Adjustable brake assembly for tricycle

A tricycle and assembly technology, applied in the direction of brake parts, slack adjusters, etc., can solve the problems of prolonged braking time, insensitive braking, waste, etc., and achieve the effect of prolonging service life and improving braking sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

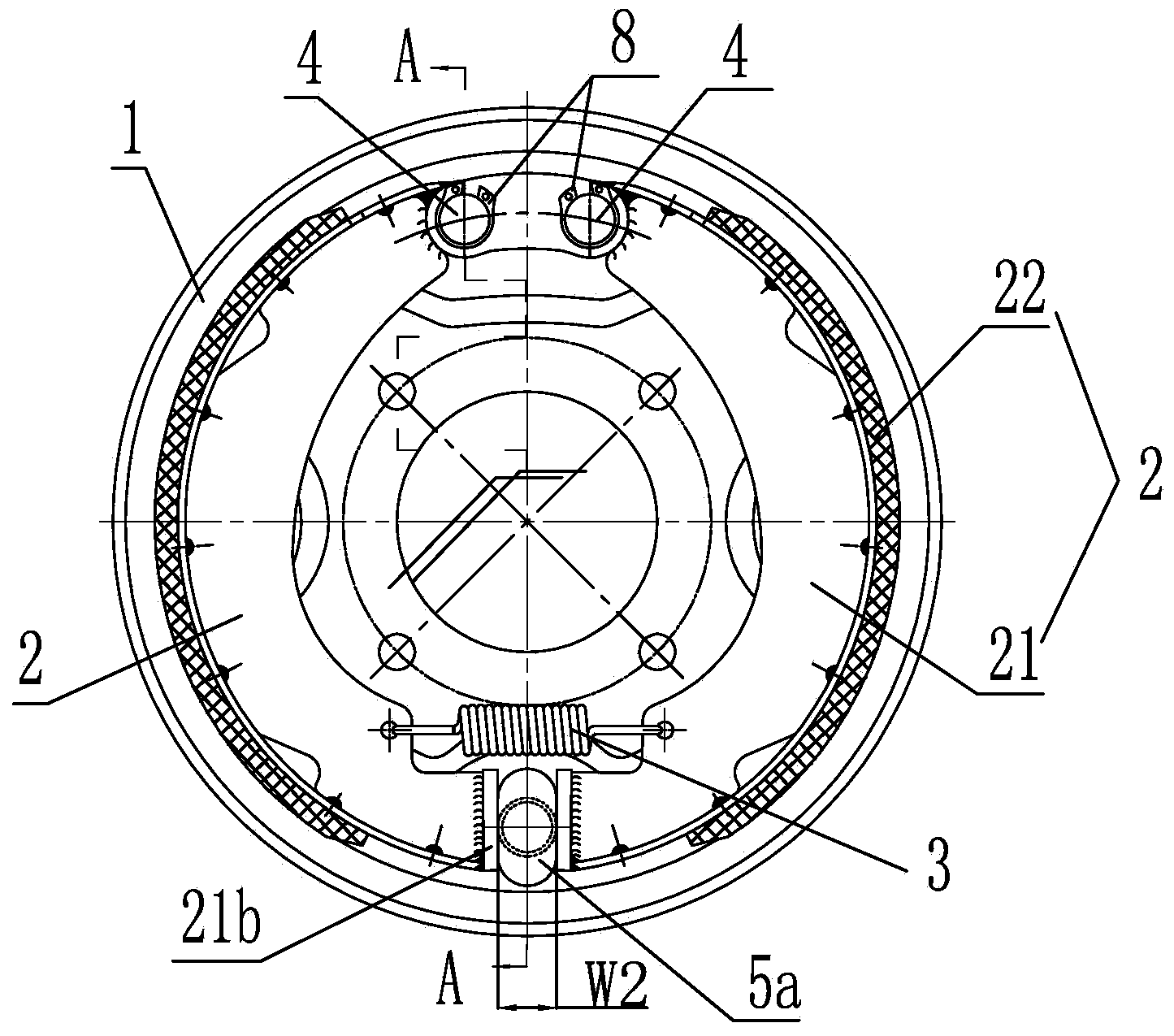

[0018] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

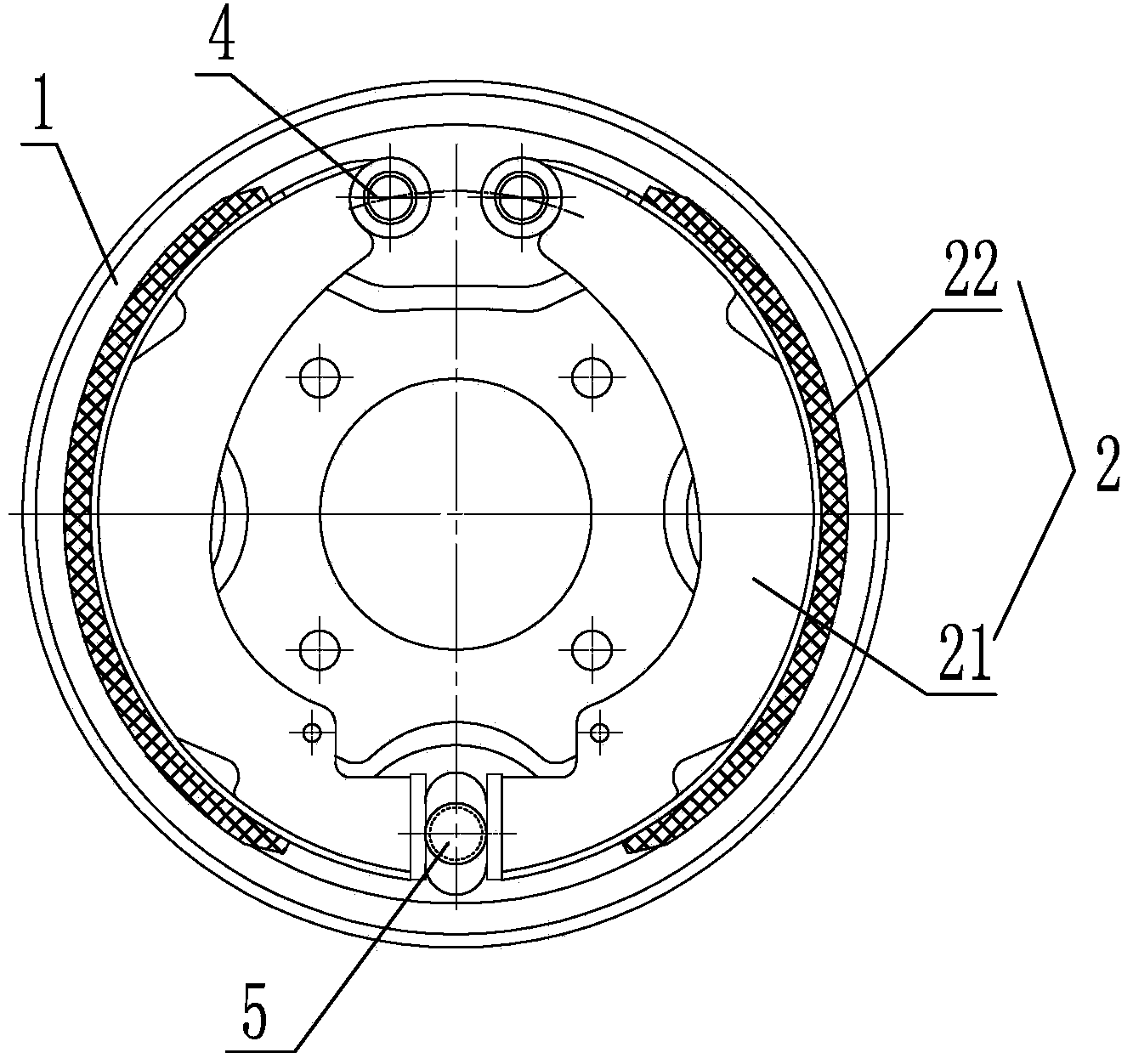

