Patents

Literature

39results about How to "With self-centering function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

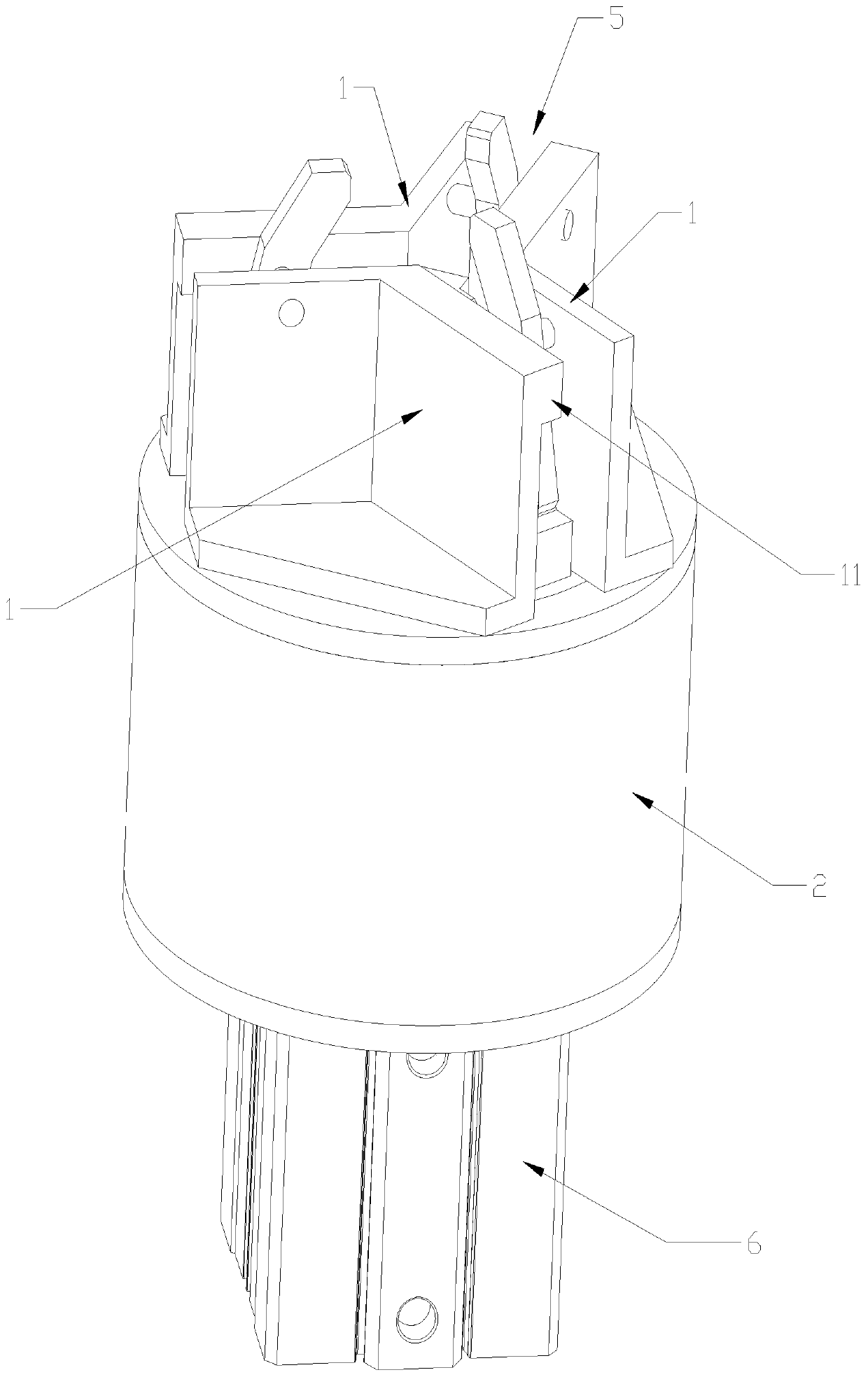

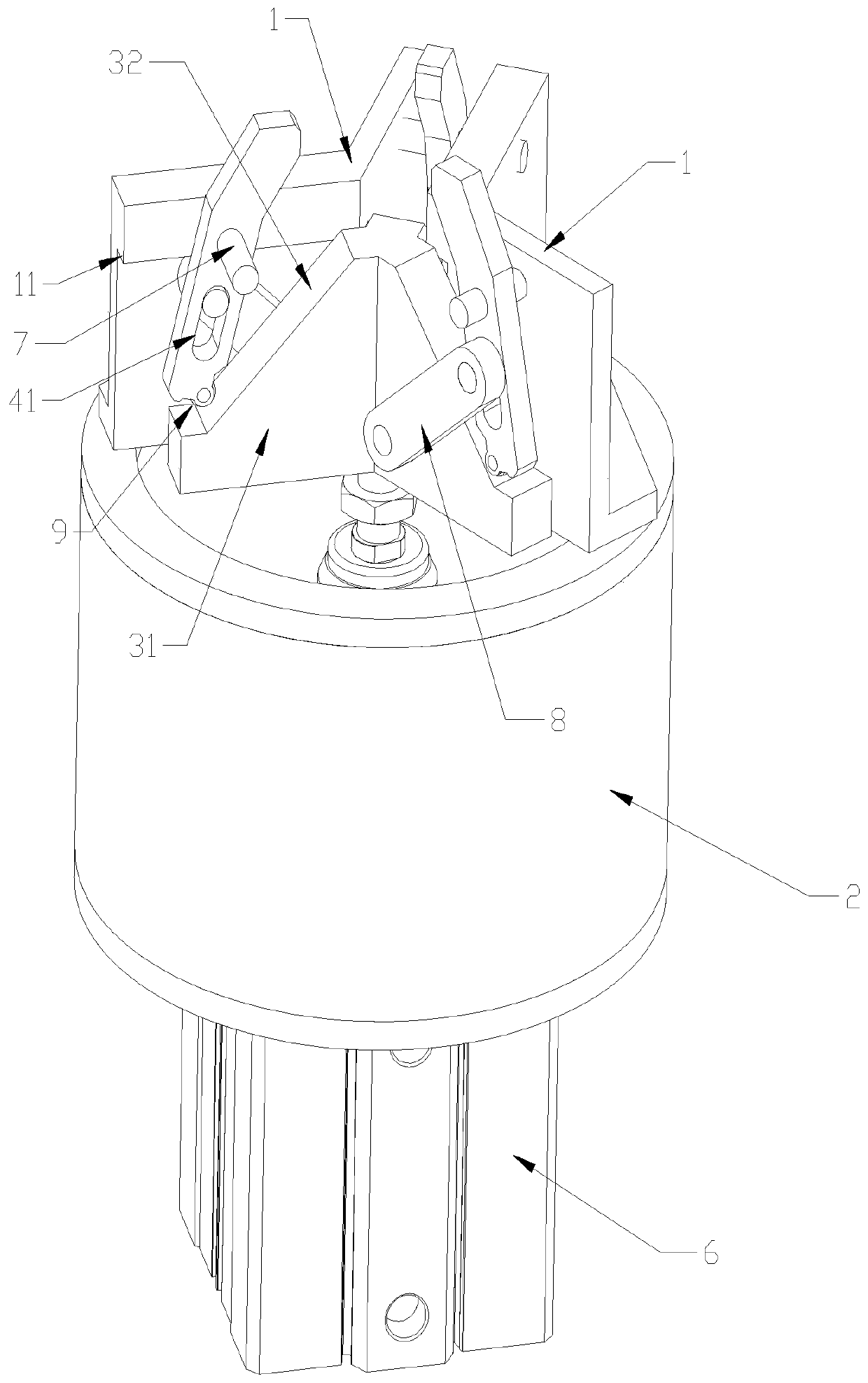

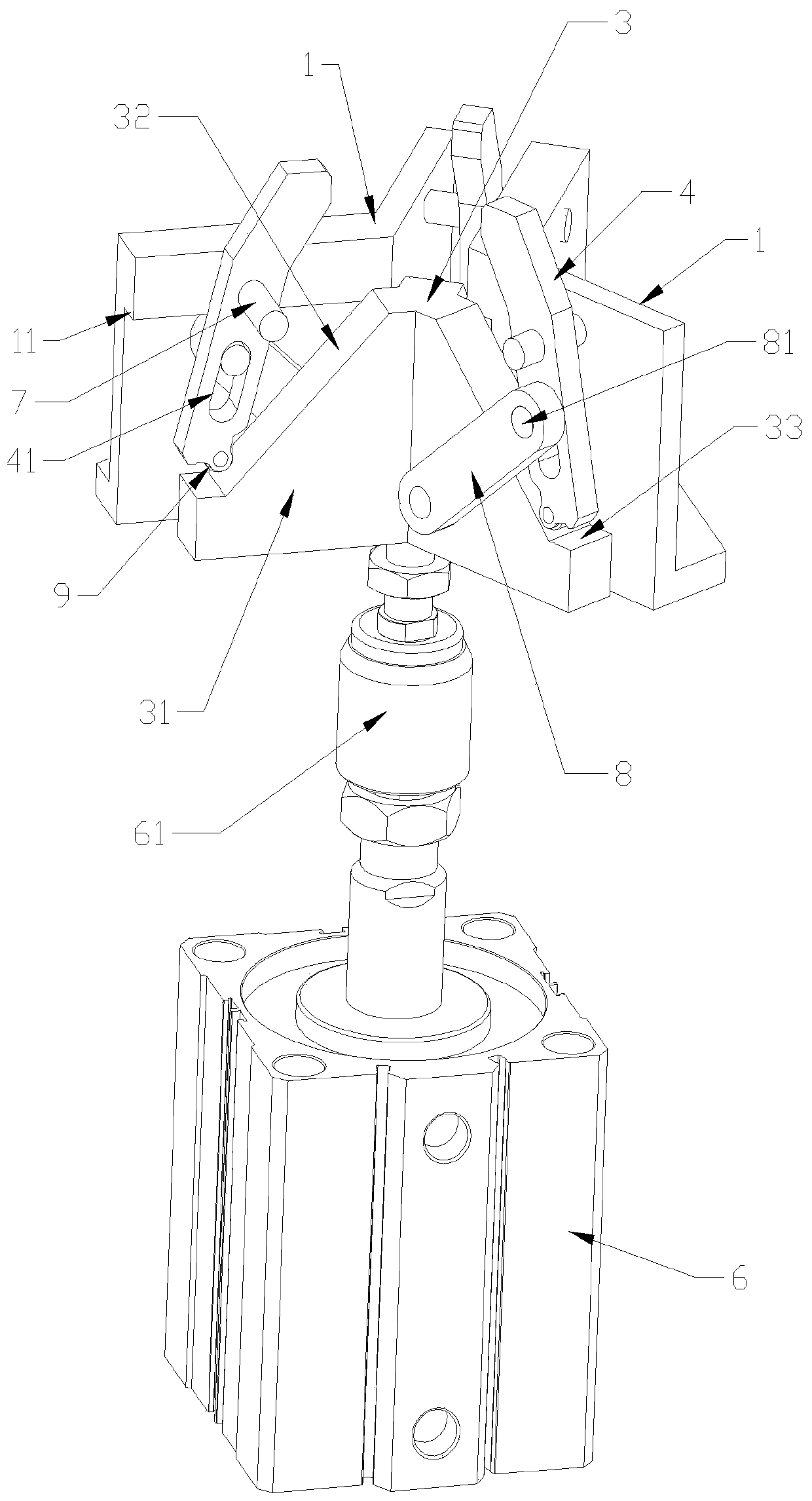

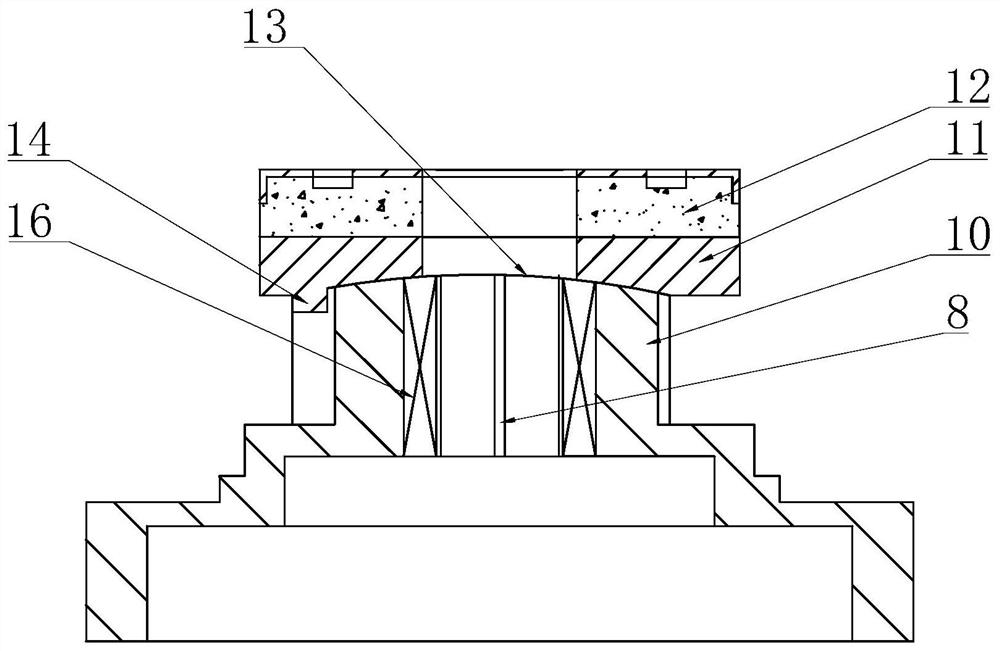

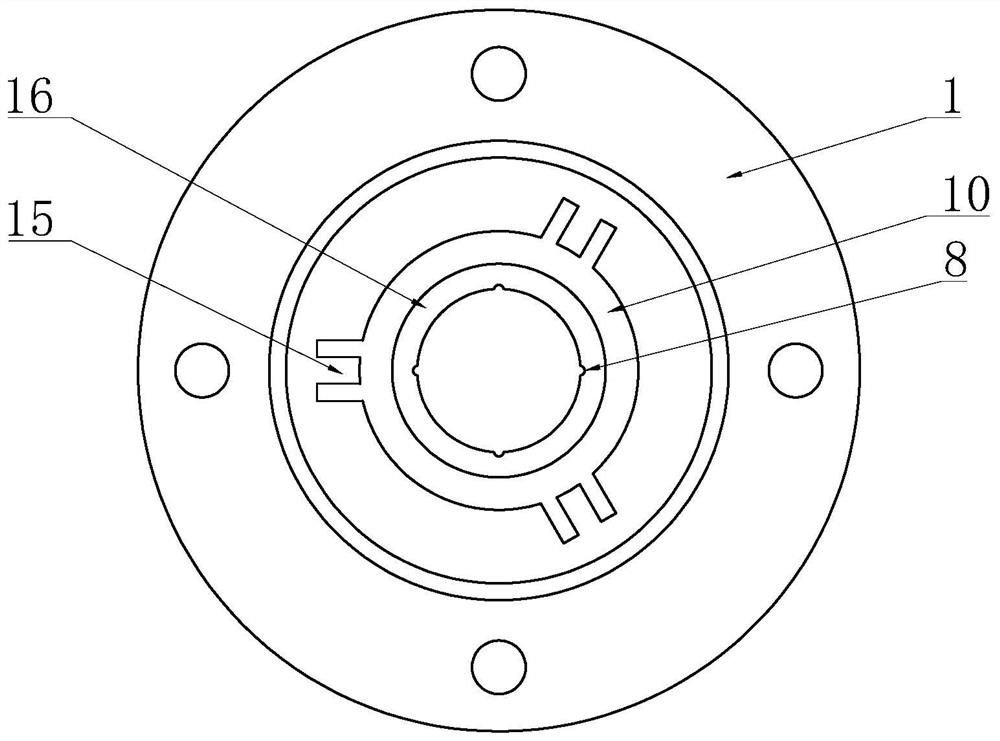

Push-type self-centering clamping jaw

PendingCN109719527AWith self-centering functionLarge clamping forcePositioning apparatusMetal-working holdersEngineeringMechanical engineering

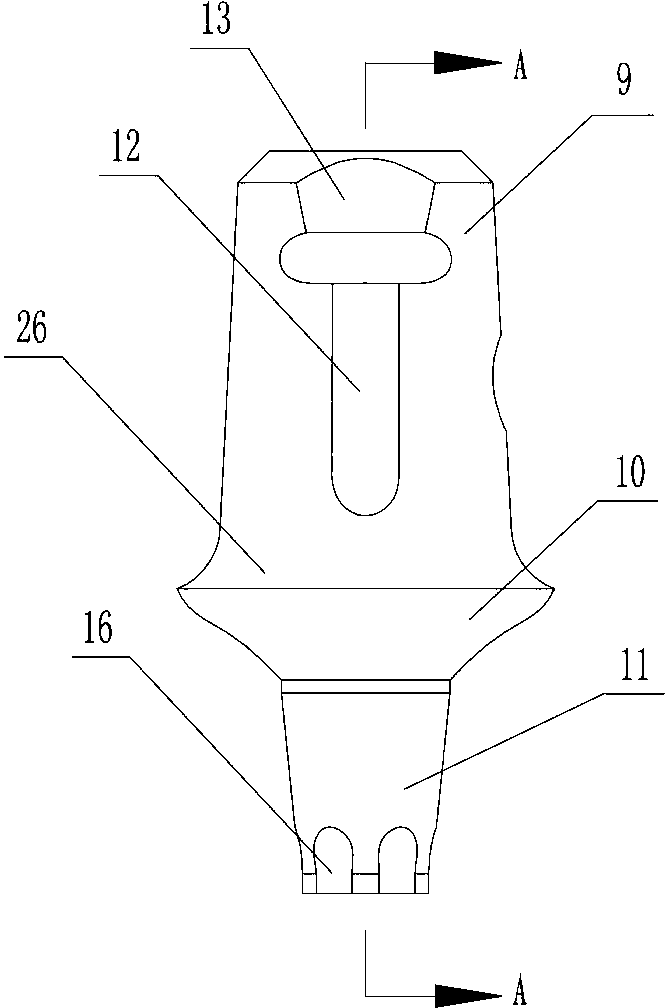

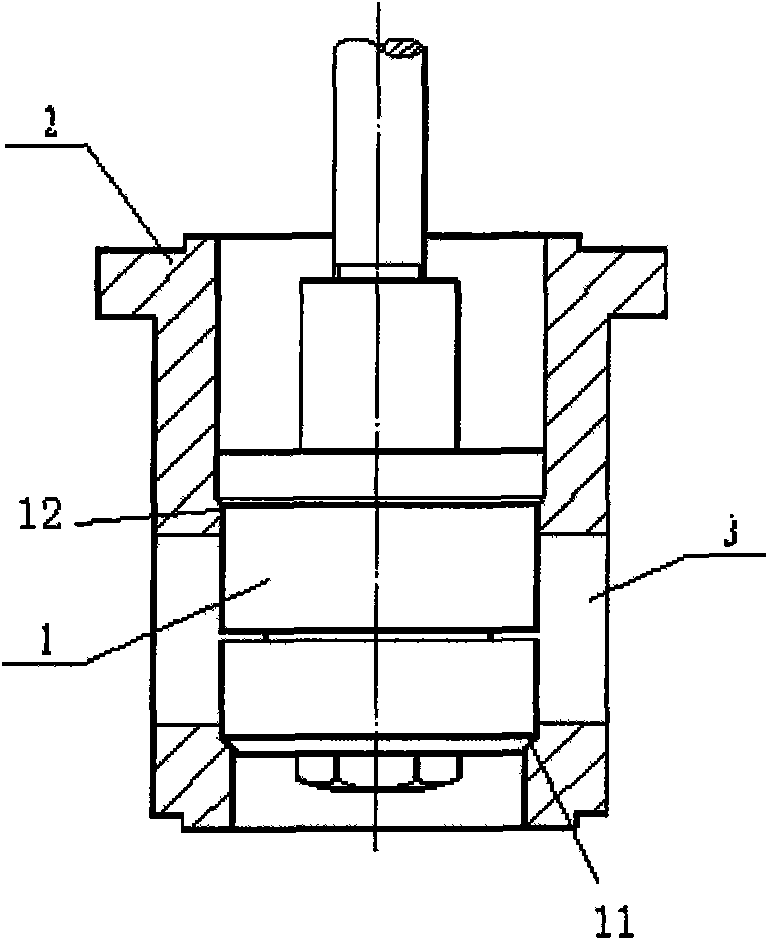

The invention discloses a push-type self-centering clamping jaw. The push-type self-centering clamping jaw comprises a mounting plate, a box body, a movable block and m clamping jaw bodies, wherein the m is a natural number greater than 2; the mounting plate is fixed to the top of the box body which is in a tubular shape, and the mounting plate is provided with m mounting cavities; the movable block is arranged in the box body and moves up and down under the drive of an air cylinder, the movable block is provided with m branch plates, each branch plate can be embedded into the corresponding mounting cavity, and each branch plate is provided with an inclined plane; the clamping jaw bodies are rotatably installed in the mounting cavities through fix shafts, the clamping jaw bodies are inclined in the same direction as the inclined planes, the heads at the upper ends of the m clamping jaw bodies are close to each other and the tails at the lower ends of the m clamping jaw bodies are awayfrom each other, and the m inclined planes can move up and act on the tails of the clamping jaw bodies to rotate around the fixed shafts, the lower ends of the clamping jaw bodies are provided with strip-shaped holes, and the strip-shaped holes of the clamping jaw bodies are rotatably connected to the inner sides of the lower ends of the branch plates through connecting rods. The push-type self-centering clamping jaw is suitable for workpieces with large dead weight.

