A kind of proton exchange membrane and preparation method thereof

A proton exchange membrane and quality technology, applied in electrochemical generators, electrical components, circuits, etc., can solve the problems of uneven dispersion of the conductivity of the proton exchange membrane, affecting the distribution of chemically synthesized water, and large changes in conductivity, etc. Uniformity and self-wetting ability, good electrochemical ability of battery, uniform effect of proton exchange membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

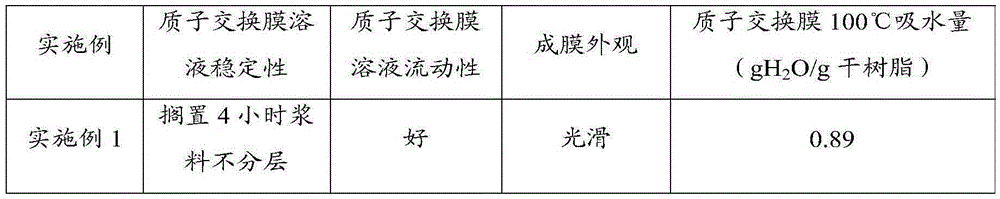

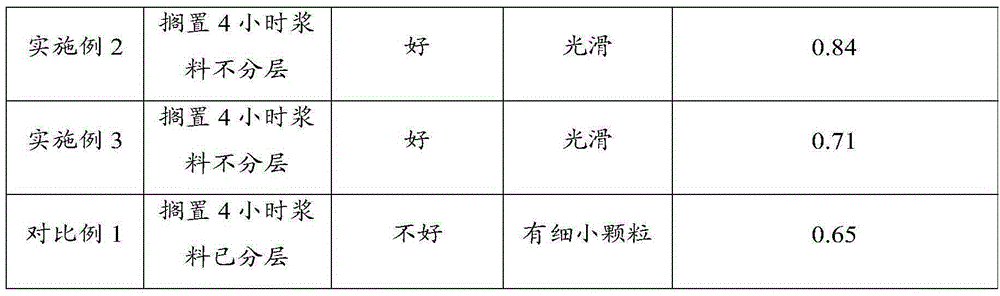

Embodiment 1

[0027] The preparation method of proton exchange membrane is as follows:

[0028] (A) Using N,N-dimethylformamide as a solvent, dissolve the perfluorosulfonic acid resin to prepare a 5% perfluorosulfonic acid resin solution.

[0029] (B) the sulfonated SiO 2 and polyvinylpyrrolidone are added to the perfluorosulfonic acid resin solution and stirred evenly to obtain a proton exchange membrane solution, wherein the perfluorosulfonic acid resin, sulfonated SiO 2 The mass ratio to polyvinylpyrrolidone is 1:0.1:0.0011;

[0030] (C) Casting the obtained proton exchange membrane solution into a membrane to obtain a proton exchange membrane.

Embodiment 2

[0032] (A) Using a mixed solution of dimethyl sulfoxide and N,N-dimethylformamide as a solvent, dissolving sulfonated polyarylether sulfone to prepare a 1% sulfonated polyarylether sulfone solution.

[0033] (B) Sulfonated TiO with a particle size of 50nm 2 Add styrene-maleic anhydride resin to the sulfonated polyarylether sulfone solution and ultrasonically mix for 2 hours to obtain a proton exchange membrane solution, wherein sulfonated polyarylether sulfone, sulfonated TiO 2 And the mass ratio of styrene-maleic anhydride resin is 100:0.1:5.005;

[0034] (C) Rinse the polyvinylidene fluoride membrane with deionized water after cleaning with a mixed solution of absolute ethanol and hydrogen peroxide, then rinse with a mixed solution of absolute ethanol and sulfuric acid and then dry it with deionized water, The polyvinylidene fluoride membrane has a pore diameter of 0.8 μm, a thickness of 5 μm, and a porosity of 70%.

