Filler yarn bar

A technology of warp yarn and bar, applied in warp knitting, flat warp knitting machine, textile and paper making, etc., can solve problems such as unfavorable additional costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

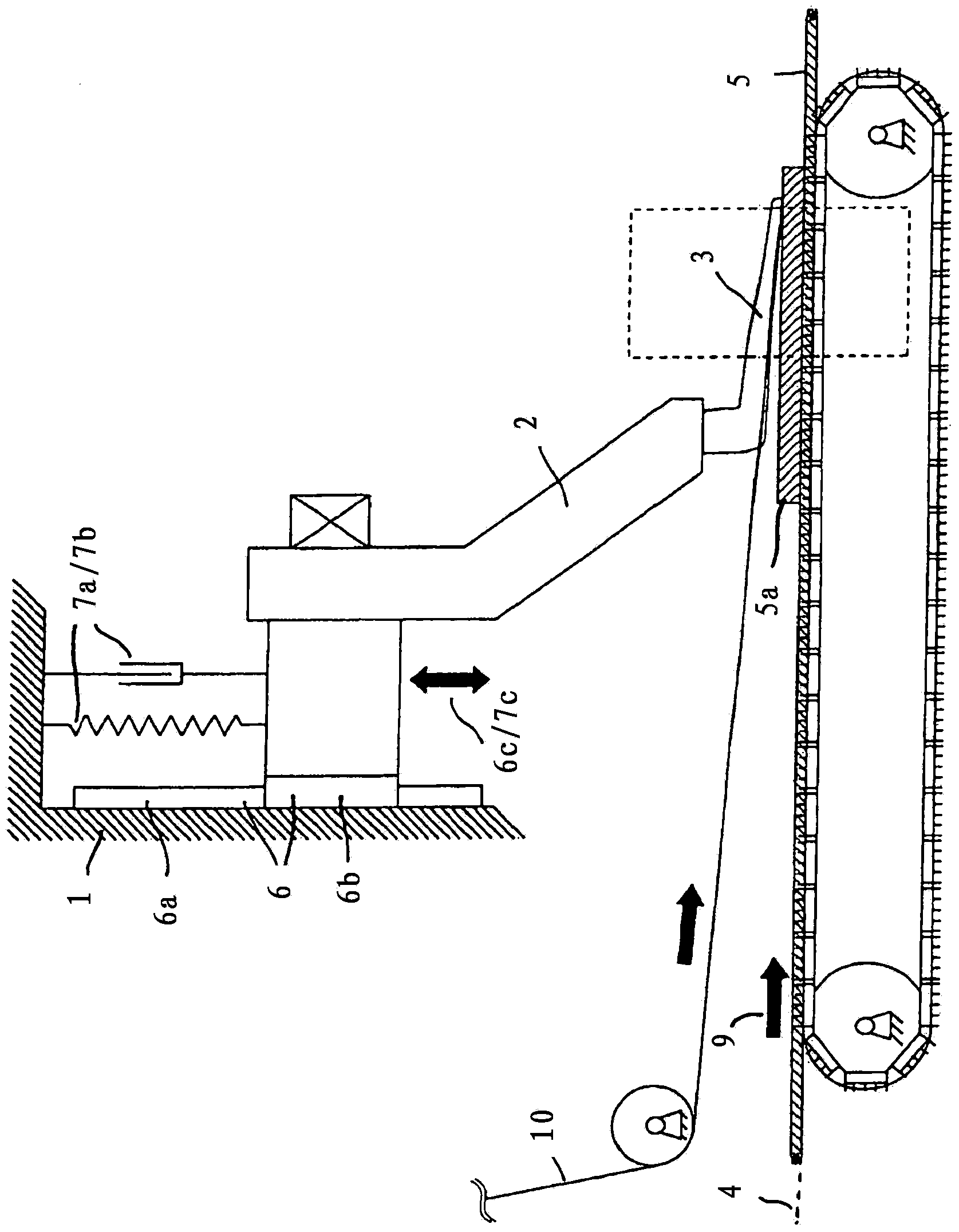

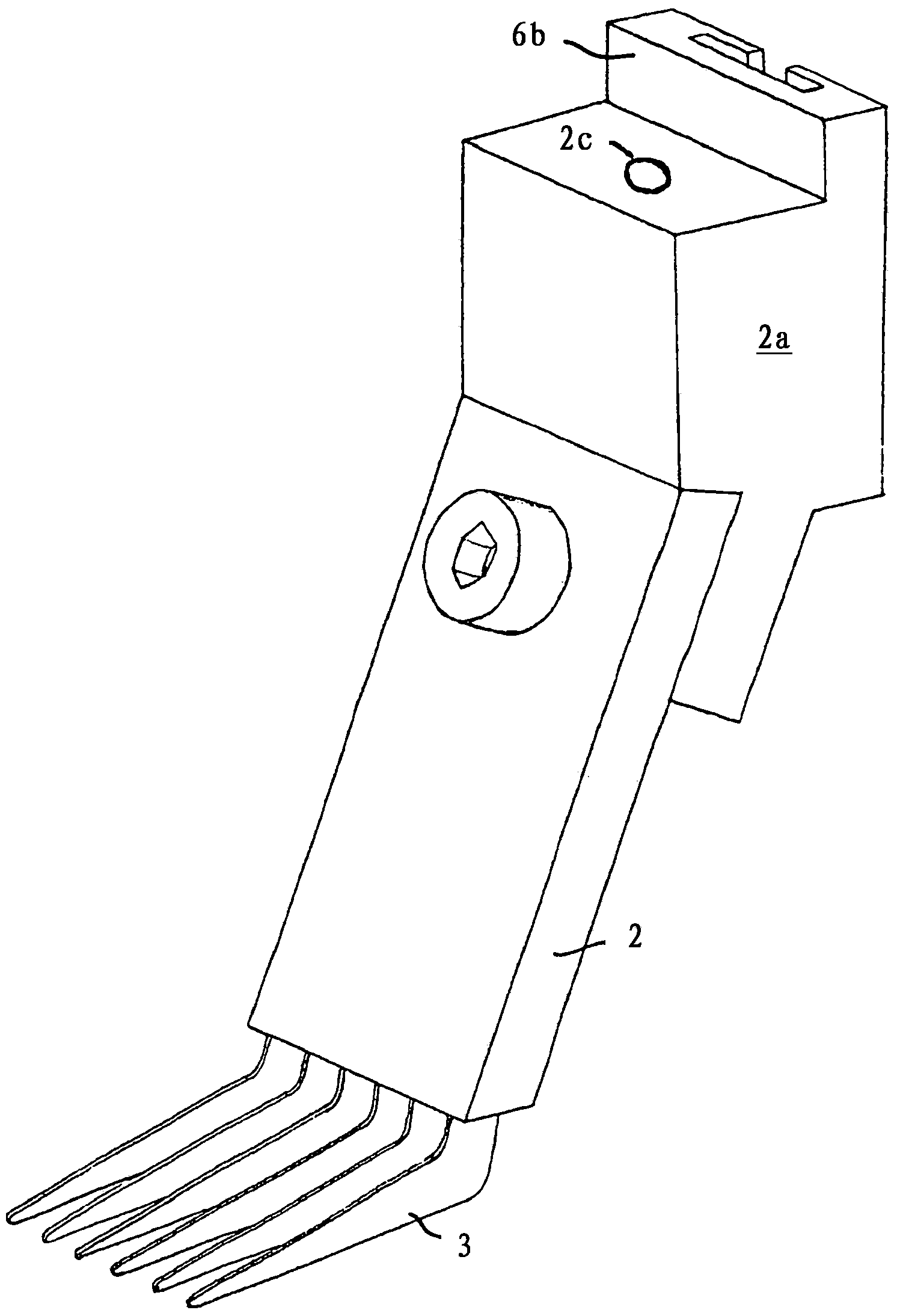

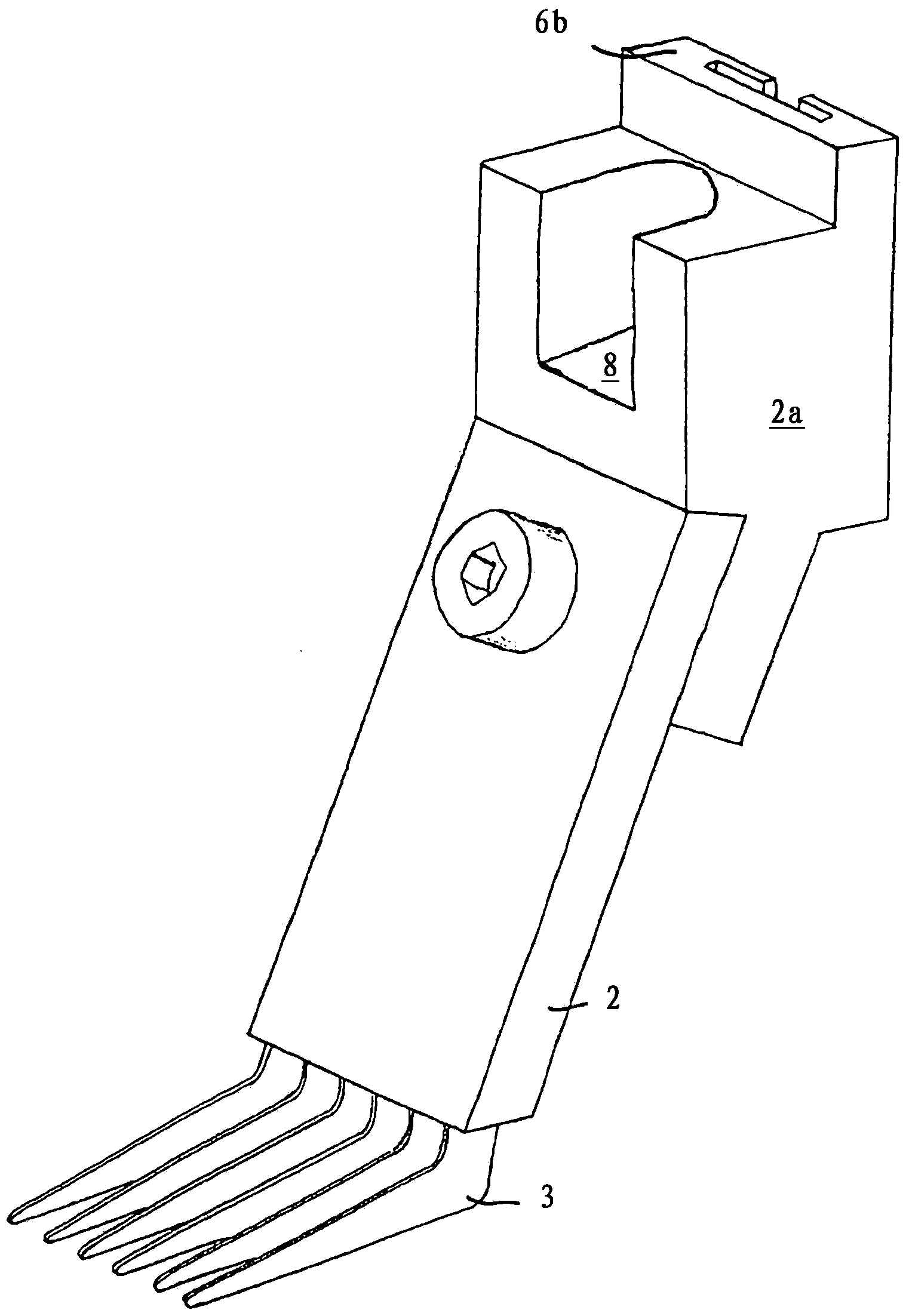

[0050] here figure 1 In particular, the remaining figures show a warp bar, which comprises a support element 1 that can be calibrated to be arranged in a warp knitting machine, on which a straight line in the structure shown schematically is fastened. Guide rail 6a of the bearing mechanism, in particular of the linear sliding bearing mechanism.

[0051] A guide carriage 6b can be moved in the vertical direction, that is to say here in a direction perpendicular to the conveying plane 4 of the warp knitting machine, on which guide carriage the warp bar bow is indirectly fastened here via the bow section support 2a. Segment 2, which has a warp thread sinker 3 arranged on it at the bottom, which is a segment of the warp bar segment.

[0052] Because the warp bar segment 2 is arranged on the support element 1 by the linear support mechanism 6, the underside of the warp sinker lying on the surface of the textile 5 to be knitted can be compared with the thickness jump in the textile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com