Electric control breathing machine or anesthesia machine active exhalation valve based automatic calibration method

A ventilator and anesthesia machine technology, which is applied in the field of automatic calibration based on electric electronically controlled ventilator or active exhalation valve of anesthesia machine, which can solve the problem of high maintenance cost, failure of exhalation valve calibration, poor product reliability and stability and other problems, to achieve accurate measurement results, reduce maintenance costs, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

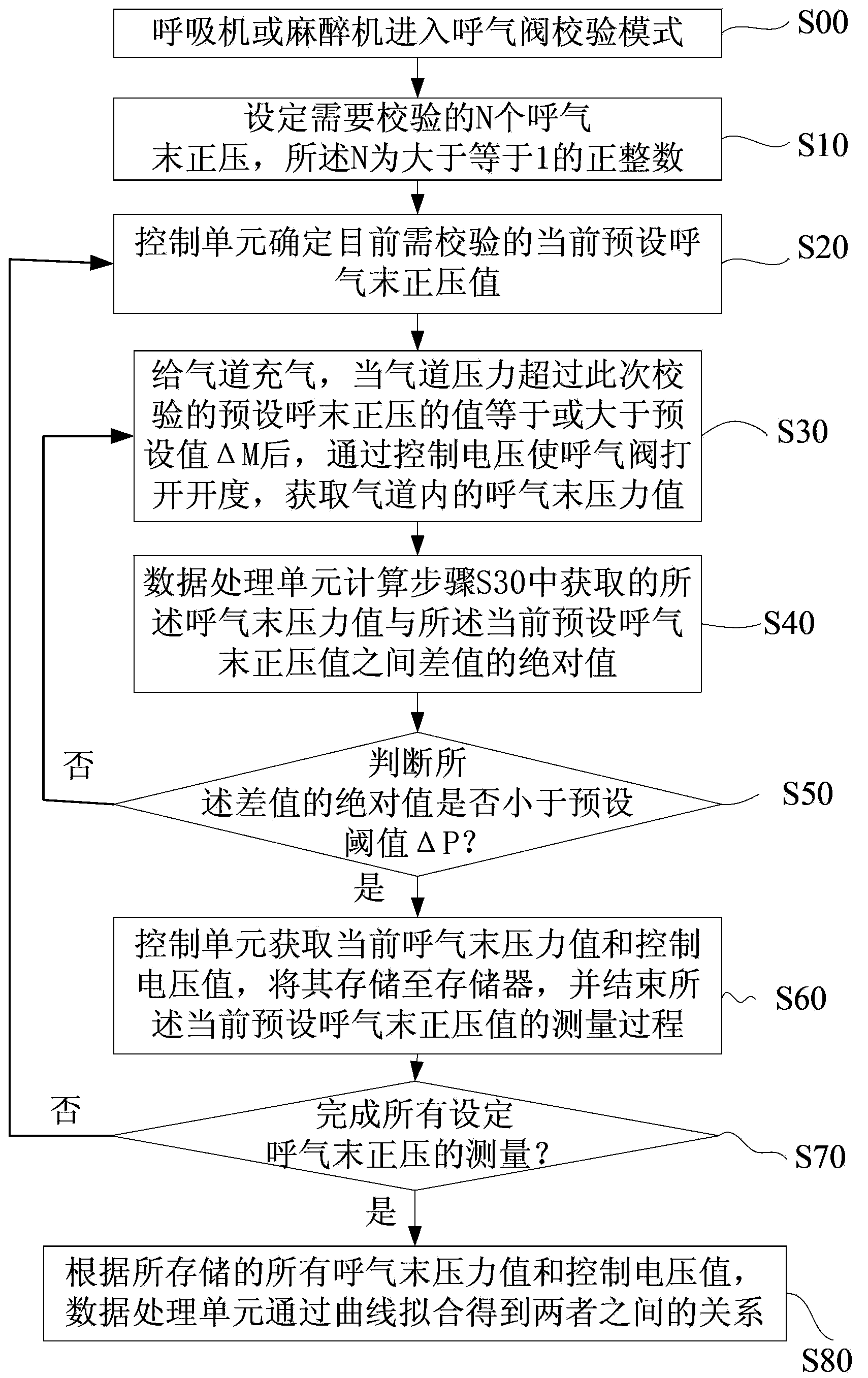

[0032] The technical solutions of the present invention will be further described below through specific embodiments.

[0033] The automatic verification method of the active exhalation valve of the present invention is mainly applied to electric and electronically controlled ventilators, anesthesia machines and other equipment that need to verify the exhalation valve.