Owner:SUZHOU HAGONG YIKE ROBOT CO LTD

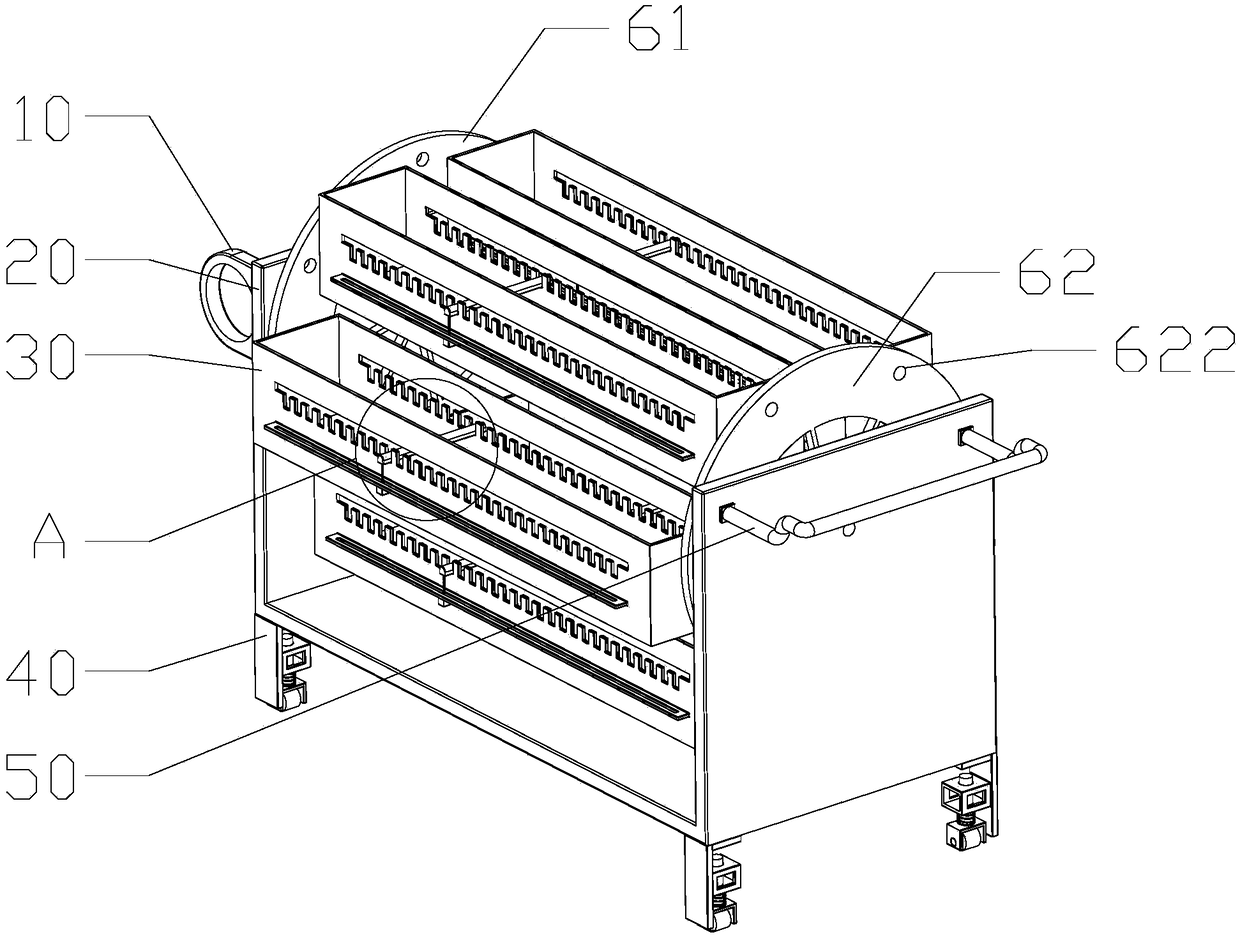

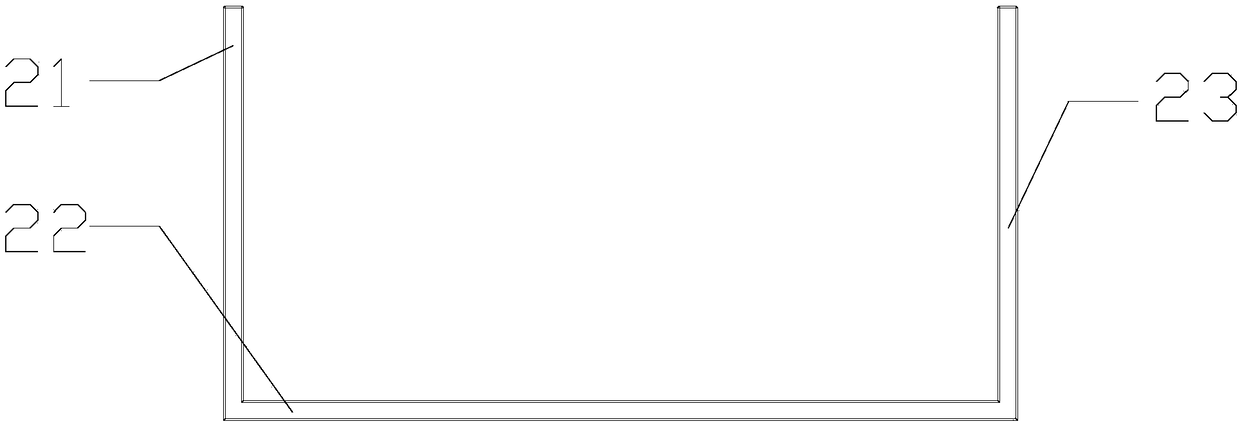

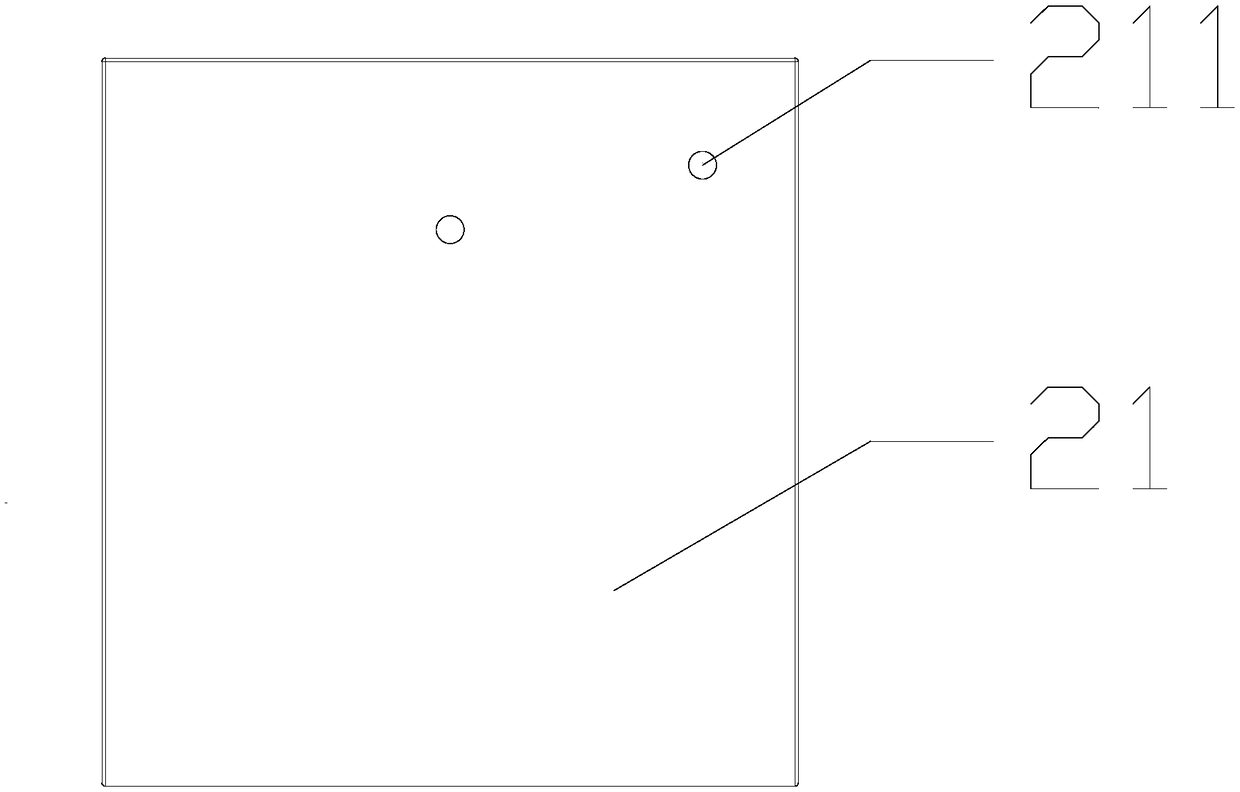

Device applicable to book sorting

ActiveCN108260954AWith self-centering functionPrevent rolloverBook cabinetsFeetEngineeringMechanical engineering

The invention relates to a device applicable to book sorting and belongs to the field of related technical equipment of a library. The device mainly comprises a main framework, wherein the top, the left side and the right side of the main framework are of an opening structure; the main framework is provided with a bottom plate, a front support plate and a rear support plate; universal wheels are mounted on the bottom plate; a front rotary disc is mounted on the front support plate, and a rear rotary disc is mounted on the rear support plate; bookshelves are arranged between the front rotary disc and the rear rotary disc; a front support shaft is arranged at the front end of each bookshelf, and a rear support shaft is arranged at the rear end of each bookshelf; the front support shafts andthe front rotary disc are in running fit, and the rear support shafts and the rear rotary disc are in running fit; distance between an axis of each front support shaft and the top of the correspondingbookshelf is smaller than distance between the axis of the front support shaft and the bottom of the bookshelf, and distance between an axis of each rear support shaft and the top of the corresponding bookshelf is smaller than distance between the axis of the rear support shaft and the bottom of the bookshelf; the front rotary disc is locked by a plug pin penetrating through a front baffle. Whenthe device is used for secondary sorting of books, the books cannot drop and slip, and a librarian is basically not required to bend down for taking the books.

Owner:开封市图书馆

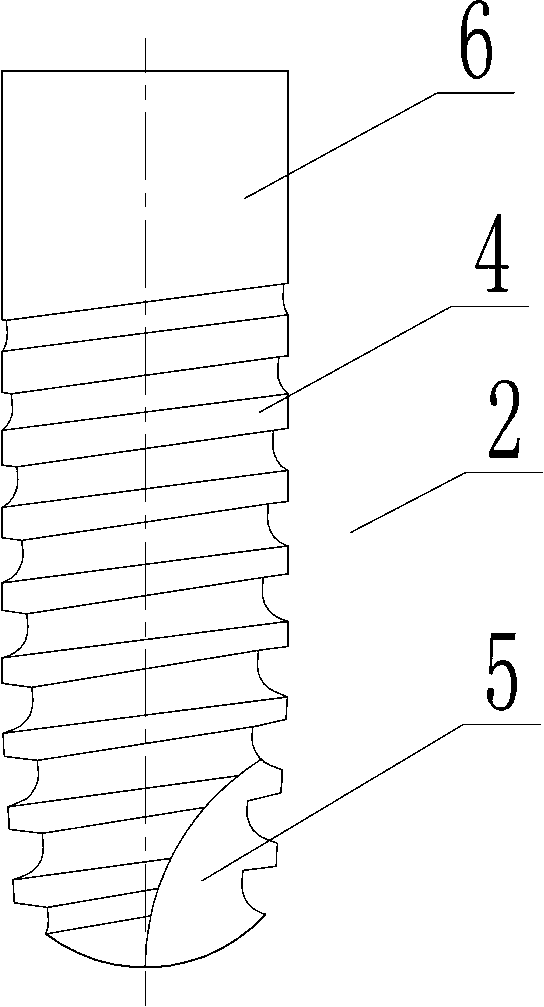

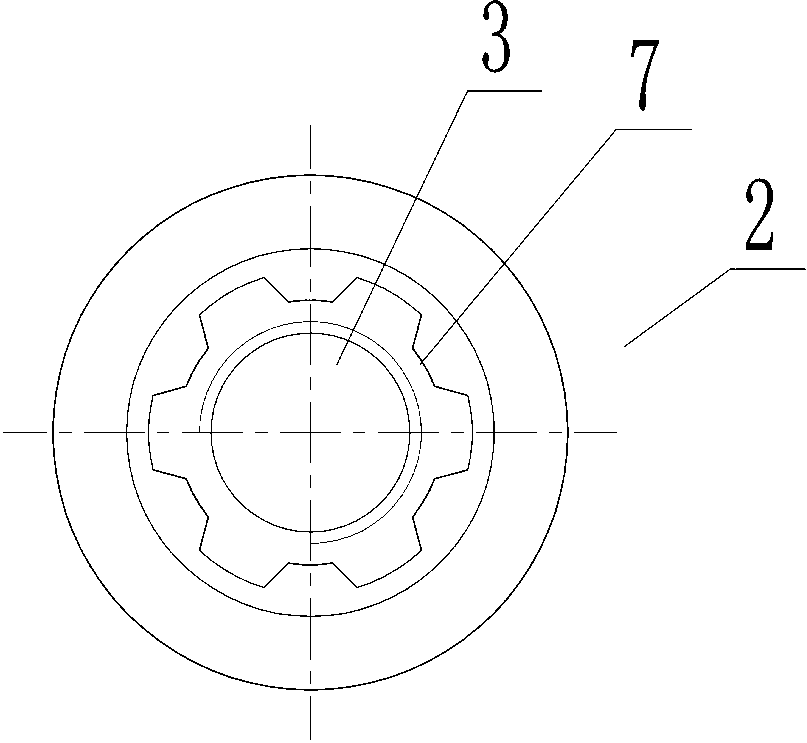

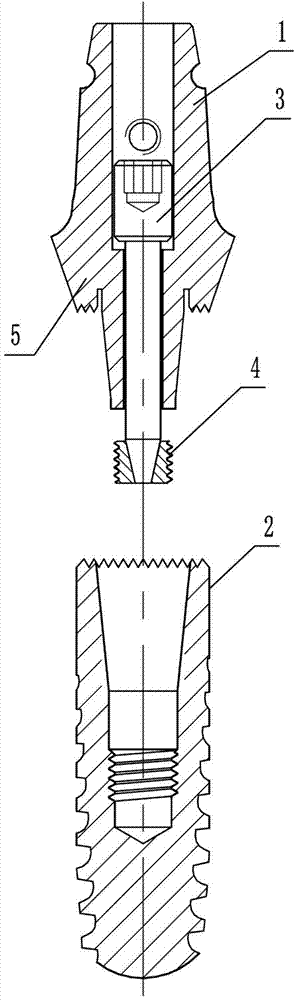

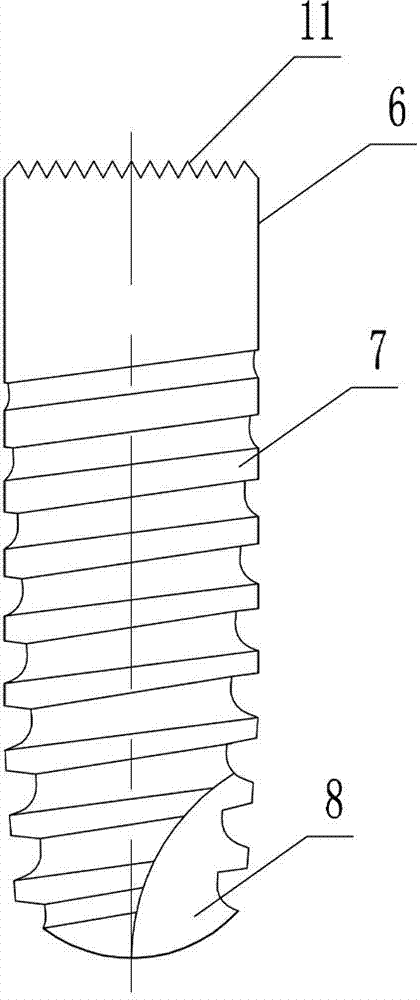

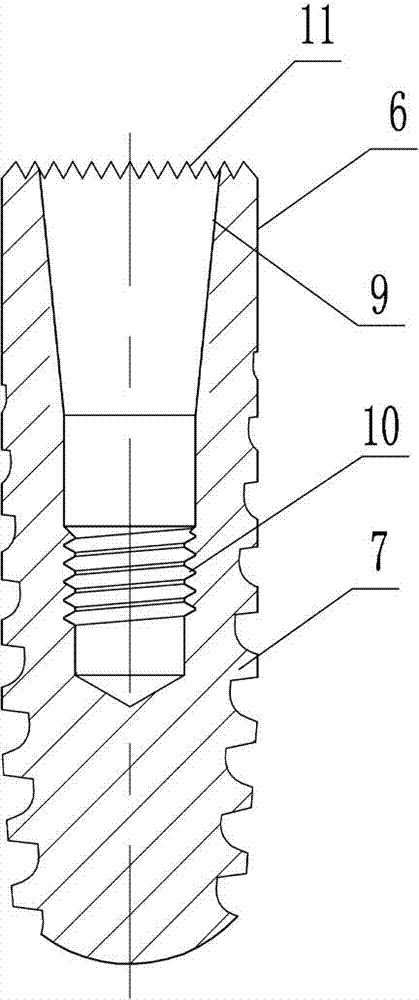

Assembled dental implant

Owner:常州百康特医疗器械有限公司

Sleeve spool valve structure featuring rigid cutting-off

The invention relates to a sleeve spool valve structure featuring rigid cutting-off, comprising a spool valve component and a sleeve. The edge of an upper spool valve boss is provided with a sealing cone of 60 degrees to 90 degrees which has the function of self-centering, and the sealing cone and a conical valve seat of 60 degrees to 90 degrees on the upper part of the sleeve form upper valve seat sealing; a lower end mouth of a lower spool valve is provided with a sealing cone of 60 degrees to 90 degrees which has the function of self-centering, and the sealing cone and the conical valve seat of 60 degrees to 90 degrees at the lower part of the sleeve form lower valve seat sealing; a group of disk-shaped springs are clamped between the upper spool valve and the lower spool valve, and bolts are used for connecting and pretightening the disk-shaped springs. The sealing surfaces of upper and lower valve seats as well as upper and lower spool valves of the sleeve are designed into conical surfaces of 60 degrees to 90 degrees, the conical surfaces can perform self-centering when contacting with each other; the spool valve is designed as a segregated structure, a group of disk-shaped springs are clamped between the upper spool valve and the lower upper spool valve, the flexible deformation thereof can remove clearance generated at the sealing part of the upper and lower valve seats due to temperature changes, so that the sealing surface can remain completely fit to meet the requirements of rigid cutting-off.

Owner:SHANGHAI INST OF PROCESS AUTOMATION & INSTR +1

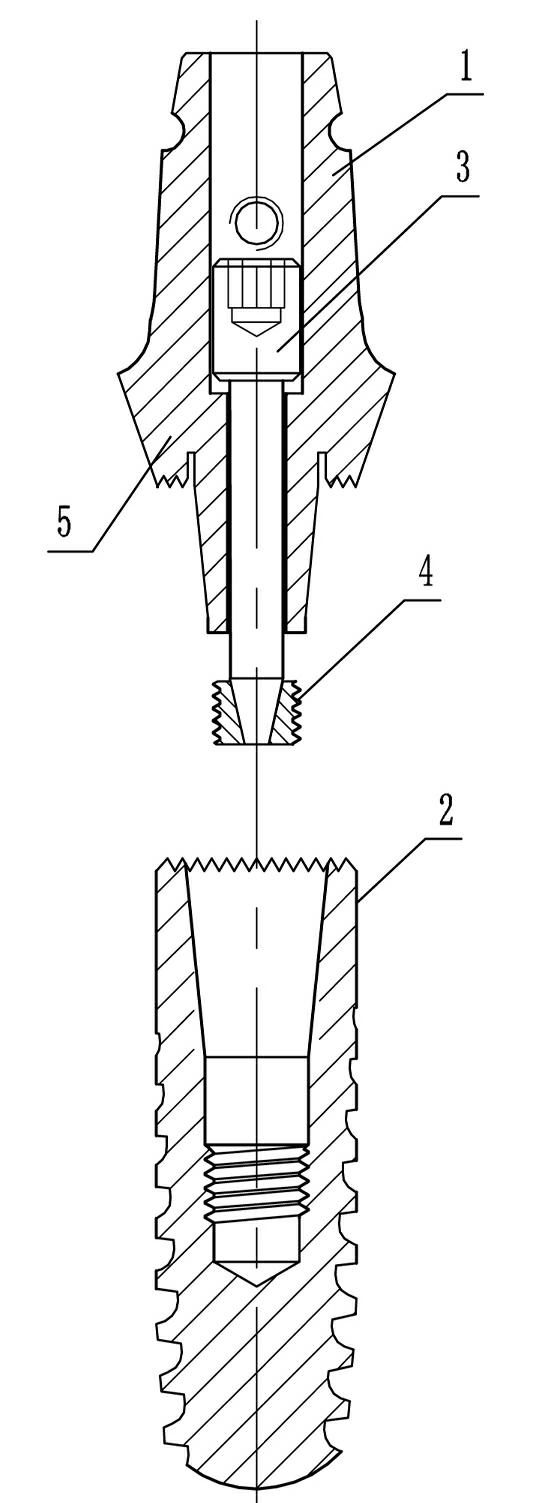

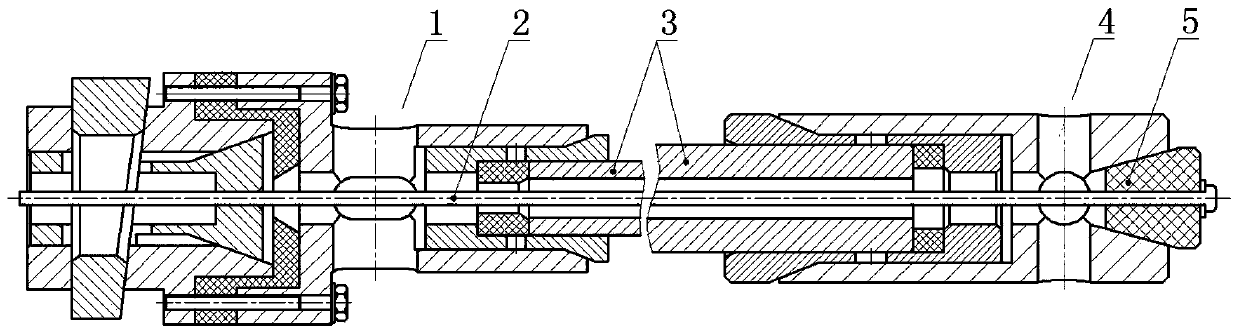

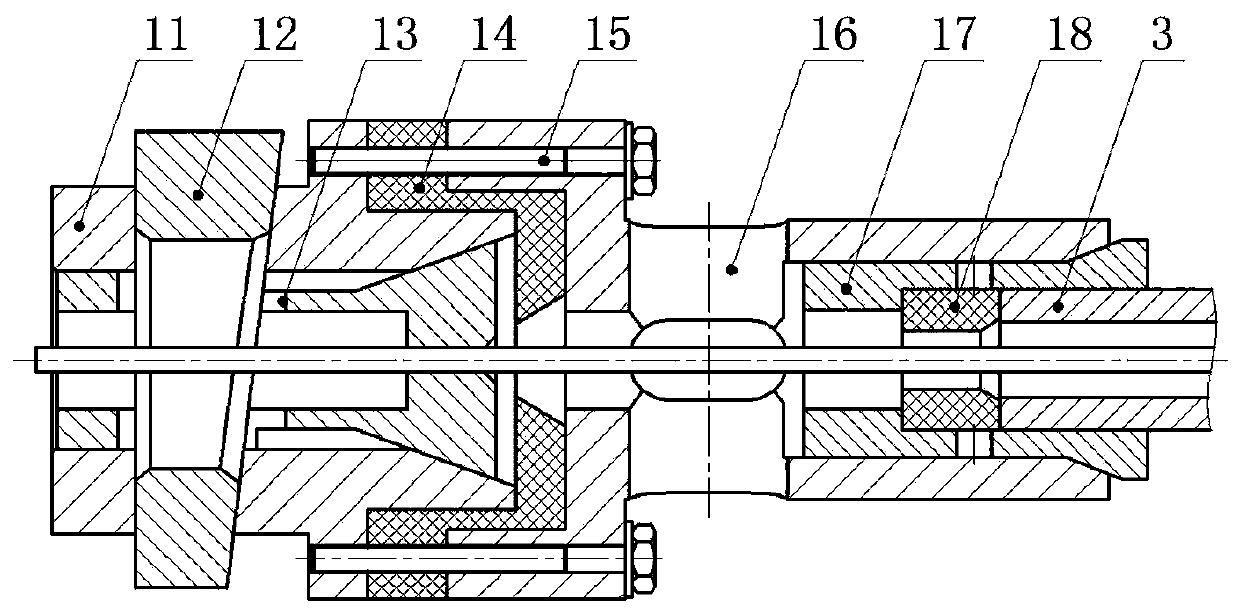

Broach for machining inner hexagonal connecting bolt and broaching method

InactiveCN110977018AImprove processing qualityExtended service lifeBroaching toolsStructural engineeringBroaching

The invention relates to a broach for machining an inner hexagonal connecting bolt and a broaching method. The broach comprises a tail handle, guide parts and a working part, and from right to left the front part is the machining reference of the rear part; and a groove connected with a machine tool is reserved in the tail handle, and the tail handle and the machine tool are clamped according to the half clamping design of a puller. The guide parts are respectively a front guide part and a rear guide part. The working part comprises rough cutting and shaping gradual cutting; the front cutter teeth and the rear cutter teeth are alternately arranged, and V-shaped chip breaker grooves are formed in the rough cutting cutter teeth; the cutter teeth of the working part are gradually cut and formed from right to left along with increase of the number of the teeth along with increase of the tooth rise amount; and the broach has an inverted cone size. The broach is long in service life, and thebroaching method is high in machining efficiency, easy to operate and high in reliability.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

