Power conversion device

A technology for power conversion devices and mounting substrates, which is applied to circuits, electrical components, electrical solid-state devices, etc., can solve the problems of reduced cooling efficiency, increased thermal resistance, and large-scale power conversion devices, and achieves the effect of miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described below with reference to the drawings.

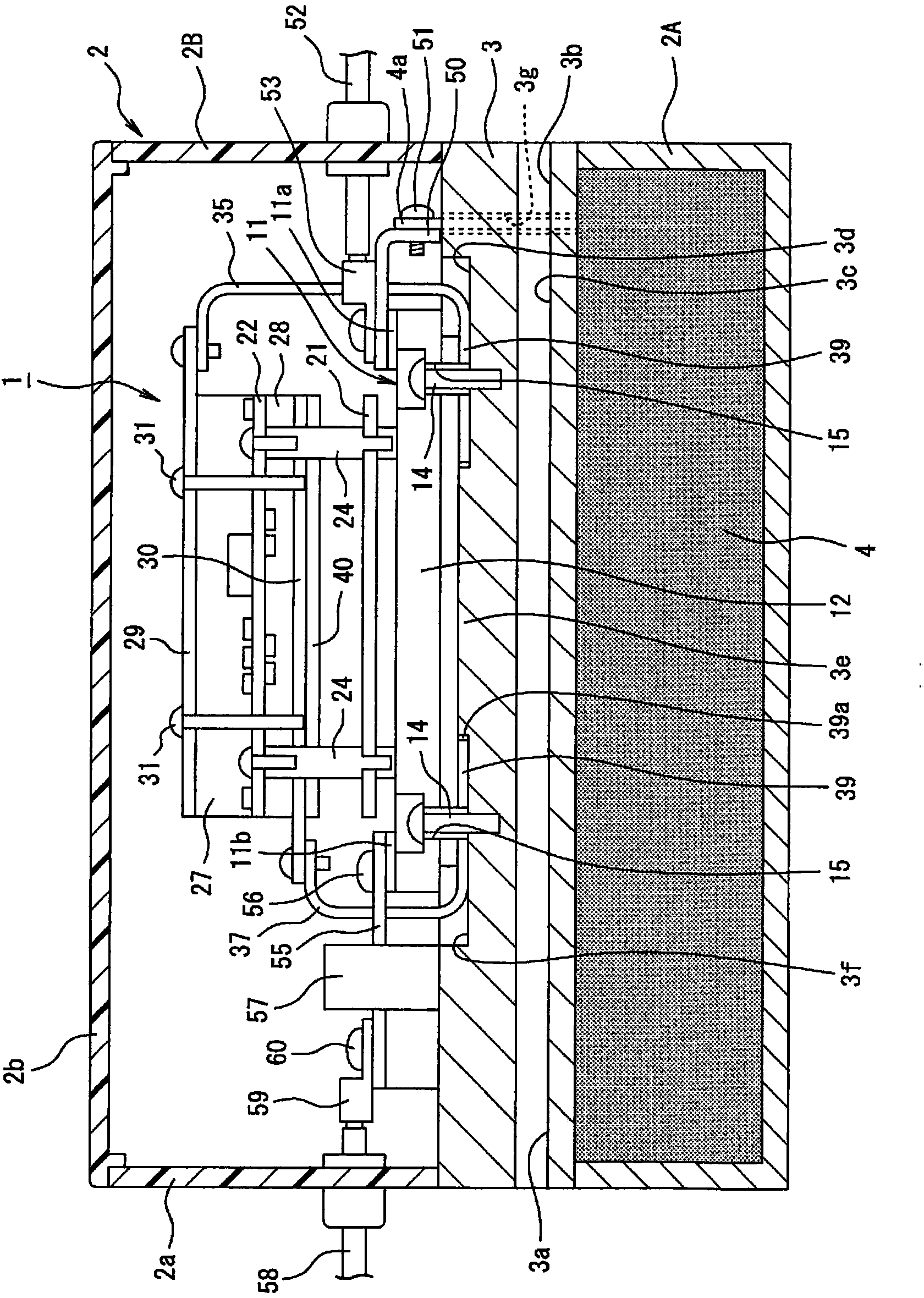

