Rolling control device and rolling control method

A technology for control devices and rolling materials, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

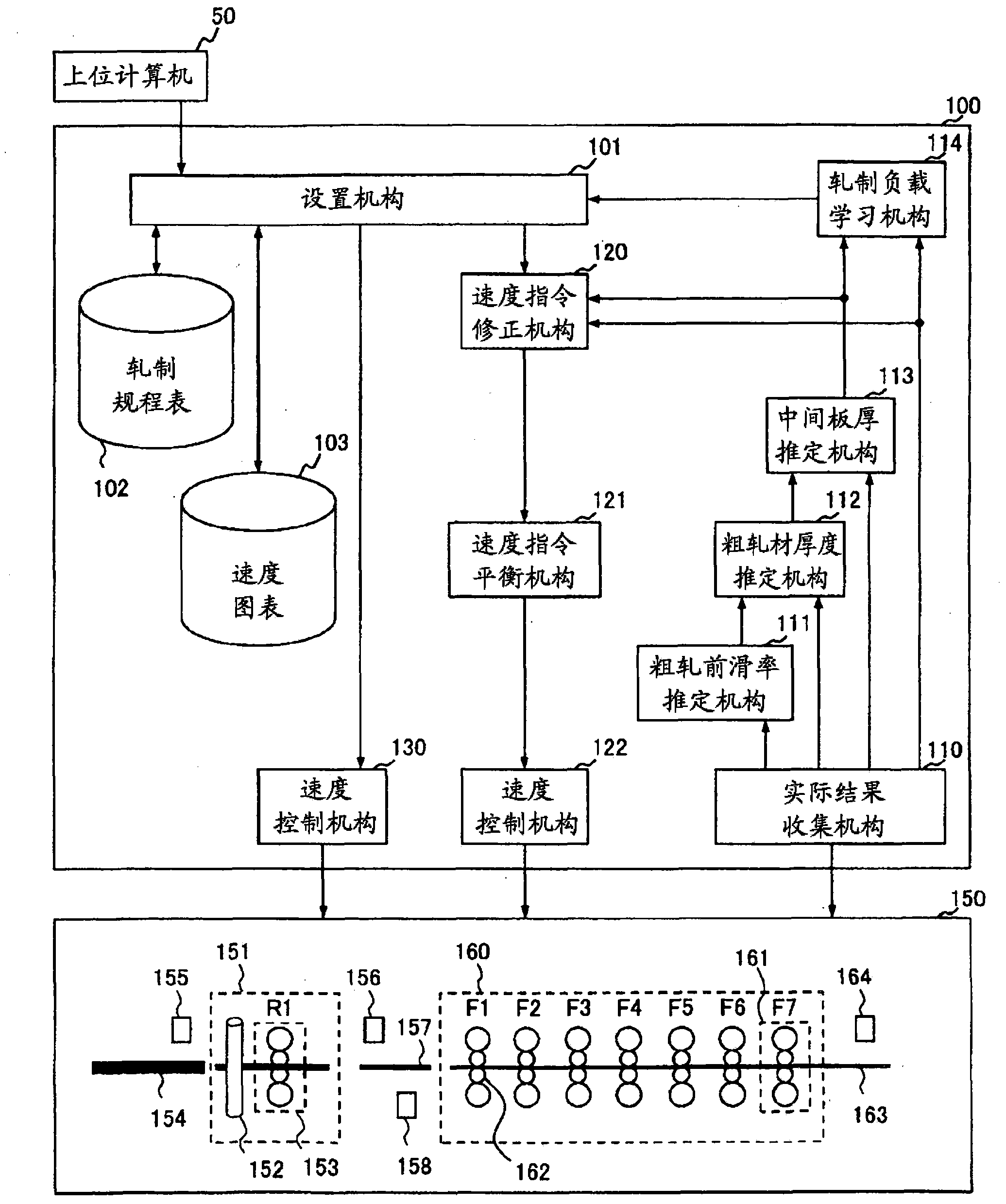

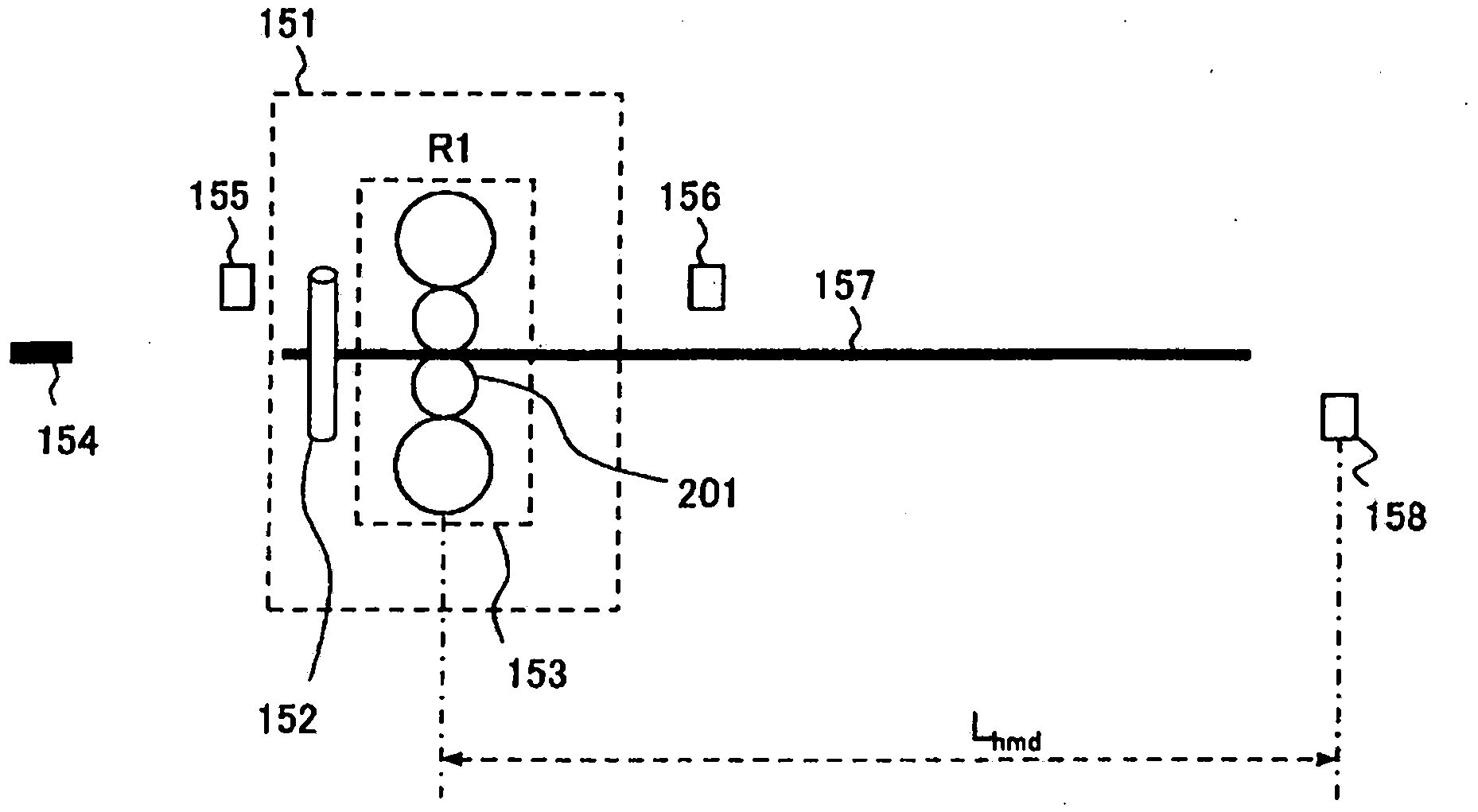

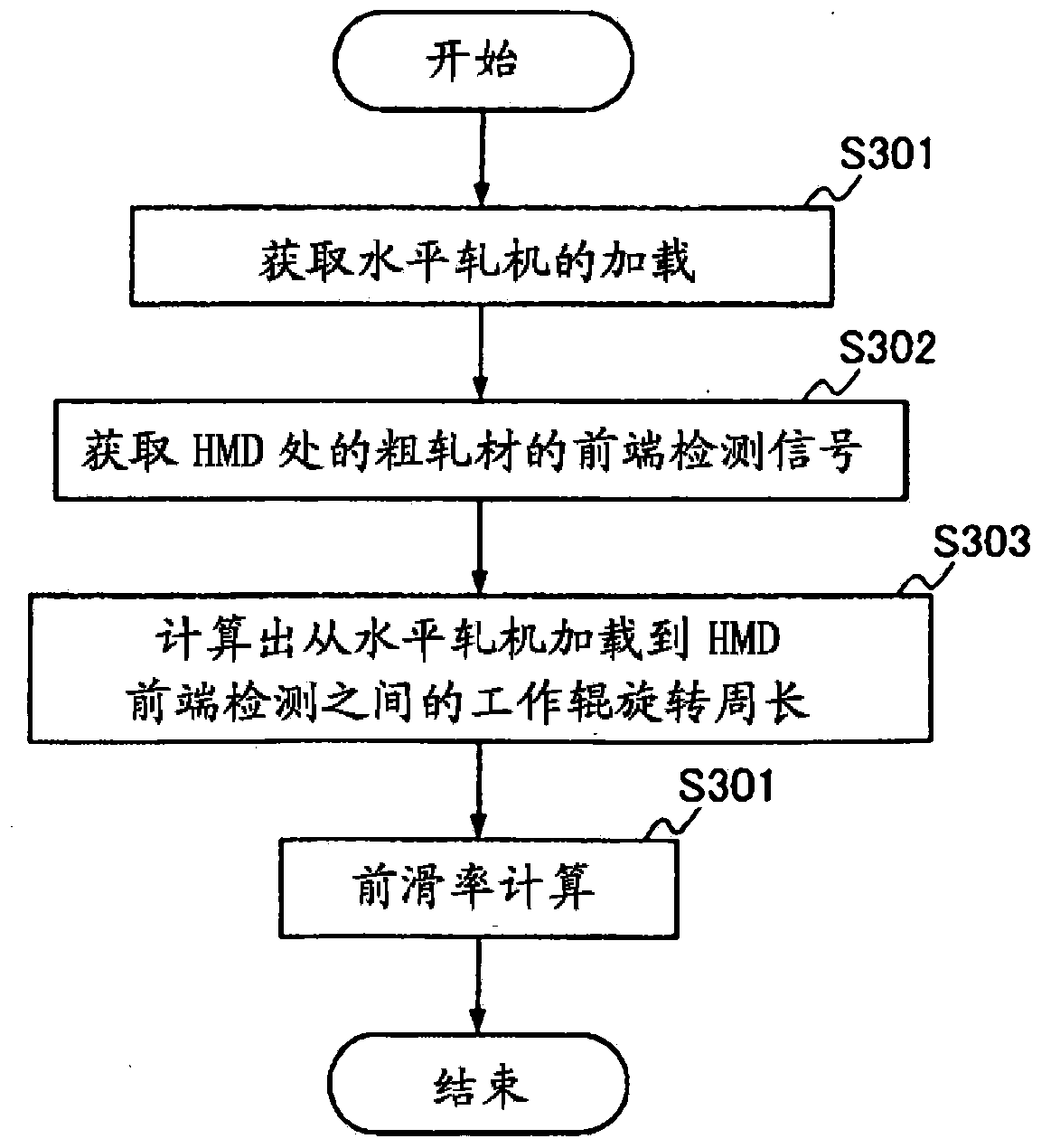

[0037] Hereinafter, embodiments of the present invention will be described in detail using the drawings. In the rolling system of the present embodiment, rough rolling in which a raw material slab is reciprocally rolled to an intermediate thickness, and finish rolling in which the rough-rolled steel material is continuously rolled to a target thickness with high precision are performed. Then, in finish rolling, based on the error between the plate thickness on the entry side of the initial mill stand obtained by the mass flow conservation law and the plate thickness on the entry side of the initial mill stand obtained by different methods, the The intermediate plate thickness obtained by the mass flow conservation law is corrected. This makes it possible to increase the accuracy of the estimated value of the intermediate thickness. As a result, it is possible to stabilize the rolling at the front end of the steel sheet and produce a high-quality steel sheet.

[0038] figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com