Three-dimensional gear transverse / vertical inside-tightening direct-type casing pipe connection structure

A connection structure, three-dimensional technology, applied in the direction of electrical components, etc., can solve the problems of threading pipe falling off, poor stability, loose screws, etc., and achieve the effect of strong fixing ability, good stability, and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

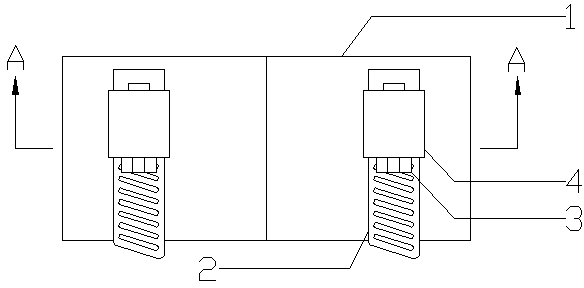

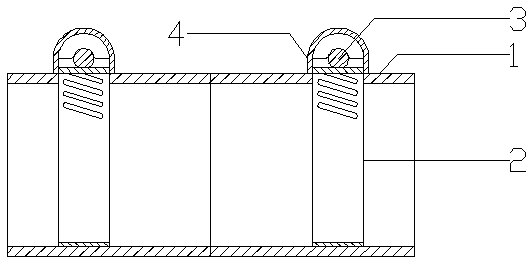

[0034] Such as figure 1 , 2 As shown, the three-dimensional gear horizontal / vertical inner tight direct threading pipe connection structure in this embodiment includes a pipe body 1 and two clamps arranged near both ends of the pipe body, and each set of clamps includes a clamp band 2 And a fixing device for fixing the band, the fixing device includes a worm 3 and a casing 4, the band 2 is provided with a helical groove, the band is arranged on the inner side of the pipe body 1, and the pipe body 1 is connected with the clamp The contact part of the band 2 is provided with an opening, and the casing 4 passes through the opening on the pipe body and is fixed on one end of the band 2, and the other end of the band 2 passes through the case 4 and is exposed outside the body 1, and the worm 3. Parallel and tangentially arranged in the case 4 on the clamp band, and rotate with the outer edge of the case. The tooth groove of the band 2 meshes with the external thread of the worm 3,...

Embodiment 2

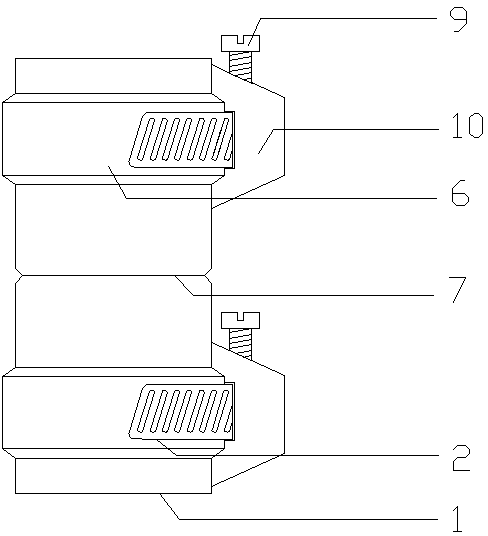

[0037] Such as image 3 , 4As shown, the three-dimensional gear horizontal / vertical inner tight direct threading pipe connection structure in this embodiment includes a pipe body 1, two clamps arranged at the positions near both ends of the pipe body 1, and two clamps arranged on the pipe body 1 A clamp cover 10 that wraps the first worm 8 and the casing 4 of the two clamps, each set of clamps includes a clamp band 2, a worm and a cover 4, and the clamp band 2 is provided with helical teeth Groove, the clamp band is set on the inner side of the tube body 1 close to the inner wall of the tube body, the contact part of the tube body 1 and the clamp band 2 is provided with an opening, and the cover 4 passes through the opening on the tube body and is fixed on the clamp One end of the band 2, and the other end of the band 2 passes through the casing 4 and is exposed outside the pipe body 1. There are two worms, which are the first worm 8 and the second worm 9 respectively. The ho...

Embodiment 3

[0040] Such as Figure 5 As shown, the three-dimensional gear horizontal / vertical inner tight direct threading pipe connection structure of this embodiment is basically the same as the first two three-dimensional gear horizontal / vertical inner tight direct threading pipe connection structures, the difference is that in An annular protrusion 6 for accommodating the clamp band is provided at the contact position of the pipe body 1 with the clamp band. The clamp band 2 is arranged in the annular protrusion 1, so that a threading pipe with a larger radius can be accommodated without increasing the inner diameter of the pipe body. In addition, when the clamp band fixes the threading pipe, the annular protrusion can clamp the clamp band to prevent the clamp band from being dislocated, or the band from being separated from the pipe body due to the action of external force. Therefore, the annular protrusion can improve the stability and tightness of the three-dimensional gear horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com