Water spraying cooling system of piston reciprocating internal combustion engine

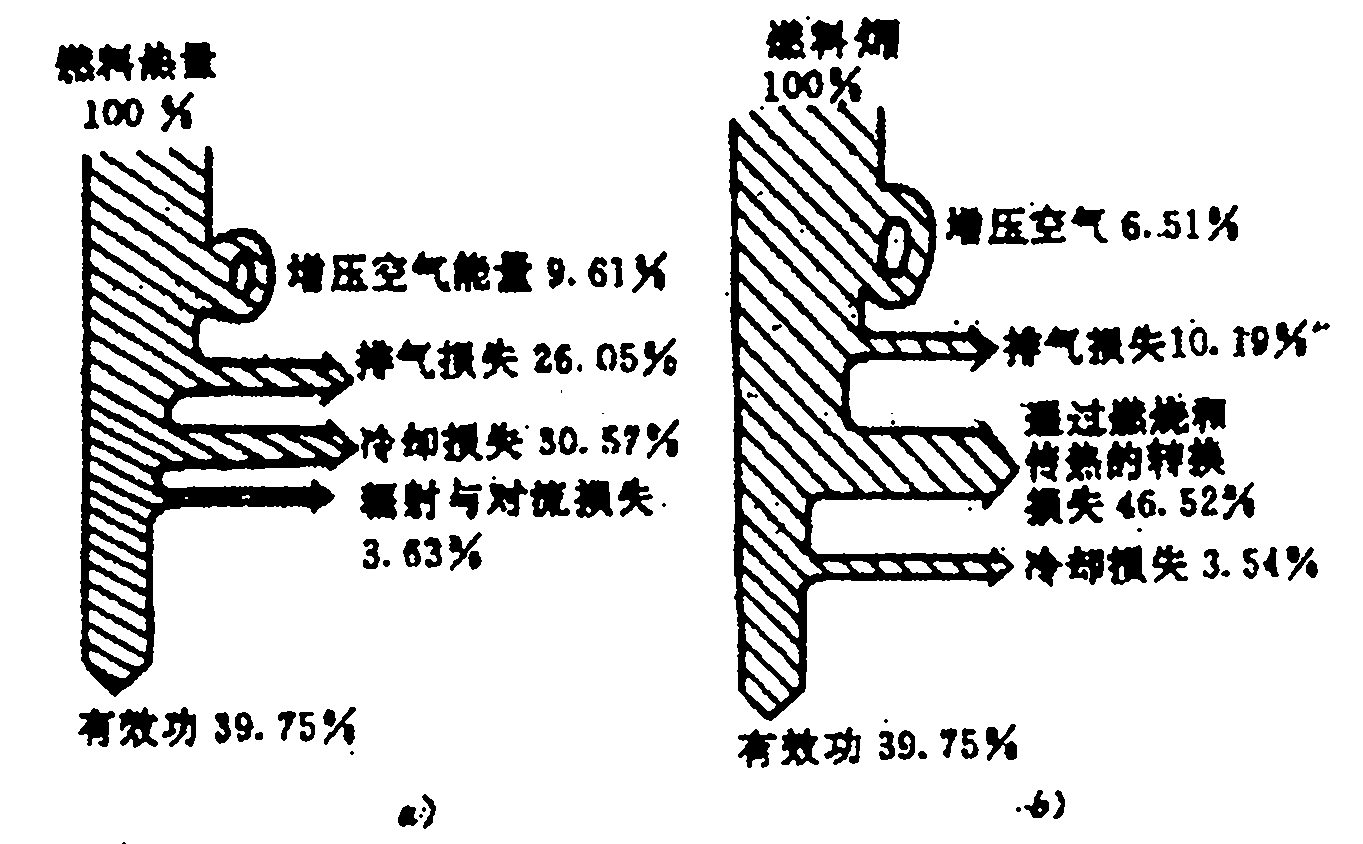

A water spray system and piston technology, which is applied in the cooling of engines, internal combustion piston engines, combustion engines, etc., can solve the problems of fuel thermal efficiency loss, loss, low temperature pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

