A filling machine and a method for protecting the last knuckle heater of the filling machine

A heater and filling machine technology, applied in packaging protection, packaging, transportation packaging and other directions, can solve the problems of low operation rate of filling machine equipment, burning of the last corner heater, failure to open the pressure regulating valve by mistake, etc. The effect of reducing maintenance time, improving equipment operation rate and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

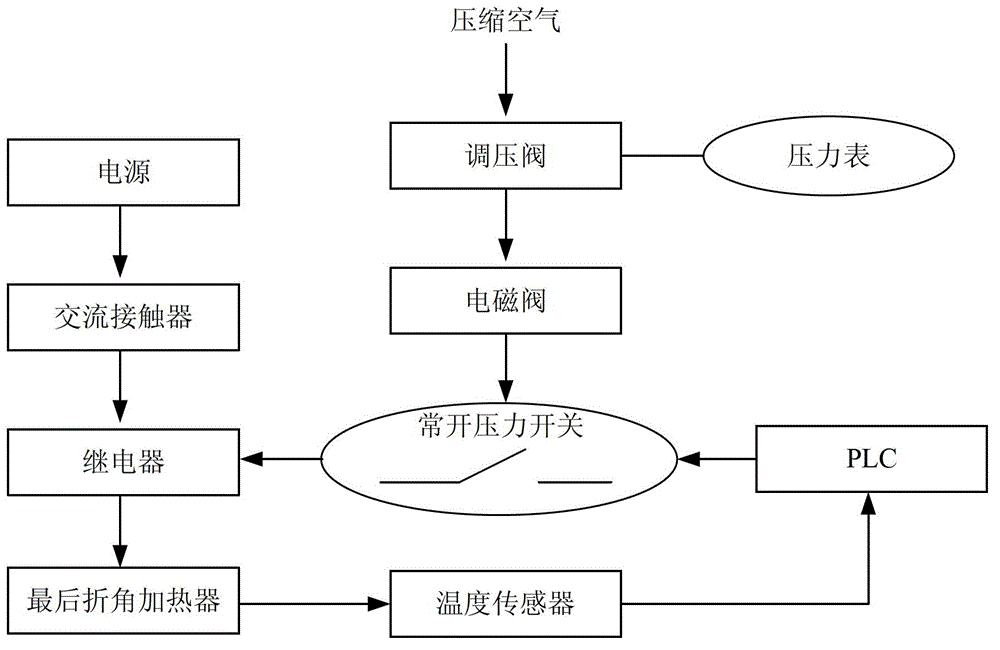

[0063] In this embodiment, protection measures for the last knuckle heater are added to the last knuckle unit of the domestic commonly used filling machine. This technical solution effectively solves the phenomenon that the last knuckle heater burns out due to the reduction of compressed air pressure when the last knuckle heater is working. It has the advantages of high reliability, simple structure, economical and practical, reduced fault maintenance time, and improved equipment operation rate.

[0064] In this embodiment, a pressure switch is added to the circuit of the last knuckle unit of the filling machine, which effectively solves the problem that the last knuckle heater burns out due to the pressure reduction of the compressed air passing through the last knuckle heater during the filling machine’s heating up, production and maintenance. Phenomenon.

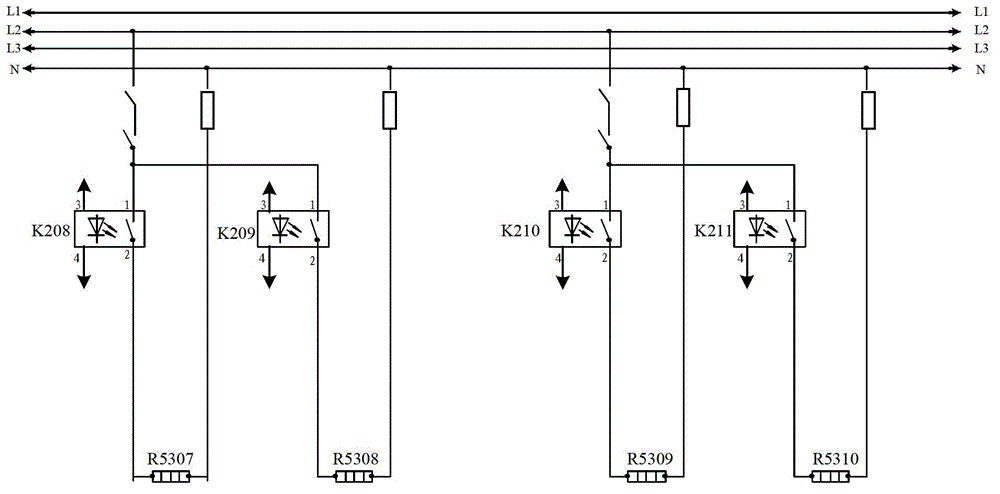

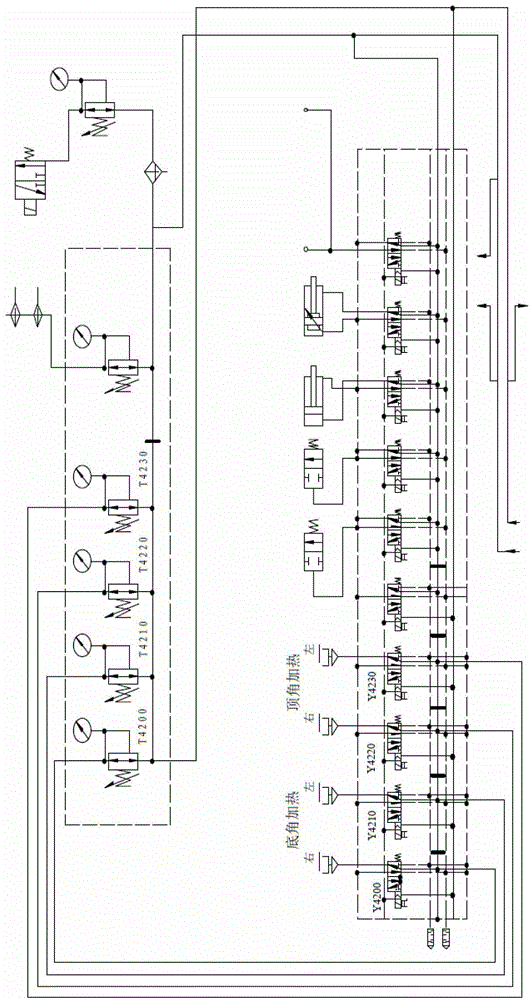

[0065] like Figure 5 Shown is the control circuit diagram of the modified last knuckle unit in the filling machine o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com