Pouch clamp mechanism for automatic sterile pouch loading filling machine

A technology of bag clamps and filling machines, applied in packaging and other fields, can solve the problems of cumbersome mechanism structure, high equipment cost, large and complex structure, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

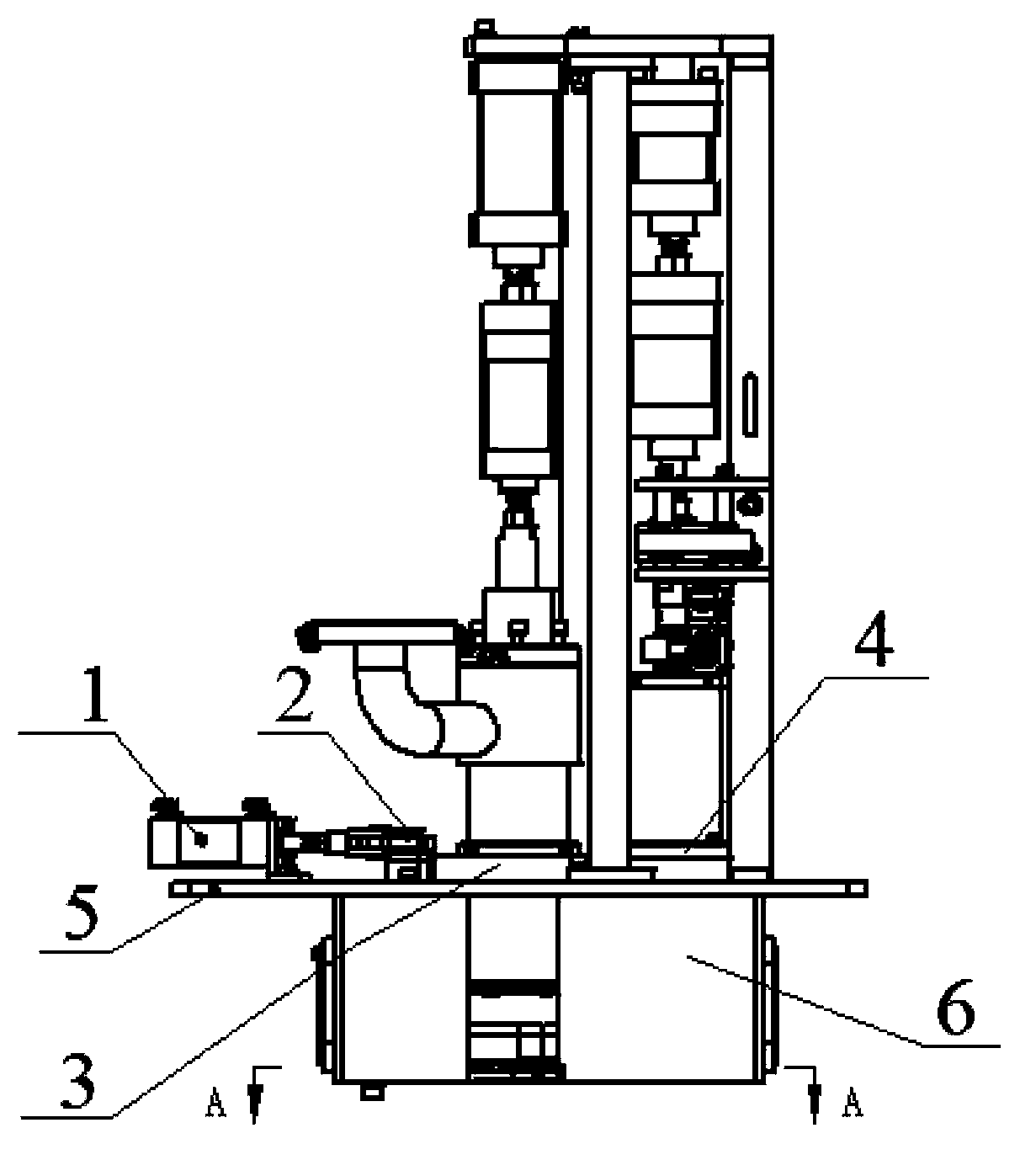

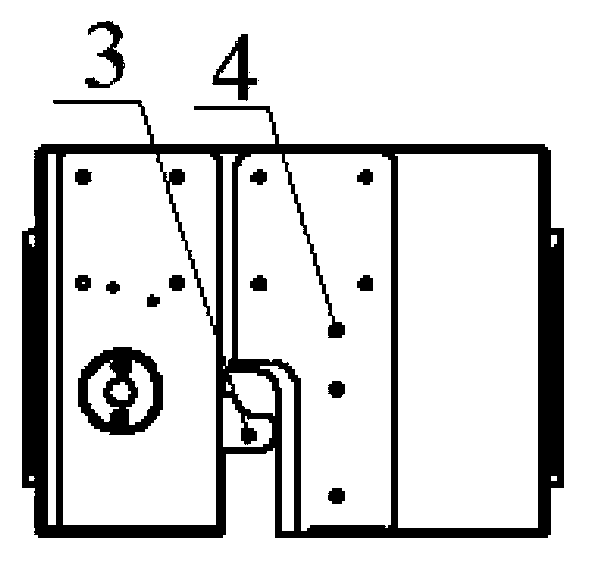

[0019] A kind of aseptic pouch automatic bag filling machine with a bag clamp mechanism, such as figure 1 , figure 2 As shown, it is set on the filling chamber 6 of the aseptic small bag automatic bag filling machine. On the support plate 5 above the filling chamber 6, the driving cylinder 1 drives the bag clamp moving tongs 3 to rotate through the rotating shaft 2, the bag clamp fixing tongs 4 are arranged next to the bag clamp moving tongs 3, and the bag tong moving tongs 3 The lower ends of the bag clamps and the fixing clamps 4 are all located inside the filling chamber 6 . One end of the lip of the pocket pliers fixing clamp 4 is linear, and the other end is arc-shaped. When the driving cylinder 1 drives the pocket pliers moving pliers 3 close to the bag pliers fixed pliers 4 through the rotating shaft 2, the lip of the bag pliers moving pliers 3 and the lip of the bag pliers fixed pliers 4 abut together to form a The ring structure that clamps the sterile bag.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com