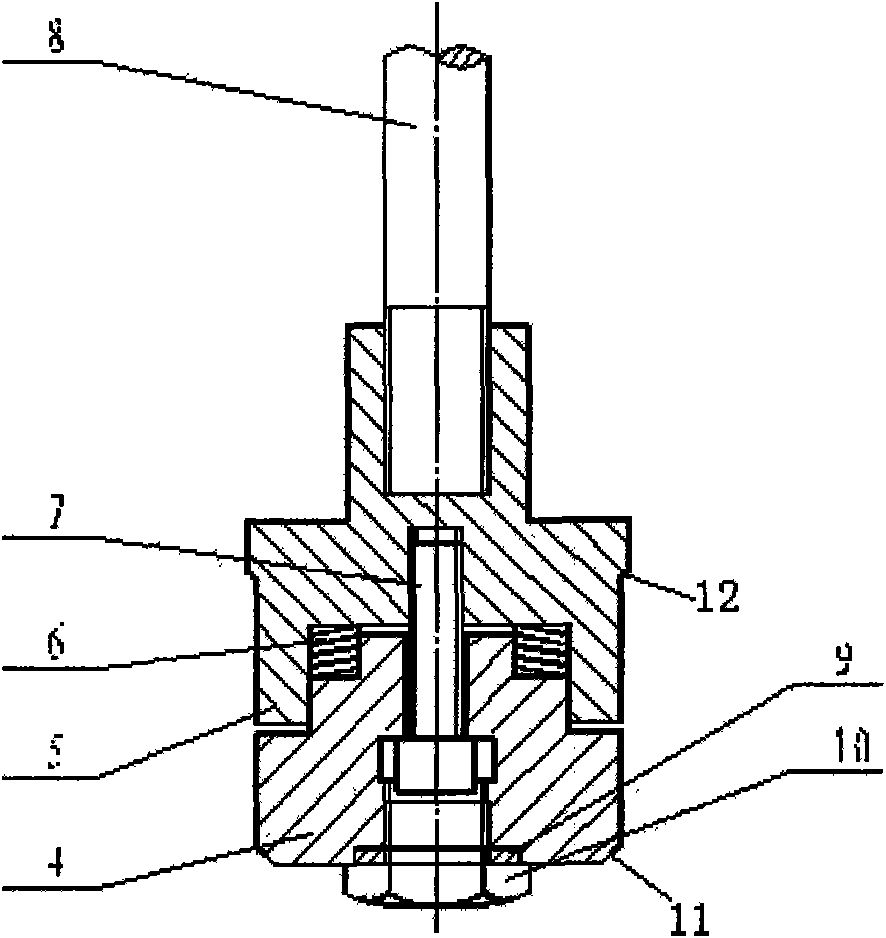

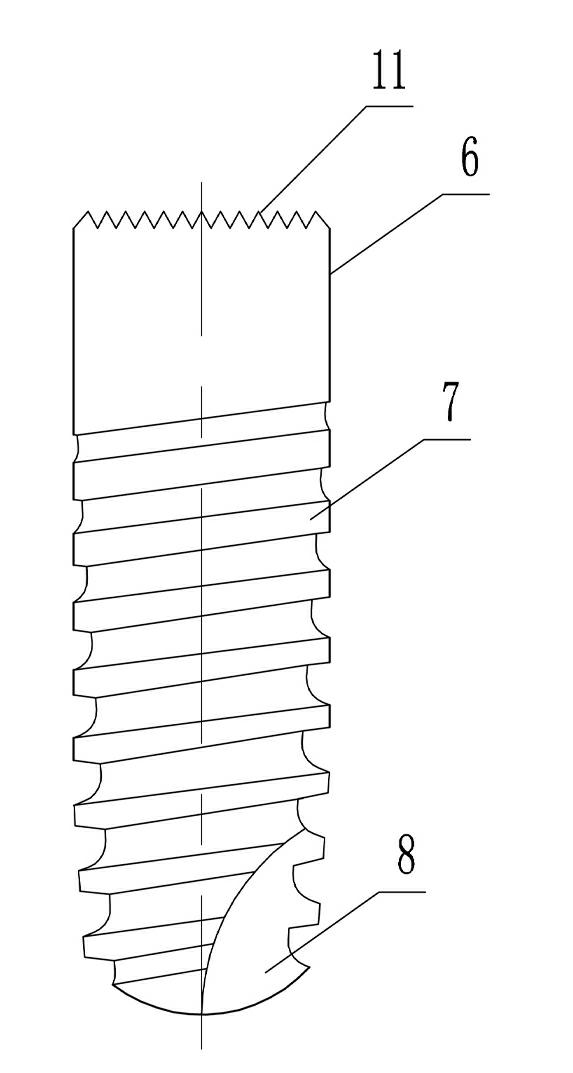

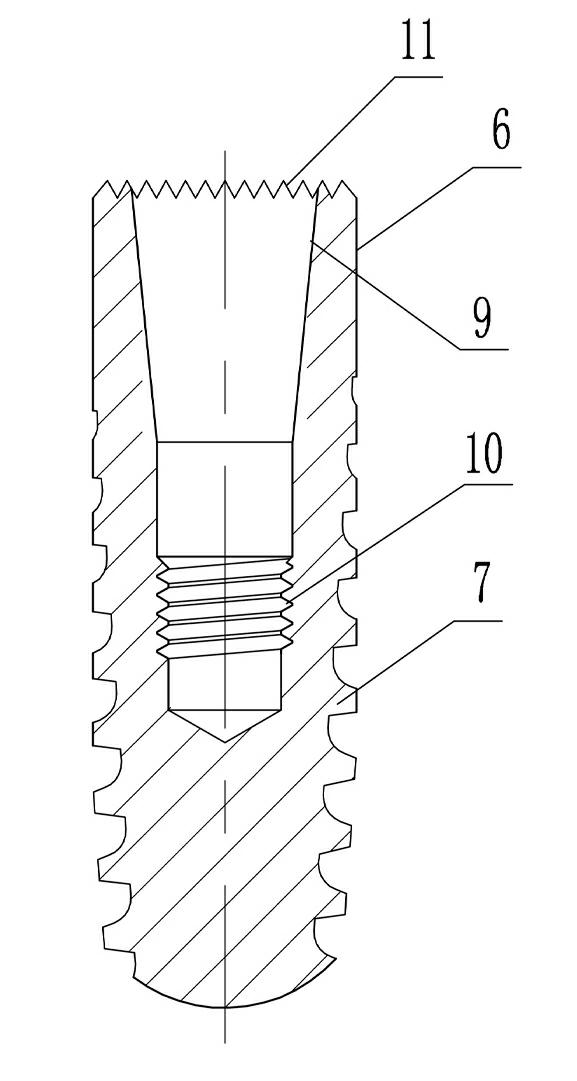

Assembled dental implant

ActiveCN102228398AReasonable designCompact structureDental implantsArtificial teethDenturesIliac screw

The invention relates to an assembled dental implant, and belongs to the technical field of dental implantation. The assembled dental implant is applicable to patients who suffer tooth decay, snaggletooth and periodontal disease, need to be surgically treated, and need tooth implantation after teeth are absent. The assembled dental implant comprises an implanting screw and an assembled base platform, and is assembled by the implanting screw and the assembled base platform; a conical threaded section is formed outside the implanting screw, and the end surface of a cylinder is provided with a plurality of dentiform protuberances or grooves of the implanting screw; the assembled base platform comprises a base platform body, a connecting screw and a thread bushing, the upper part of the base platform body is provided with an artificial tooth connection part, the middle part of the base platform body is provided with a transgingival part, the lower part of the base platform body is provided with an implanting screw connection part, and the assembled base platform is arranged in the implanting screw; the lower end surface of the transgingival part is provided with a plurality of dentiform grooves or protuberances of the base platform body which are matched with the dentiform protuberances or grooves of the implanting screw; and the thread bushing is matched with an internal thread of the implanting screw and is used for connecting the assembled base platform with the implanting screw.

Owner:常州百康特医疗器械有限公司

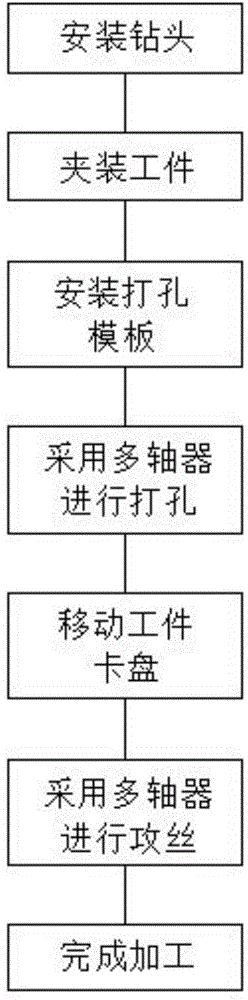

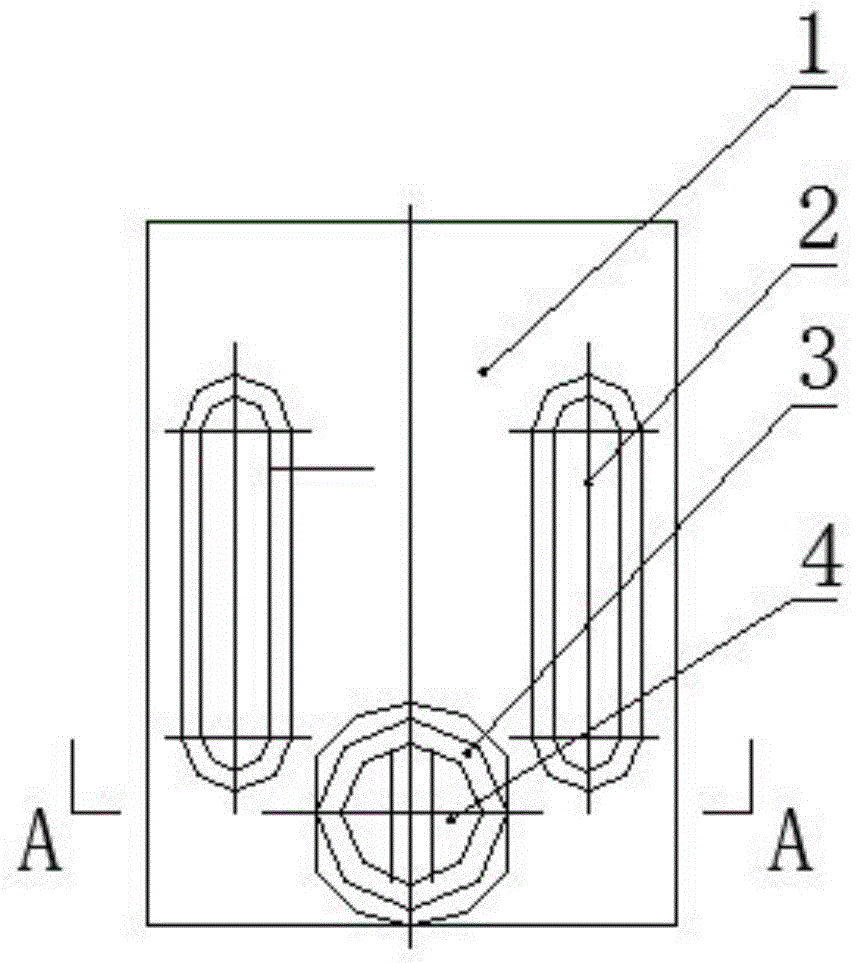

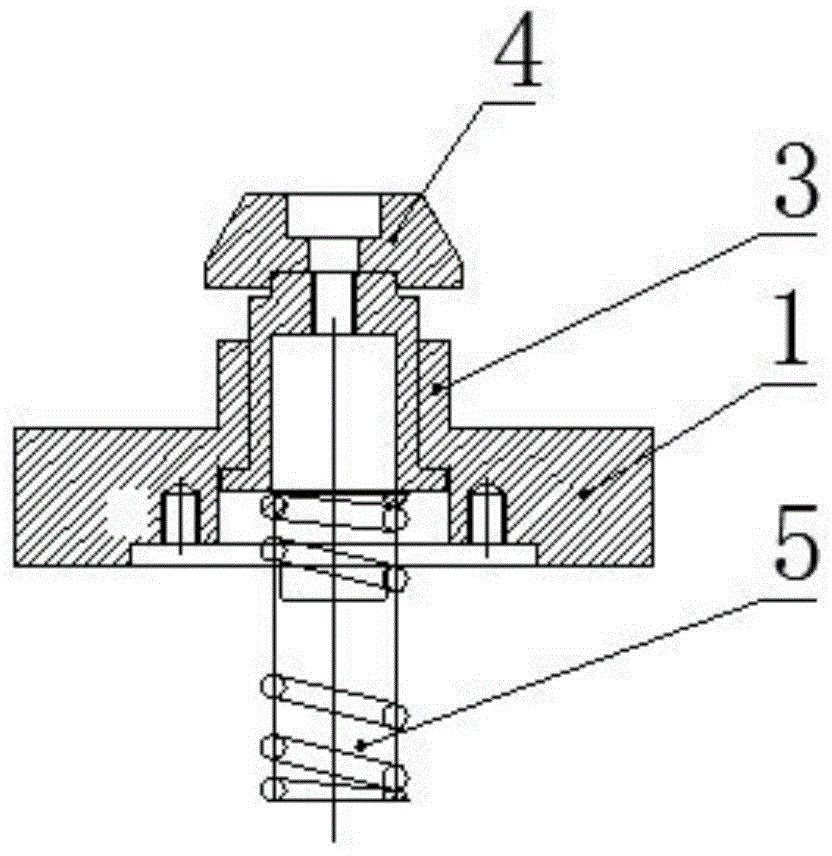

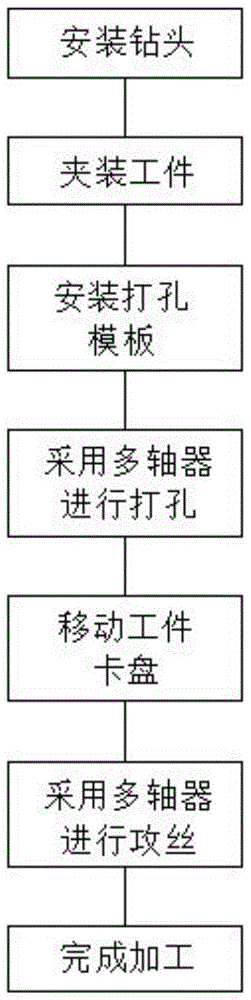

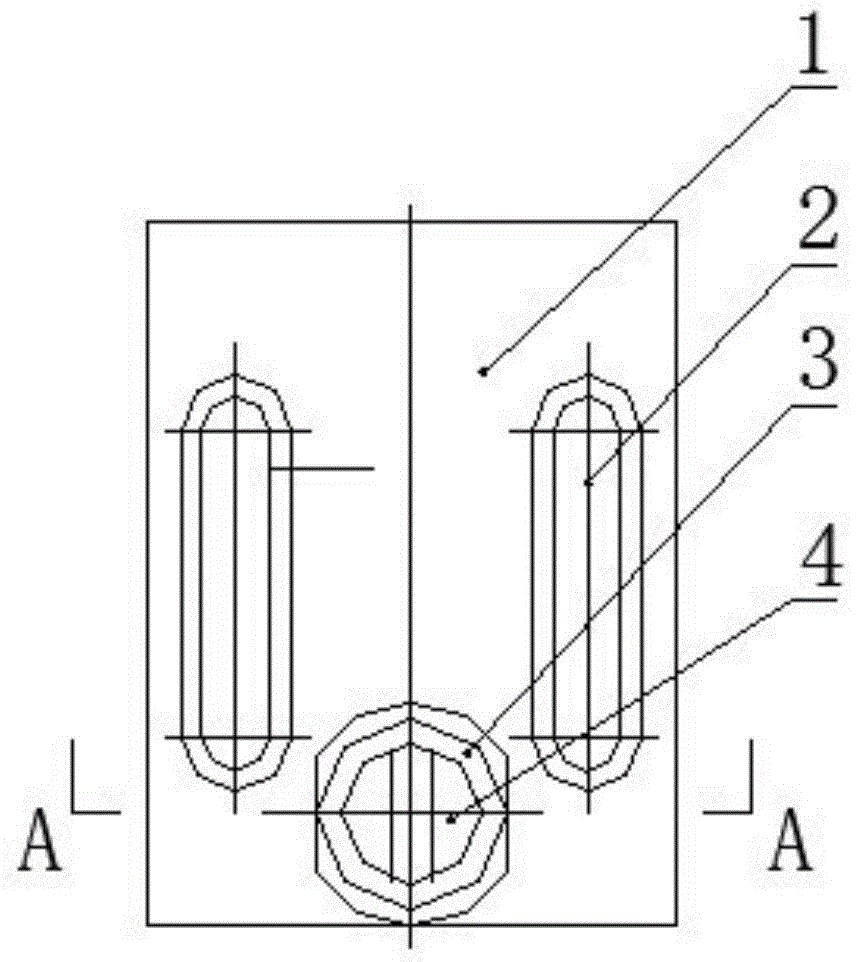

Aluminum alloy wheel punching method

ActiveCN104475795AReduce the number of feedingImprove processing efficiencyThread cutting machinesChucksPunchingProduct processing

The invention relates to an aluminum alloy wheel punching method. The aluminum alloy wheel punching method includes 1, mounting a drill bit; 2, clamping a workpiece; 3, mounting a punching die plate; 4, performing punching by a multi-spindle tool; 5, moving a workpiece chuck; 6, adopting the multi-spindle to perform tapping; 7, finishing process and detaching wheel workpiece. According to the arrangement, one-piece product processing time is saved by 70 seconds, machining efficiency and yield are effectively increased, scrapping caused by hole deviation is reduced, output is increased, and production cost is lowered.

