Automatic straightener of inductance coil lead pins

An inductive coil and wire needle technology is applied in the field of an automatic straightening device for wire pins of an inductive coil, which can solve the problems of increased labor cost, poor manual operation accuracy, and high cost, and achieves improved automation, low work intensity, and simple work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

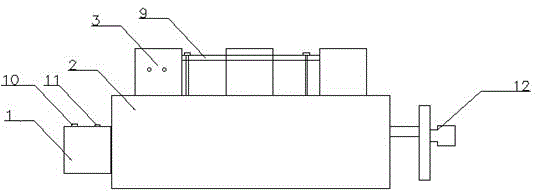

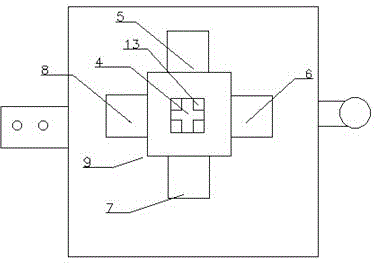

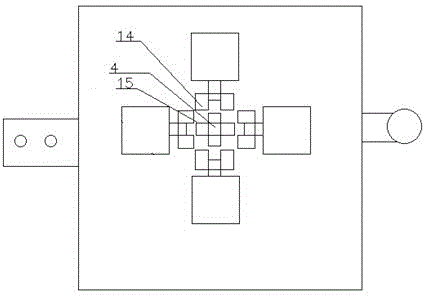

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0039] The technical solution of this embodiment is: an automatic straightening device for inductance coil wire pins, including a controller 1, a straightening part 3 and a fixing part; the straightening part is located above the fixing part; the straightening part includes a Mold core 4 and a plurality of cylinders located around; the upper surface of the mold core is set in a horizontal shape, and pin positions 13 are set around; the number of cylinders, the number of pin positions and the specifications of the mold core are compatible with the specifications of the inductance coil; the cylinder and the mold The core fits together at the stitch position; the cylinder completes the action of clamping the mold core and moving away from the mold core under the control of the controller, thereby straightening the wire stitch 16.

[0040] Among them, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com