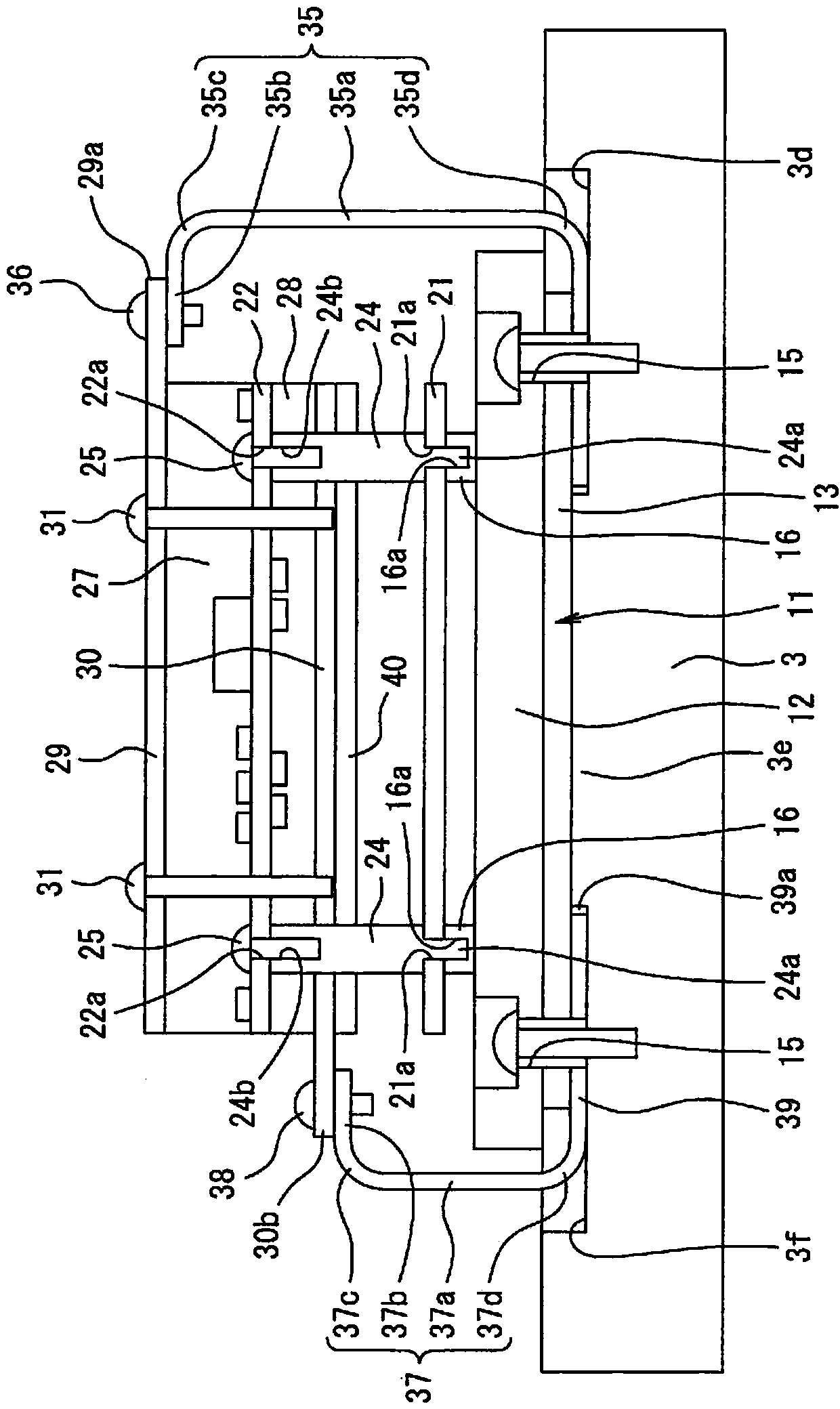

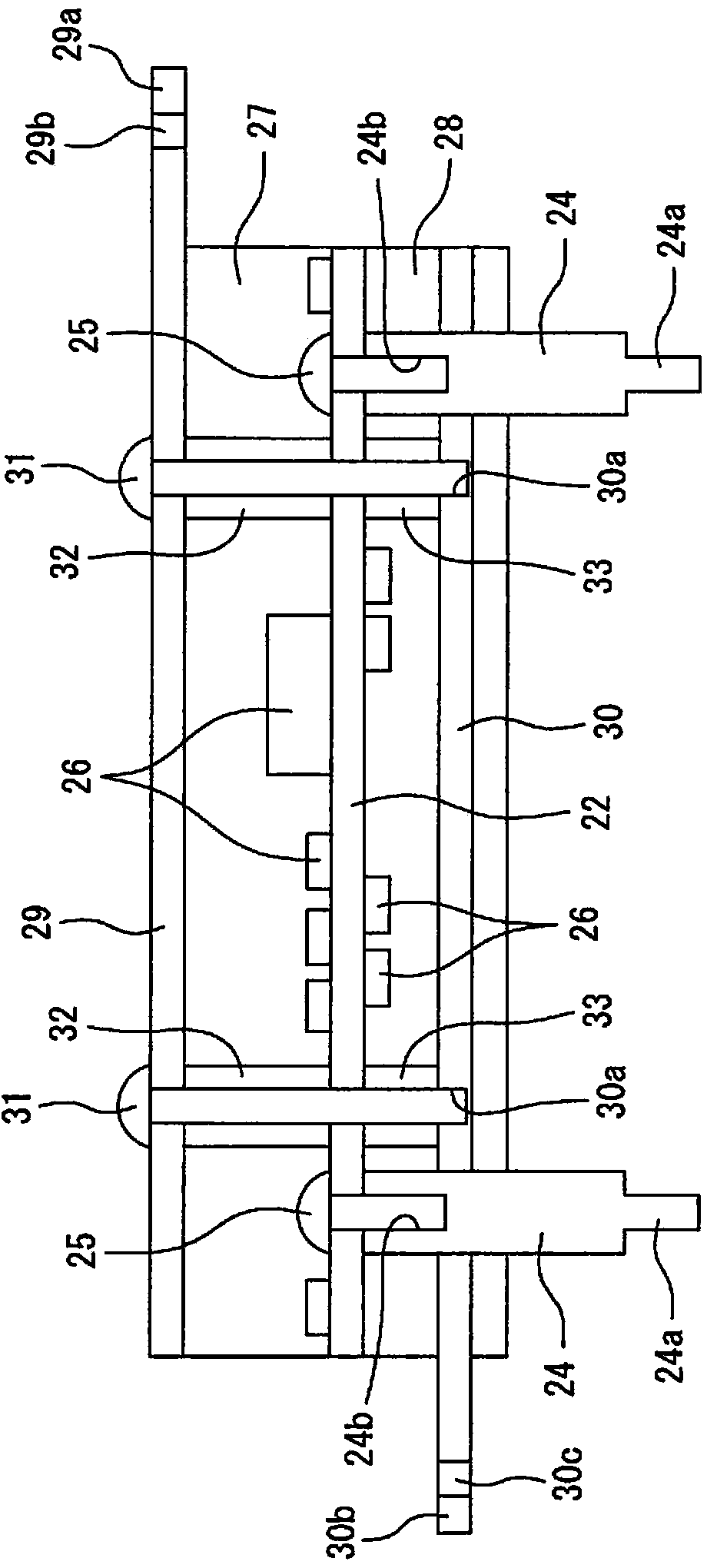

[0035] figure 1 It is a sectional view showing the overall structure of the power conversion device of the present invention.

[0036] In the drawings, reference numeral 1 denotes a power conversion device, and the power conversion device 1 is accommodated in a casing 2 . The frame body 2 is a frame body molded from a synthetic resin material, and is composed of a lower frame body 2A and an upper frame body 2B which are vertically divided through a cooling body 3 having a water jacket structure.

[0037] The lower housing 2A is composed of a bottomed square cylinder. The open upper portion of the lower housing 2A is covered with a cooling body 3 , and a smoothing film capacitor 4 is housed inside the lower housing 2A.

[0038] The upper frame 2B includes a square cylinder 2a with open upper and lower ends and a cover 2b for closing the upper end of the square cylinder 2a. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com