Rotation load applying device for tail rotor shaft fatigue test

An application device and fatigue test technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as the load that cannot simulate the periodic change of rotating parts, and achieve the effect of true and accurate test results and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below.

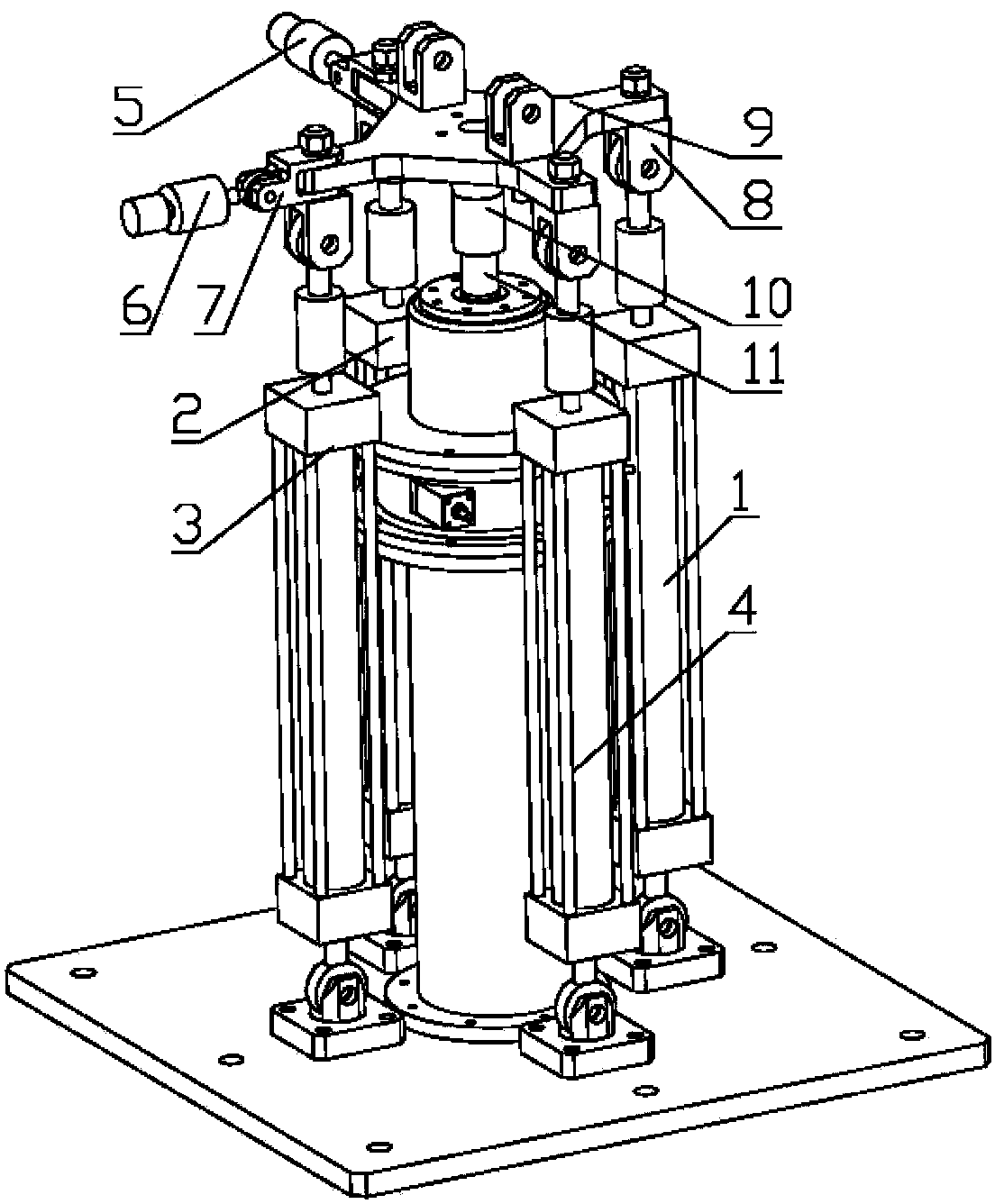

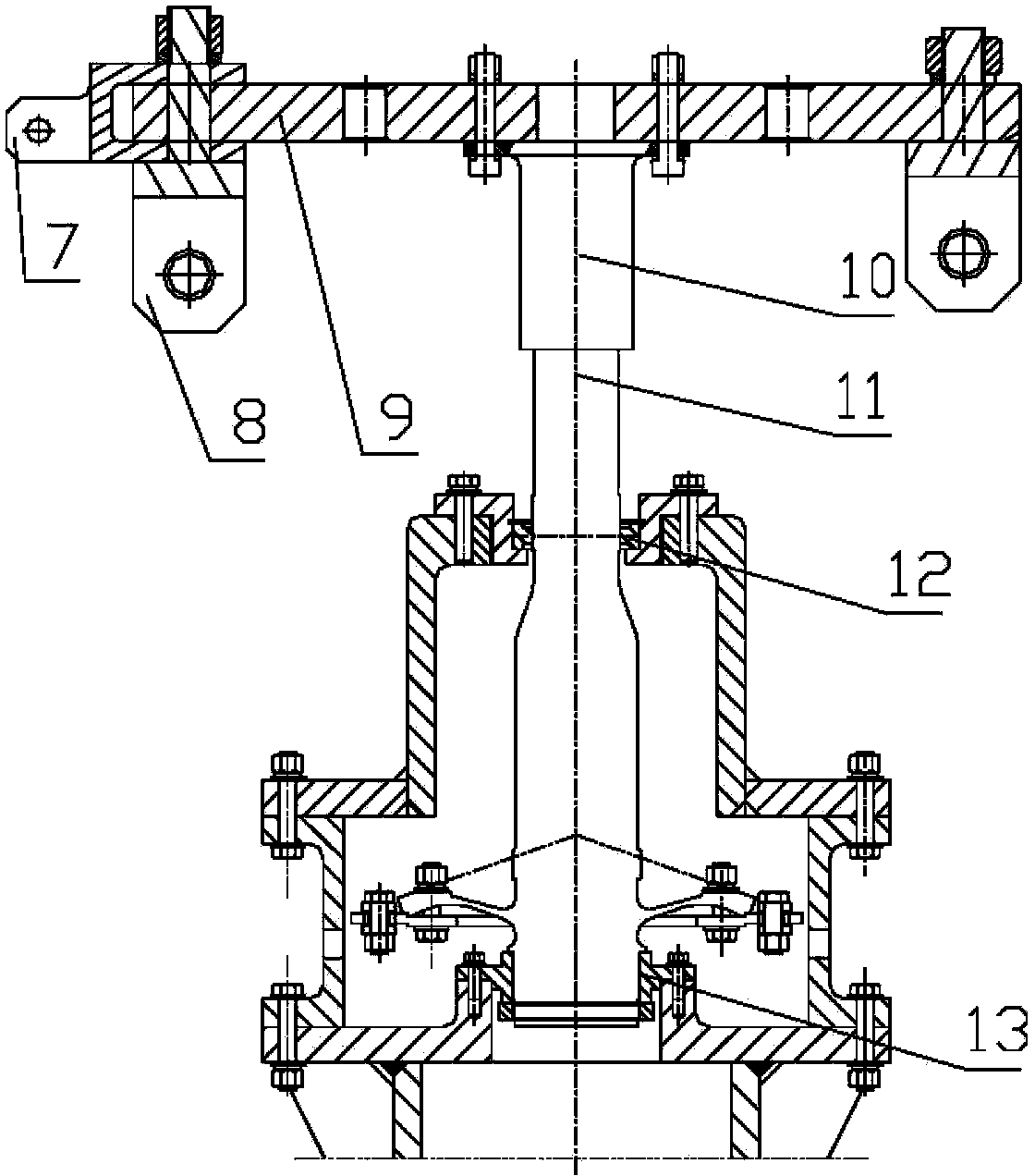

[0010] Such as figure 1 , 2 As shown, the present invention is specifically: the first hydraulic actuator 1, the second hydraulic actuator 2, the third hydraulic actuator 3, and the fourth hydraulic actuator 4 rotate the bending moment loading joint 8 and the loading plate 9 Connected and perpendicular to the disk surface of the loading disk 9, the first hydraulic actuator 1, the second hydraulic actuator 2, the third hydraulic actuator 3, and the fourth hydraulic actuator 4 are symmetrical to the tail rotor with the same force arm The shaft test piece 11 is arranged. The fifth hydraulic actuator 5 and the sixth hydraulic actuator 6 are connected to the two arms of the loading disk 9 with a difference of 90° through the rotating shear loading joint 7 and are parallel to the disk surface of the loading disk 9 . The tail rotor shaft test piece 11 is fixed with the test bench through the upper support be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com