Owner:BAODING CITY LIZHONG WHEEL MFG

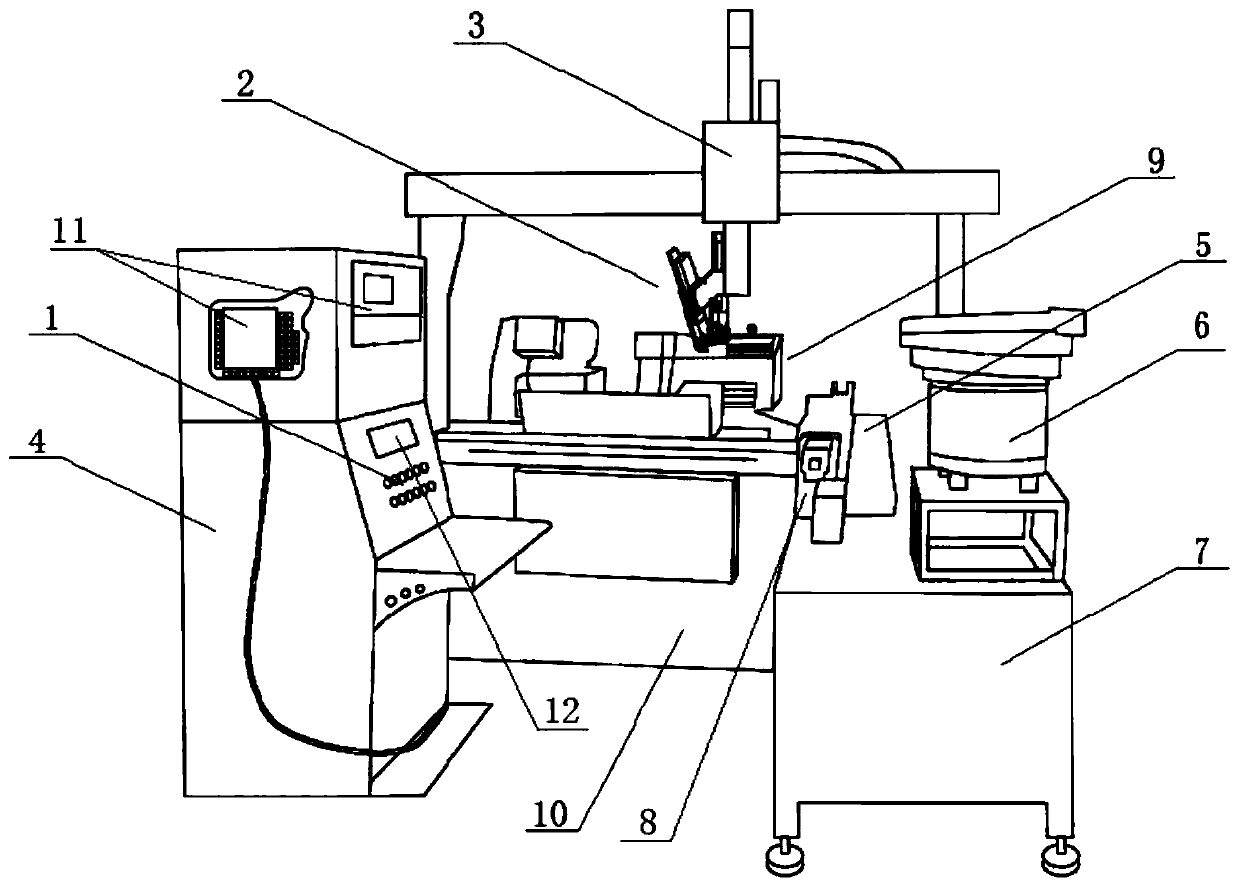

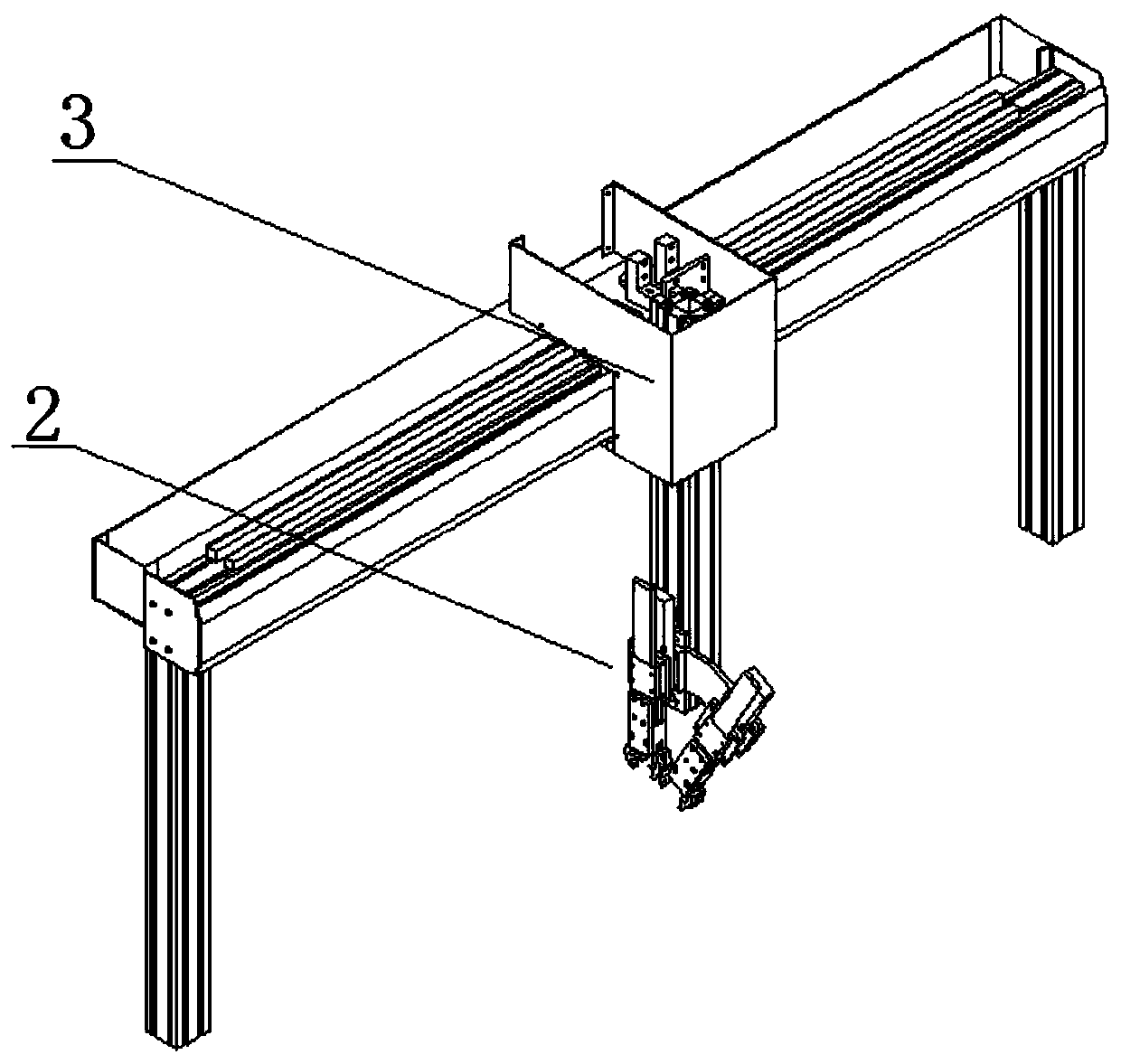

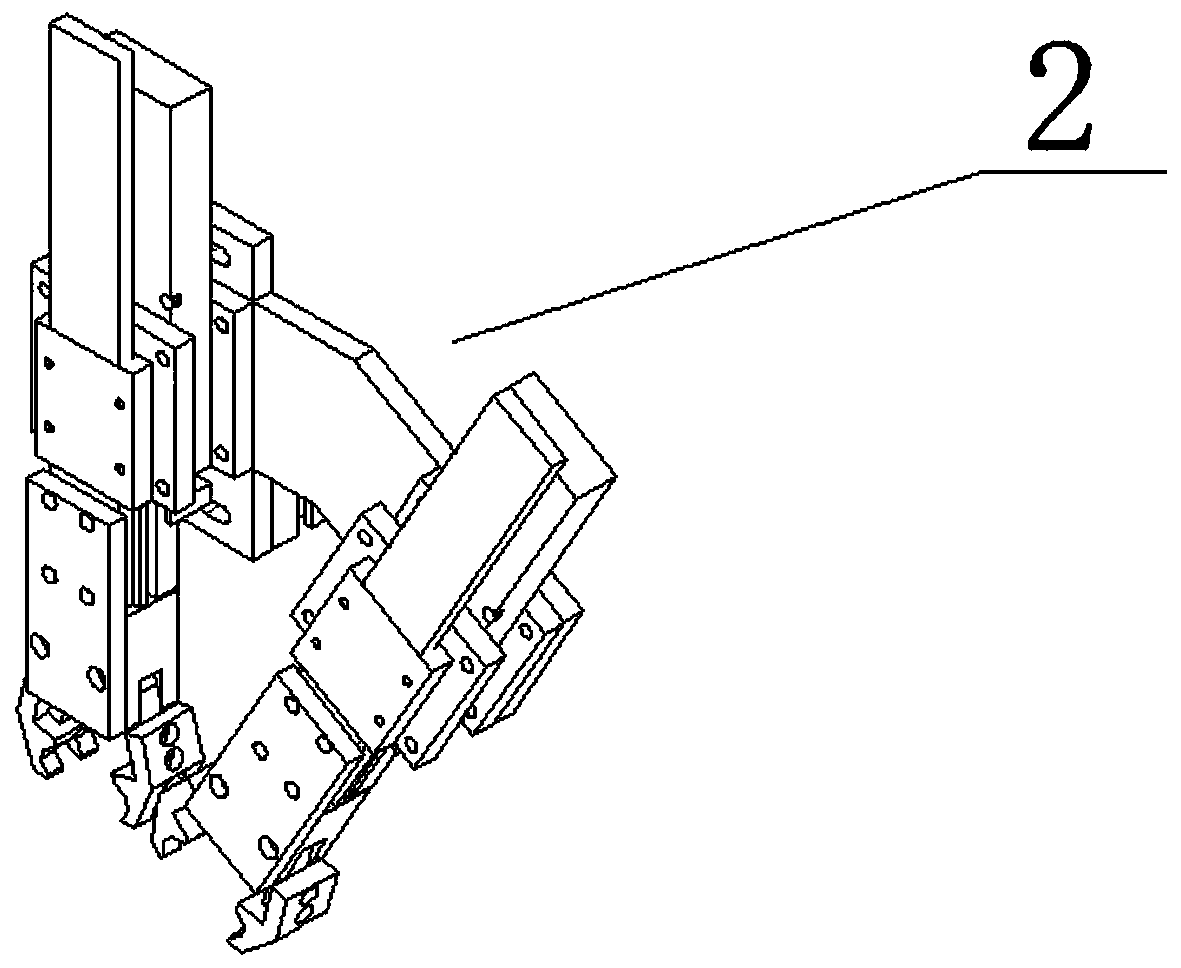

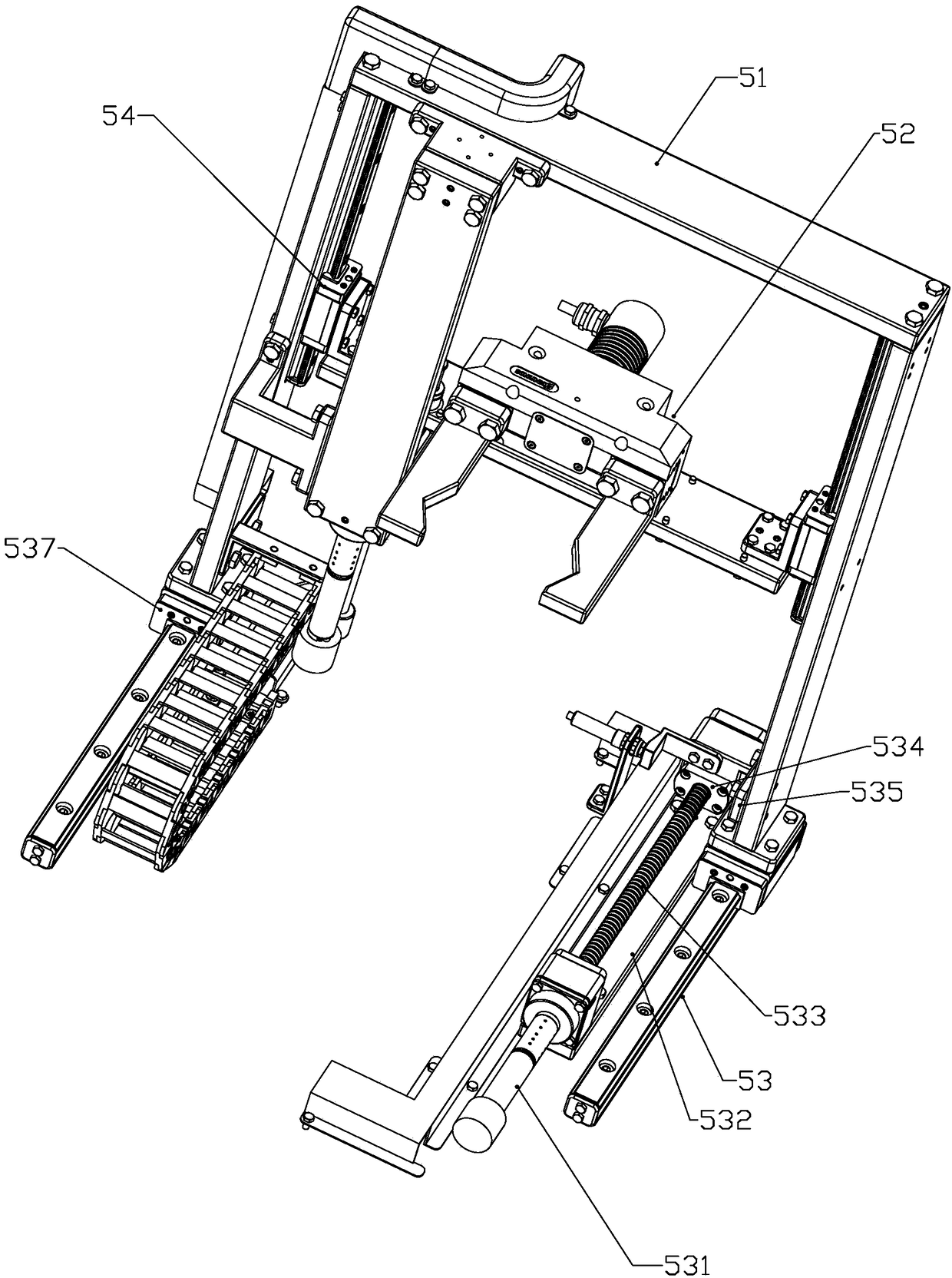

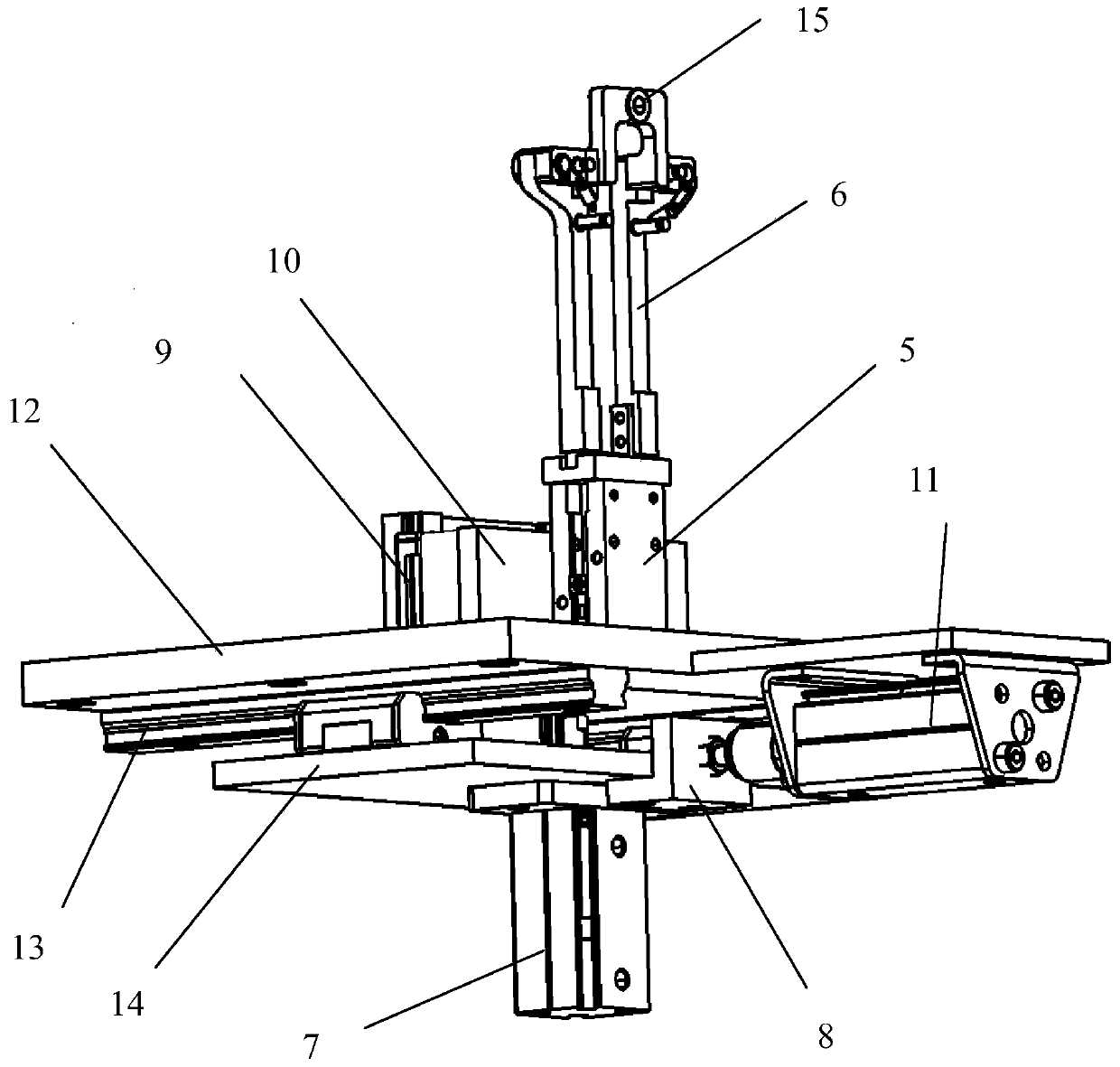

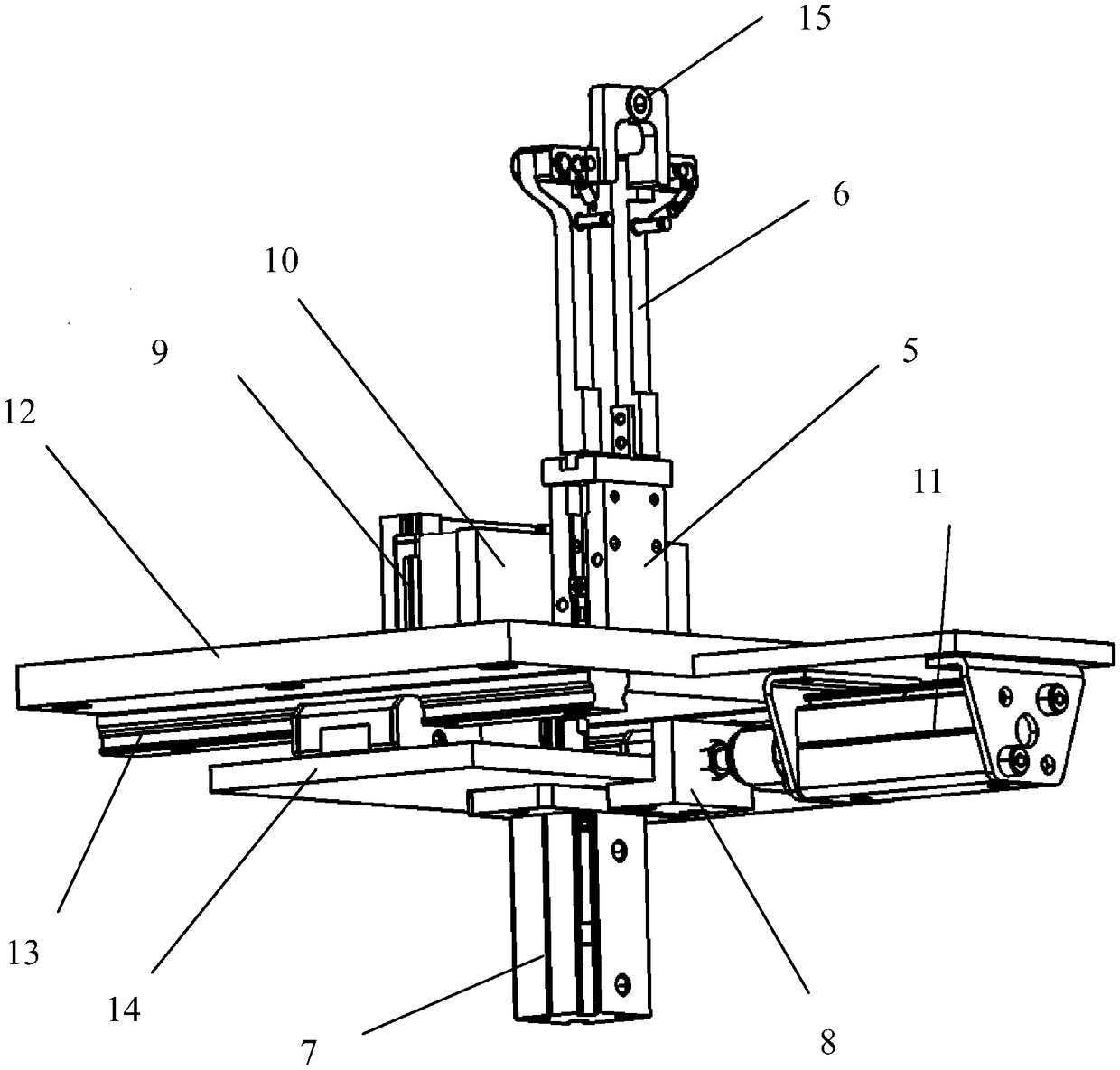

Machining tool truss manipulator

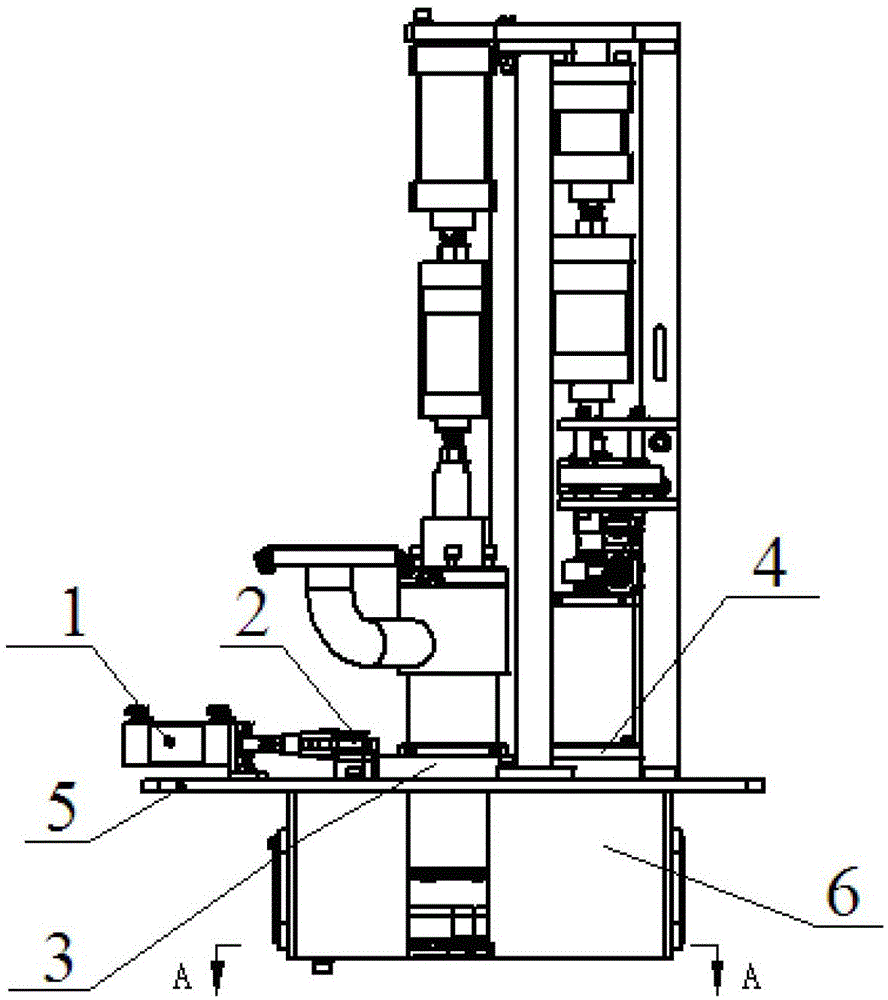

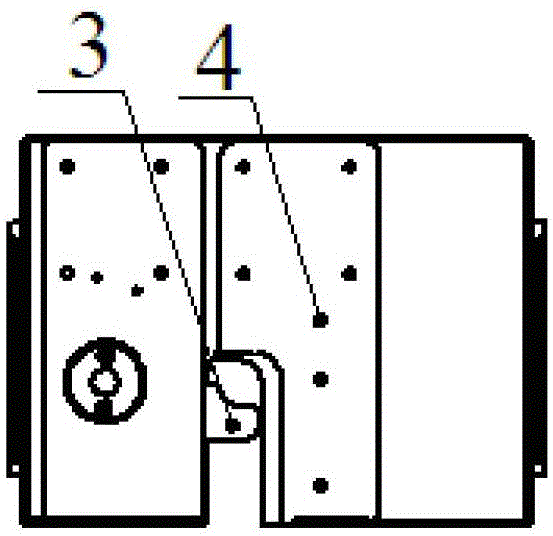

InactiveCN111215912ASave human resourcesNot easy to rustLarge fixed membersMetal working apparatusManipulatorNumerical control system

The invention discloses a machining tool truss manipulator. The machining tool truss manipulator comprises a rack, wherein a machine tool machining mechanism is arranged at the top of the rack; a workpiece and tool clamp loading and unloading mechanism is arranged at the top of the rack and is positioned right above the machine tool machining mechanism; the workpiece and tool clamp loading and unloading mechanism comprises a clamping jaw mechanism and a truss manipulator; the truss manipulator comprises an aluminum alloy section horizontal beam and an aluminum alloy section vertical arm; the clamping jaw mechanism is arranged on the vertical arm; a base is arranged on one side of the rack; a movable workbench and a loading, unloading, conveying and receiving mechanism are arranged at the top of the base; an electric control box is arranged on one side of the rack; and a switch button knob, two numerical control system controllers and a motion controller are arranged on the surface of the electric control box. According to the machining tool truss manipulator, steel beams and columns are replaced with aluminum alloy sections, secondary machining of mounting holes is not needed, thelength is random, large equipment for machining the mounting holes is omitted, tedious machining procedures and tool clamps are omitted, and manpower resources required by secondary machining are saved.

Owner:宁波广博瑞数控设备有限公司

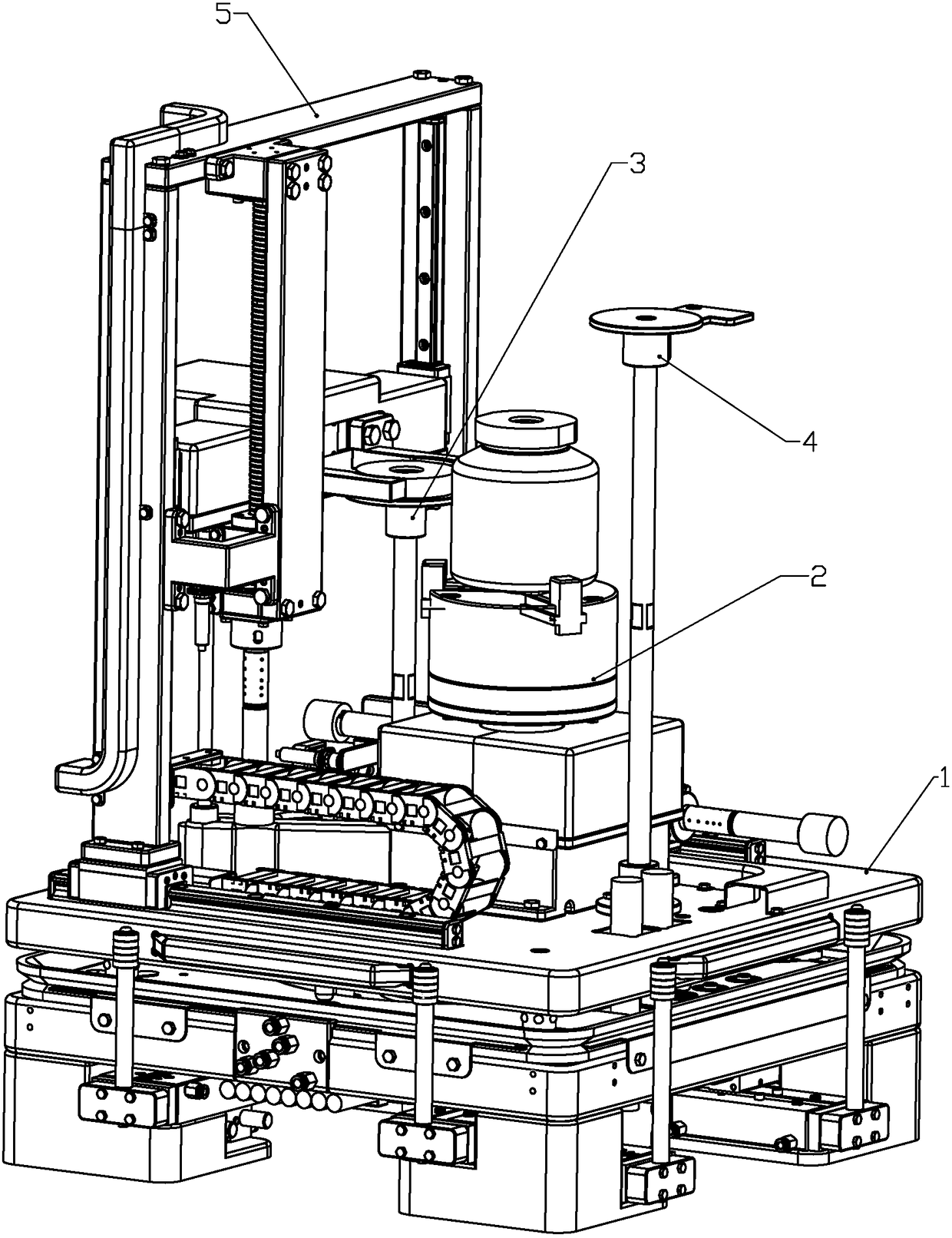

Automatic cover opening and closing device for industrial container

The invention discloses an automatic cover opening and closing device for an industrial container and belongs to the field of cover opening and closing devices. The automatic cover opening and closingdevice for the industrial container structurally comprises a base, a container rotary table mechanism, a container cover temporary storage base, a funnel temporary storage base and an automatic clamping and taking mechanism. The container rotary table mechanism, the container cover temporary storage base, the funnel temporary storage base and the automatic clamping and taking mechanism are arranged on the base. The container rotary table mechanism is located at the middle position of the upper portion of the base, and the front end and the rear end of the container rotary table mechanism areprovided with the funnel temporary storage base and the container cover temporary storage base. The automatic cover opening and closing device for the industrial container has the beneficial effects that manual operation is not needed, automatic and intelligent work is completely achieved, the automatic cover opening and closing device is suitable for occasions where manual work is not convenient,taking, putting, automatic clamping and loosening of the container are achieved, opening and screwing of large-specification threads and fine threads are achieved, meanwhile, the automatic cover opening and closing device can adapt to opening and screwing work of various customized funnels and the like and the container, the working intensity is lowered, and the working efficiency is improved.

