Medical low-temperature steam formaldehyde sterilization cabinet and sterilization method thereof

A formaldehyde sterilization cabinet and low-temperature steam technology, applied in heating, chemical and other directions, can solve the problems of low sterilization effect, poor sterilization effect, incomplete sterilization, etc., to avoid dead corners of sterilization and maximize sterilization effect The effect of reducing pollution and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below through specific examples.

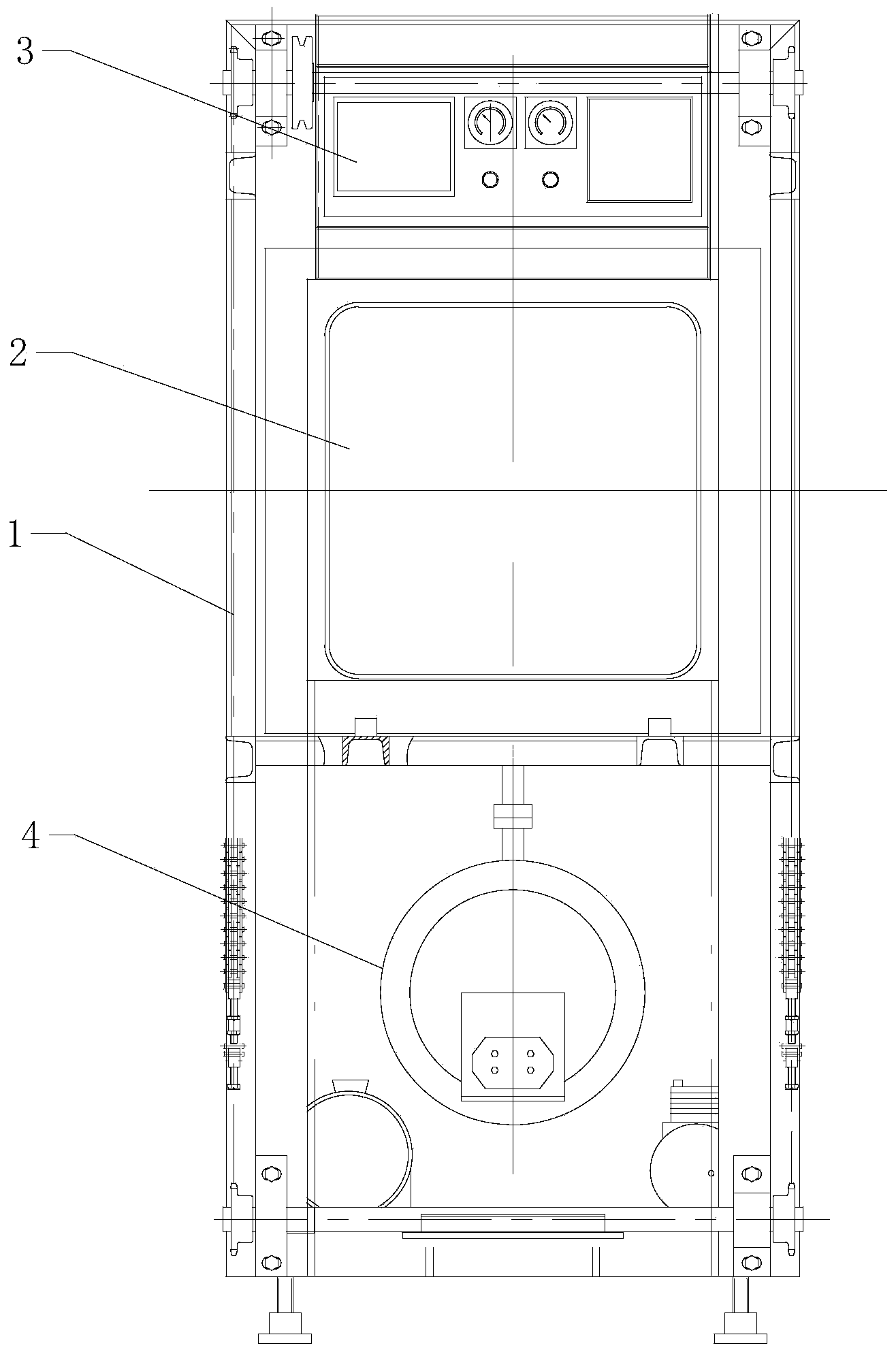

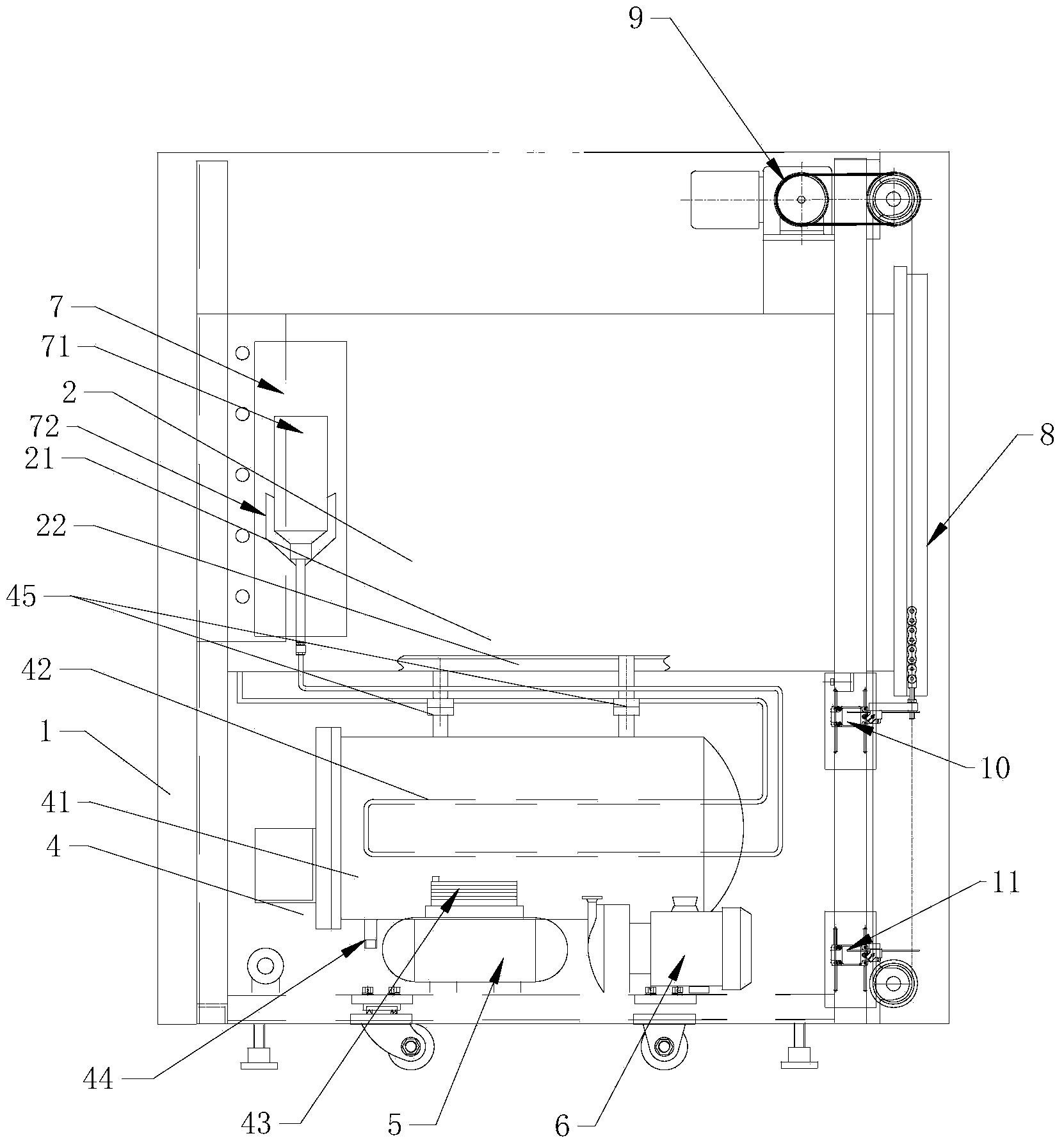

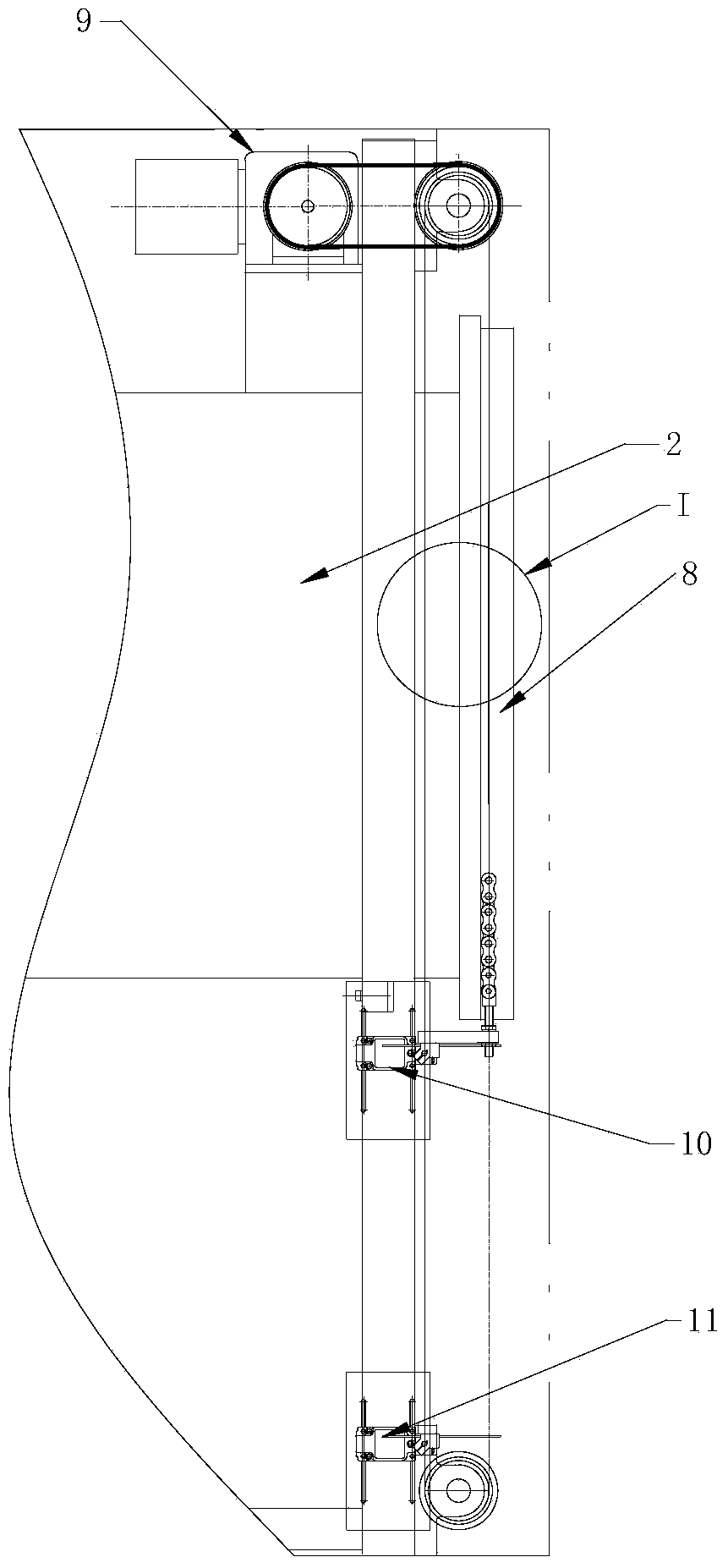

[0031] Such as Figure 1 to Figure 4 As shown, a medical low-temperature steam formaldehyde sterilization cabinet includes a cabinet body 1, a sterilization chamber 2, a formaldehyde solution feeding device 7, a steam generator 4, an electric control device 3, a vacuum device 6 and a clean air supply System 5.

[0032] The cabinet body 1 is used as the installation bearing support for the above components; the bottom of the cabinet body 1 is equipped with rollers for easy movement; the bottom of the cabinet body 1 is also provided with lifting support feet, and when rolling is required, the lifting support feet can be lowered to make the rollers Supported on the ground; when there is no need to move, raise the lifting support feet so that the lifting support feet can support the weight of the entire sterilization cabinet.

[0033] The sterilization cavity 2 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com