A rotary buffer with adjustable hydraulic damping

A hydraulic damping and buffer technology, which is applied in the field of hydraulic damping buffers, can solve the problems of large assembly space occupied by the cover plate of the buffer, unfavorable miniaturization design, etc., and achieve the advantages of convenient assembly or adjustment, simple structure, and reduced length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 (the adjustment hole runs through the axis of the shaft)

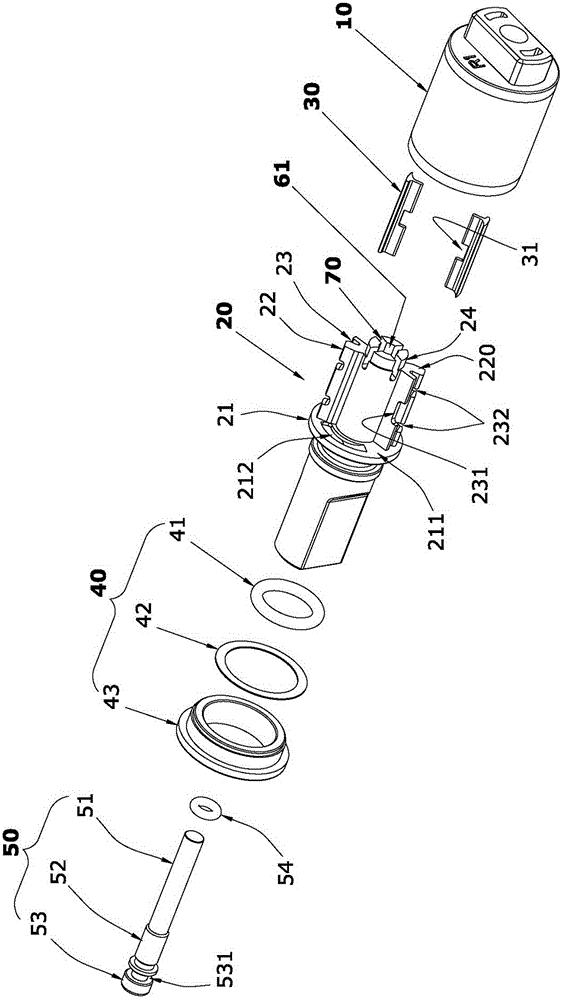

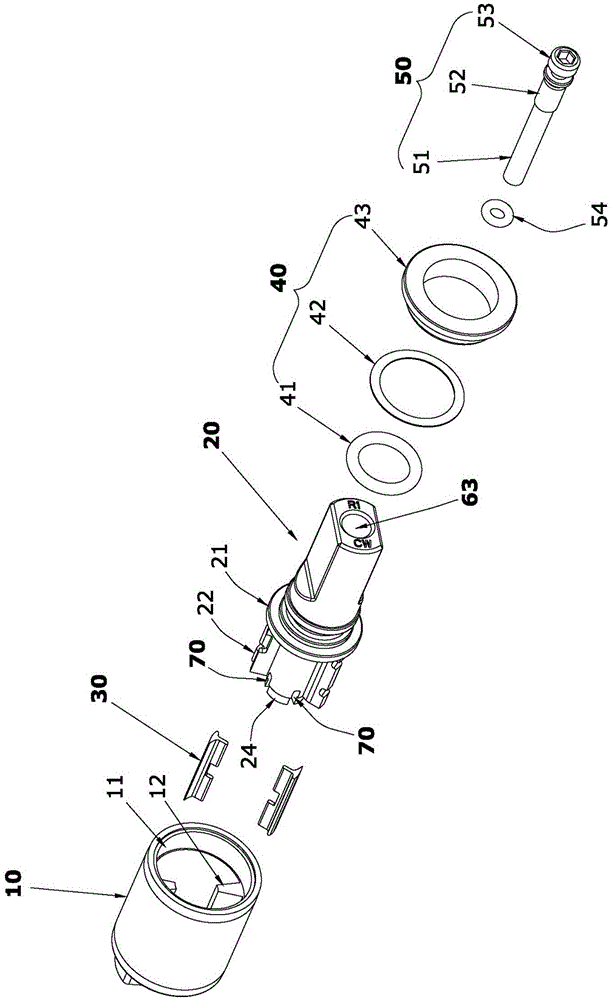

[0034] like figure 1 , figure 2 and Figure 10 The rotary buffer with adjustable hydraulic damping shown is mainly composed of a shaft sleeve 10 , a rotating shaft 20 , an oil-passing valve plate 30 , a sealing assembly 40 and an adjusting screw 50 .

