Rotary buffer with adjustable damping magnitude

A buffer and damping technology, which is applied in the direction of shock absorbers, shock absorbers, liquid shock absorbers, etc., can solve the problems of low assembly efficiency, unstable oil core 1 speed, hydraulic instability, etc., and achieve simple structure and high damping Easy adjustment, stable and reliable function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

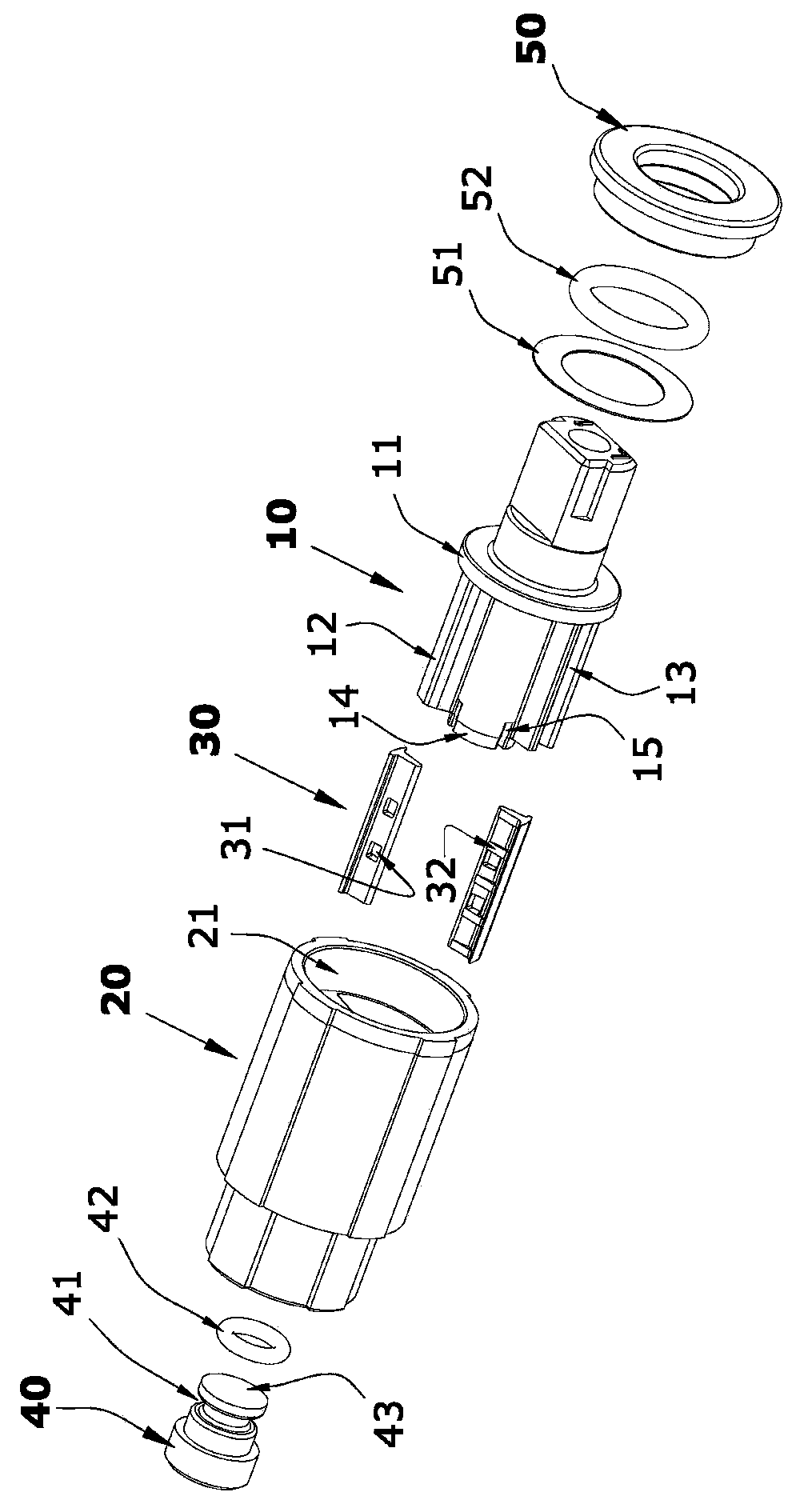

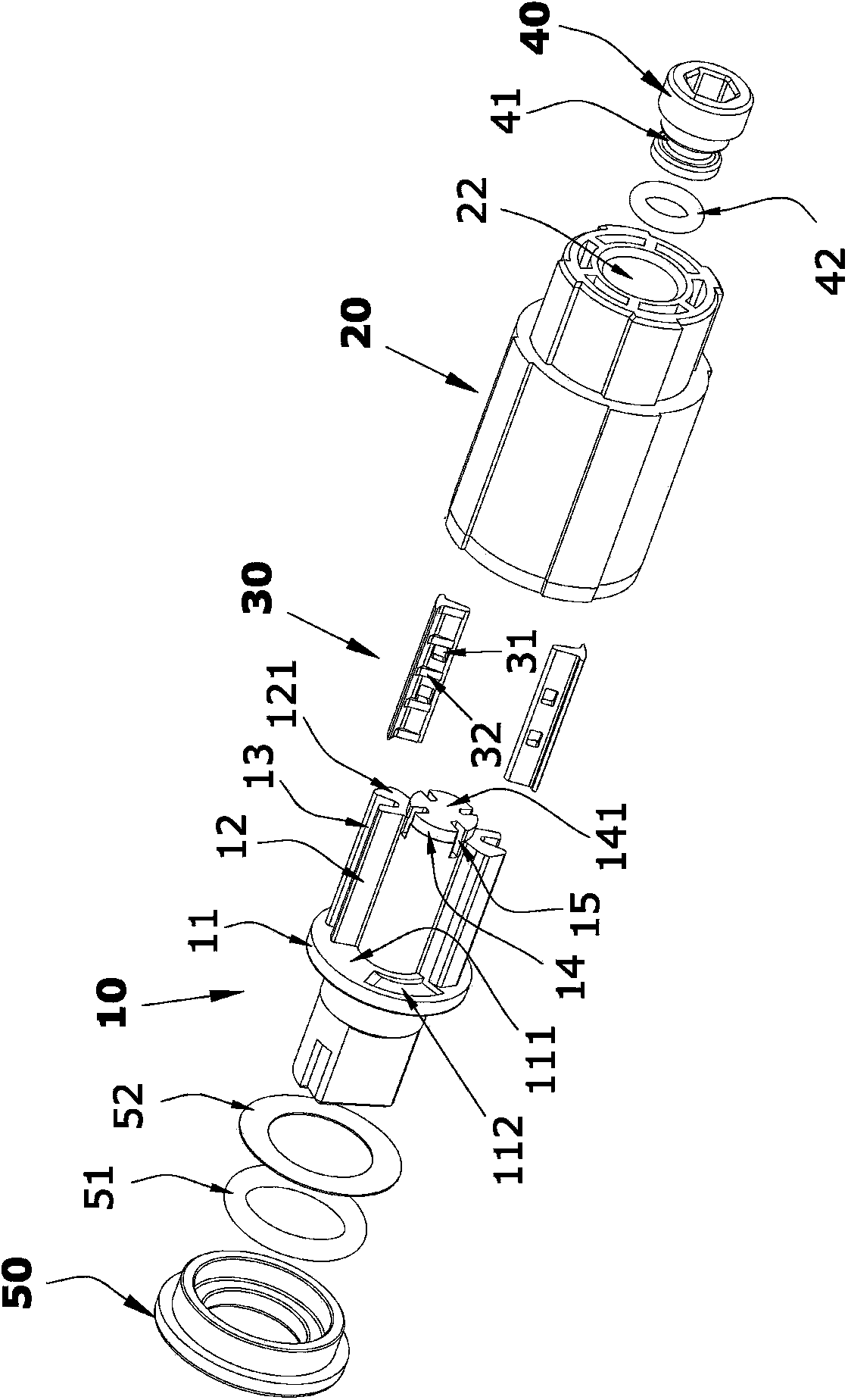

[0032] Embodiment 1 (the pressure-regulating channel is a sinker).

