Combined type counteractive fly wheel

A reaction flywheel, composite technology, applied in the flywheel field, can solve the problems of speed saturation, reaction flywheel failure, etc., to delay the phenomenon of flywheel speed saturation and improve controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

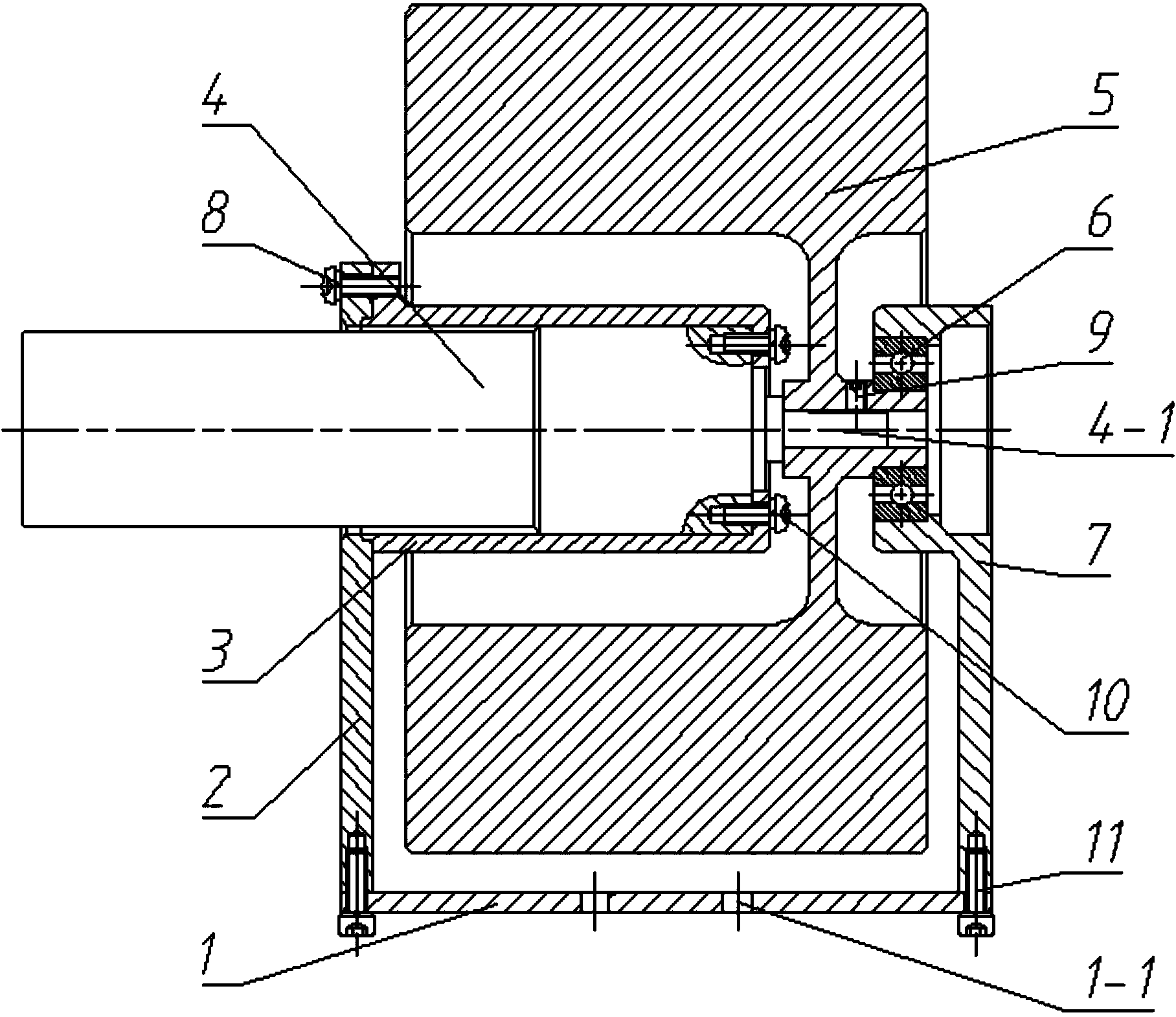

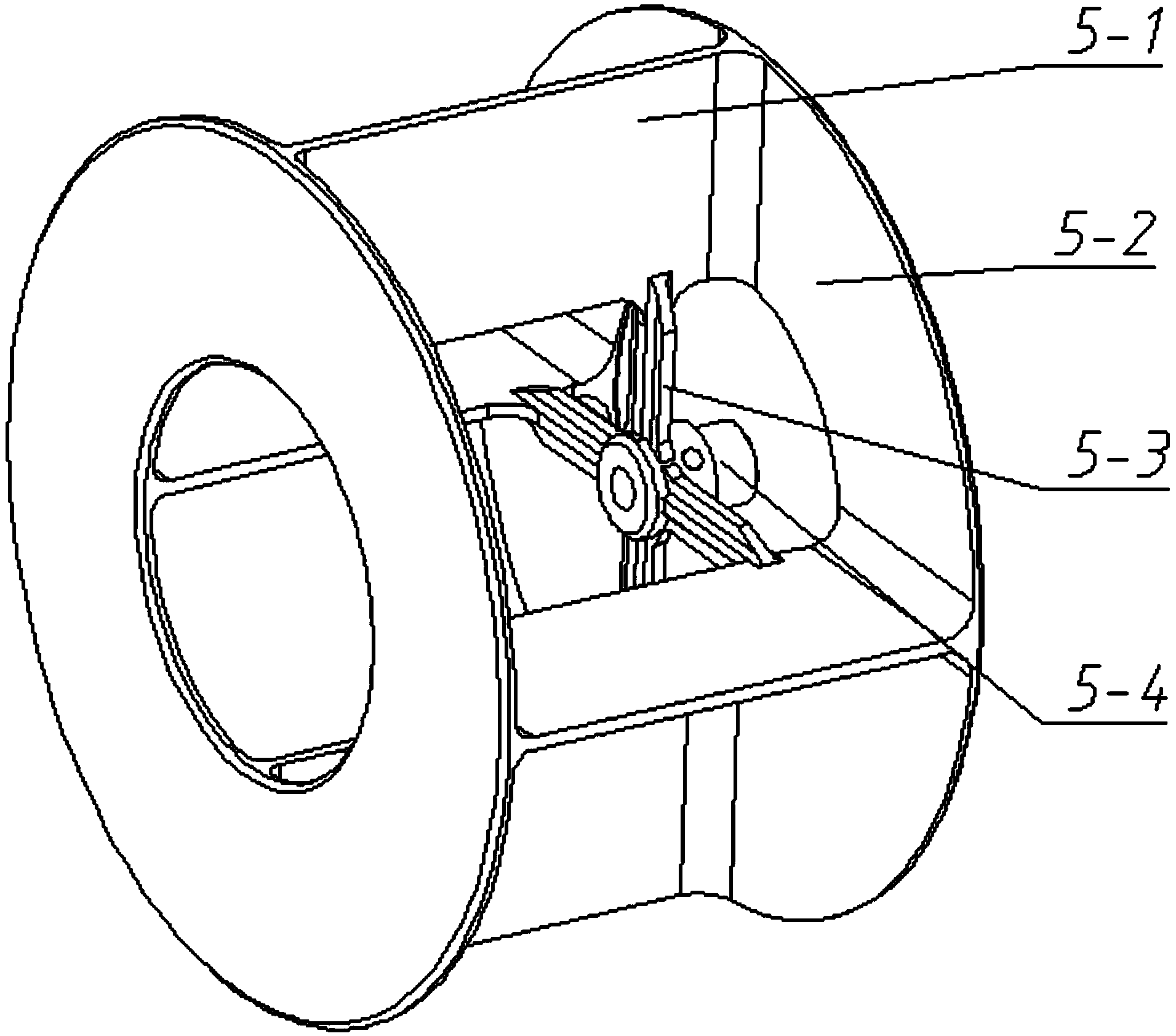

[0015] like figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the flywheel structure of the present invention, and the composite reaction flywheel includes a fixed plate 1, a support plate 2, a motor fixing seat 3, a reduction motor 4, a flywheel 5, a bearing 6, a bearing support 7, a screw a8, and a set screw 9 , screw b10, screw c11, wherein the support plate 2 and the bearing support 7 are fixed on the fixing plate 1 through the screw c11; The plate 2 is fixed, and the reduction motor 4 and the three motors are fixed by screws b10; the flywheel 5 includes a blade 5-1, a flange 5-2, a spoke plate 5-3 and a hollow flywheel shaft 5-4, of which four The two blades 5-1 are evenly arranged along the circumference, the two ends of the four blades 5-1 are respectively connected with the flange 5-2, the spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com