Owner:山东爱通代代良智能科技有限公司

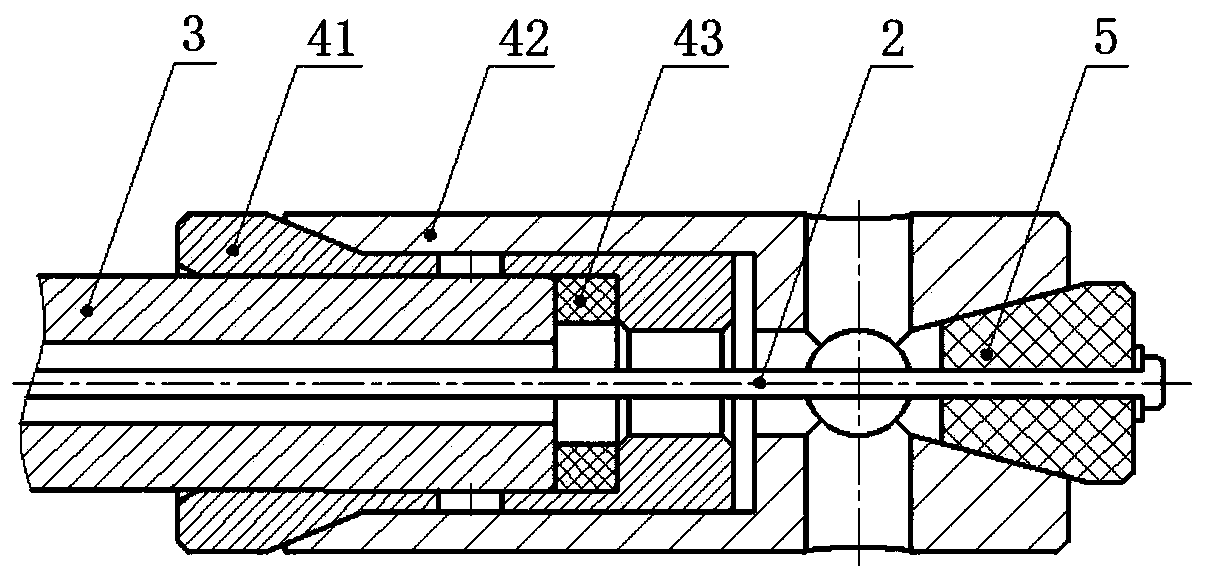

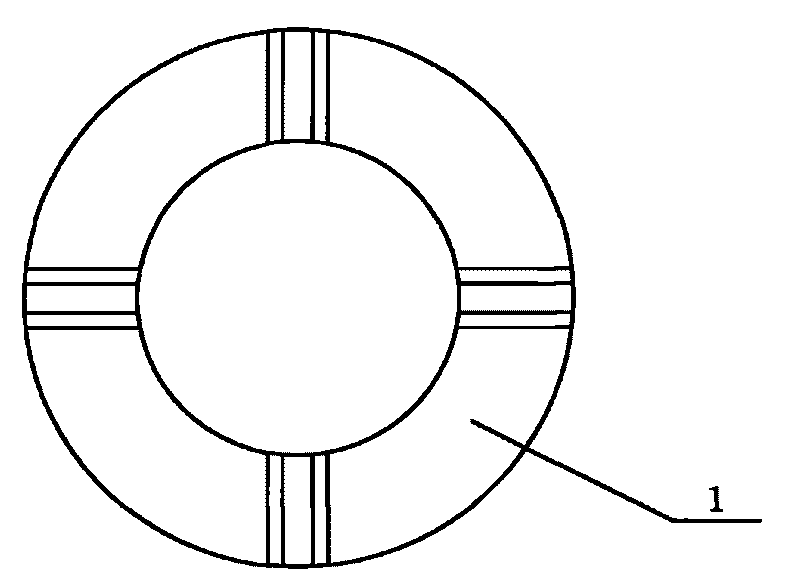

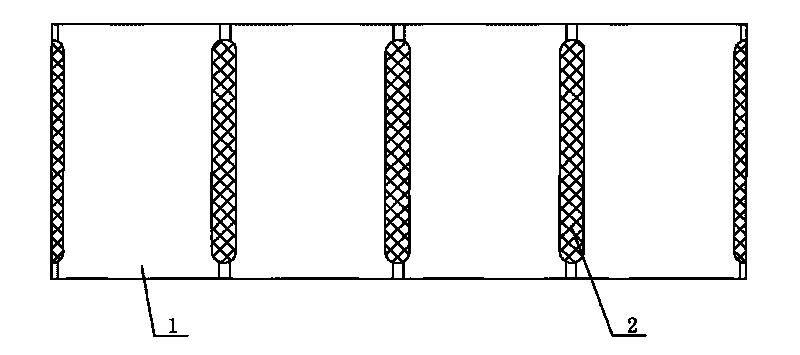

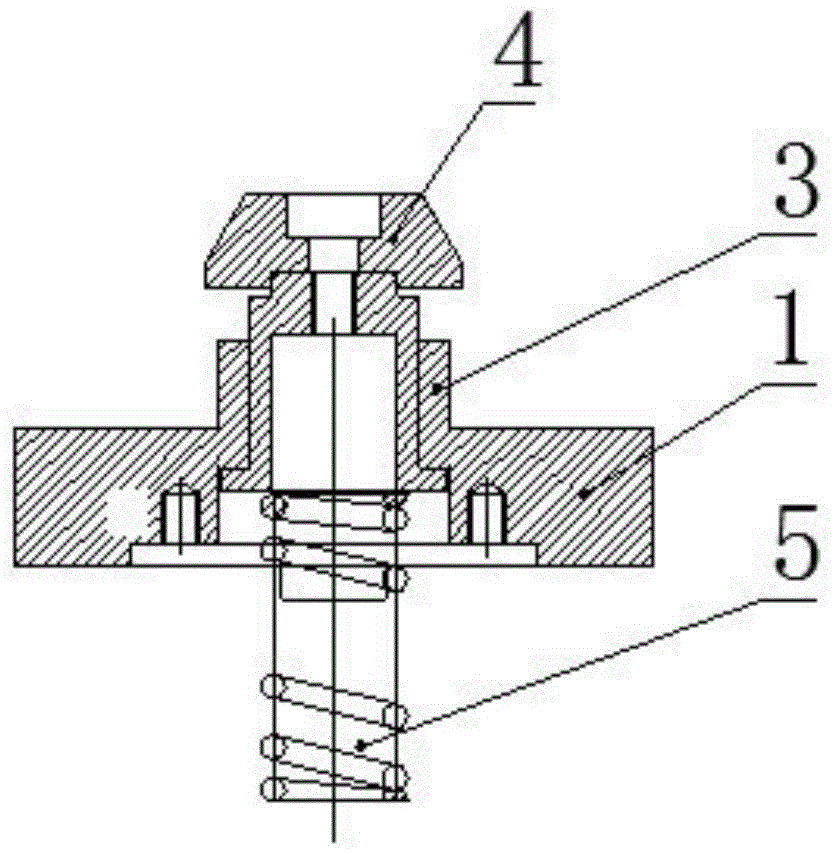

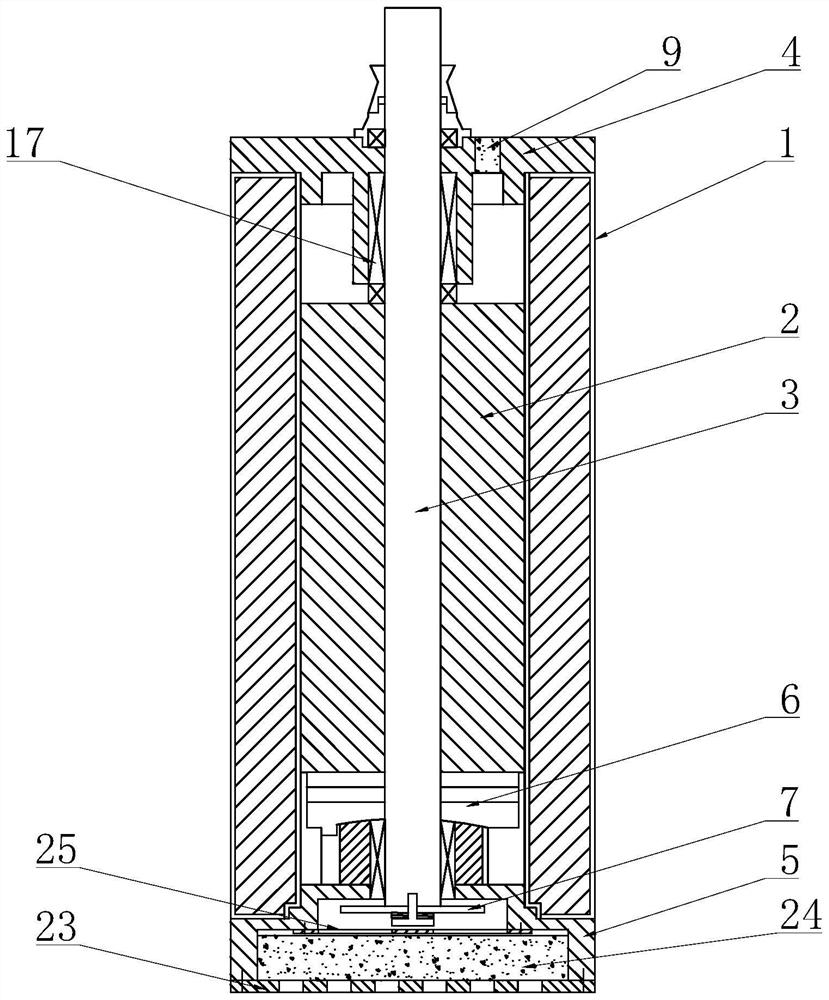

Long and thin pipe deep hole inner wall chromeplating self-centering clamping cap

PendingCN110670100AWith self-centering functionAvoid eccentricityElectrolysis componentsStructural engineeringChrome plating

The invention discloses a long and thin pipe deep hole inner wall chromeplating self-centering clamping cap. The long and thin pipe deep hole inner wall chromeplating self-centering clamping cap comprises an upper cap, a lower cap, a long and thin pipe and an anode steel wire. The upper cap comprises an anode steel wire locking mechanism body, an anode steel wire locking mechanism spring jacket, awedge-shaped locking block, an insulation gasket, an upper cap body and an upper cap self-centering spring jacket. The lower cap comprises a lower cap body and a lower cap self-centering spring jacket. The anode steel wire locking mechanism spring jacket is arranged in the anode steel wire locking mechanism body. The wedge-shaped locking block is arranged on the front portion of the anode steel wire locking mechanism body, and the upper cap body is arranged at the rear end of the anode steel wire locking mechanism body. The insulation gasket is arranged between the anode steel wire locking mechanism body and the upper cap body, and the upper cap self-centering spring jacket is arranged in the rear end of the upper cap body. The lower cap self-centering spring jacket is arranged in the front end of the lower cap body, the rear end of the lower cap body is sleeved with the anode steel wire limiting insulation block, and the anode steel wire is limited and self-centered. The long and thin pipe deep hole inner wall chromeplating self-centering clamping cap has a self-centering function, and decentration of the anode steel wire in the long and thin pipe is avoided.

Owner:CHONGQING JIANSHE IND GRP

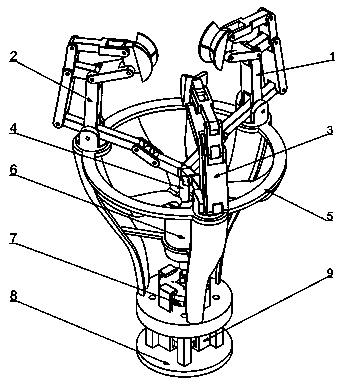

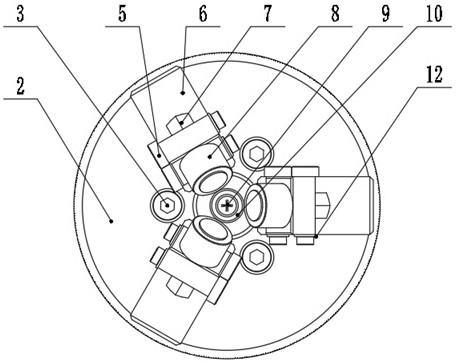

Multifunctional robotic gripper

InactiveCN108818583AImprove finger stiffnessGuaranteed centeringGripping headsGrippersPneumatic cylinder

The invention relates to an industrial robot end effector, in particular to a multifunctional robotic gripper. The multifunctional robotic gripper comprising a underframe is characterized in that theunderframe is equipped with a mechanical arm; the power source of the mechanical arm is provided by a pneumatic cylinder; power is transmitted through a compressed disc spring, a connecting support and multiple hinged supports so that the mechanical arm completes the grasping action on the underframe; the mechanical arm is installed with a mechanical finger claw consisting of a finger end frame sensor and a half moon shape inner concave block; with the mechanical arm to grip products, the mechanical finger claw is self-centering and can grasp products of different shapes and sizes.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

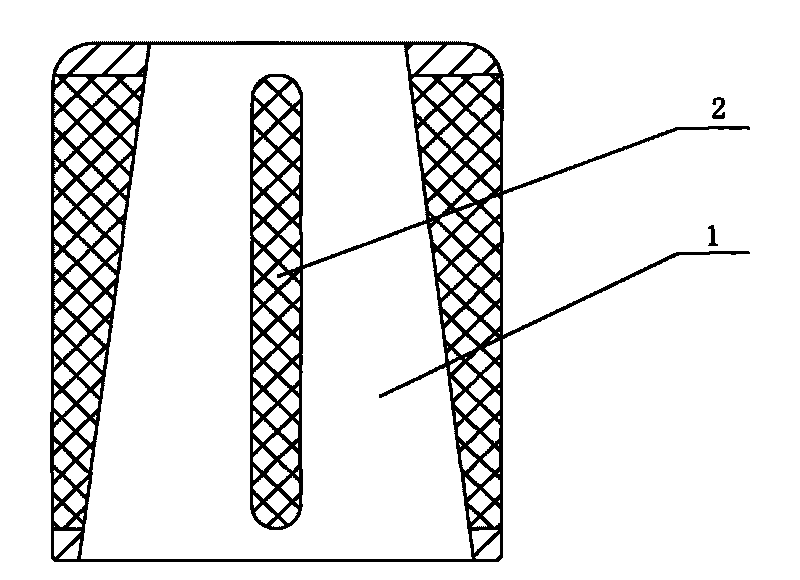

Flexible self-centering device with high stiffness

InactiveCN101722338AEasy to moveGuaranteed matching accuracyGear-cutting machinesGear teethHigh stiffnessEngineering

The invention relates to a flexible self-centering device with high stiffness, which comprises a plurality of positioning elements. The positioning elements are connected into an integral structure through rubber strips, the outer part of the integral structure is in a column shape, and the inner part forms a circular conical surface. The invention has the advantages of high precision, long service life, self-centering, simple structure and low cost.

