Truss system used for cold-formed thin-walled steel structure

A truss system, cold-formed thin-walled technology, applied in the field of truss systems, can solve problems such as local compression buckling damage, weak node stiffness, etc., to increase the force-bearing area, improve stiffness and strength, and enhance the ability to resist external forces and deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

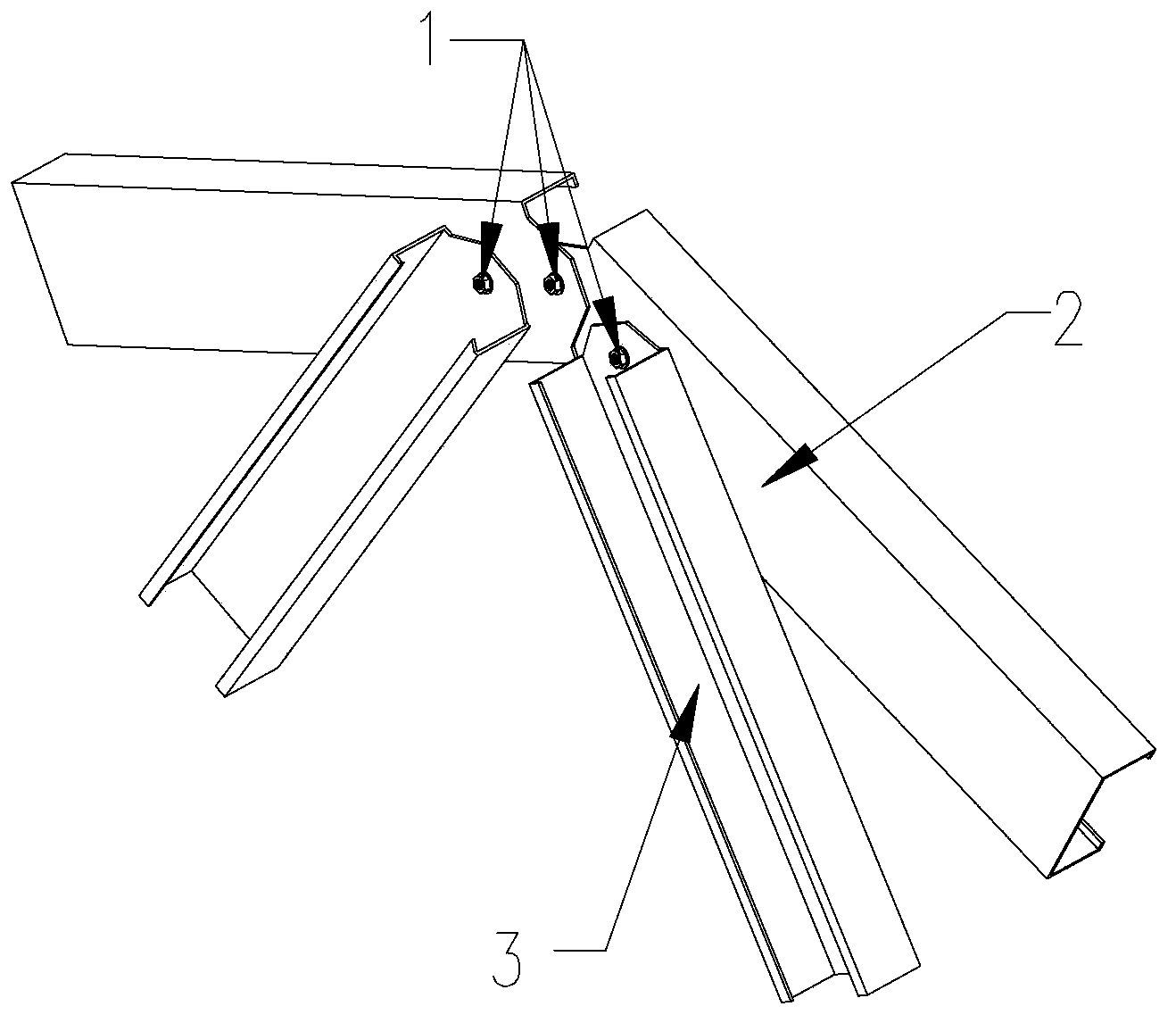

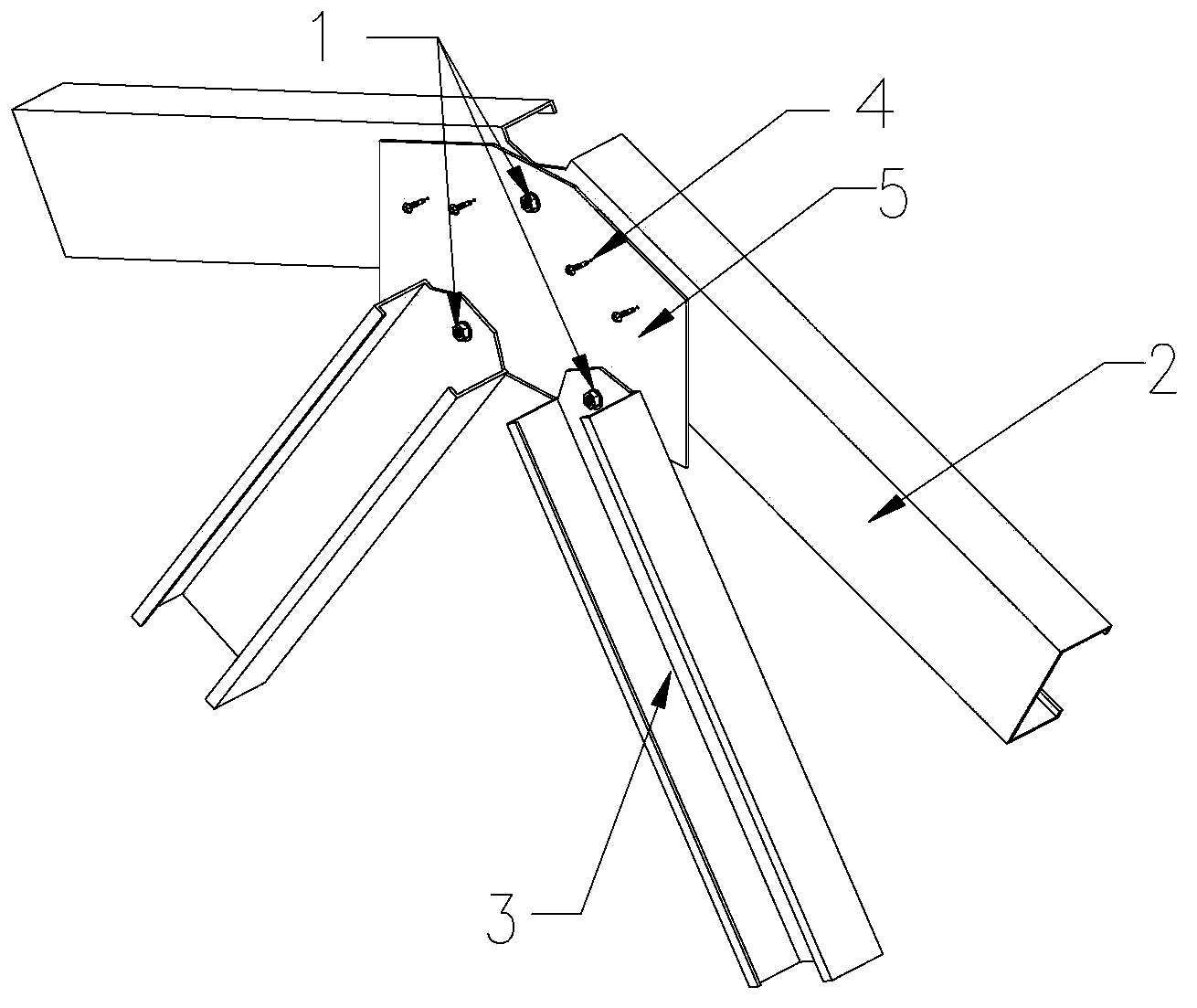

[0019] like figure 2 As shown, a truss system for cold-formed thin-walled steel structures includes truss chords 2, truss webs 3 and roof gussets 5, and the truss chords 2 and truss webs 3 are connected through the roof gussets 5 .

