Rapid construction method for seepage-proof dam of salt pan

A construction method and fast technology, applied in the direction of filling, etc., can solve the problems of increasing the cost of anti-seepage dams, consumption of anti-seepage materials, and complicated process connection, so as to achieve the effects of reducing loss, reducing investment, and reducing construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

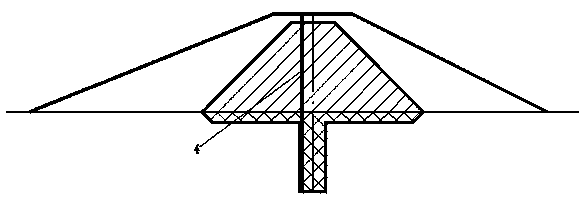

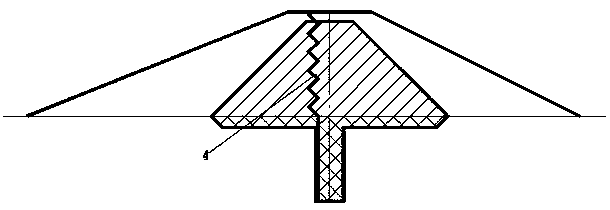

[0026] see Figure 1-Figure 2 , the ultimate goal of the present invention is to combine the anti-seepage material 4 such as figure 2 The correction shown is figure 1 shown.

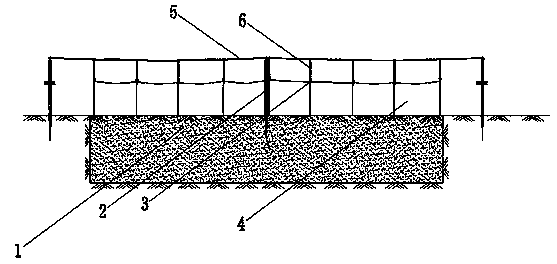

[0027] refer to Figure 3-Figure 9 , the rapid construction method of the salt field anti-seepage dam in this embodiment, its construction process is excavating the foundation trench - lowering the membrane - filling the foundation trench - pulling the membrane - covering the soil - rolling - re-covering the soil - rolling again, the specific steps are:

[0028] First dig the foundation trench 1, after digging the foundation trench 1, lower the anti-seepage material 4 from the ground surface to the bottom of the foundation trench 1, then fill the foundation trench 1 with soil and roll, after the rolling, put the anti-seepage material near the ground surface 4, assemble and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com