Pneumatic fuse terminal crimping mold

A technology for crimping dies and terminals, applied in the direction of connection, electrical components, circuits, etc., can solve problems such as low efficiency, unstable crimping quality, and inability to ensure crimping consistency, achieve stable feeding, and prevent unstable feeding. , the effect of stable crimping state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

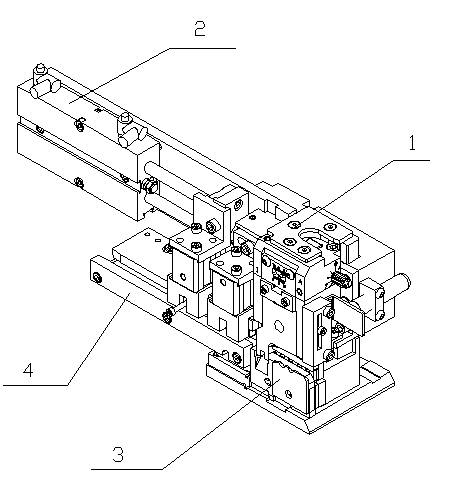

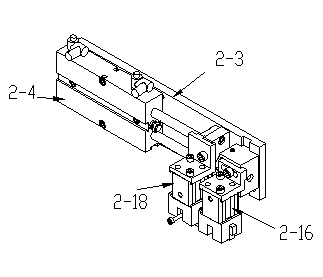

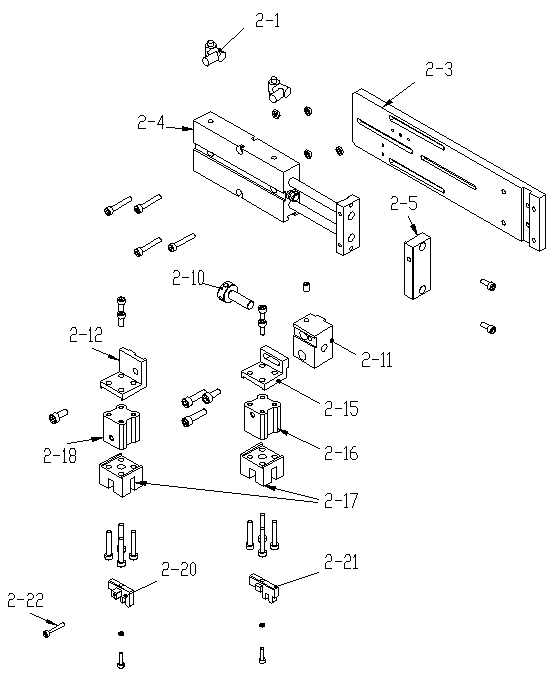

[0021] Such as figure 1 As shown, a pneumatic crimping die for a fuse terminal includes a hanger assembly 1 , a feeding assembly 2 , a mold base assembly 3 and a feeding base assembly 4 . The slide block 3-2 in the hanging head assembly and the formwork assembly is connected together by screws, and the slide block 3-2 in the formwork assembly is fixed on the side of the formwork 3-11 by the left pressing plate 3-19 and the right pressing plate 3-20. In the groove, the feeding assembly mounting plate 2-3 in the feeding assembly is connected together with the mold base 3-11 in the mold base assembly by screws, and the feeding bottom plate assembly is connected with the base plate spacer 3-15 in the mold base assembly by screws. Together, and a screw is connected to the mold base 3-11 in the mold base assembly through the through hole in the feeding base plate 4-3, through which the front and rear positions of the feeding base plate assembly can be adjusted to achieve the pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com