Gravel pump gravel filling method

A gravel pump and gravel filling technology, applied in the field of gravel filling with sand and gravel pumps, can solve the problems of bridging, time-consuming, poor accuracy of gravel throwing, etc. The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

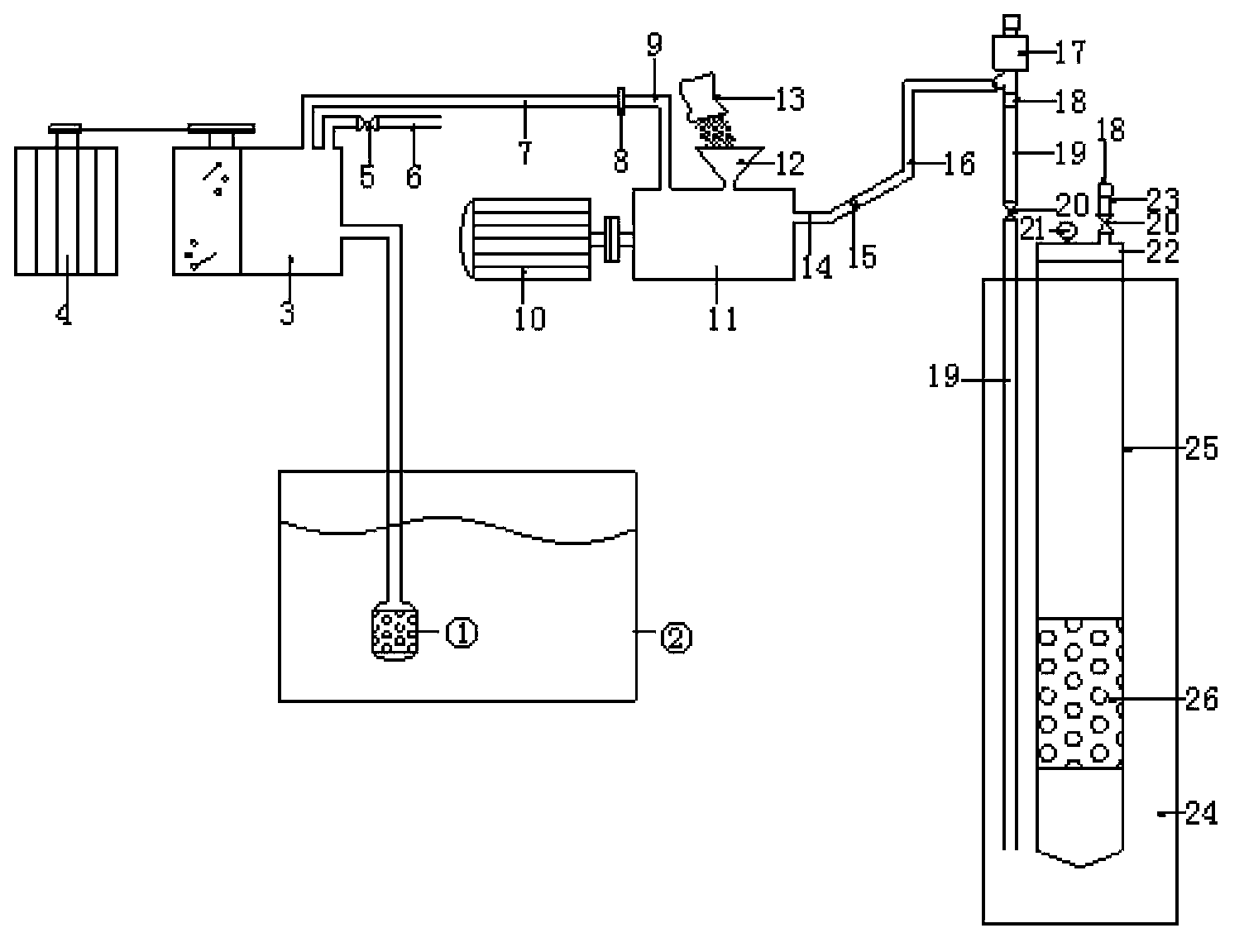

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] The invention provides a gravel filling method of a sand and gravel pump, which comprises the following steps in turn:

[0017] Step 1, installing the gravel throwing pipe 19 to a position 1 meter below the lower end of the filter 26;

[0018] Step 2, open the valve 5 of the mud pump 3, start the mud pump 3 to supply water to the gravel pump 11, and then start the gravel pump 11 to pump clean water into the backfill gravel space 24;

[0019] Step 3. After the top opening of the backfill gravel space 24 returns water, add the cleaned gravel 13 to the gravel funnel 12. When starting to put the gravel 13, first add a small amount of gravel 13 evenly. When the gravel 13 is conveyed evenly and smoothly Increase the throwing amount of gravel 13 again;

[0020] Step 4. When the gravel 13 is poured into the gravel funnel 12 for water gushing or the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com