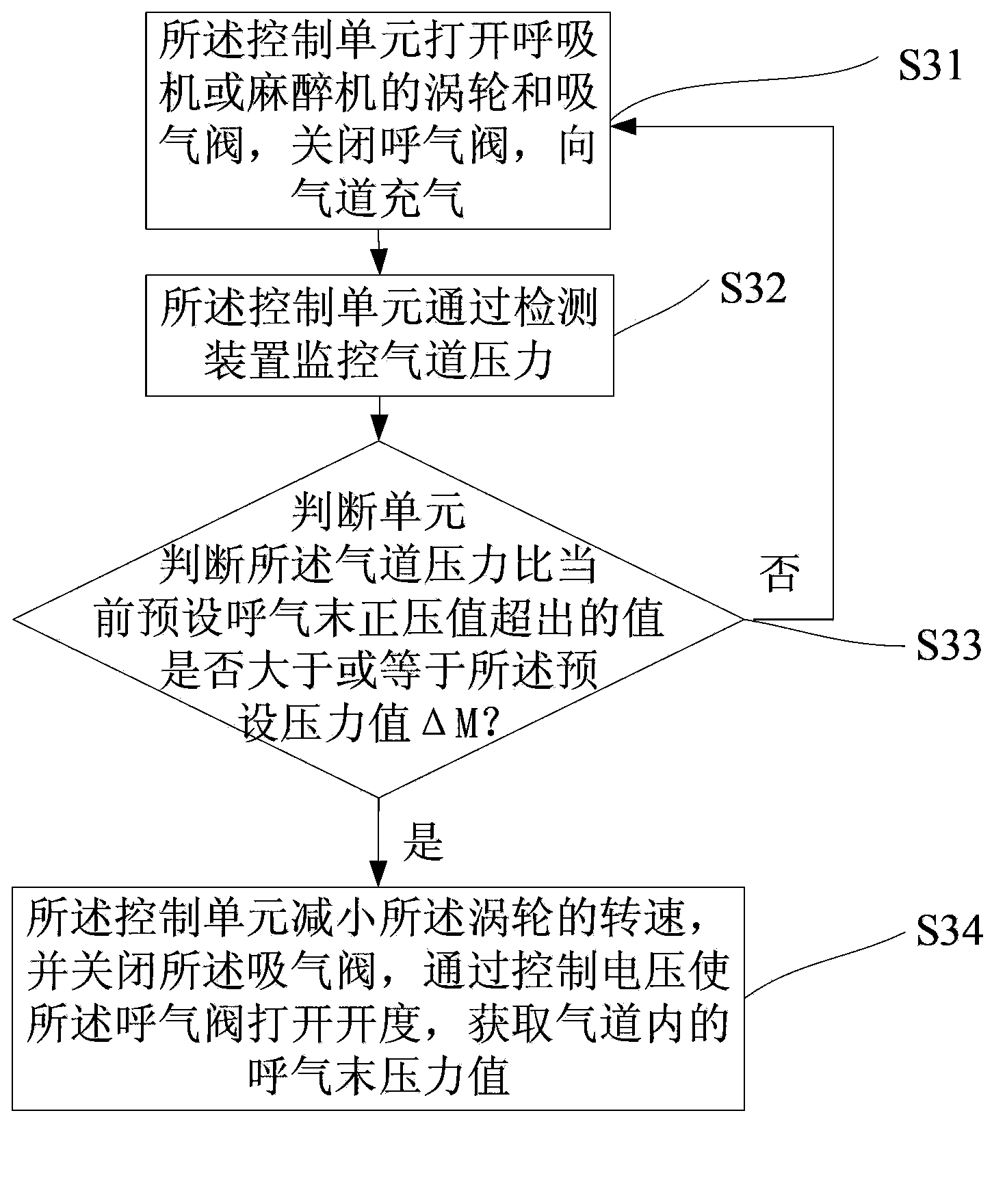

[0034] The electric electronically controlled ventilator is mainly composed of a motor with a turbine to control the flow rate, an inhalation valve, a pipe, and an exhalation valve. The specific connection structure is: the rear end of the motor with a turbine is connected to the inhalation valve, and the inhalation The rear end of the valve is connected with an air intake pipeline, the air intake pipeline leads to the lungs, the other end of the lungs communicates with the air outlet pipeline, and the other end of the air outlet pipeline is connected with an exhalation valve.

[0035] Moreover, the rotational...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com