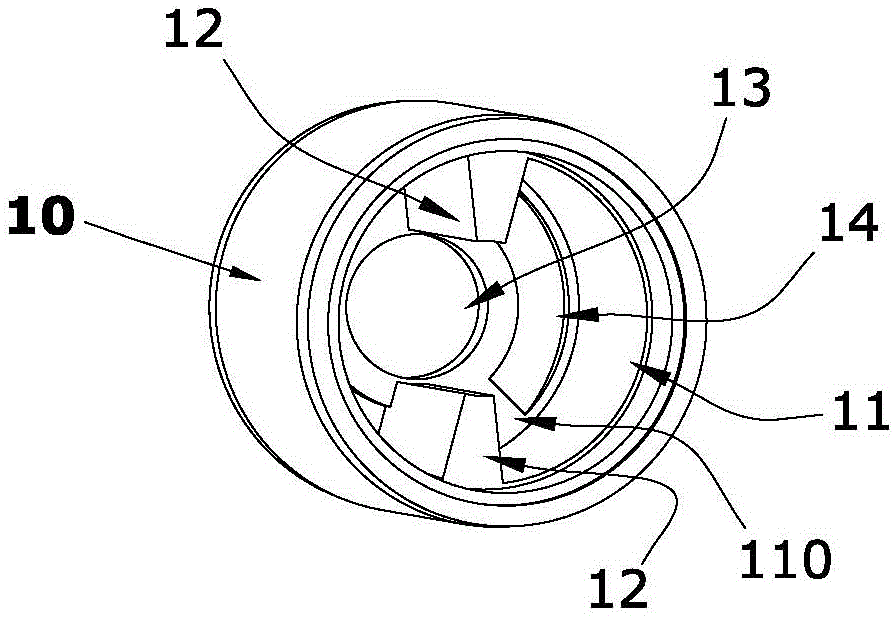

[0035] like figure 2 , image 3 and Figure 4 As shown, the shaft sleeve inner cavity 11 of the shaft sleeve 10 of the present invention is used to support the rotation of the rotating shaft 20, and the two oil-separating ribs 12 are symmetrically arranged on the wall of the shaft sleeve inner cavity 11, and the oil-separating ribs 12 are separated from the inner cavity 11. The opening extends to the bottom surface 110 of the inner cavity and is fixed. The center of the bottom of the inner cavity 11 of the shaft sleeve is provided with a bearing hole 13 for supporting the rotation of the supporting shaft 24 at the end of the rotating shaft 20. ...

Embodiment 2

[0045] Embodiment 2 (the adjustment hole does not pass through the axial direction of the rotating shaft).

[0046] like Figure 12 and Figure 13 As shown, the difference between this embodiment and Embodiment 1 is that the axial rear end of the socket 61 is not arranged on the support shaft 24, the adjustment hole 60 does not penetrate to the support shaft 24, and the throttle port 70 still communicates through the socket 61. When the adjusting screw 50 makes the bottom end surface of the round bar section 51 touch the jack 61, the round bar section 51 of the adjusting screw 50 completely closes and blocks the orifice 70, so that the orifices 70 cannot communicate with each other. When the rotation speed of the rotating shaft 20 is fixed; when the adjusting screw 50 is turned to make the round bar section 51 form a gap with the bottom of the socket 61 and each throttle port 70 at the same time, each throttle port 70 is connected through the socket 61, and the circle The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com