Swing arm type pipe rod spatial slideway

A swing arm and slideway technology, which is applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of unfavorable operation system automation, semi-automation situation development, failure to meet the requirements of operation and production safety situation, troublesome wellhead operators, etc. , to achieve the effect of protecting the oil pipe thread, eliminating potential safety hazards, and reducing back and forth walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

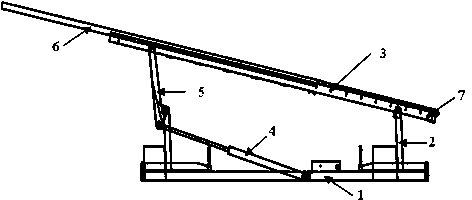

[0025] The utility model relates to a swing arm type pipe rod space slideway, which is characterized in that it is composed of a mechanical part, a hydraulic system and an electrical system connected.

[0026] The mechanical part is composed of a base 1, a swing arm 2, a platform 3, a main hydraulic cylinder 4, a turning arm 5, a slideway 6 and a horizontal conveying hydraulic cylinder 7, and is characterized in that: the base 1 is connected to the swing arm 2, the swing arm 2 One group is connected to the platform 3, the other group is connected to the rotating arm 5, one end of the rotating arm 5 is connected to the main hydraulic cylinder 4, the other end is embedded in the platform 3 to slide, the slideway 6 is installed on the platform 3, and the horizontal feeding hydraulic cylinder 7 is installed on the platform. 3, connected with the slideway 6, which can push the slideway 6 to slide back and forth on the platform 3.

[0027] The hydraulic system consists of a hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com