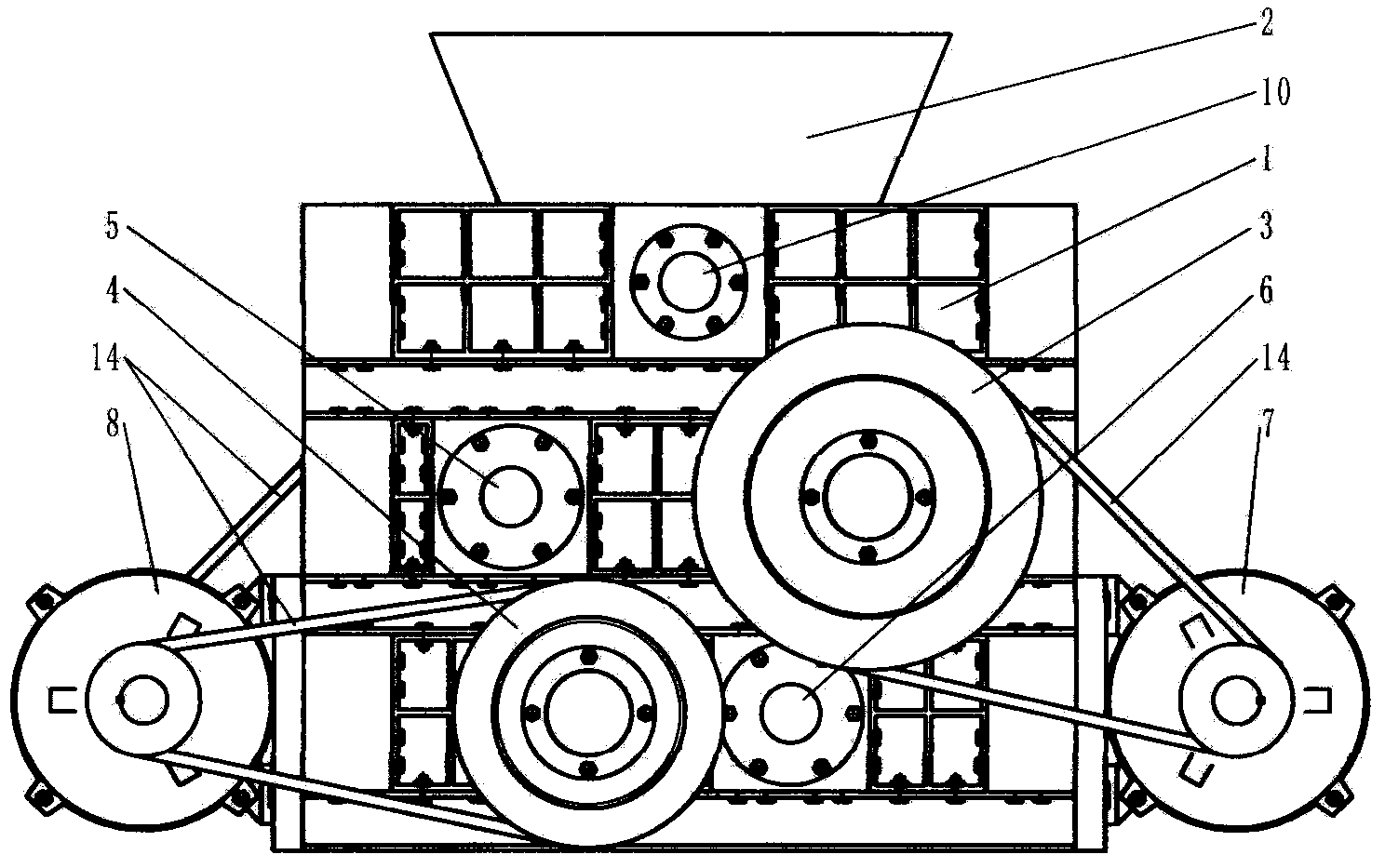

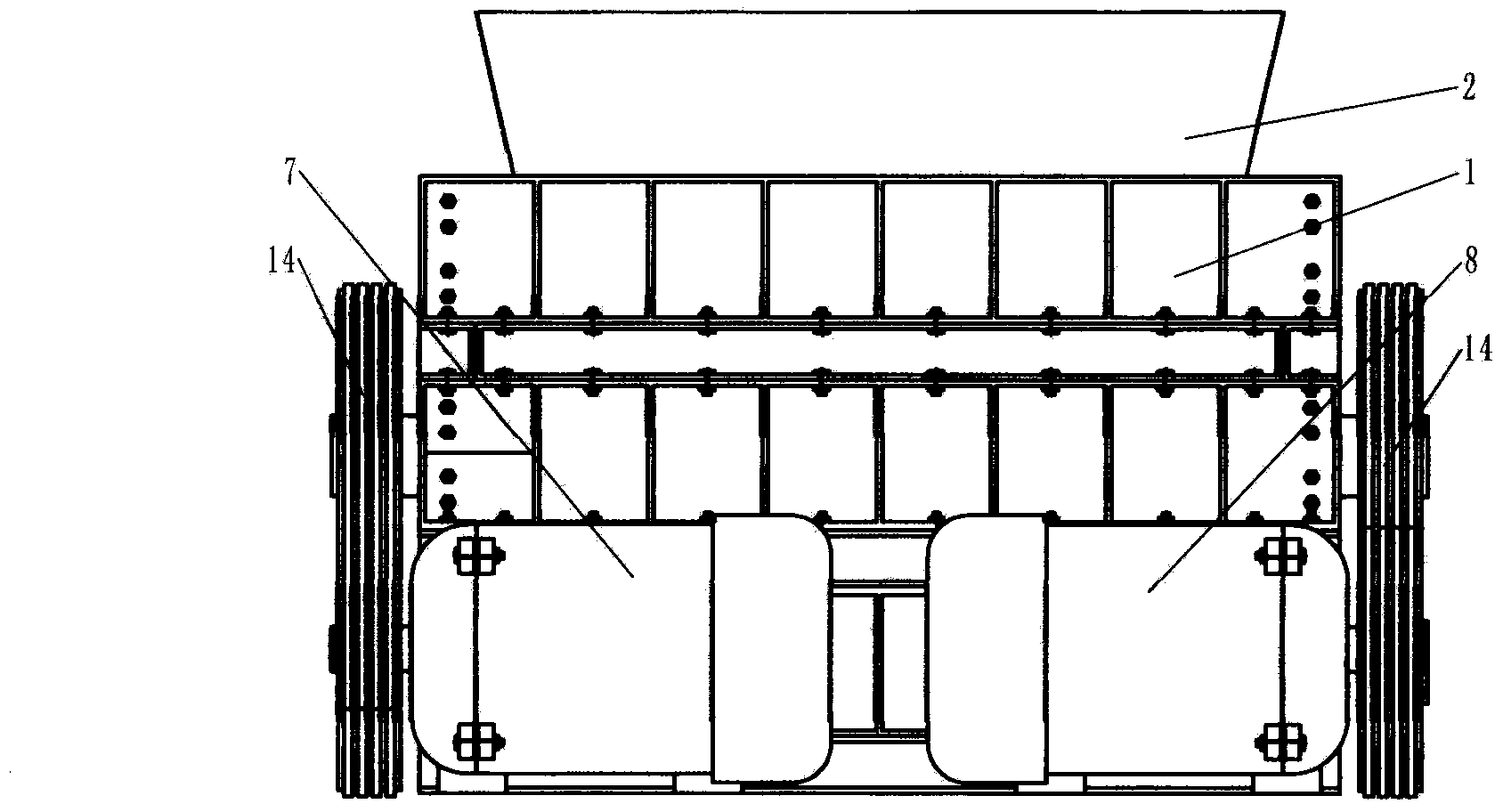

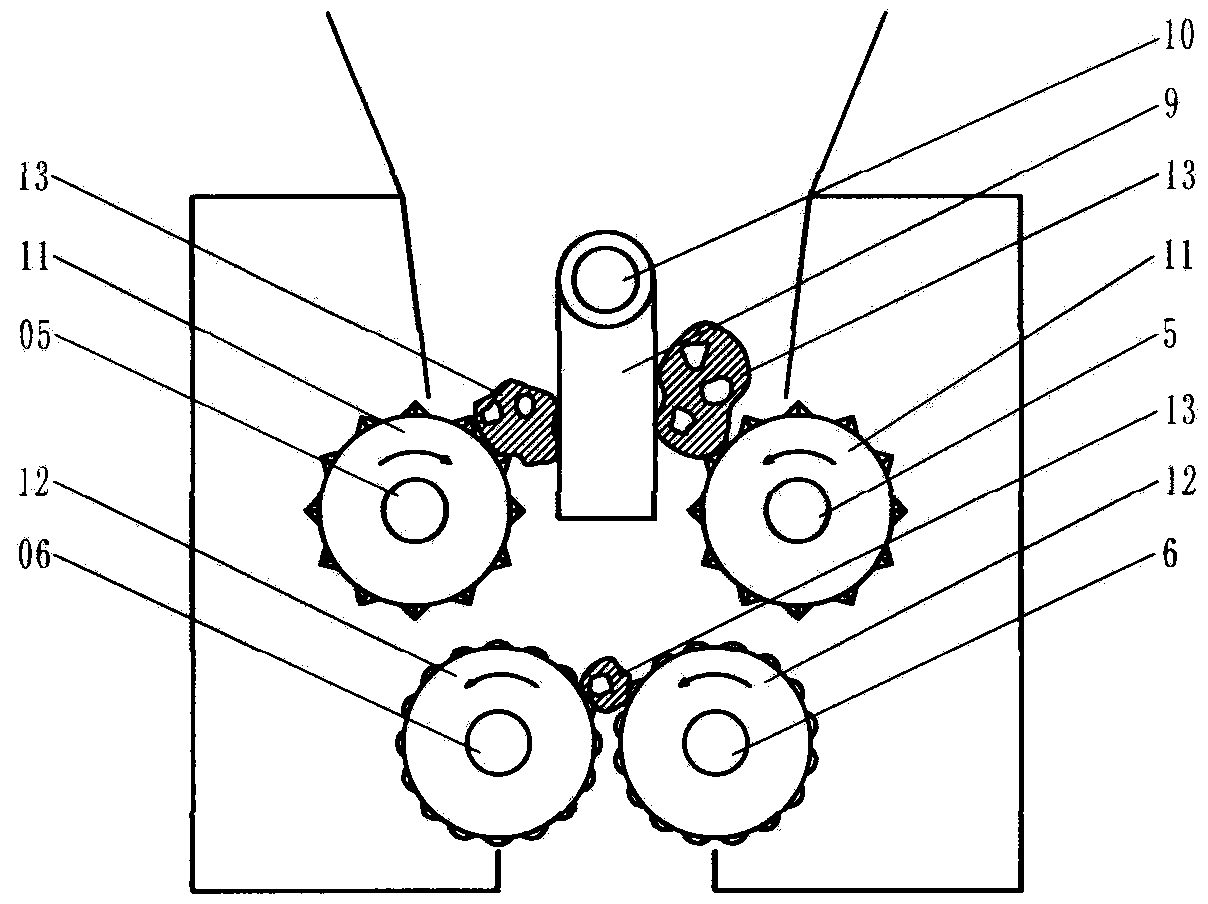

[0013] Such as figure 1 , figure 2 As shown, a concrete aggregate recycling device for construction waste and construction waste slag treatment includes a frame (1), a feed hopper (2), a crushing roller (11), a stripping roller (12), a pendulum plate (9 ) and auxiliary facilities, the shaft (10) of the pendulum plate (9), the shaft (5) of a pair of crushing rollers (11), and the shaft (6) of a pair of peeling rollers (12) are respectively fixed on the frame (1 ), a pair of crushing rollers (11) are respectively equipped with two pulleys (3) on the shaft (5), connected with the motor (7) through a belt (14), and the shaft (6) of a pair of peeling rollers (12) Belt pulley (4) is installed, links to each other with motor (8) by belt (14), so just formed the upper segment in frame (1) for crushing function, and the lower segment is the concrete aggregate recycling device of stripping function.

[0014] Such as image 3 , Figure 4 As shown, the rotation directions of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com