Owner:HANGZHOU JIE DRIVE TECH

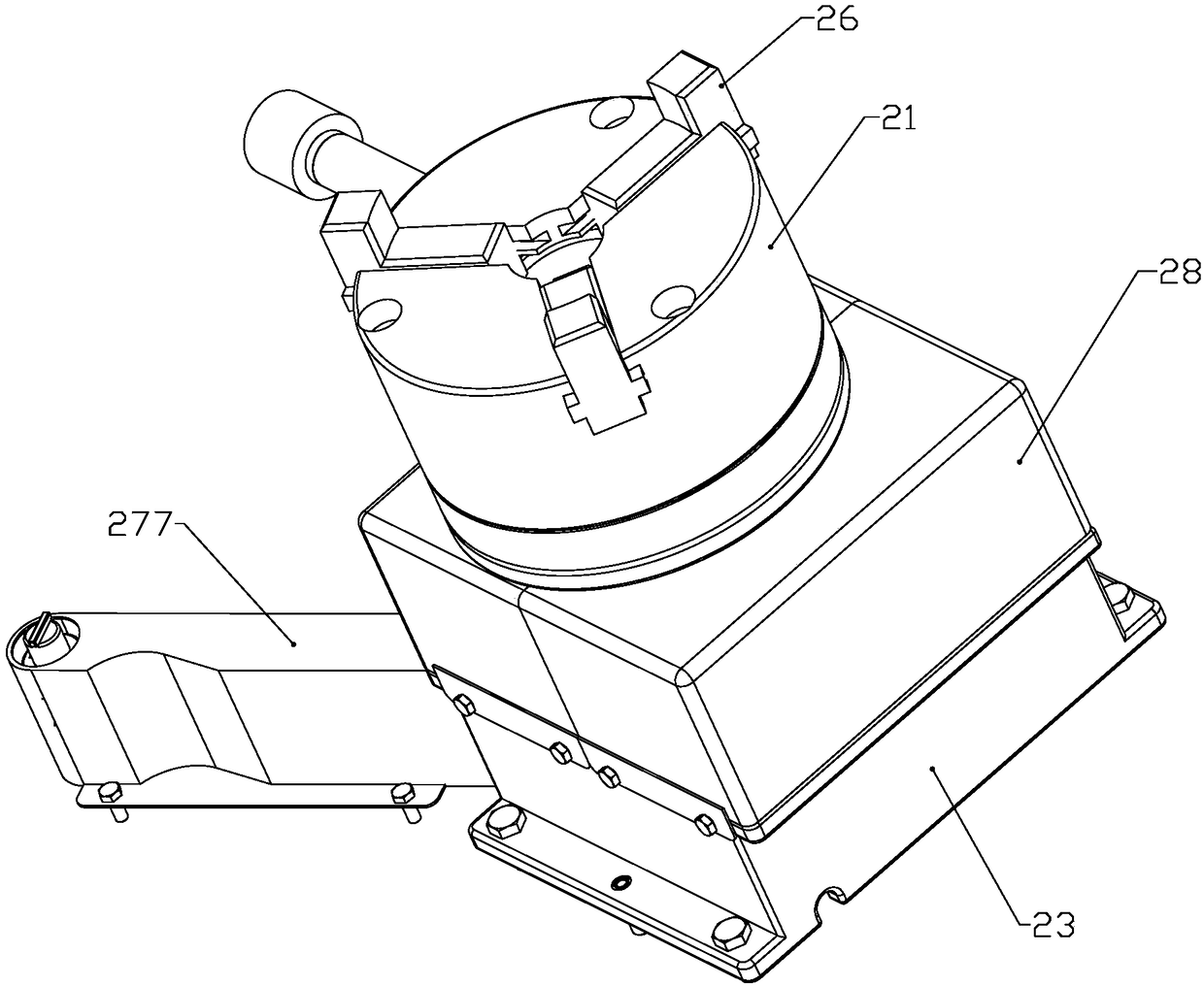

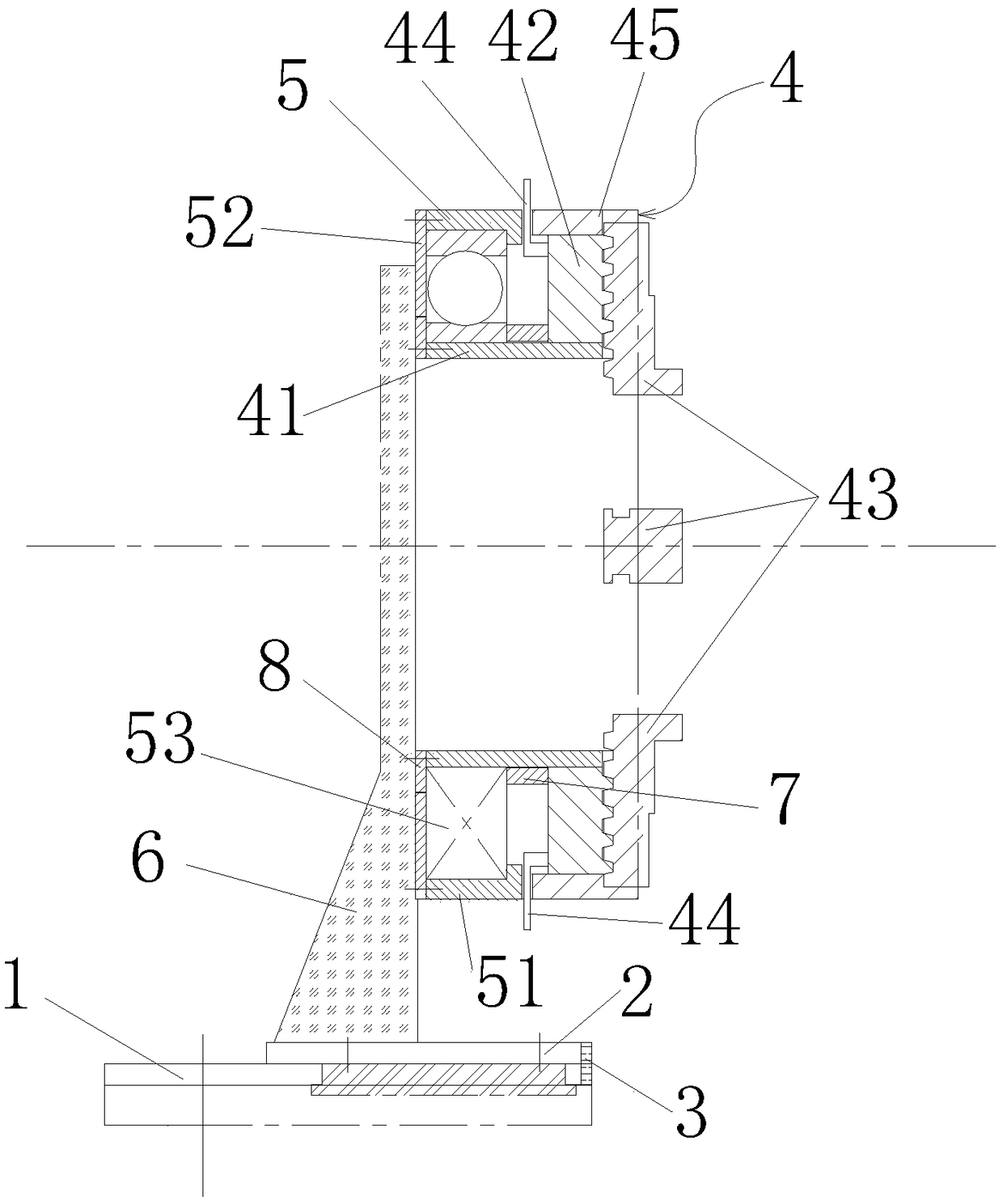

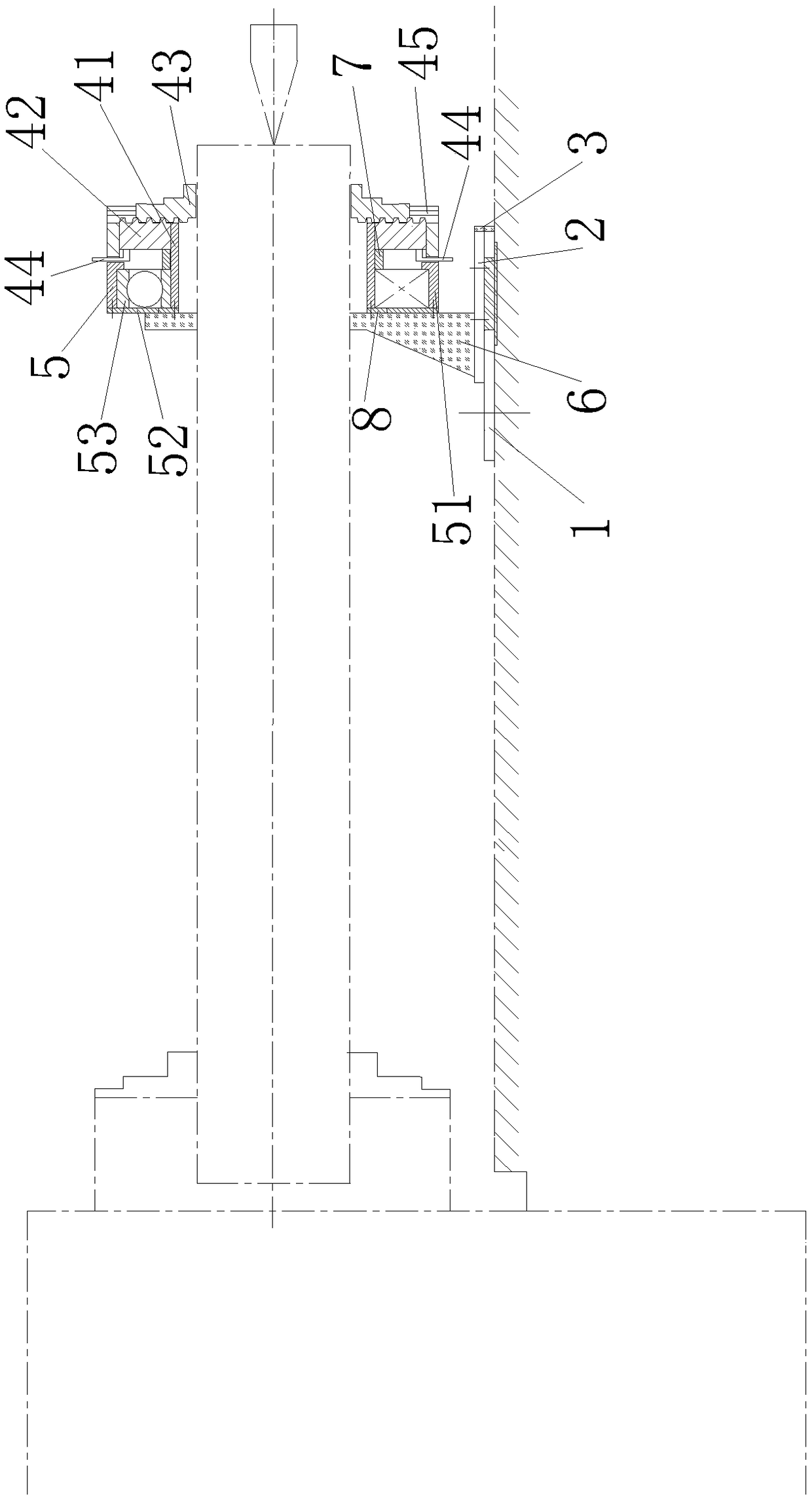

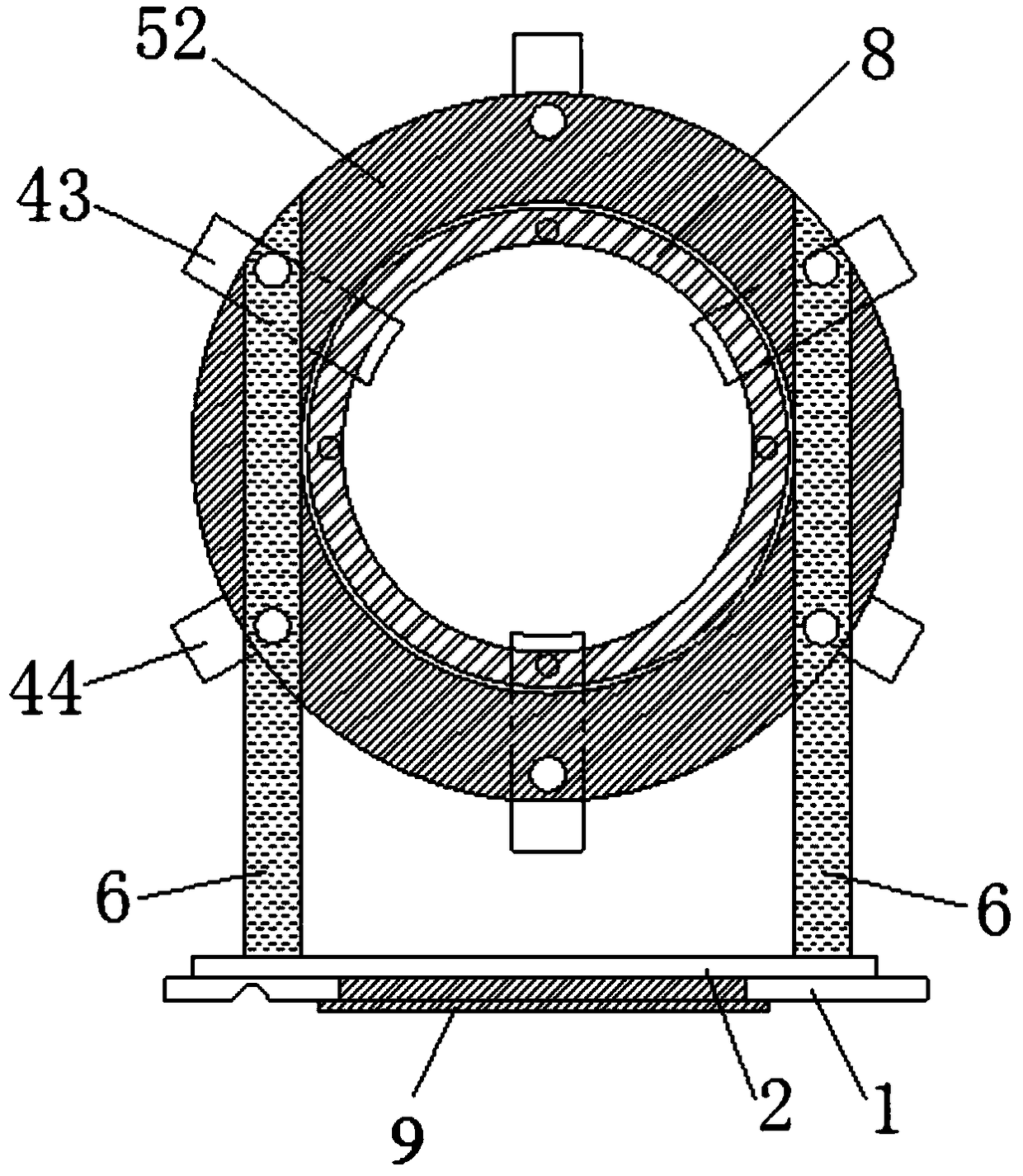

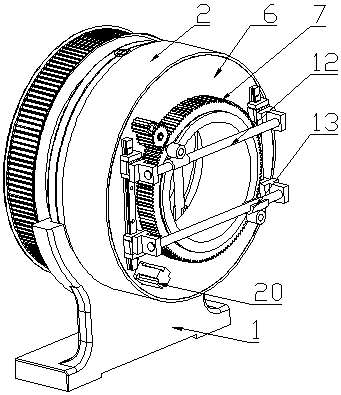

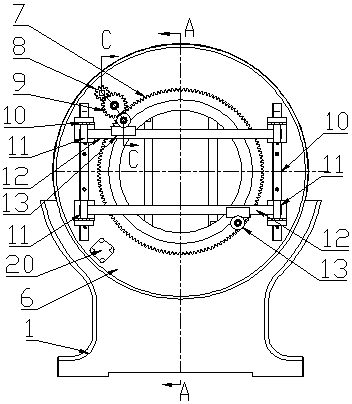

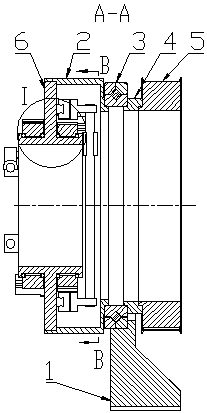

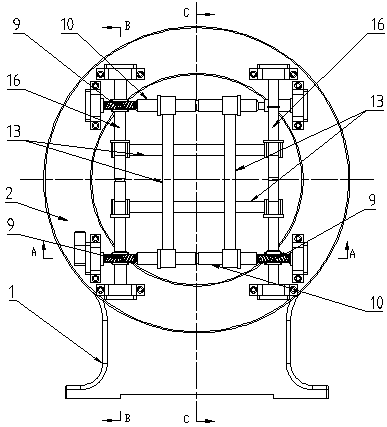

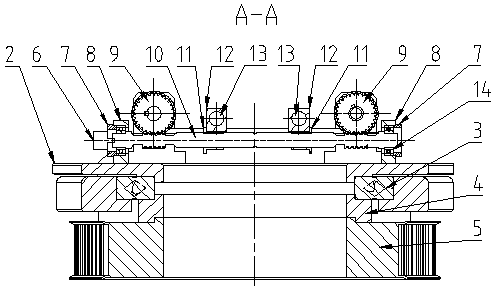

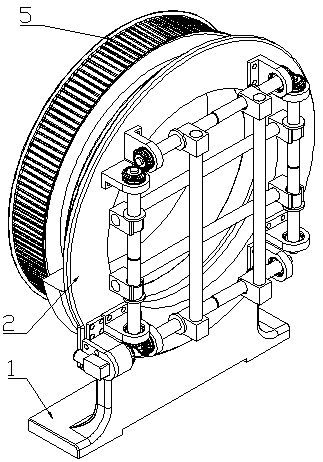

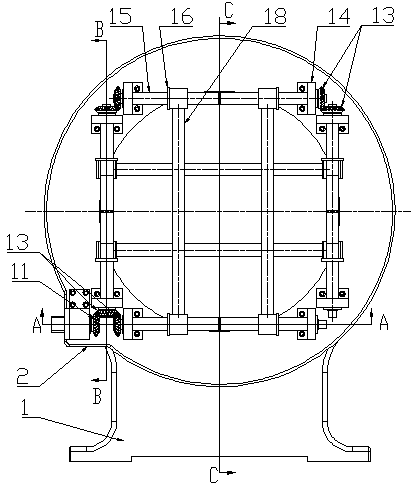

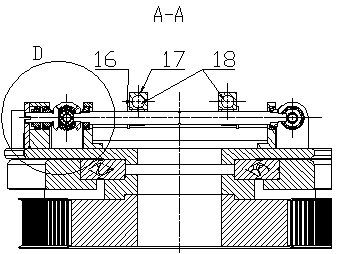

Rotating table type self-centering rotating center frame of lathe

The invention discloses a rotating table type self-centering rotating center frame of a lathe. The rotating table type self-centering rotating center frame comprises an installing fixing base, a bottom plate, a chuck and a bearing pedestal, wherein the installing fixing base is used for being connected with the lathe, and a rotating table structure is arranged in the center of the installing fixing base; the bottom plate is arranged on the rotating table structure of the installing fixing base; the chuck comprises a chuck inner core, three clamping claws used for clamping workpieces, a chuck body, end face thread discs and poking blocks, wherein the chuck body and the chuck inner core are of an integrated structure; the bearing pedestal is fixedly connected with the bottom plate through two stand column rods, a bearing is arranged inside the bearing pedestal, and the chuck inner core is sleeved with an inner ring of the bearing, wherein the chuck can support the workpieces and can rotate synchronously with the workpieces when the workpieces are machined. The chuck in the rotating table type self-centering rotating center frame rotates synchronously along with the workpieces, in this way, there is no friction between the workpieces and the chuck, it is guaranteed that the workpieces can rotate without noise, friction and jump under the condition that the surfaces of the workpieces are not machined, then the machining stability of the workpieces is guaranteed, machining precision is easily improved, and machining difficulty is lowered.

Owner:田小东

Bag clamp mechanism for aseptic small bag automatic bag filling machine

ActiveCN103910092BWith guiding functionWith self-centering functionPackagingMechanical engineeringEngineering

The invention relates to a pouch clamp mechanism for an automatic sterile pouch loading filling machine. The pouch clamp mechanism is arranged on a filling chamber of the automatic sterile pouch loading filling machine; the mechanism comprises a driving cylinder, a rotating shaft, a movable pouch clamp and a fixed pouch clamp; the driving cylinder is fixed on a support plate above the filling chamber, the driving cylinder drives the movable pouch clamp to rotate by virtue of the rotating shaft, the fixed pouch clamp is arranged beside the movable pouch clamp, and the lower ends of the movable pouch clamp and the fixed pouch clamp both are located inside the filling chamber. Compared with the prior art, the pouch clamp mechanism for the automatic sterile pouch loading filling machine has the advantages such as simple structure and wide application range, and also has a guide function and a self-centering function.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

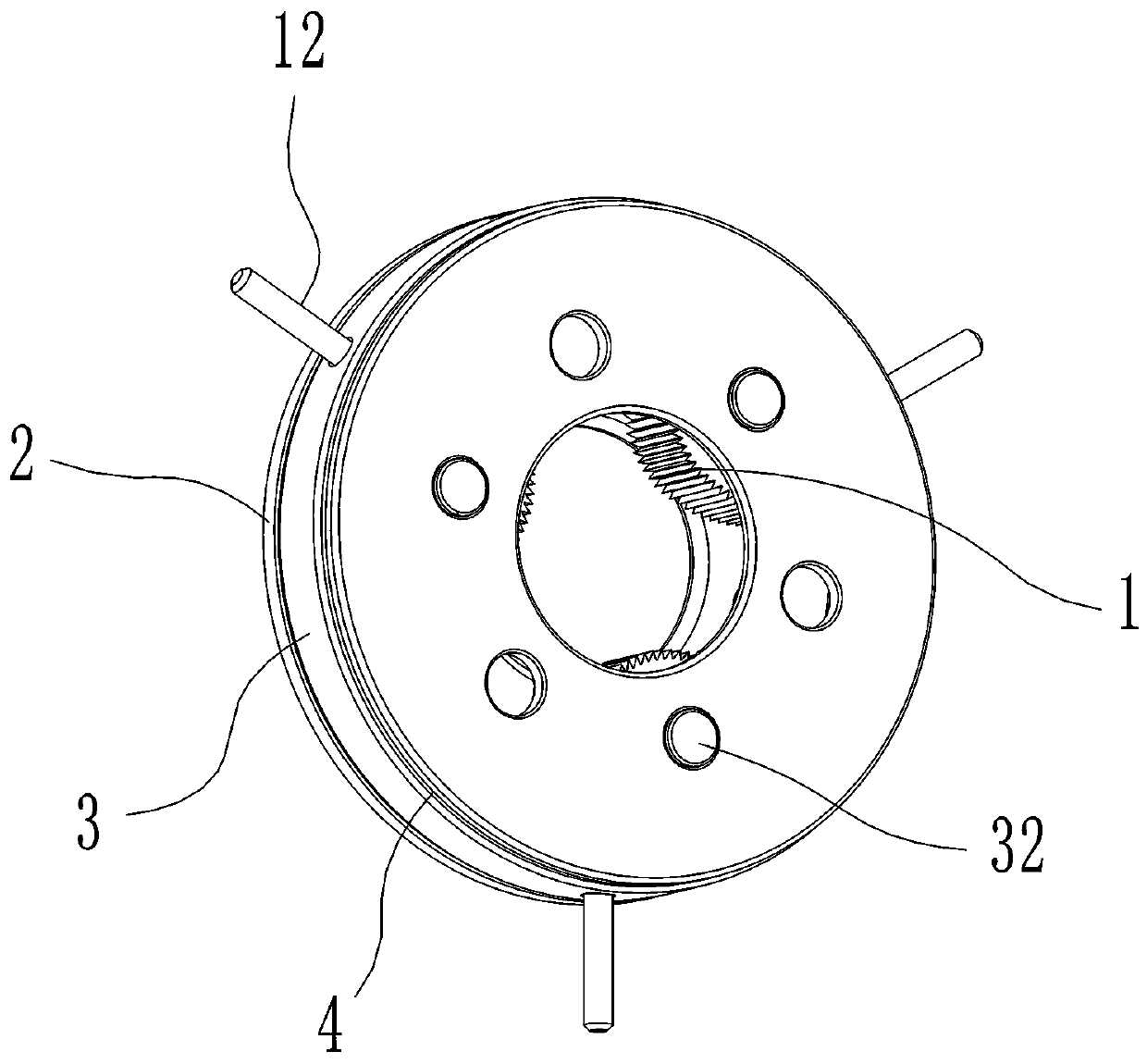

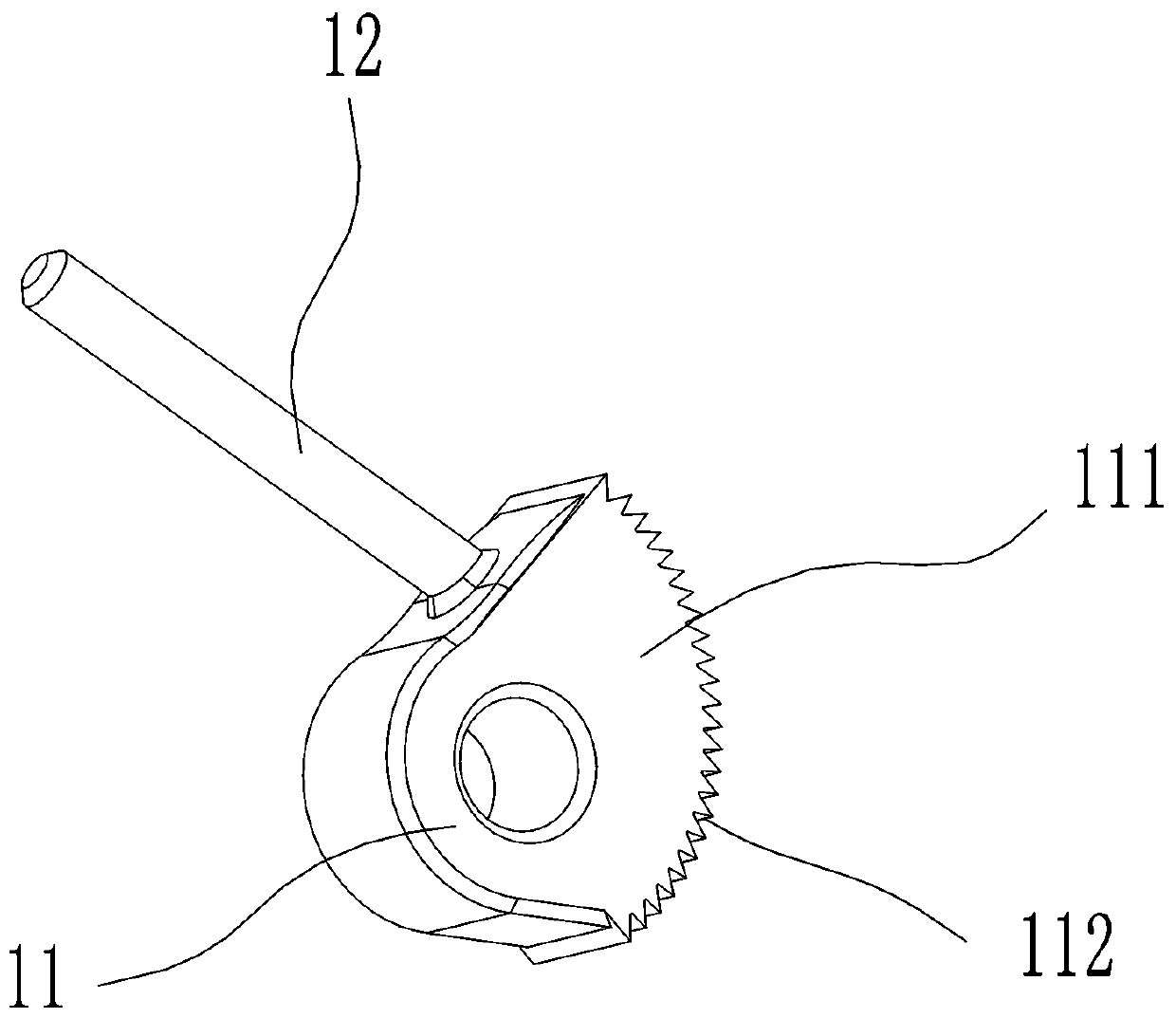

Spanner with detachable ejector header

PendingCN109877750AEasy to change and adjustImprove performanceSpannersWrenchesSoftware engineeringPipe wrench

In order to solve the technical problems of instable working efficiency and incapability of reutilization, the invention designs a spanner with a detachable ejector header. The spanner with the detachable ejector header comprises a clamping part, a linkage ring and an installation panel, wherein the clamping part comprises a clamping wheel and a holding rod; the clamping wheel is connected with the holding rod; the linkage ring is provided with a connecting hole; the holding rod penetrates through the connecting hole so as to be connected with the linkage ring; a through hole and an installation column are arranged on the installation panel; and the clamping part is connected with the installation panel through the installation column. According to the spanner with the detachable ejector header provided by the invention, the specially processed clamping part is adopted, the performance of the clamping part is not lower than the performance of a pipe wrench bayonet, and the clamping part has automatic compensation, self-centering, quick-changing and linkage functions so as to be conveniently changed and adjusted.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD +1