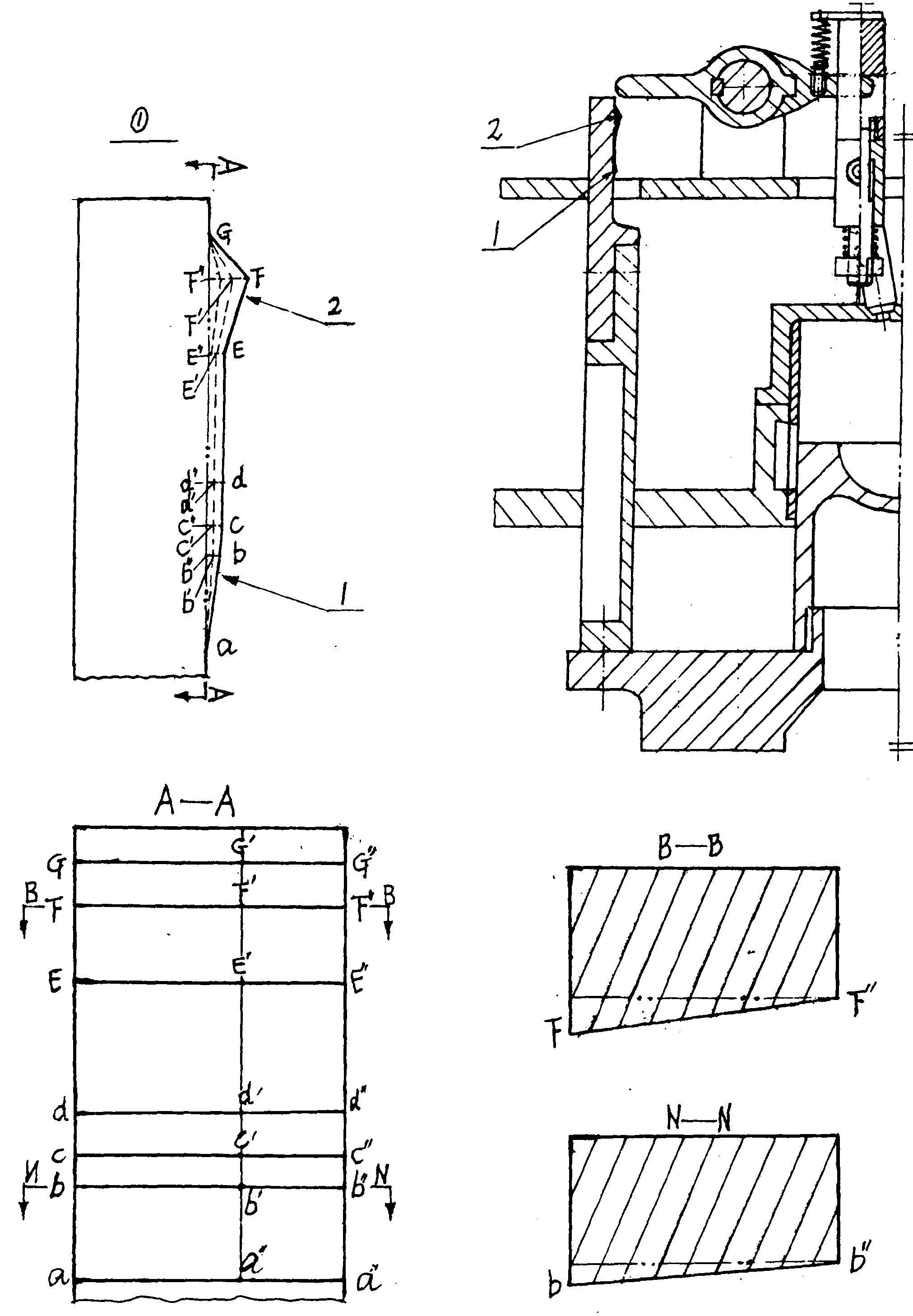

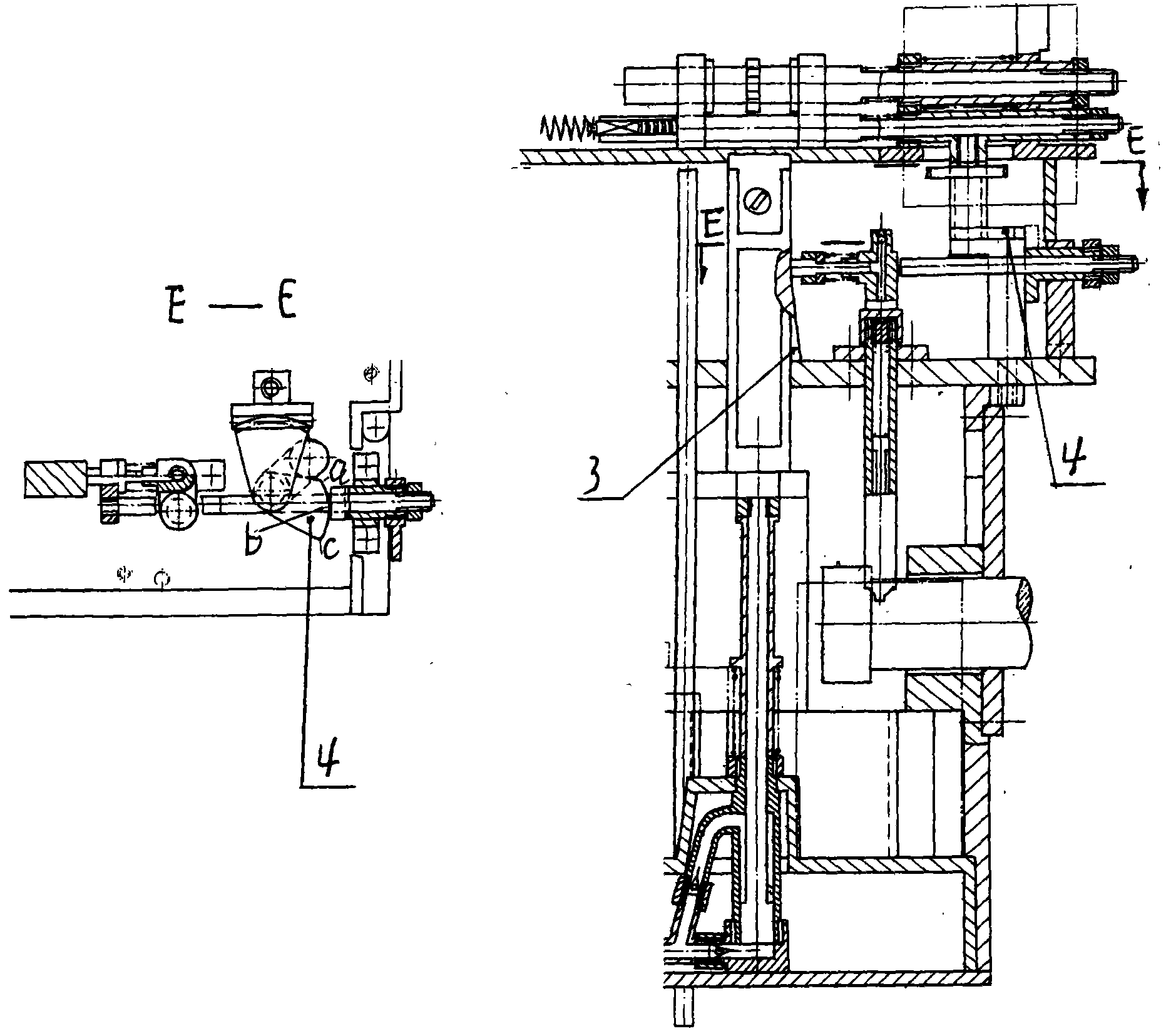

[0083] A water injection cooling system for a piston reciprocating internal combustion engine of the present invention will be described in detail below in conjunction with the accompanying drawings for specific implementations of the present invention.

[0084] Announced in the invention patent "ZL200710193940.7 'a tappet and the combined mechanism and control system of the tappet'": described in claim 2 and claim 6, in the newly invented overhead integrated control system (instructions [ [0021] The specific method is recorded) [note: the control system has proposed a divisional application, application number 201110283190.9, name 'a kind of piston reciprocating internal combustion engine overhead integrated control system'] traction, synchronously with the change of the engine working conditions in their own The "top-mounted secondary engine in-cylinder water spray system" and the "supercharged in-cylinder intercooling compression water spray system" constitute a water spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com