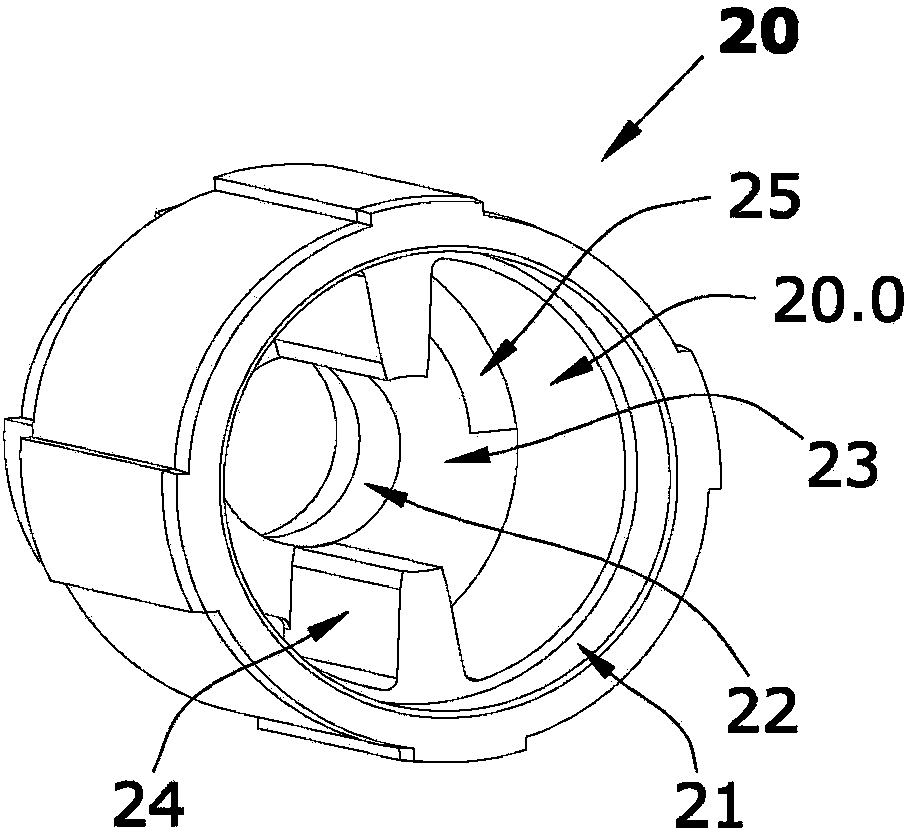

[0033] Such as figure 1 , figure 2 with Figure 9 The rotary buffer with adjustable damping shown is mainly composed of a rotating shaft 10, a shaft sleeve 20, a one-way oil-passing valve plate 30, an adjusting screw 40 and a gland 50; Figure 3 to Figure 9 As shown, the shaft sleeve inner chamber 20.0 of the shaft sleeve 20 of the present invention has an inner cavity opening 21 that can be inserted into the rotating shaft 10 and a shaft through hole 22 for supporting the rotation of the end of the rotating shaft 10. The shaft sleeve inner chamber 20.0 and the shaft through hole 22 forms the bottom surface 23 of the inner cavity, and the center of the two oil-separating ribs 24 is symmetrically arranged on the cavity wall of the inner cavity 20.0 of the shaft sleeve. The opening 21 extends to the inner cavity bottom surface 23 and is fixed, the oil separating rib 24 is flush with the inner cavity openin...

Embodiment 2

[0038] Embodiment 2 (the pressure regulating channel is an L-shaped hole).

[0039] Such as Figure 14 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the pressure regulating channel 15 is an L-shaped hole arranged from the radial surface of the end of the rotating shaft 20 to the shaft end surface 141 of the supporting shaft 14. In this way, the The rotation fit of the support shaft 14 is smoother, and the other structures and working principles of this embodiment are the same as those of the first embodiment.

Embodiment 3

[0040] Embodiment 3 (the pressure regulating channel is an oblique straight hole).

[0041] Such as Figure 15 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the pressure regulating channel 15 is an oblique straight hole arranged from the radial surface at the end of the rotating shaft 20 to the axial end surface 141 of the supporting shaft 14. In this way, The oblique straight-hole pressure-regulating channel 15 is easier to process and ensures smoother rotation of the support shaft 14. The other structures and working principles of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com