Direct pipelayer

A pipelayer, direct technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of wasted construction time, low slag discharge efficiency, small drilling diameter, etc., to improve construction efficiency and high degree of mechanical automation , the effect of shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

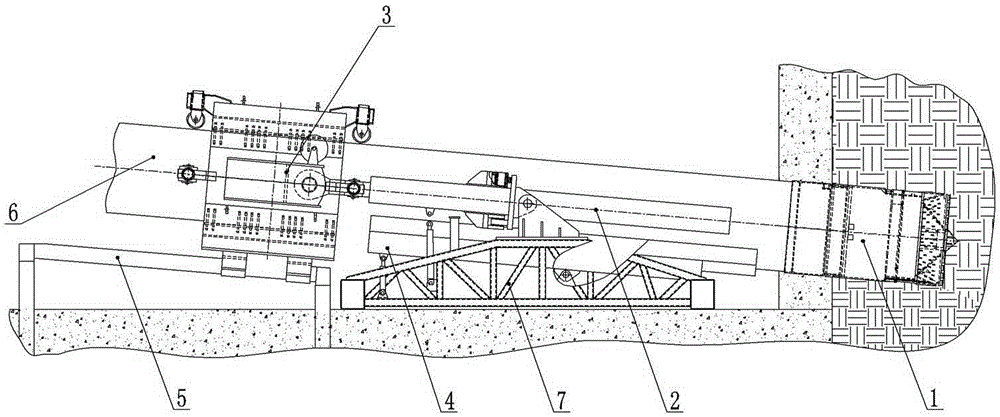

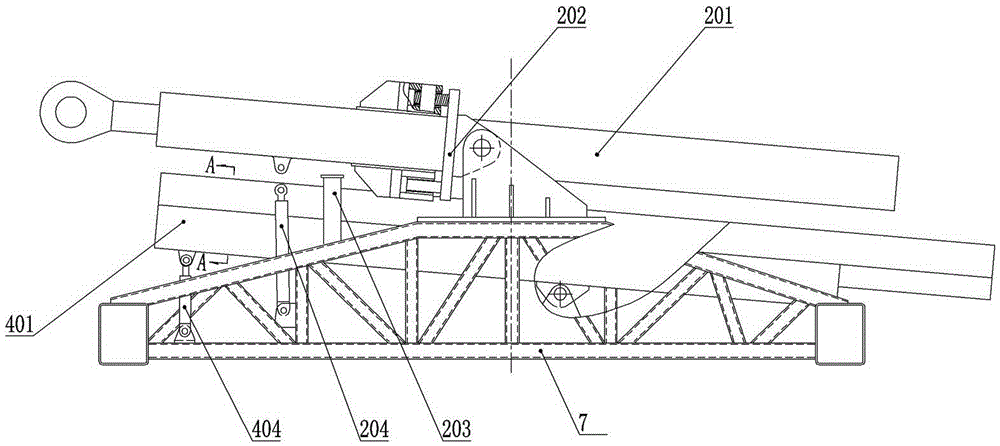

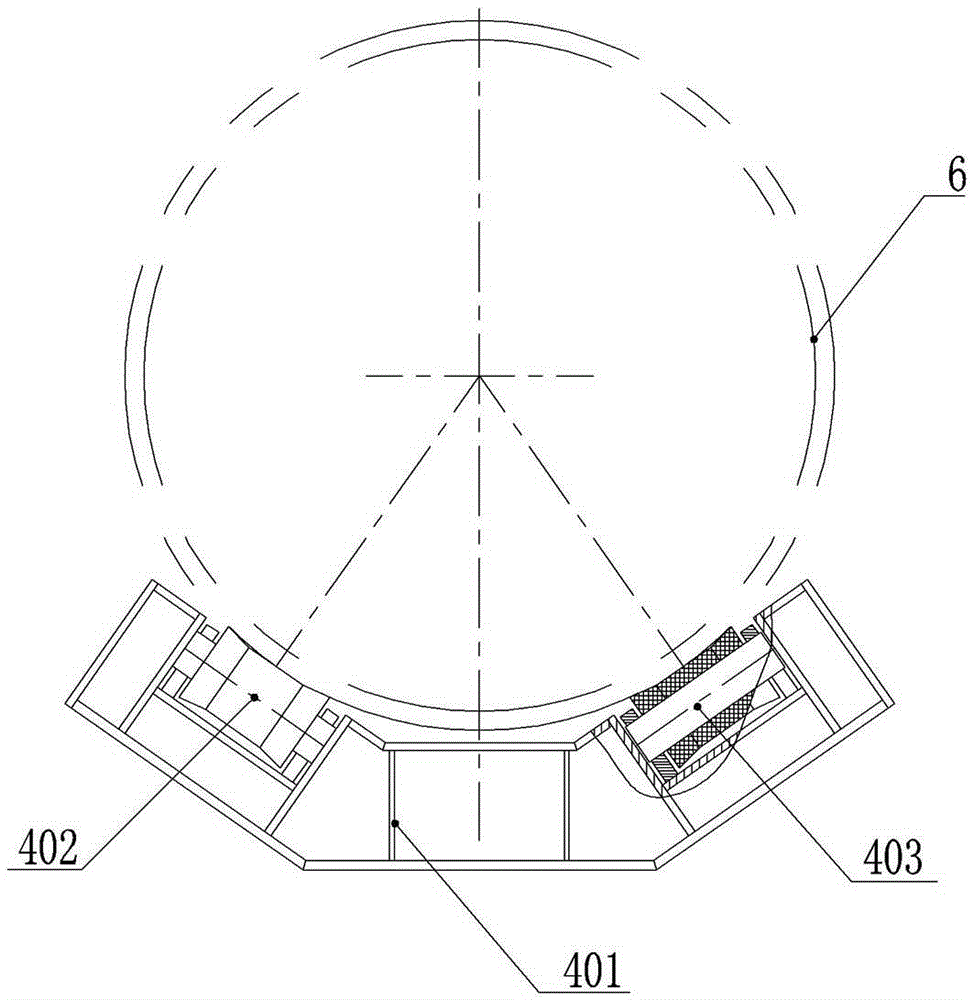

[0025] see Figure 1-Figure 6 , a direct pipe-laying machine, comprising an underframe 7, a roadheader 1 arranged at the front end of the underframe 7, a supporting device 4 arranged at the lower part of the roadheader 1 for supporting and guiding the roadheader 1, and a The pipeline 6, the clamping device 3 arranged at the back of the boring machine 1 to support the pipeline 6, and the propulsion device 2 arranged between the clamping device 3 and the supporting device 4, the supporting device 4 includes a The joist matching the pipeline 6, the joist includes a groove-shaped joist main body 401 and a rubber wheel 402 arranged in the groove for supporting the roadheader 1 or the pipeline 6, the rubber wheel 402 is connected with the mandrel 403 The joist main body 401 is connected, one end of the bottom of the joist main body 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com