Steam pressure reducing cooling valve

A desuperheating valve and steam technology, which is applied in sliding valves, valve details, safety valves, etc., can solve the problems that desuperheating water cannot be vaporized, water hammer, and the effect of desuperheating and vaporization is reduced, so as to ensure the decompression effect and shorten the equipment structure. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

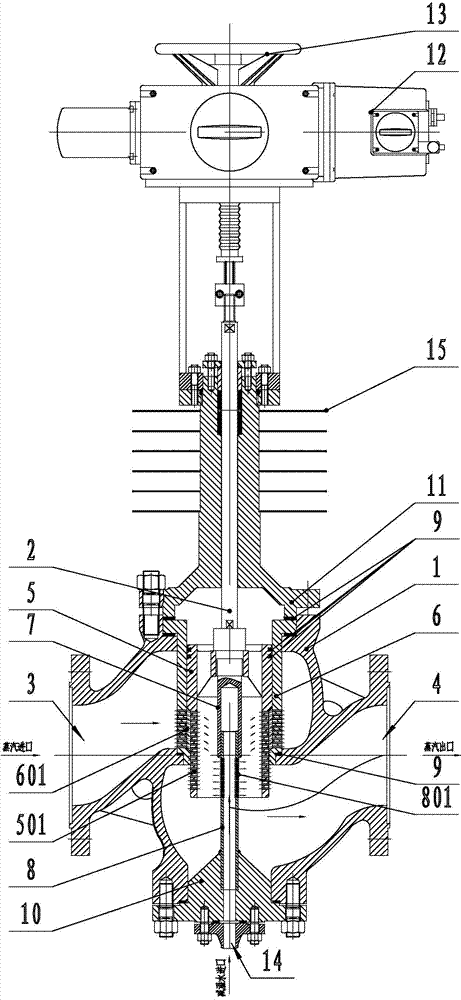

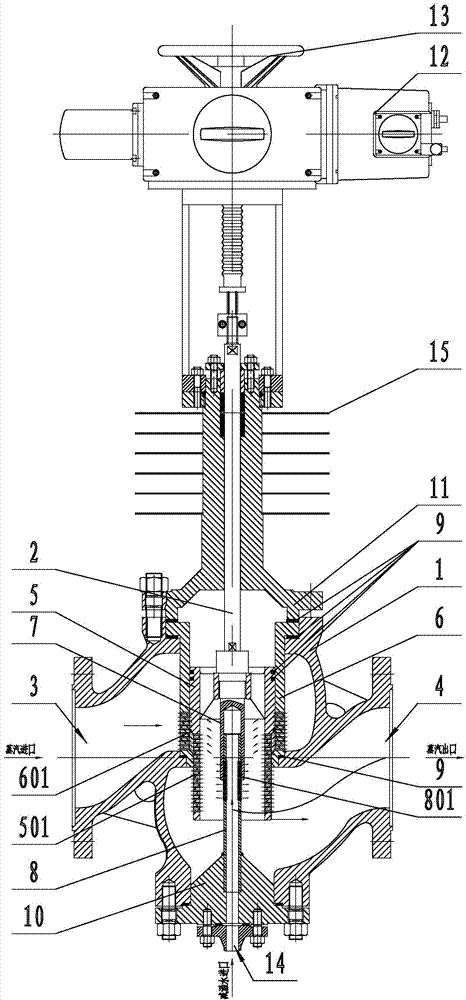

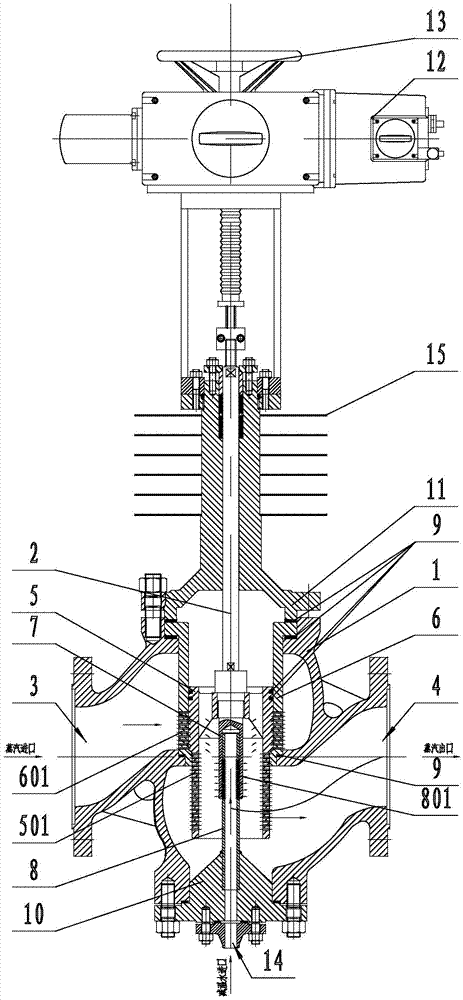

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the present invention includes a valve body 1, a spool 2 disposed in the valve body 1, an inner sleeve 5, an outer sleeve 6 that is overlaid on the inner sleeve 5, an actuator that drives the spool 2 to move up and down, and the valve body 1 Steam inlet 3 and steam outlet 4 are respectively provided on the left and right sides, a plurality of second small holes 501 and first small holes 601 are respectively provided on the inner sleeve 5 and the outer sleeve 6, and the outer sleeve 6 is fixed on the valve body 1, cut off the passage of the steam inlet 3 into the valve, the first small hole 601 of the outer sleeve 6 communicates with the steam inlet 3, the inner sleeve 5 is fixed on the valve core 2 by fasteners, and the valve core 2 moves up and down The inner sleeve 5 is driven to move accordingly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com