Construction method for shield machine to enter hole to receive concrete box

A construction method and concrete technology, which can be used in earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as low construction efficiency and uncertainty in risk control, so as to prevent soil collapse, facilitate recharge, and maintain earth pressure balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

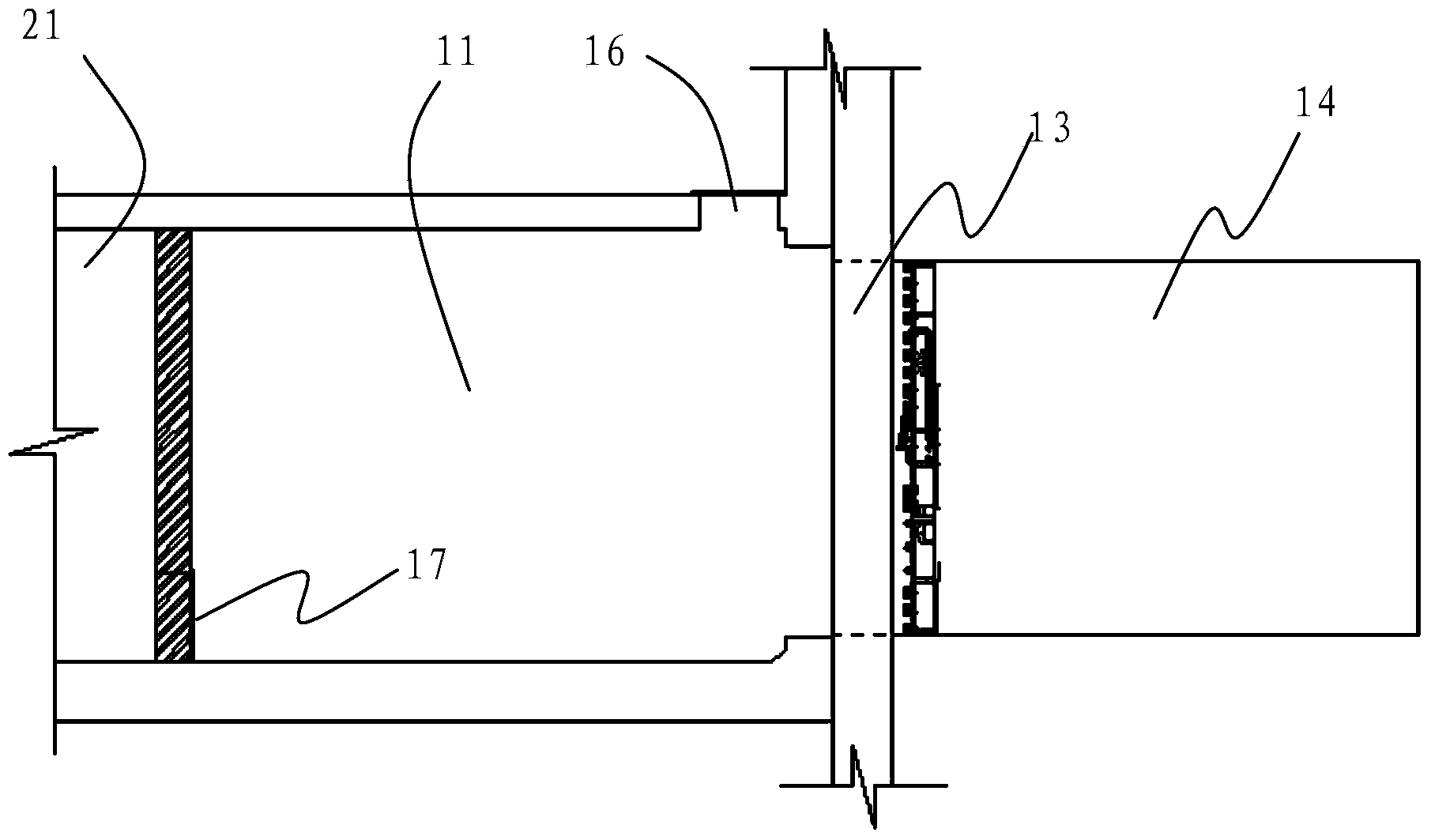

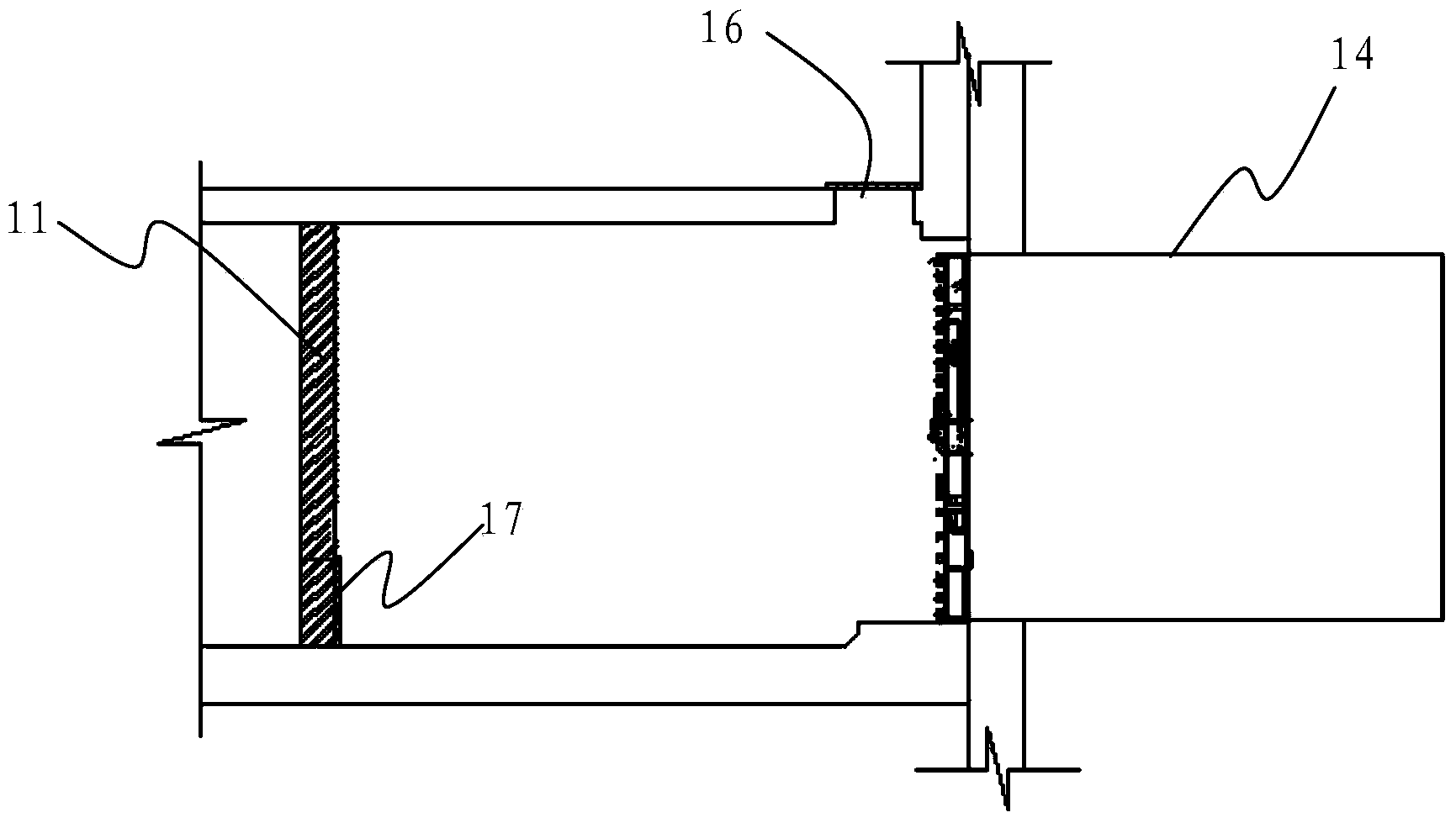