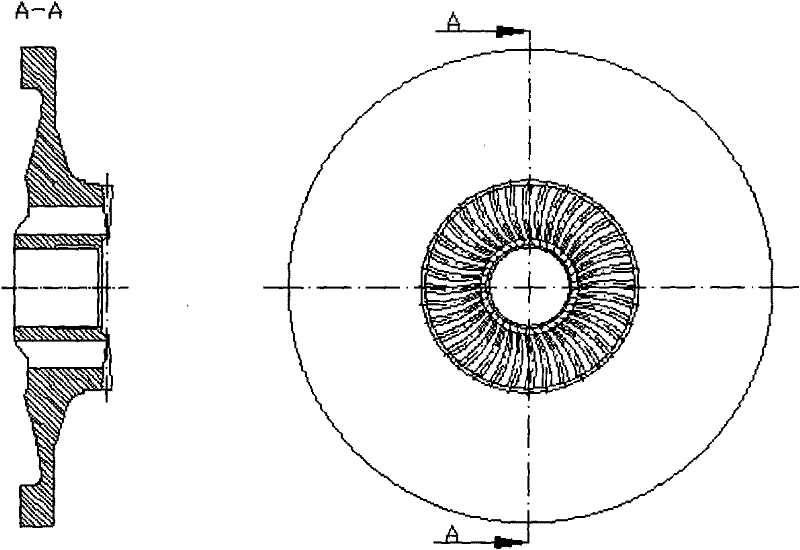

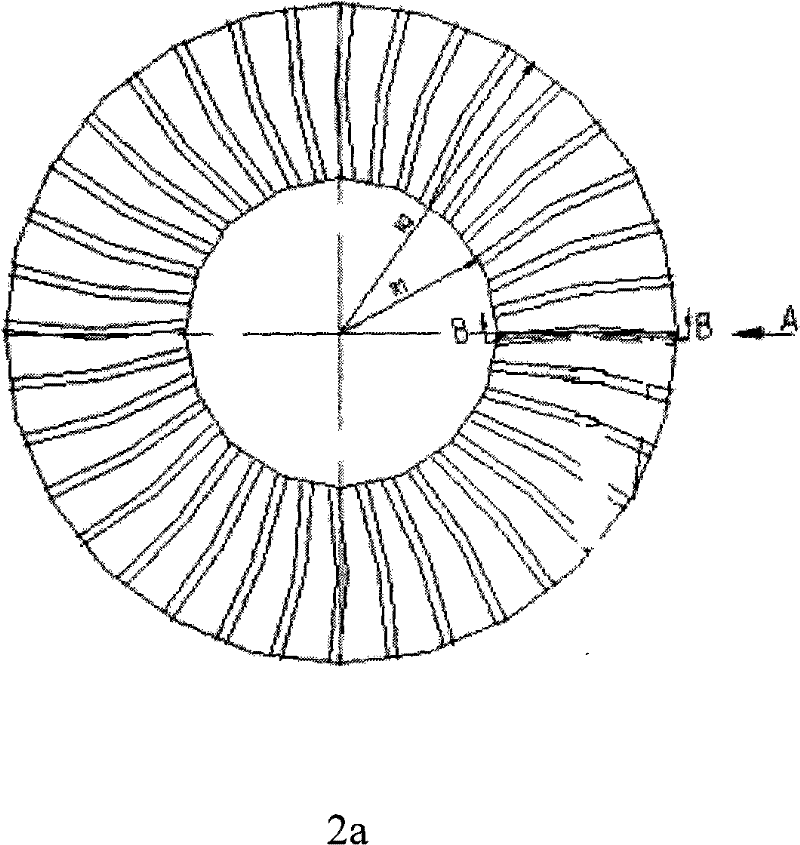

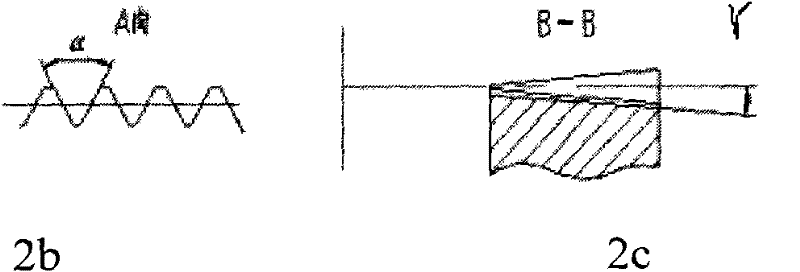

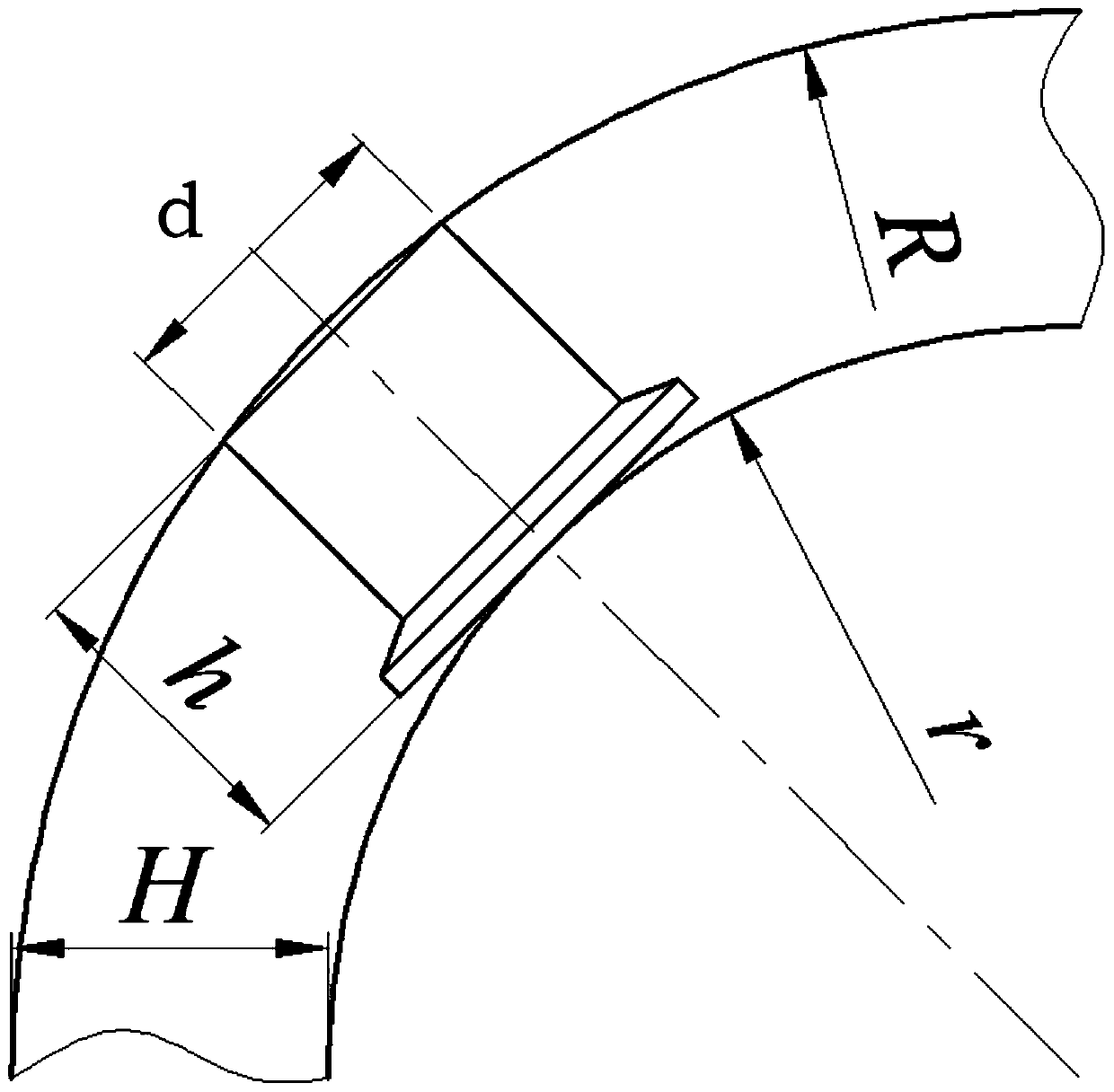

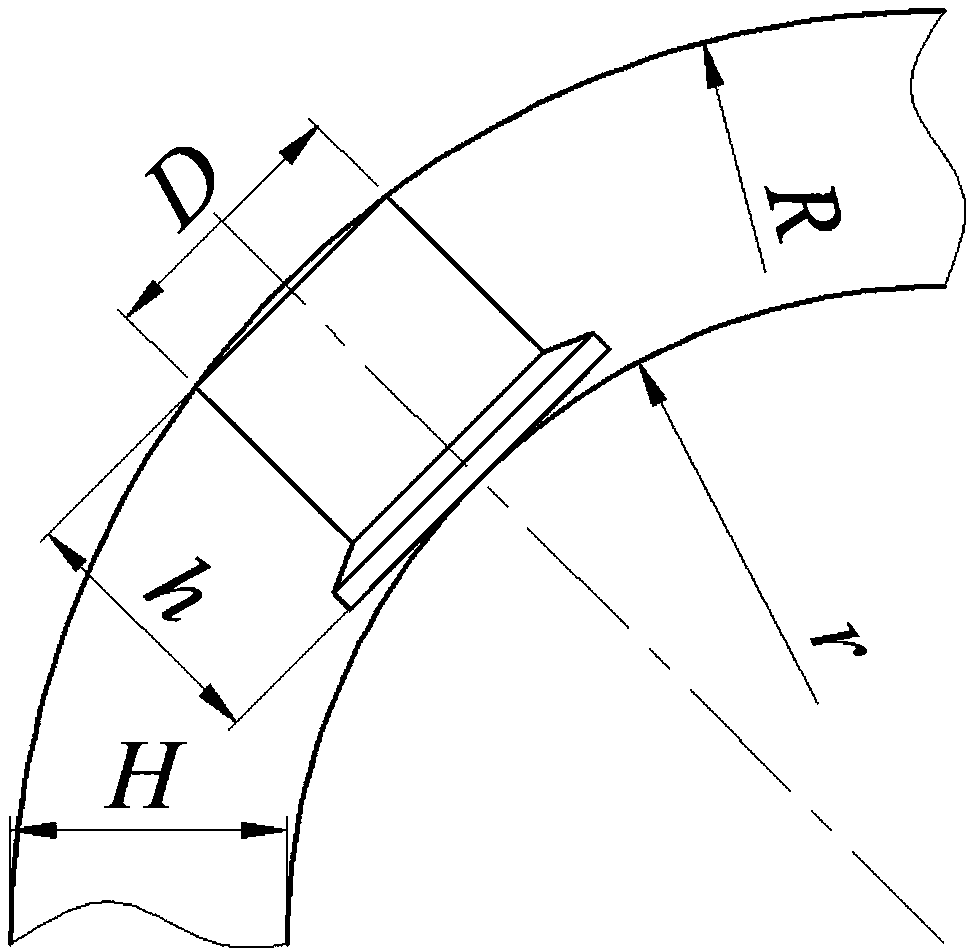

Method for machining tooth profile of circular arc end tooth

The invention discloses a method for machining a tooth profile of a circular arc end tooth. End-toothed disc blank is machined into the circular arc end tooth by adopting the modes of a formed cup type grinding wheel cutting and a formed end facially grinding. The machining comprises the following technical conditions: (1), the end-toothed disc blank being a tubular shape, the end face of the blank needing to be machined to a cone shape, an included angle between a conic section and a horizontal line being a gullet obliquity gamma of the tooth profile; (2), machining the tooth profile by using an end-toothed cutting tool, wherein the profile angle of the cutting tool meets the condition of alpha d=2tan-1(tan(a / 2) / cos gamma); and the radius of the grinding wheel meets the condition of RD=Rw; (3), the end-toothed disc blank having the oblique gullet obliquity gamma relative to the end-toothed cutting tool; and (4) in a nodal plane that the end tooth is joggled, the transverse distance between the gyration center of the cutting tool and the gyration center of the end-toothed disc being d1=R1+(R2-R1) / 2; and the vertical distance between the gyration center of the cutting tool and the gyration center of the end-toothed disc being d2=Rw. The method for forming the tooth profile of the circular arc end tooth can ensure a correct circular arc end tooth profile, and provide an available manufacturing method for the circular arc end-toothed disc which is widely used in axial connections of tubular structures.

Owner:SOUTHWEST JIAOTONG UNIV

Radially-adjustable three-jaw self-centering spindle clamp

The invention relates to an adjustable spindle clamp, and particularly relates to a radially-adjustable three-jaw self-centering spindle clamp. The spindle clamp is structurally characterized in thata spindle is fixed to a machine tool through a lathe chuck, the spindle is a stepped shaft, a key groove is formed in the spindle, and the position of an adjusting disk can be fixed through a steppedtable and a flat key. The adjusting disk has a self-centering function by using a three-jaw lathe chuck principle, and the transmission of a large bevel gear is driven by adjusting a square adjustinghole in a small bevel gear so that it can be achieved the positions of adjusting jaws are adjusted; a supporting jaw is fixed to the adjusting jaw through fastening bolts, the fastening position of the supporting jaw can be adjusted so that the adjusting range can be effectively expanded, and the obstruction to the feed path is reduced. The position of a right adjusting disk body is adjusted through a fastening nut so as to clamp a workpiece, it is achieved that a thin-plate disk-like part is quickly clamped, the clamping rigidity is ensured, and the machining quality is improved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

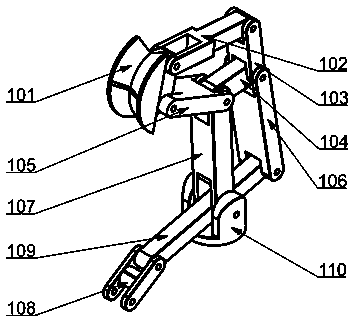

Reducing roll riveting mounting tool for knuckle bearing

PendingCN114083264APrevent prolapseWith self-centering functionWork holdersMetal working apparatusClassical mechanicsEngineering

The invention discloses a reducing roll riveting installation tool for a knuckle bearing, which comprises a connecting screw handle, one end of the connecting screw handle is fixedly connected with one end of a supporting disc body, the other end face of the supporting disc body is provided with three soil-shaped groove structures evenly distributed along the axis, and each soil-shaped groove is correspondingly provided with a moving body. A roller support is fixedly installed on the upper side of each moving body, a roller assembly is arranged at the upper end of each roller support, a mandrel assembly is arranged on the central axis of the other end face of the supporting disc body, the mandrel assembly is clamped and positioned through the end faces of the three moving bodies at the same time, and the mandrel assembly comprises a positioning mandrel and a lubricating sleeve; the knuckle bearing variable-diameter roll riveting installation tool is matched with different core shaft assemblies according to knuckle bearings of different models and sizes. The roll riveting installation tool adapts to roll riveting work of bearings of different specifications and models by replacing the positioning mandrel to change the position of the rolling wheel, the tool utilization rate is increased, the economic cost is reduced, and the universality is improved.

Owner:鹰领航空高端装备技术秦皇岛有限公司

Pouch clamp mechanism for automatic sterile pouch loading filling machine

ActiveCN103910092AWith guiding functionWith self-centering functionPackagingEngineeringMechanical engineering

The invention relates to a pouch clamp mechanism for an automatic sterile pouch loading filling machine. The pouch clamp mechanism is arranged on a filling chamber of the automatic sterile pouch loading filling machine; the mechanism comprises a driving cylinder, a rotating shaft, a movable pouch clamp and a fixed pouch clamp; the driving cylinder is fixed on a support plate above the filling chamber, the driving cylinder drives the movable pouch clamp to rotate by virtue of the rotating shaft, the fixed pouch clamp is arranged beside the movable pouch clamp, and the lower ends of the movable pouch clamp and the fixed pouch clamp both are located inside the filling chamber. Compared with the prior art, the pouch clamp mechanism for the automatic sterile pouch loading filling machine has the advantages such as simple structure and wide application range, and also has a guide function and a self-centering function.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

A High-Precision Self-Centering Clamping Mechanism Applied to Clamping of Thin-wall Kits

The invention discloses a high-precision self-centering clamping mechanism applied for clamping a thin-wall external member. The high-precision self-centering clamping mechanism is mainly composed of a motion rod, conical guide sleeves, a clamping support, an expansion sleeve, compressing steel balls, a spring, a front-end mounting plate, a front-end mounting flange, a rear-end mounting flange, an O-shaped ring, and other parts. According to the clamping mechanism, the compressing steel balls are outwards extruded through the combined action of outer conical surfaces of the conical guide sleeves and a cylindrical surface in the clamping support so as to clamp the thin-wall external member. The processing precision of the compressing steel balls and the conical guide sleeves is high, and the expansion sleeve produces uniform elastic deformation in a radial direction when clamping the thin-wall external member every time, so that the clamping precision in clamping a workpiece every time is ensured; and each compressing ball can universally rotate during clamping, with the design, the mechanism can fulfill a self-centering function during a process of clamping the thin-wall external member, so that the center of the thin-wall external member and the center of the motion rod of the clamping mechanism are kept consistent.

Owner:安徽航大智能科技有限公司

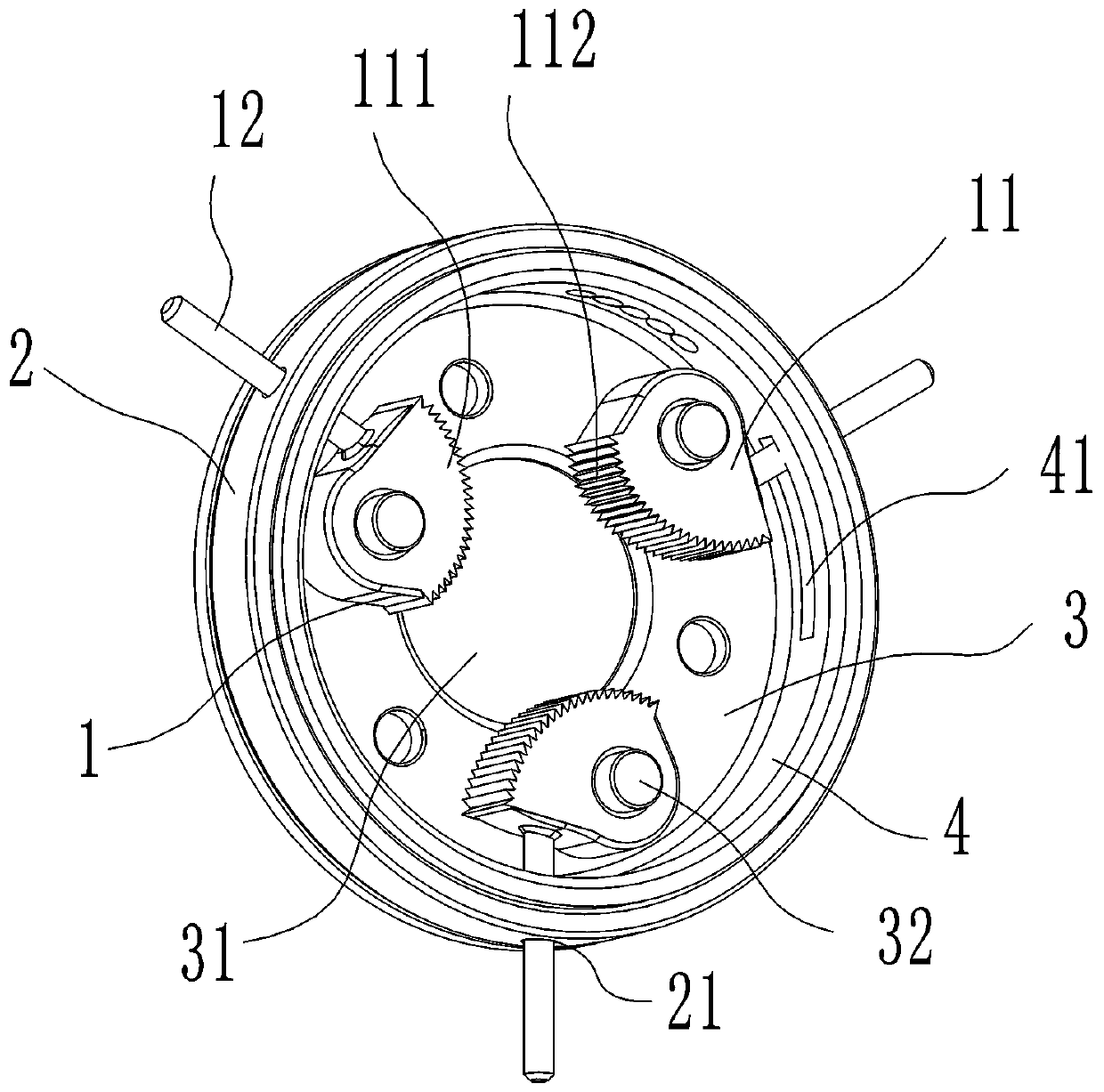

Electric chuck of gear guide rod mechanism

PendingCN108145373AImprove work efficiencyWith self-centering functionWelding/cutting auxillary devicesAuxillary welding devicesOptical axisEngineering

An electric chuck of a gear guide rod mechanism consists of a base, a rotating disc, a cross roller guide way, a connecting disc, a synchronous wheel, a rotating seat, a main gear I, a pinion gear I,an intermediate transmission gear I, linear guideways I, optical axis seats I, optical axes I, sliding blocks I, steel balls I, a motor I, an intermediate shaft I, bearings, retaining ring for bores,sliding block fixed shafts, a motor II, a pinion gear II, an intermediate transmission gear II, a main gear II, sliding blocks II, optical axes II, optical axis seats II, linear guideways II and steelballs II. The optical axes I and the optical axes II which are perpendicular mutually in the mechanism get close to or far away from the center so as to clamp a steel pipe.

