Formulation of insulating sheath for 105 DEG C-grade cable

A cable insulation and formula technology, applied in the direction of organic insulators, rubber insulators, etc., can solve the problems of general insulation performance, fire, leakage, etc., to avoid leakage or high-voltage breakdown, life and property safety, and reasonable material matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

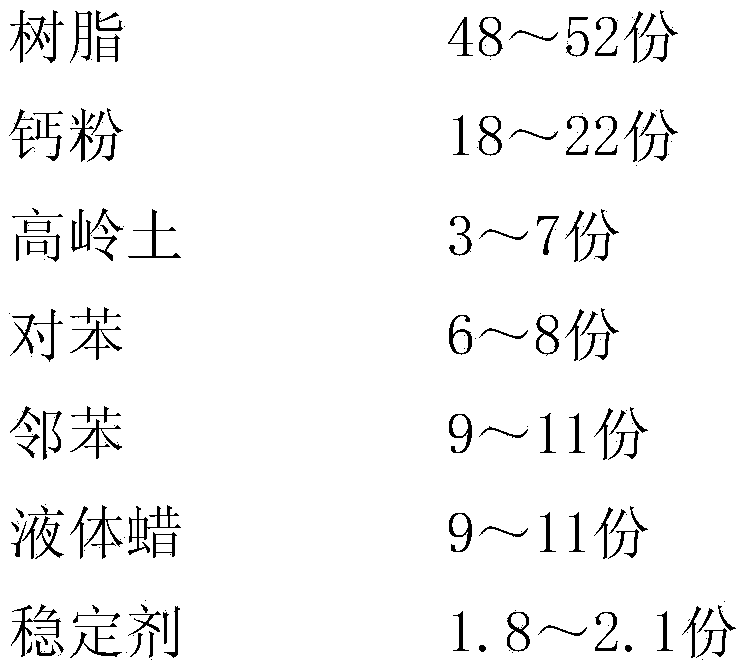

[0020] A formulation for 105°C cable insulation sheath, which comprises resin, calcium powder, kaolin, p-benzene, o-benzene, liquid wax, stabilizer, hard barium, fatty wax acid, hard wax, partial phenylene and plasticizer, The parts by weight of each component are as follows:

[0021]

[0022]

Embodiment 2

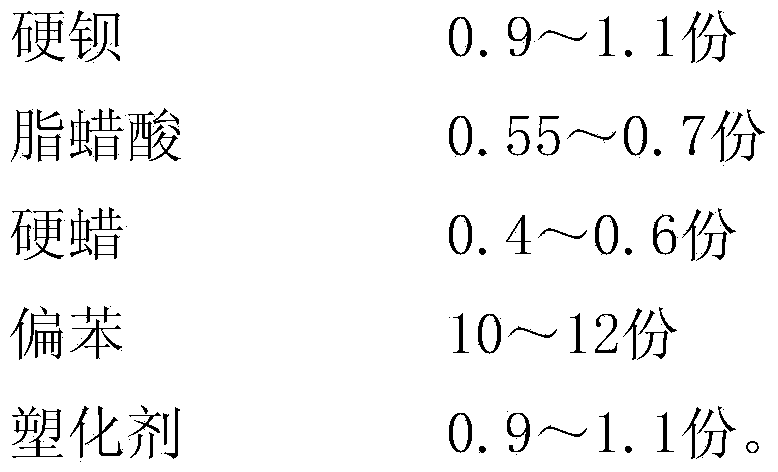

[0024] A formulation for 105°C cable insulation sheath, which comprises resin, calcium powder, kaolin, p-benzene, o-benzene, liquid wax, stabilizer, hard barium, fatty wax acid, hard wax, partial phenylene and plasticizer, The parts by weight of each component are as follows:

[0025]

Embodiment 3

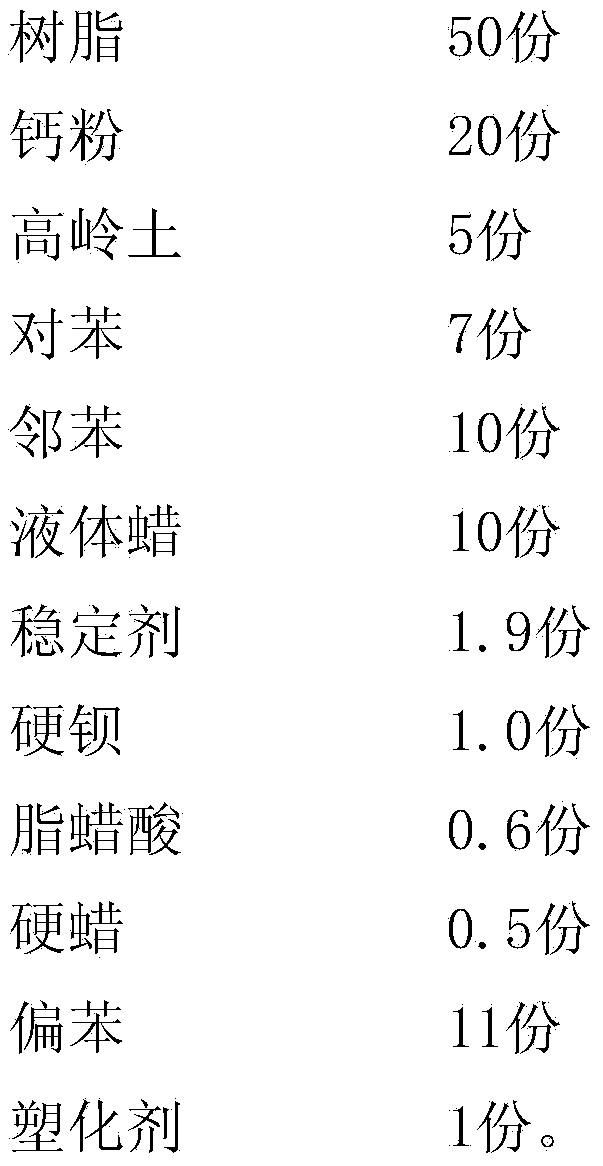

[0027] A formulation for 105°C cable insulation sheath, which comprises resin, calcium powder, kaolin, p-benzene, o-benzene, liquid wax, stabilizer, hard barium, fatty wax acid, hard wax, partial phenylene and plasticizer, The parts by weight of each component are as follows:

[0028]

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com