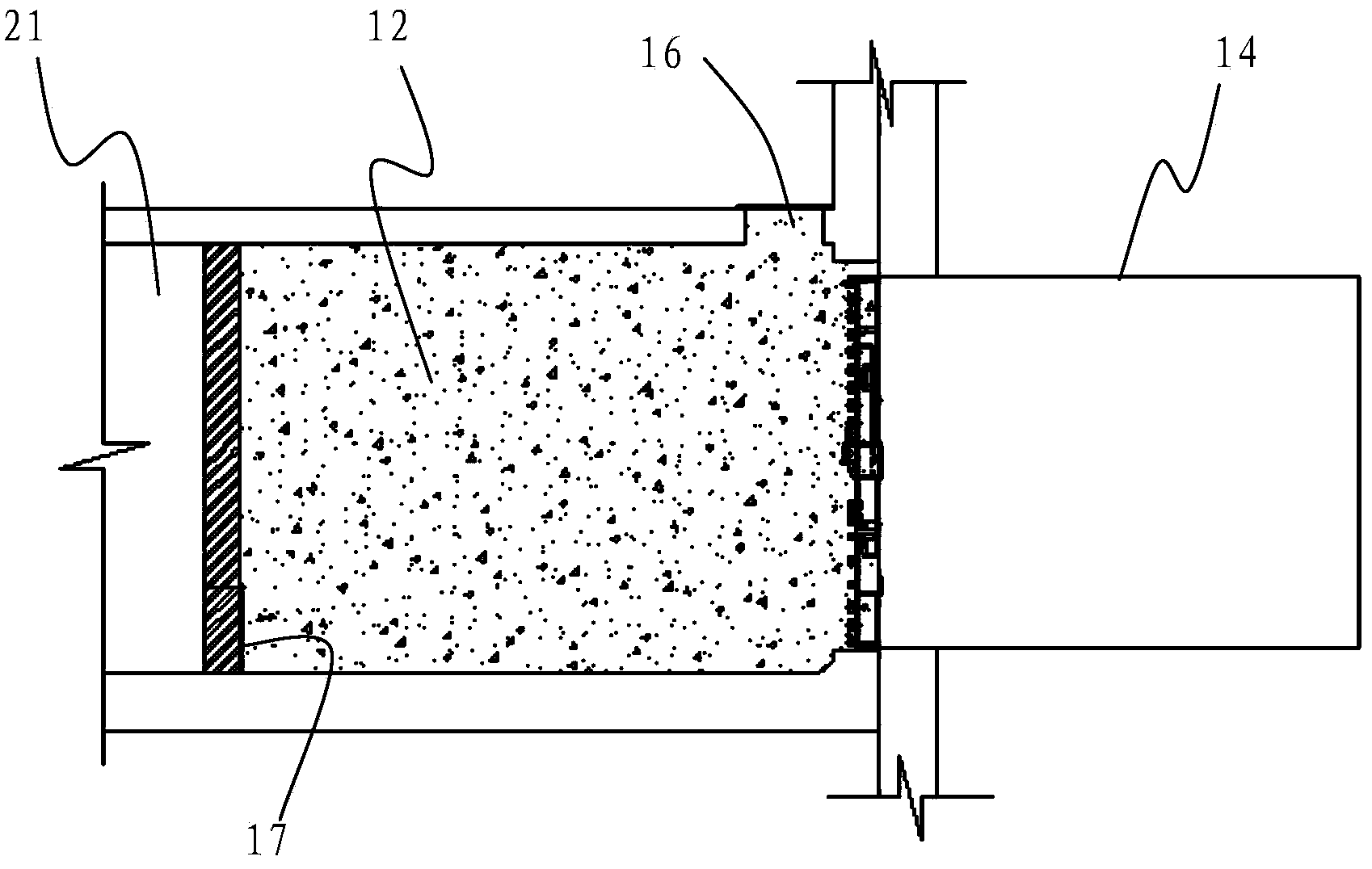

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0054] see first figure 1 and figure 2 As shown, the construction method of the concrete box shield tunneling reception of the present invention mainly adopts the closed concrete box 11 mode to implement the shield tunneling reception, and constructs a concrete box 11 in the receiving shaft 21, and cooperates with image 3 As shown, the concrete box 11 is filled with foamed lightweight concrete 12, and the foamed lightweight concrete 12 reaches a compressive strength ≥ 1 MPa after pouring and curing for 3 days, which meets the cutting and bearing capacity requirements of the shield machine. The backfilling operation is carried out after the opening 13 is broken. . recombine Figure 4~6 As shown, after the strength index of the foam lightweight concrete 12 meets the design requirements, the shield tunneling 14 receiving operation i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com