Hairpin-type bar connection mechanism and hairpin-type winding motor equipped with the connection mechanism

A connecting mechanism and hairpin technology, which is applied to the shape/style/structure of windings, electromechanical devices, and winding conductors, can solve the problems of poor connection of hairpin bars and reduced production efficiency, and achieve increased efficiency and production efficiency. The effect of securing ease and improving insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following description will be made in detail with reference to the accompanying drawings of the embodiments of the present invention. The following embodiments are only to help the understanding of the present invention, and the scope of the present invention is not limited to the following embodiments. In addition, in order to provide a comprehensive description for practitioners with general knowledge, the following embodiments will omit the description of known structures that may cause ambiguous judgment of the technical gist of the present invention.

[0024] For the convenience of description, the structure of the hairpin-type winding motor is firstly described comprehensively, and then the hairpin-type connection mechanism of the present invention and the hairpin-type winding motor equipped with this component are described.

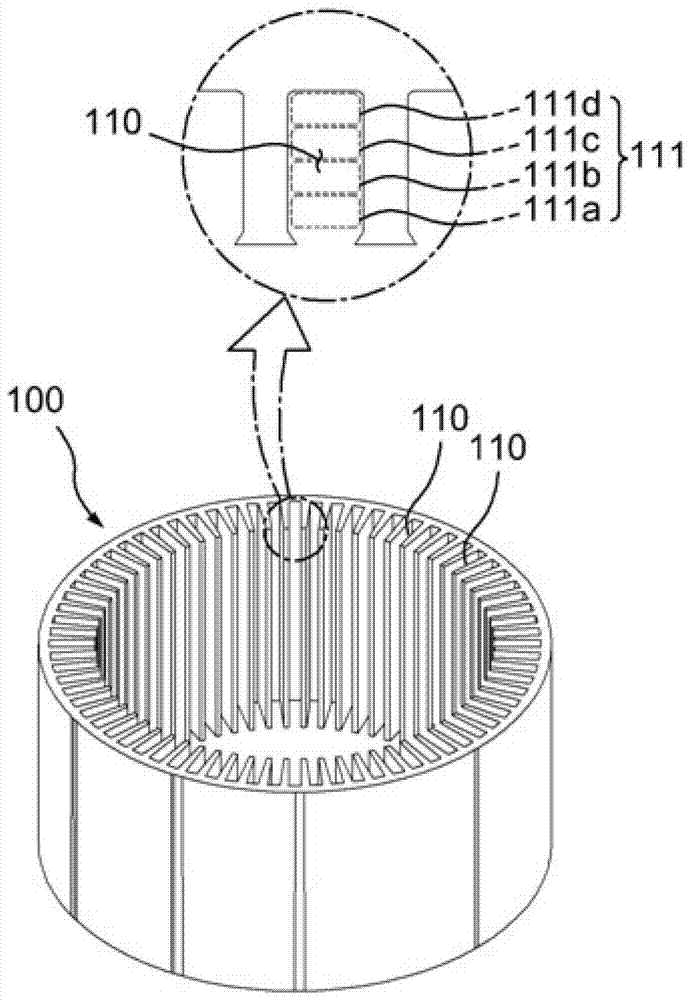

[0025] figure 1 It is a three-dimensional view of the stator core of the hairpin winding motor.

[0026] refer to figure 1 , the sta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap