Device and method for strengthening multistage A/O process biological nitrogen removal

A biological denitrification and process technology, applied in the field of sewage treatment, can solve the problems of SND accumulation of nitrogen, inability to remove COD, no refinement of specific forms and operating parameters, etc., to save denitrification carbon sources, strengthen SND phenomenon, The effect of increasing the accumulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The same domestic sewage as the above comparative example was used as the research object.

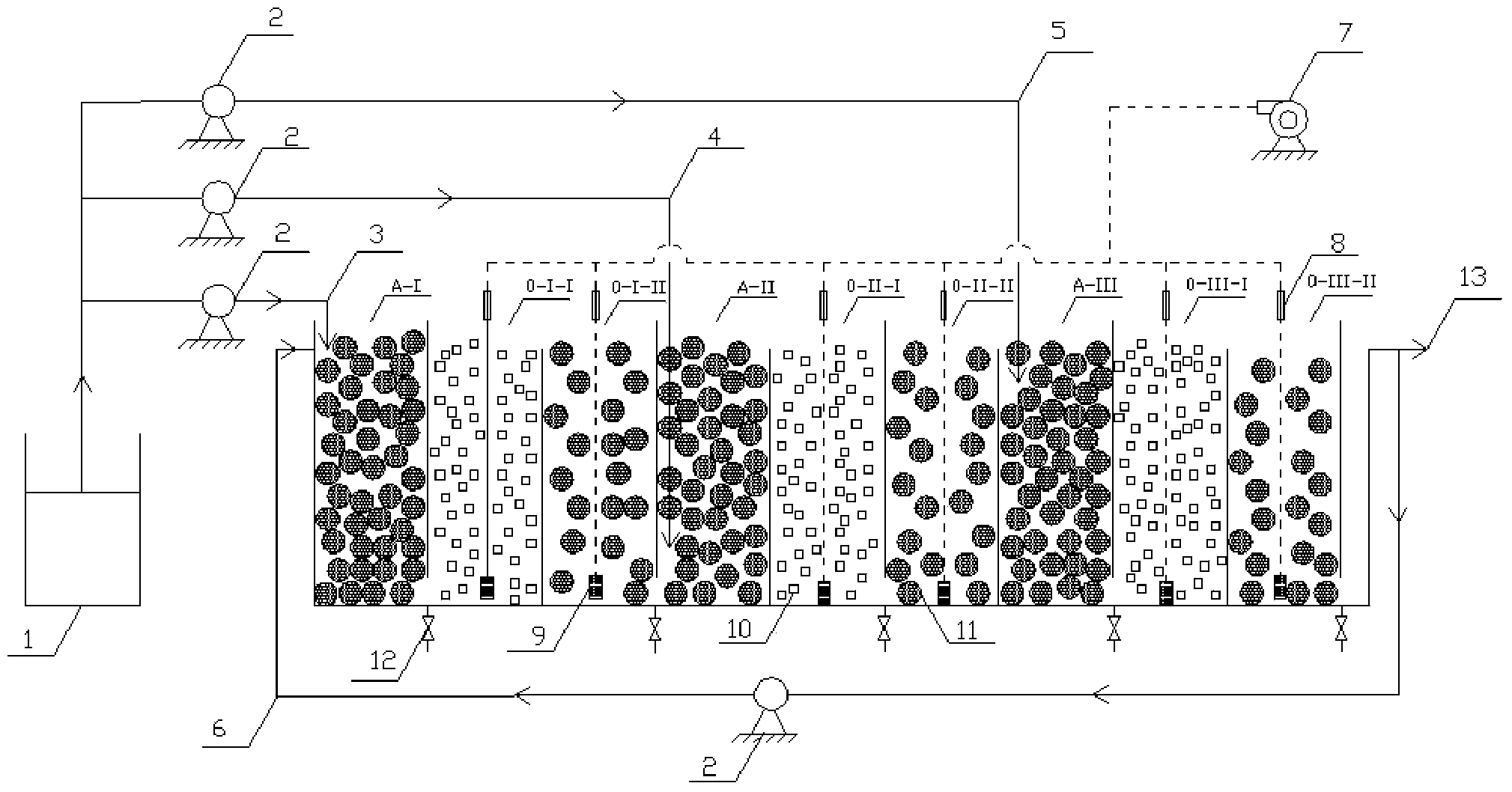

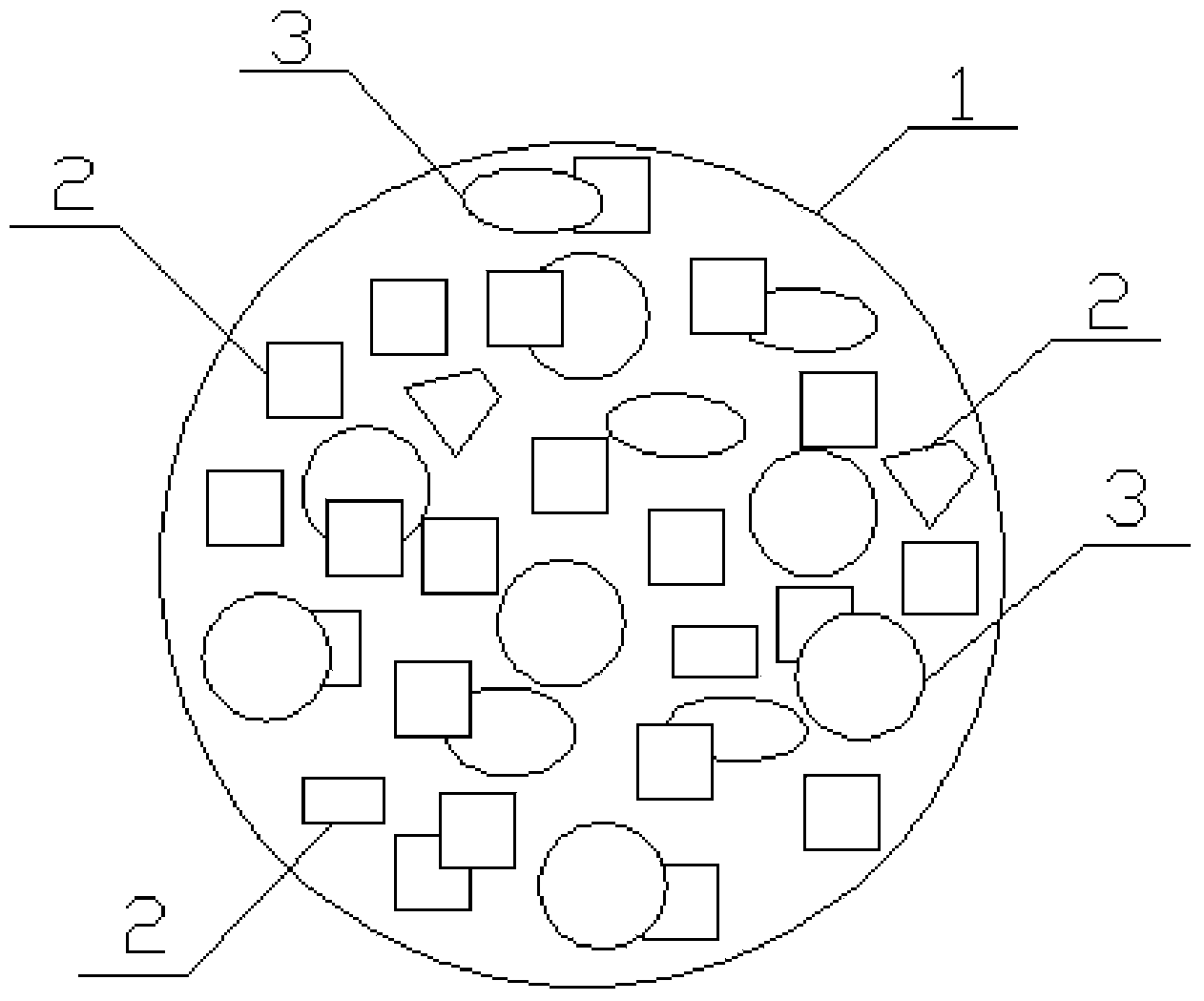

[0040] Three-stage A / O process is adopted, followed by anoxic zone A-I, aerobic zone O-I-I, aerobic zone O-I-II, anoxic zone A-II, and aerobic zone O-II-I , aerobic zone O-Ⅱ-Ⅱ, anoxic zone A-Ⅲ, aerobic zone O-Ⅲ-Ⅰ, aerobic zone O-Ⅲ-Ⅱ, the volume ratio of each aerobic zone to anoxic zone is (0.8~ 1) : 1. Fill the suspended floating balls in A-Ⅰ, O-Ⅰ-Ⅱ, A-Ⅱ, O-Ⅱ-Ⅱ, A-Ⅲ, O-Ⅲ-Ⅱ respectively, and fill the inside of the suspended floating balls with three-dimensional sponge and abalone Erhuan, the ratio of the two is 2:1, and the filling ratio is controlled between 70% and 80%. The filling rate of drift balls in the anoxic zone A-Ⅰ, A-Ⅱ, A-Ⅲ is controlled between 80% and 90%. The filling rate of drift balls in O-Ⅰ-Ⅱ, O-Ⅱ-Ⅱ, O-Ⅲ-Ⅱ in aerobic zone is controlled between 40% and 50%. In the aerobic zone O-I-I, O-II-I, and O-III-I, the three-dimensional sponge fillers are respectively fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com