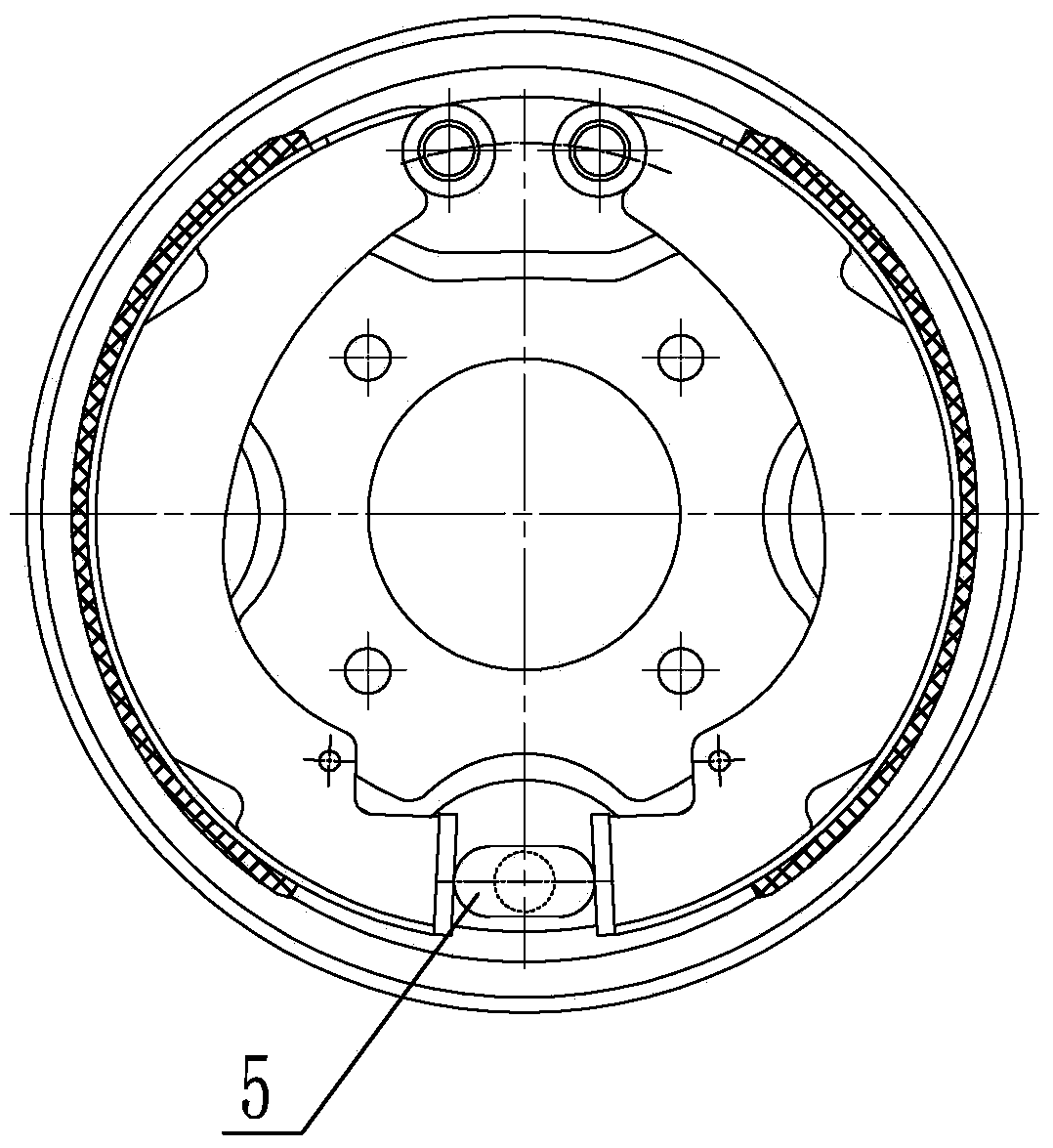

[0019] combine image 3 —— Figure 5 As shown, an adjustable brake assembly for a tricycle has a left-right symmetrical structure as a whole, consisting of a brake disc 1, a pair of brake shoe assemblies 2, a tension spring 3, a brake pin 4, a brake shaft 5, and a scale pointer steel plate 6 , Nut 7, limit jumper 8 etc. are formed.

[0020] A pair of brake shoe assemblies 2 are relatively installed on the front of the brake disc 1, and a tension spring 3 is installed between the two brake shoe assemblies 2, and the upper part of the back of the brake disc 1 is welded with two left and right symmetrical brake pads. Pin sleeve 1a, a brake pin 4 is housed in each brake pin sleeve 1a, a brake shaft sleeve 1b is welded at the lower center position of the brake disc 1 back, and a brake shaft 5 is housed in the brake shaft sleeve 1b. The brake shoe assembly 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com