Fabrication of Nanofibrous Membrane Biosensors by Electrospinning

A biosensor, nanofiber membrane technology, applied in instruments, scientific instruments, material analysis by electromagnetic means, etc., can solve the problems of accuracy, sensitivity, operational stability, service life, insufficient selectivity, etc., and achieve high sensitivity , good reproducibility and high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

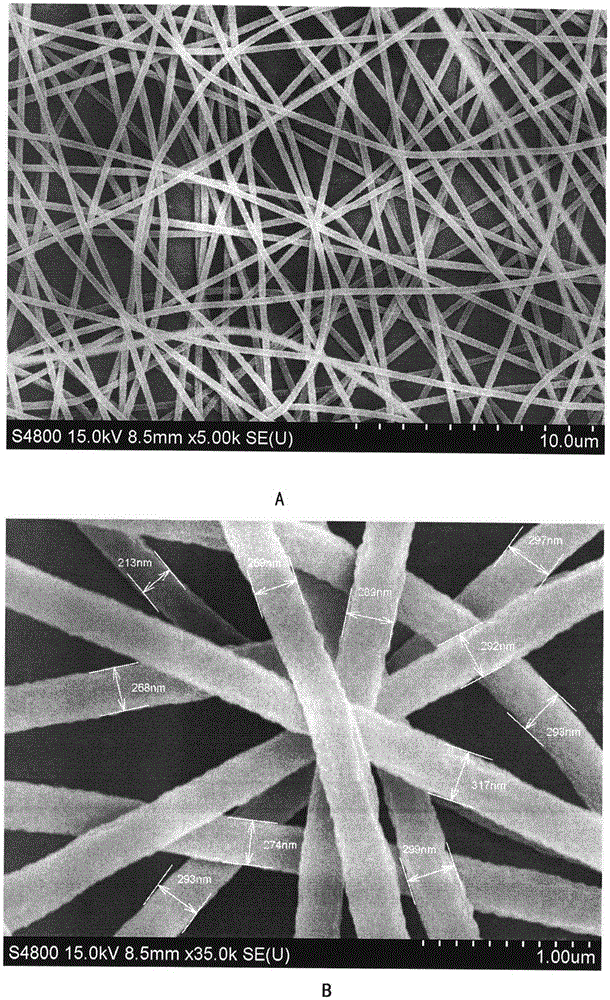

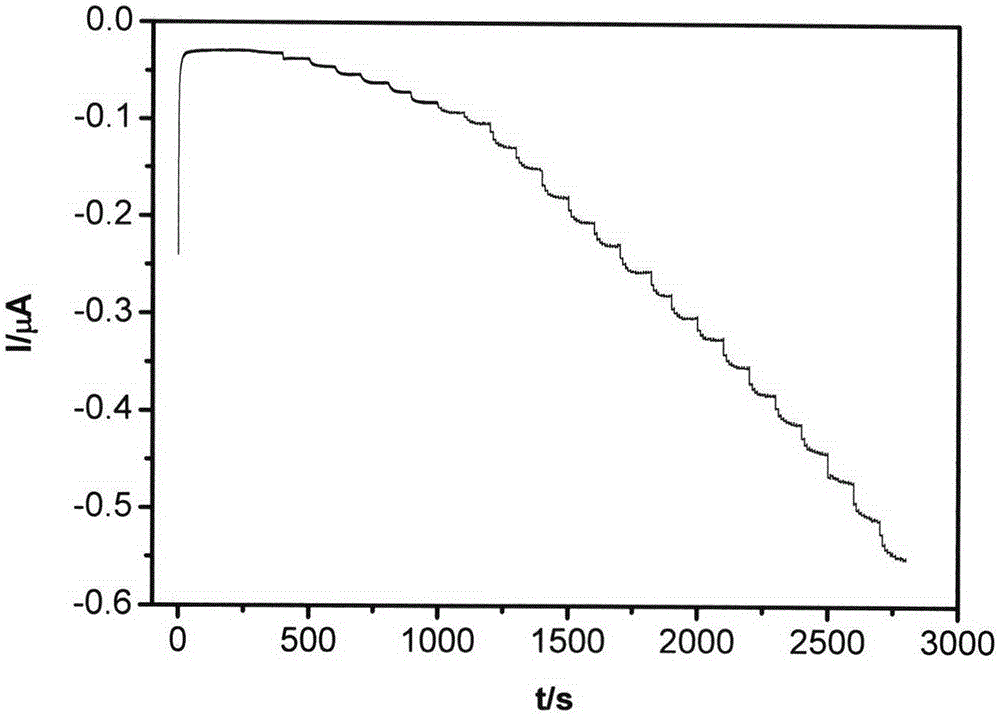

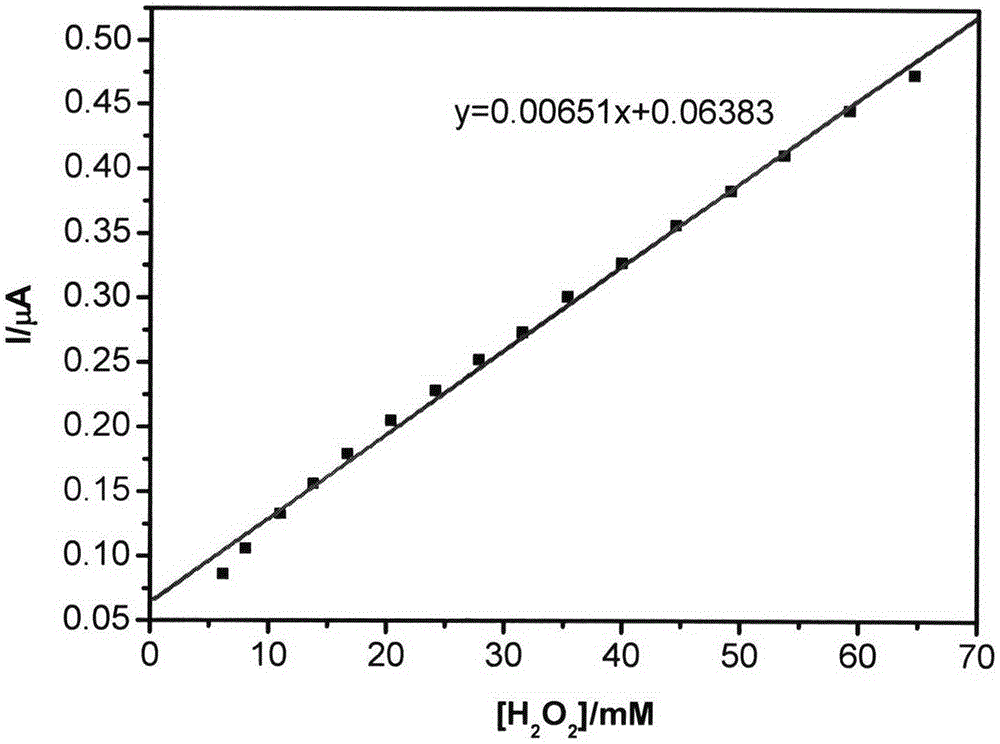

[0032] Preparation of the hemoglobin enzyme sensor

[0033] The acrylonitrile-acrylic acid copolymer is prepared into a 6% N,N-dimethylformamide solution, and then a 8 mg / ml hemoglobin enzyme solution is prepared with a phosphate buffer solution, the polymer solution is used as the outer layer, and the enzyme solution is used as the inner layer. layer, then 15KV voltage, 15cm spinning distance, 40% humidity, and room temperature for electrospinning, the outer injection speed is set to 0.3mm / min, the inner injection speed is set to 0.1mm / min, spinning The time is set to 40 s, and a conventional glassy carbon electrode (0.3 mm in diameter) is used as a receiver to prepare a nanofiber membrane biosensor. With the electrode as the working electrode, the platinum wire electrode as the auxiliary electrode, and the saturated calomel electrode as the reference electrode, the biosensor has a constant potential of -0.3V and a phosphoric acid buffer solution with a pH of 7.0. 2 o 2 sol...

Embodiment 2

[0036] Preparation of polyphenol oxidase sensor