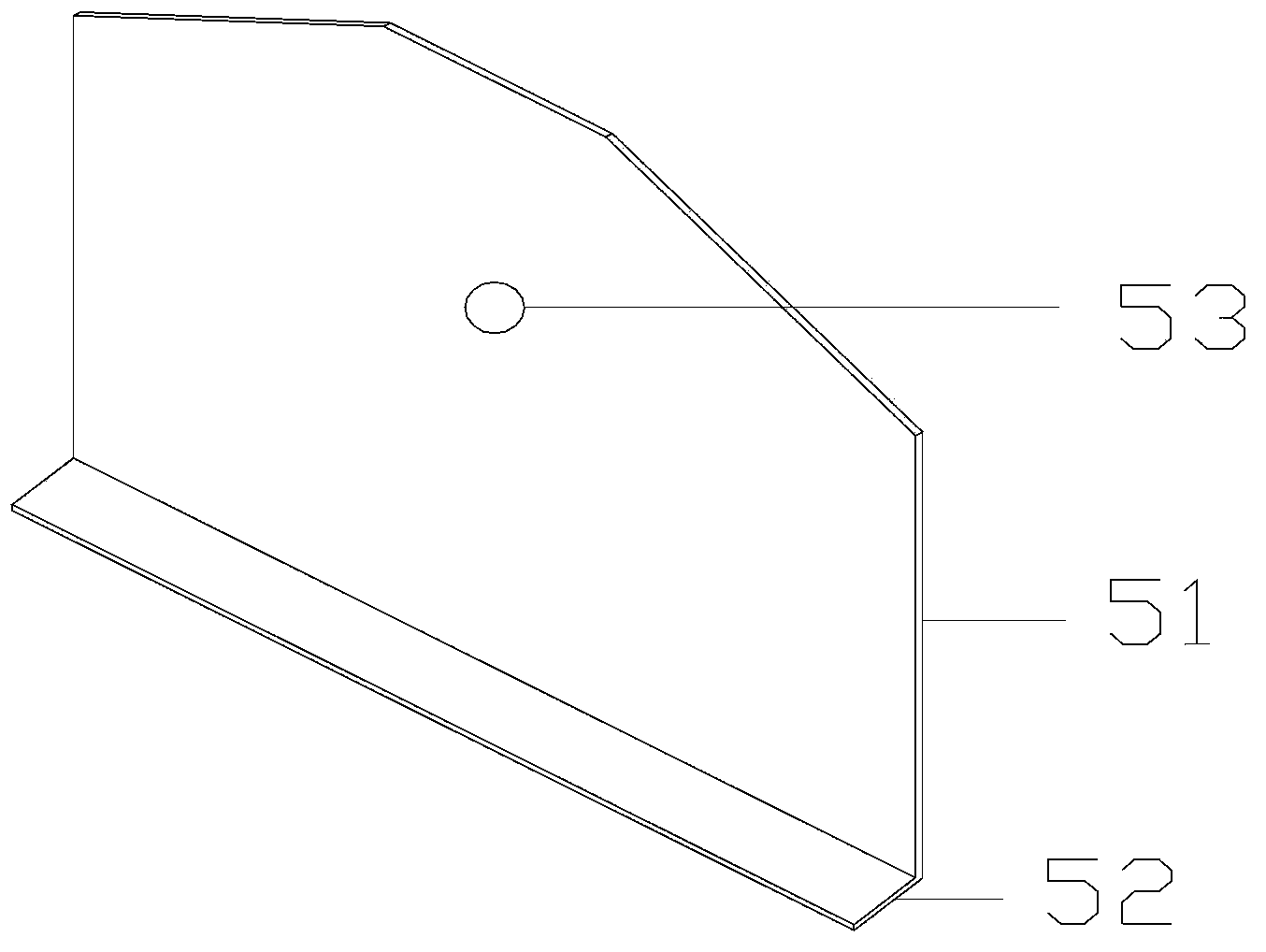

[0020] like image 3 As shown, the ridge gusset plate 5 includes an upper flat plate 51 and a lower folded edge 52, and the upper flat plate 51 and the lower folded edge 52 are connected at an angle of 90 degrees. The upper plate 51 is provided with an upper plate opening 53 .

[0021] There are two truss chords 2 , and the ends of the two truss chords 2 are connected by positioning structural bolts 1 , and then connected with the ridge gusset plate 5 through the upper plate opening 53 . The truss chord 2 is fixed on the upper plate 51 of the ridge gusset plate 5 by self-drilling screws 4 . 2 to 6 self-drilling screws can be provided as required, and 4 self-drilling screws are used in this embodiment. The truss web member 3 is fixed on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com