[0035] (D) Casting the obtained proton exchange membran...

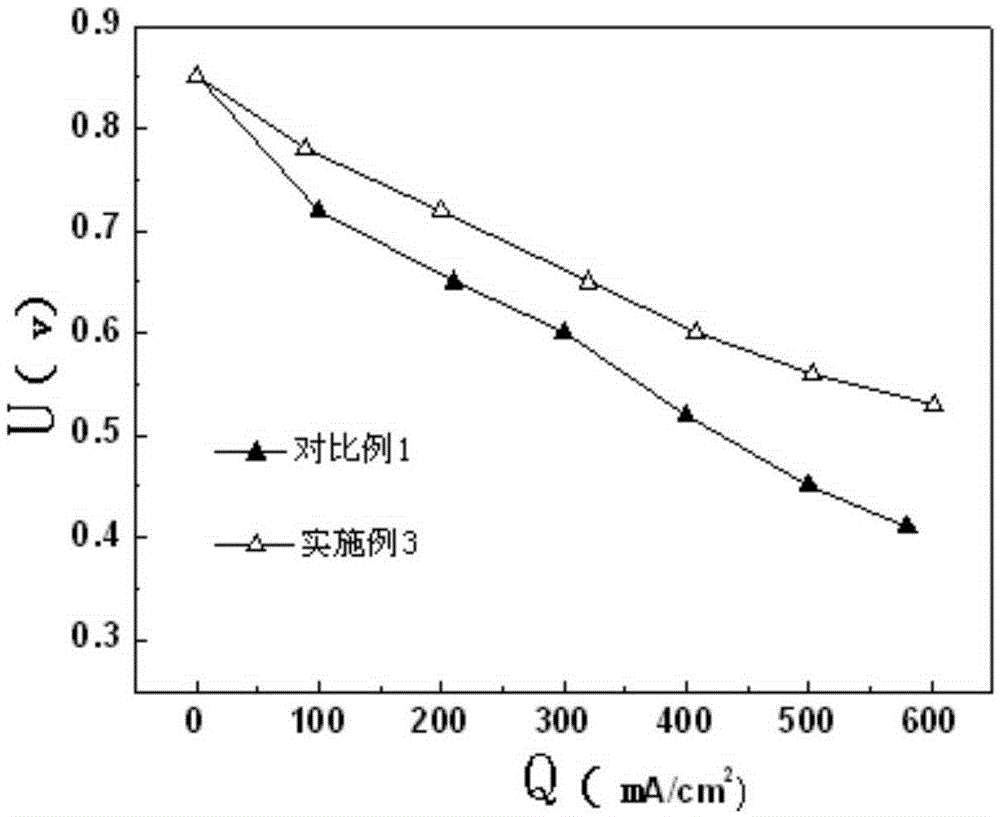

Embodiment 3

[0037] (A) Dissolving fluorinated sulfonated polystyrene with 1-methyl-2-pyrrolidone solution as a solvent to prepare a 20% fluorinated sulfonated polystyrene solution.

[0038] (B) Sulfonated ZrO with a particle size of 30nm 2 with SiO 2 The mixture and sodium dodecylbenzenesulfonate are added to the fluorinated sulfonated polystyrene solution and ultrasonically mixed for 2 hours to obtain a proton exchange membrane solution, wherein fluorinated sulfonated polystyrene, sulfonated ZrO 2 with SiO 2 The mass ratio of the mixture and sodium dodecylbenzenesulfonate is 50:0.1:1.503;

[0039] (C) the polyimide membrane is cleaned with deionized water after cleaning with a mixed solution of absolute ethanol and hydrogen peroxide, and then rinsed with deionized water with a mixed solution of absolute ethanol and sulfuric acid and then dried, The polyimide membrane has a pore diameter of 0.1 μm, a thickness of 40 μm, and a porosity of 90%.

[0040] (D) Casting the obtained proton e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com