Drilling device for the production of training shoes

A drilling device and drill pipe technology, which is applied in the field of training shoes production, can solve problems such as high-speed splashing of metal shavings and potential safety hazards for operators, and achieve the effect of improving fatigue strength and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is a further detailed description through specific implementations:

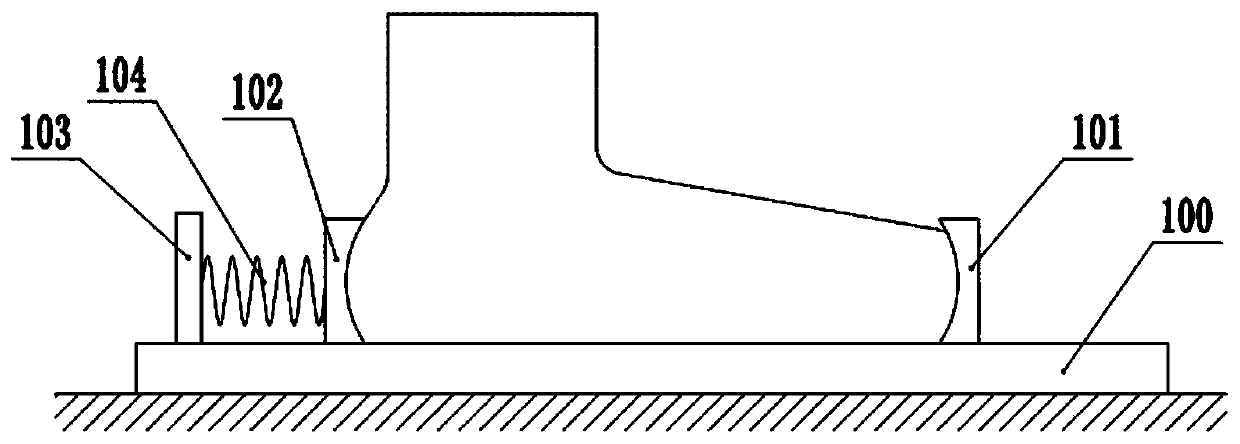

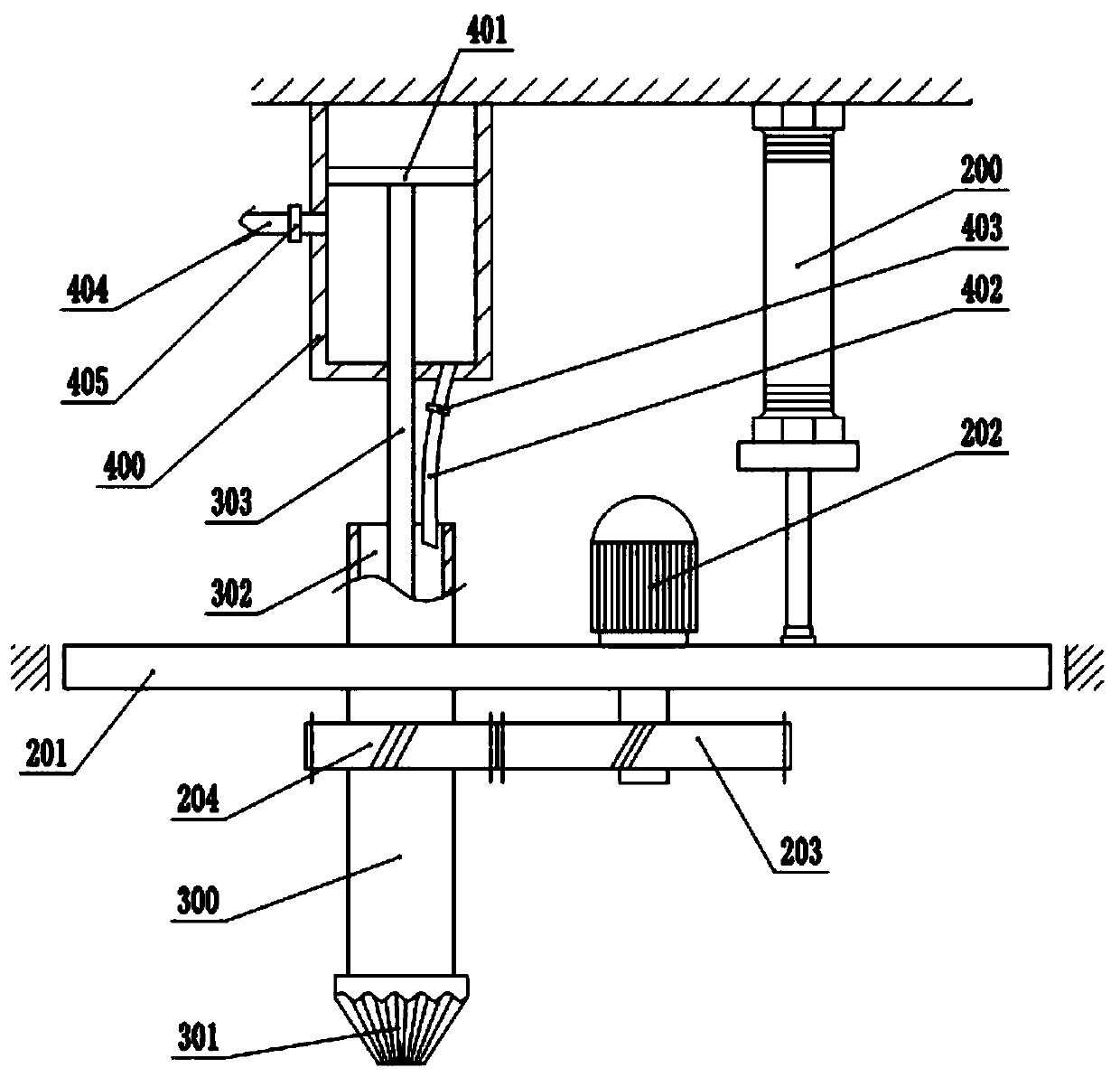

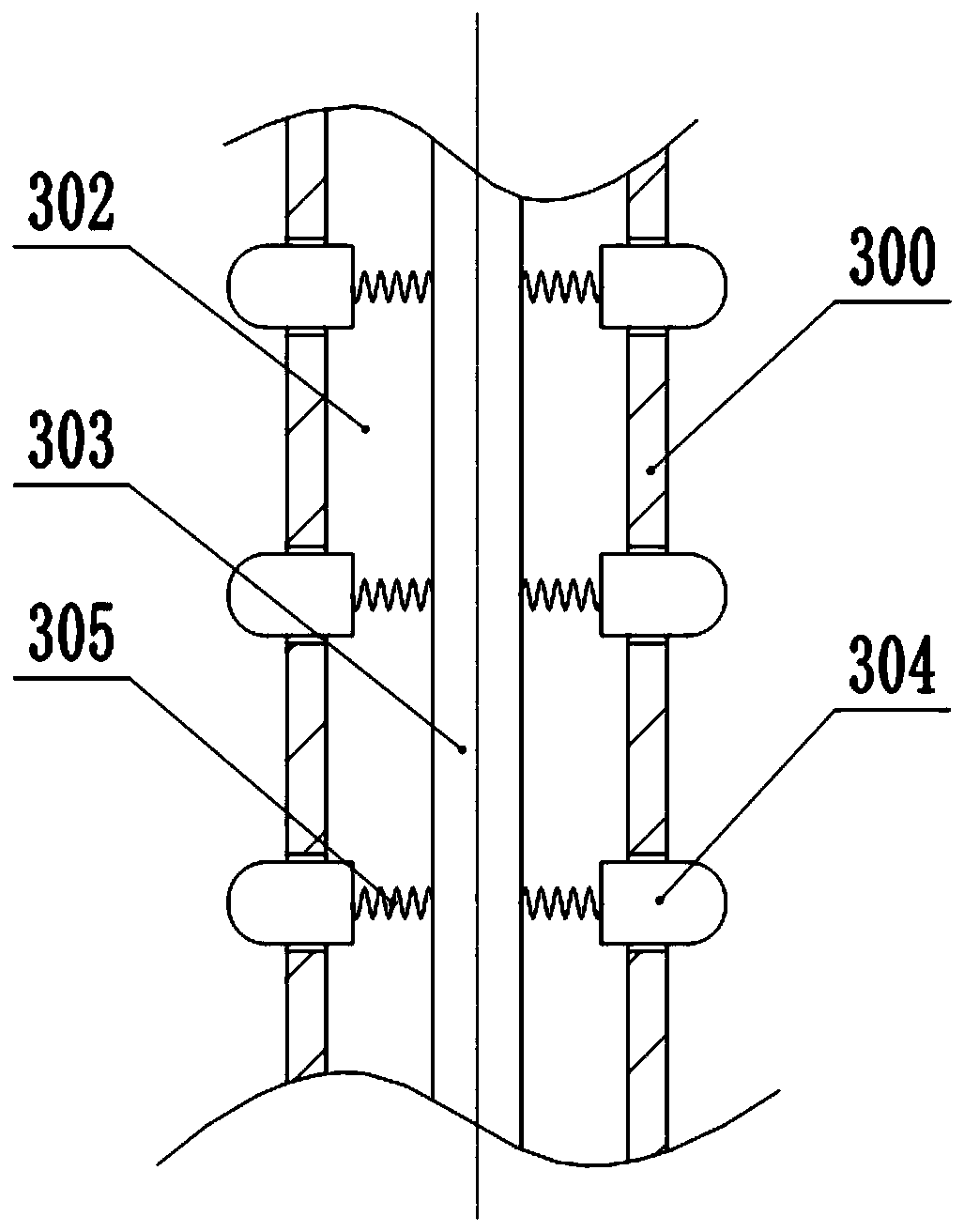

[0028] The reference signs in the drawings of the specification include: workbench 100, positioning block 101, support block 102, mounting plate 103, second spring 104, hydraulic cylinder 200, positioning plate 201, motor 202, driving gear 203, driven gear 204 , Drill rod 300, drill bit 301, oil cavity 302, limit rod 303, impact block 304, first spring 305, cylinder 400, piston 401, oil outlet pipe 402, oil outlet check valve 403, oil supply pipe 404, inlet Oil check valve 405.

[0029] The embodiment is basically as attached figure 1 versus figure 2 Shown:

[0030] The drilling device for training shoe production includes a workbench 100 on which a fixing unit for fixing the shoe last and a drilling unit for drilling the shoe last are provided, such as figure 1 As shown, the fixing unit includes a positioning block 101 fixed on the workbench 100 and a support block 102 slidably connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com