[0037] First prepare acrylonitrile-acrylic acid copolymer into N,N-dimethylformamide solution with a concentration of 6%, and then configure 8 mg / ml polyphenol oxidase solution with phosphate buffer solution. The polymer solution is used as the outer layer, enzyme The solution is used as the inner layer, and electrospinning is carried out at 15KV voltage, 15cm spinning distance, 40% humidity, and room temperature. The injection speed of the outer layer is set to 0.3mm / min, and the injection speed of the inner layer is set to 0.1m / min. , the spinning time was set to 40 s, and a conventional glassy carbon electrode (0.3 mm in diameter) was used as a receiver to prepare a nanofiber membrane biosensor. Using the electrode as the working electrode, the platinum wire electrode as the auxiliary electrode, and the saturated calomel electrode as the reference electrode, the response of the biosensor to the catechol solution was measured...

Embodiment 3

[0040] Preparation of glucose oxidase sensor

[0041] First prepare the acrylonitrile-acrylic acid copolymer into a 6% N,N-dimethylformamide solution, then use a phosphate buffer solution to configure an 8 mg / ml glucose oxidase solution, the polymer solution as the outer layer, and the enzyme solution As the inner layer, electrospinning is carried out at 15KV voltage, 15cm spinning distance, 40% humidity, and room temperature. The injection speed of the outer layer is set to 0.3mm / min, and the injection speed of the inner layer is set to 0.1mm / min. The spinning time is set to 40 s, and a conventional platinum electrode (0.2 mm in diameter) is used as a receiver to prepare a nanofiber membrane biosensor. Using the electrode as the working electrode, the platinum wire electrode as the auxiliary electrode, and the saturated calomel electrode as the reference electrode, the response of the biosensor to the glucose solution was measured in a phosphate buffer solution with a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com