Owner:焦彬彬

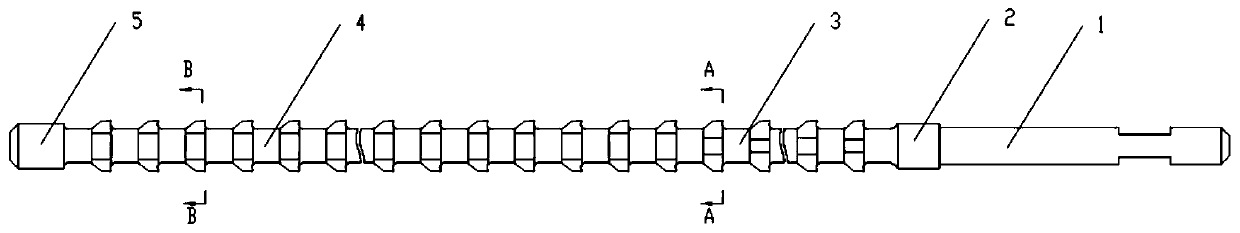

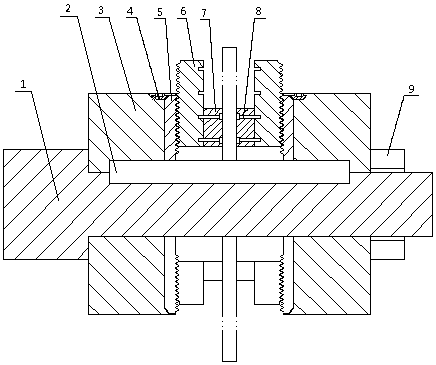

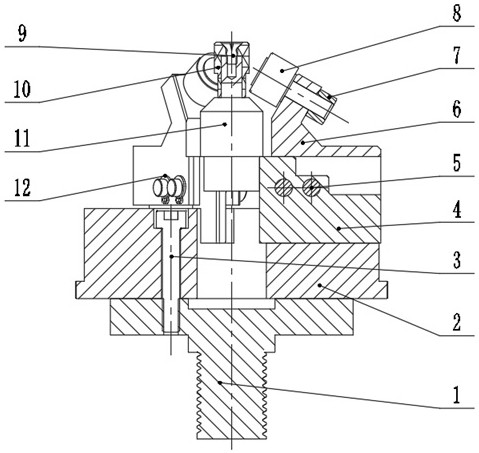

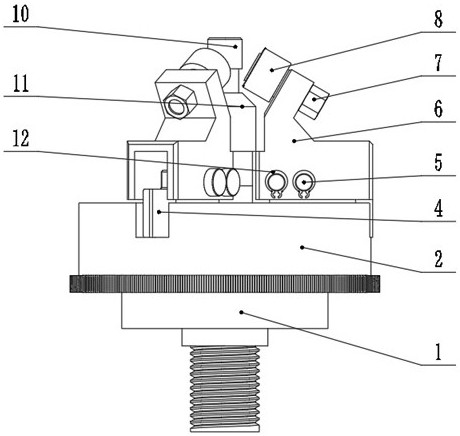

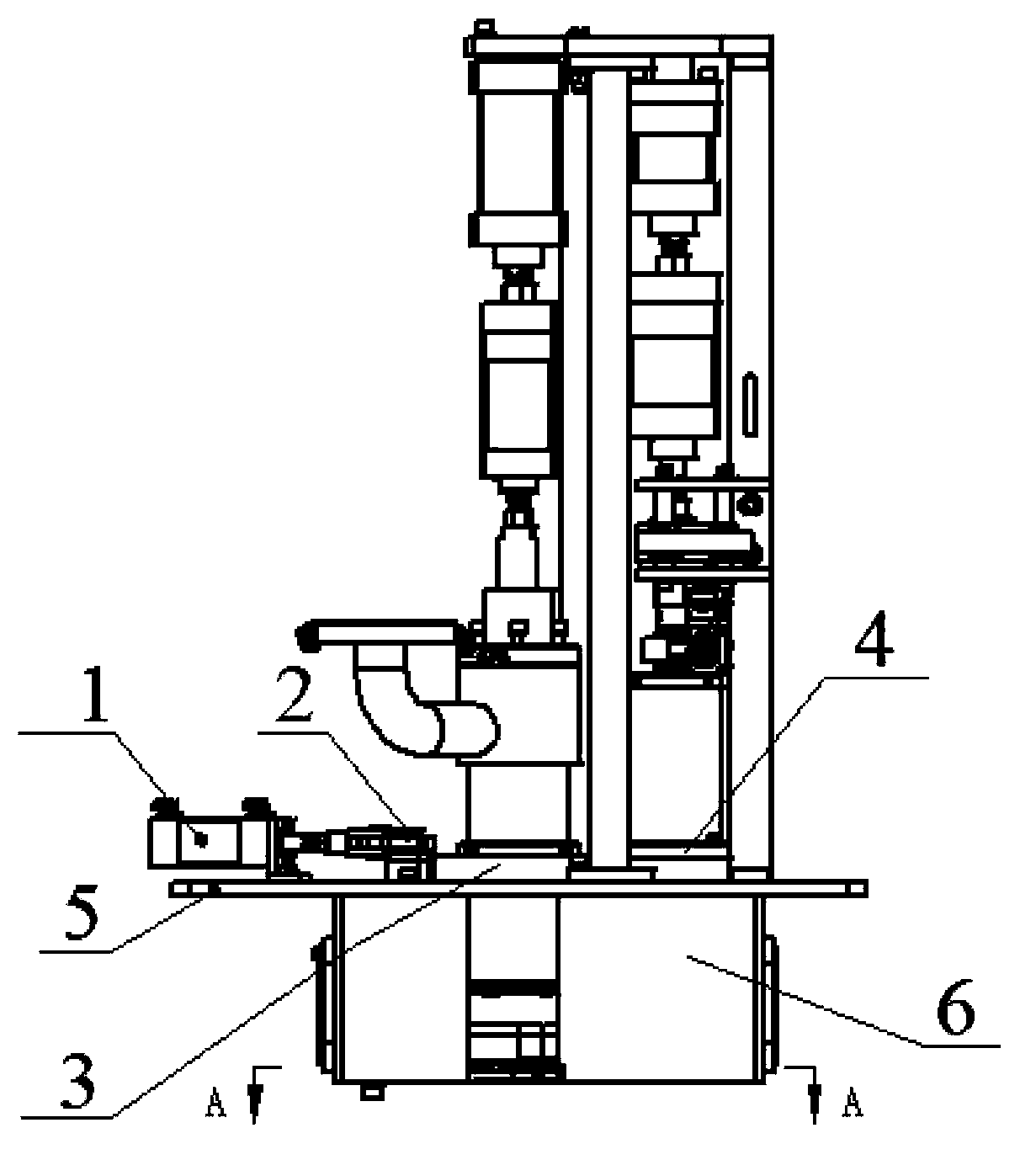

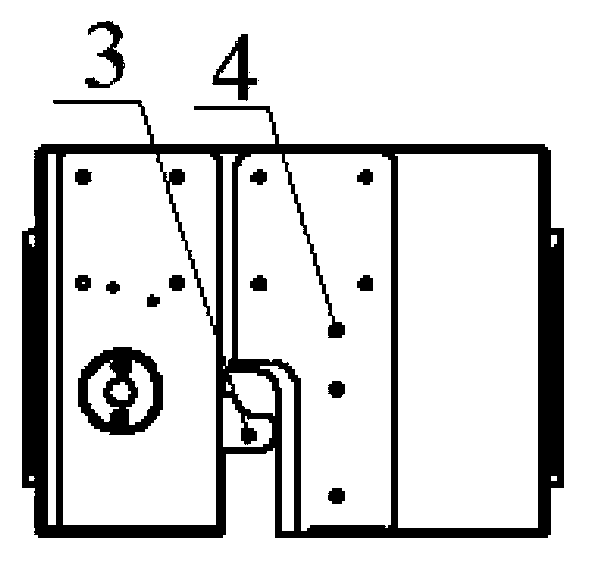

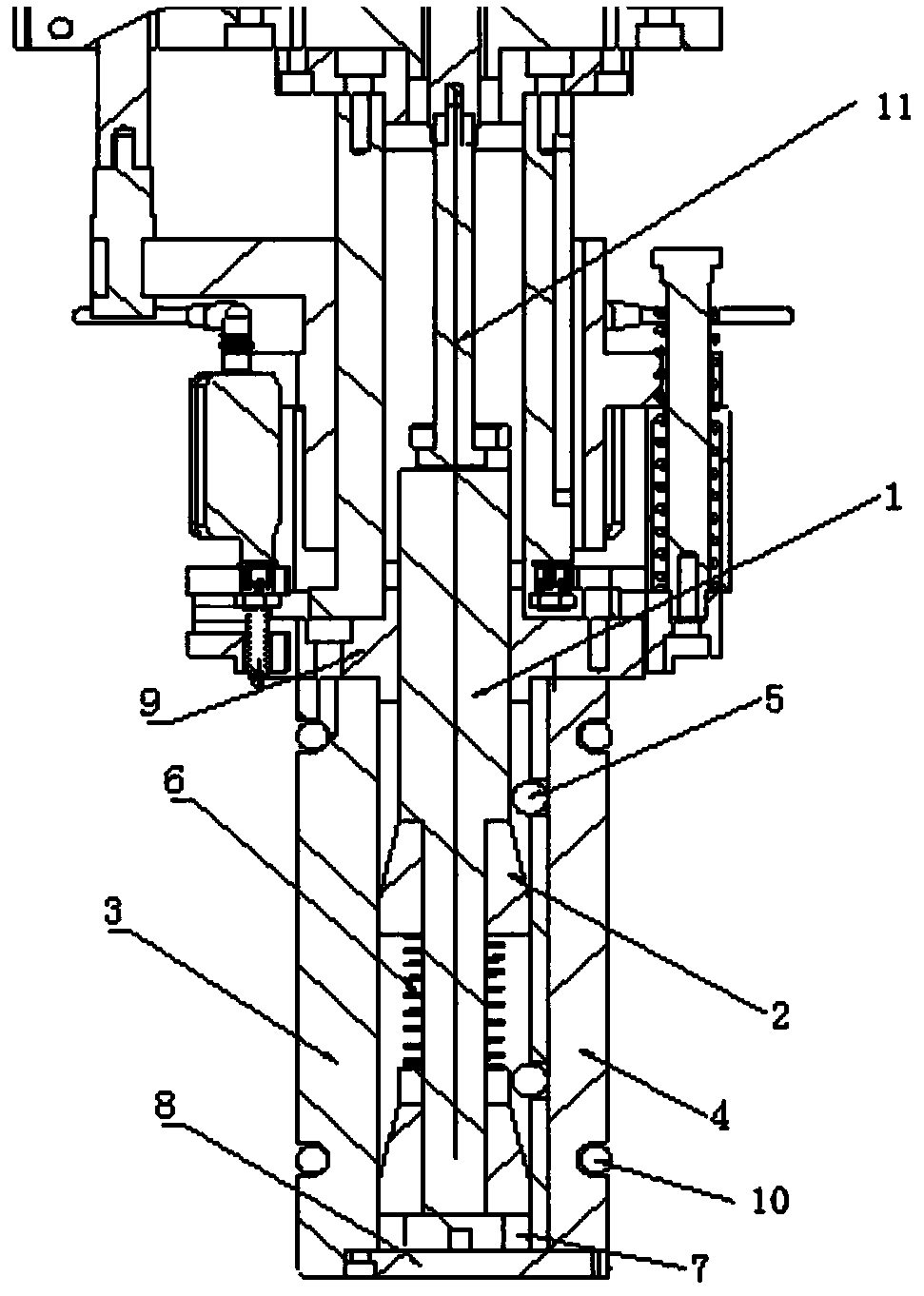

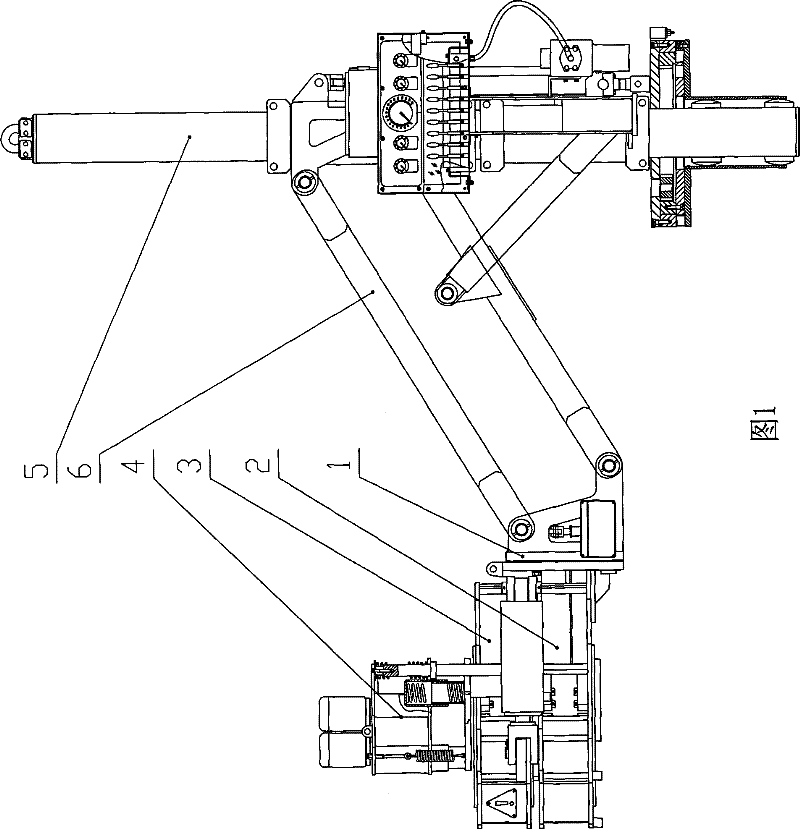

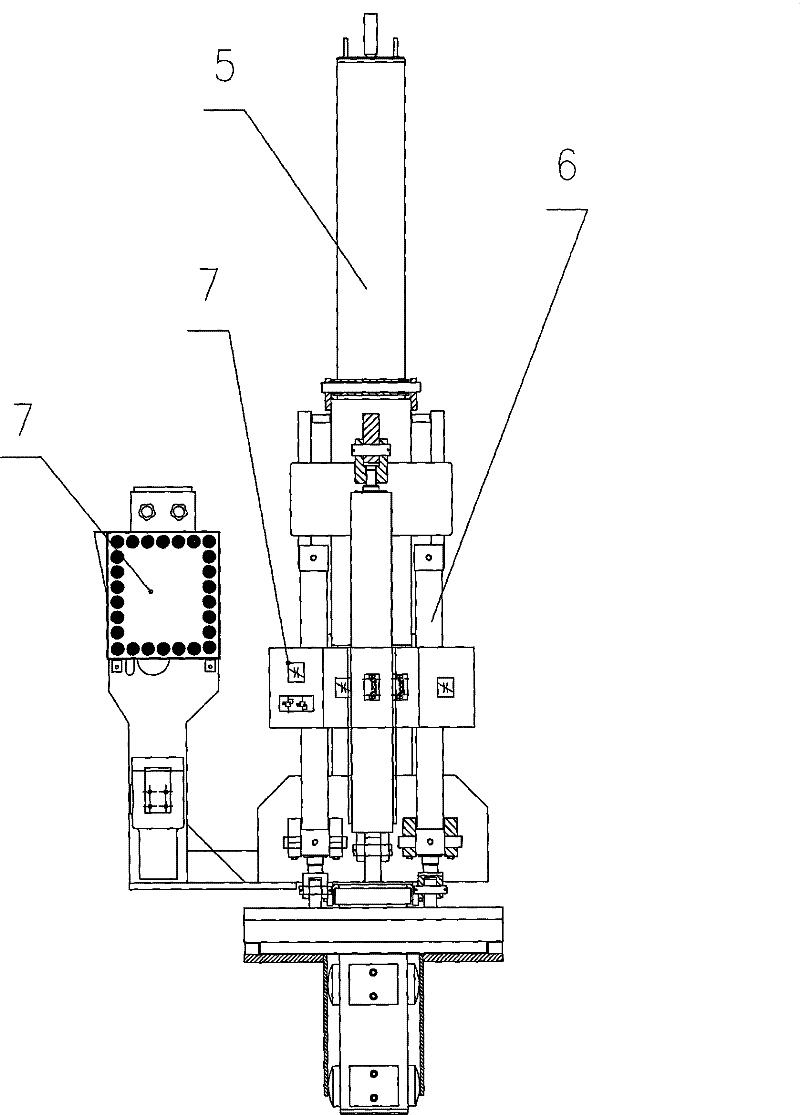

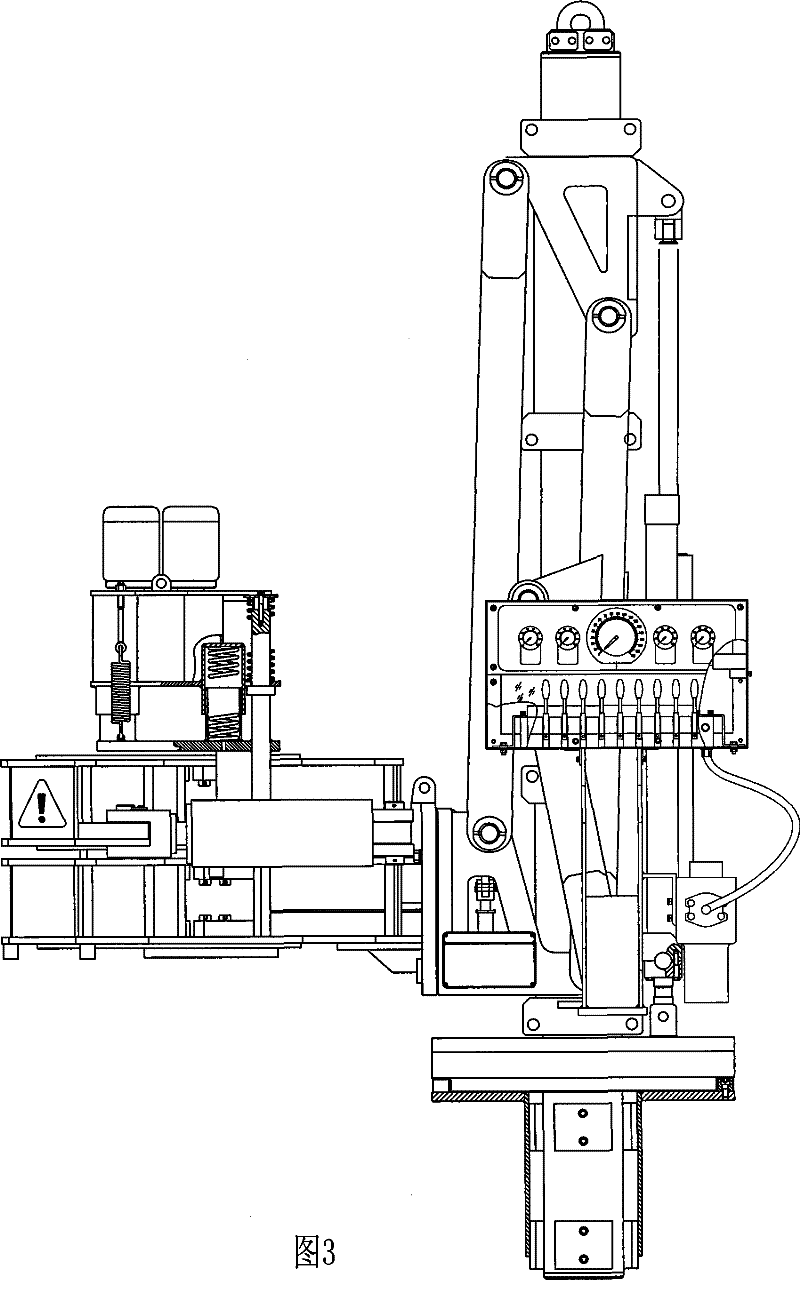

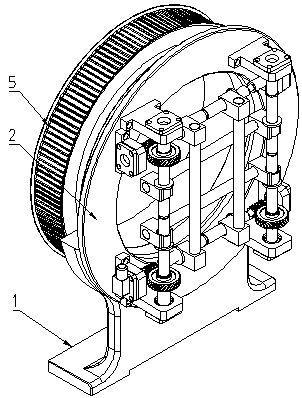

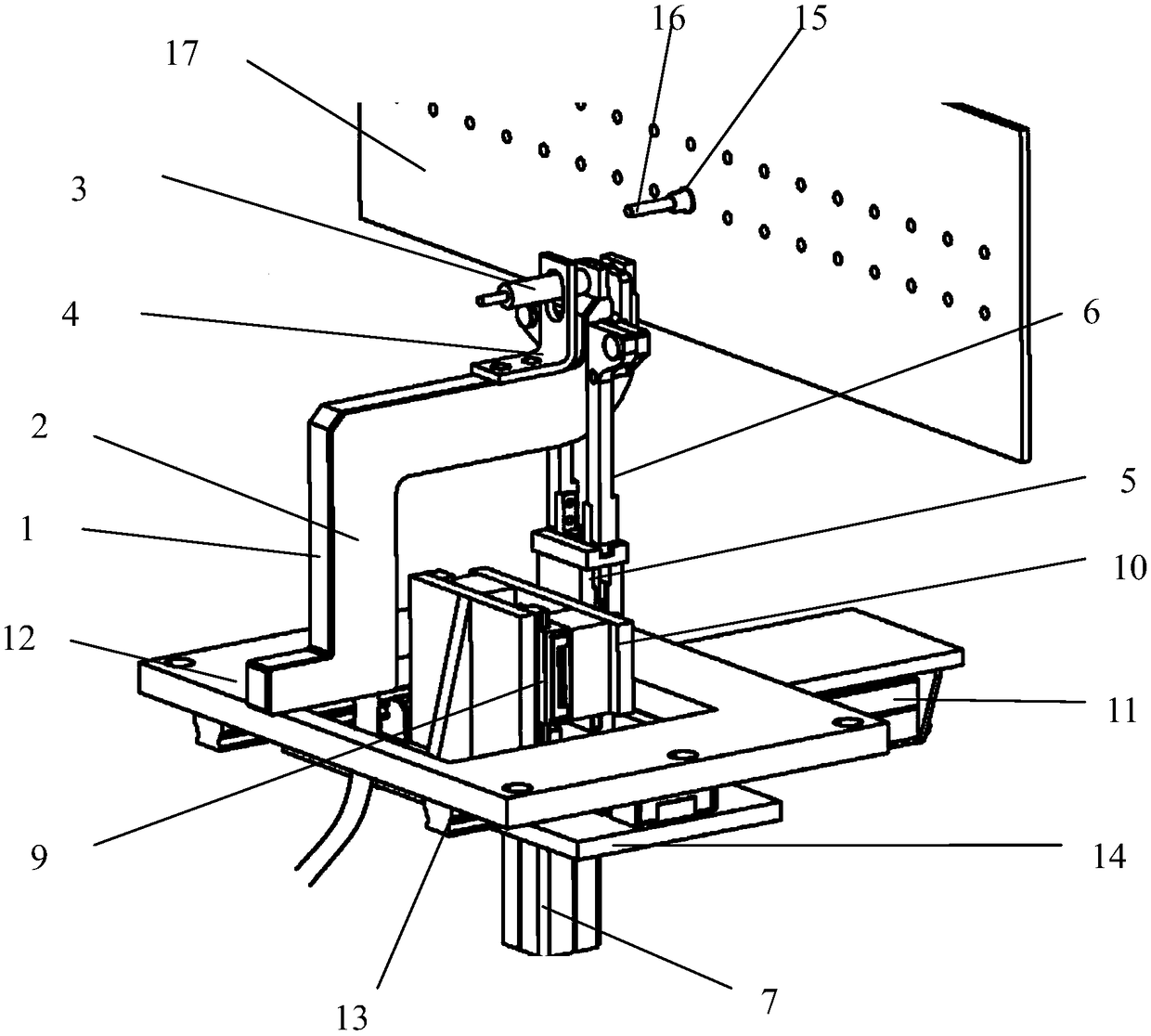

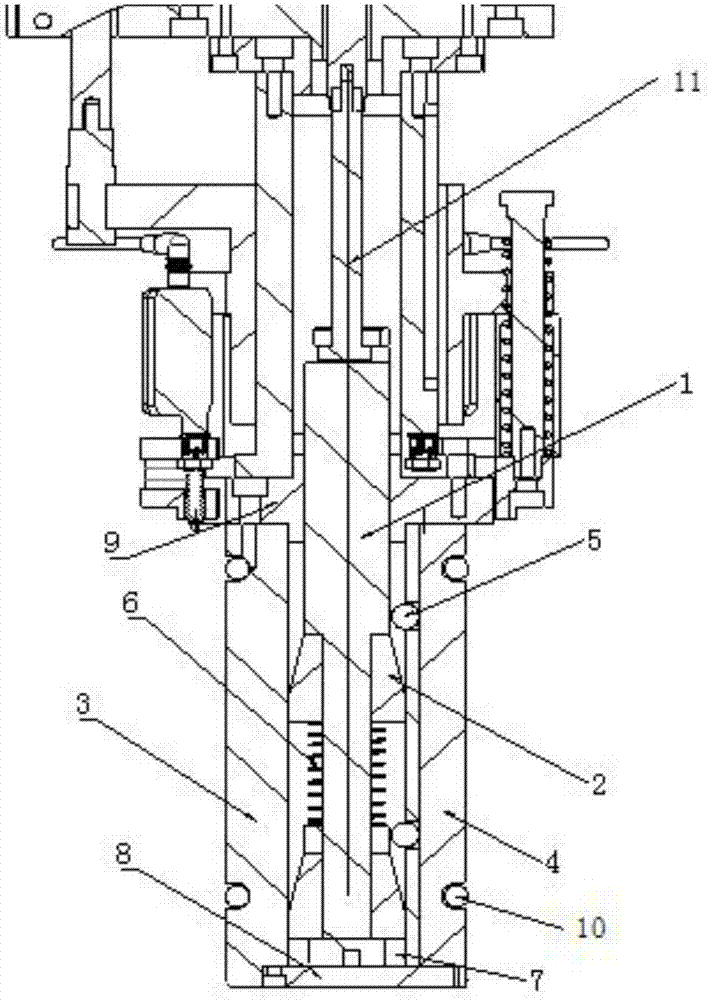

Iron driller

ActiveCN101397892BEasy to clipSolve operational problemsDrilling rodsDrilling casingsHydraulic cylinderRoughneck

The invention provides an iron roughneck, which relates to an assorted wellhead operation device of a petroleum drilling machine and aims at solving the problem of inconvenient operation in the prior art. The wellhead operation device comprises a tong head assembly, a support arm assembly and an electrohydraulic control system; the tong head assembly comprises a spinner assembly, a driving tong assembly and a driven tong assembly as well as a lifting mechanism and a swing mechanism. One end of the support arm assembly is movably connected on the lifting mechanism while the other end is movably connected with the swing mechanism. The swing mechanism is connected with the driving tong assembly and the driven tong assembly; the tong head assembly is arranged above the driving tong assembly and the driven tong assembly; the electrohydraulic control system consists of a hydraulic control system and an electronic control system; the swing mechanism, the lifting mechanism, the support arm assembly, the spinner assembly, the driving tong assembly and the driven tong assembly respectively contain respective hydraulic cylinder drive parts and the hydraulic cylinder drive parts of all the assembly are connected with and controlled by the hydraulic control system; and the electronic control system controls the hydraulic control system. The wellhead operation device is applicable to wellhead operation during petroleum drilling.

Owner:四川劳玛斯特高胜石油钻采设备有限公司

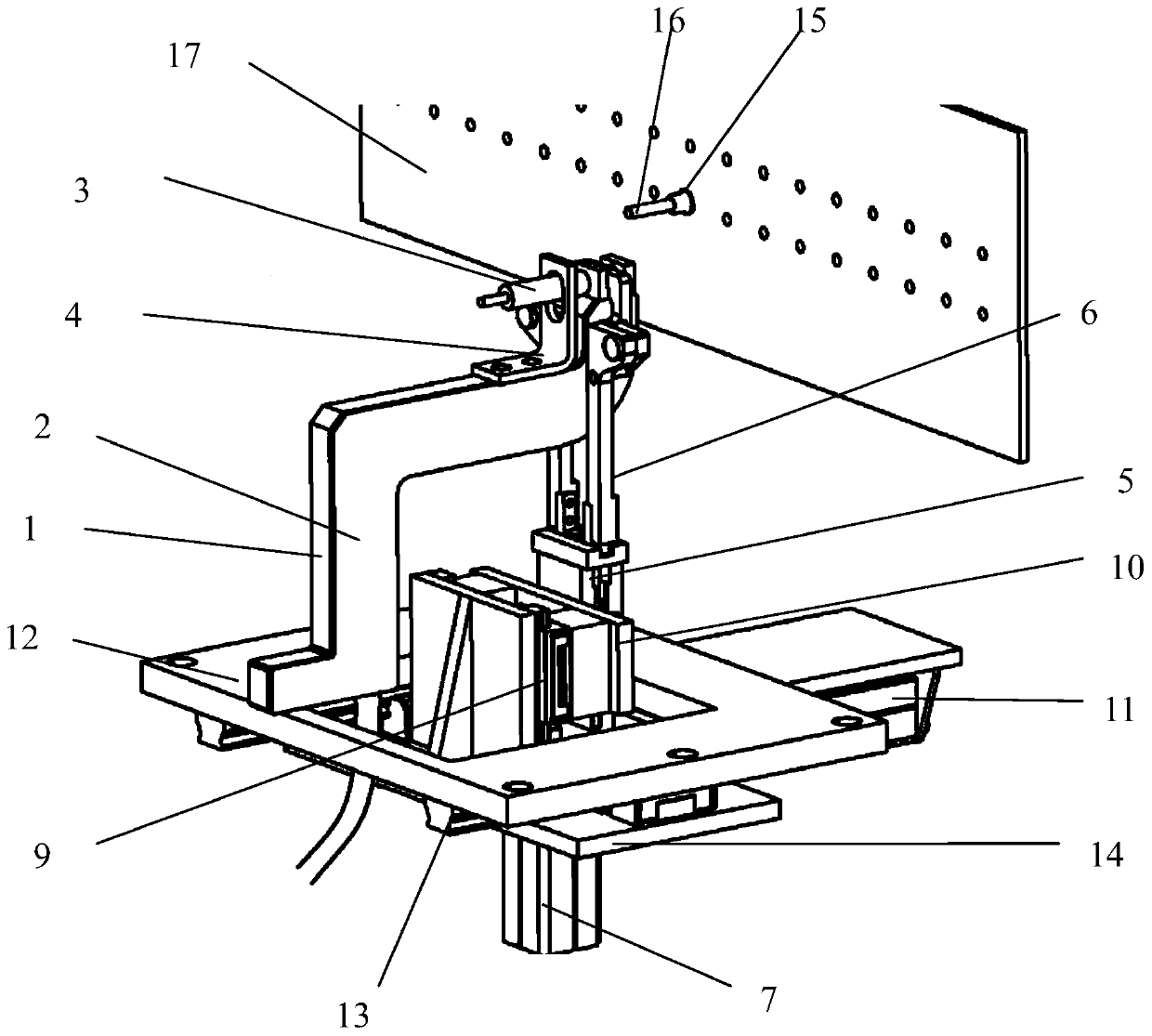

A ring groove rivet sleeve automatic feeding and positioning device and method

The invention relates to an automatic feeding and positioning device for a ring groove rivet sleeve, and a method. The automatic feeding and positioning device comprises a feeding device, an automaticclamping mechanism, a vertical movement mechanism, a horizontal movement mechanism and a controller, wherein the controller controls the ring groove rivet sleeve to reach a clamping position along the feeding device, the initial position of the automatic clamping mechanism is positioned at the output end of the feeding device, the ring groove rivet sleeve reaching the clamping position is automatically clamped under the control of the controller, the controller controls the vertical movement mechanism and the horizontal movement mechanism to drive the automatic clamping mechanism to transferthe ring groove rivet sleeve to the riveted position, and the consistency of the axis of the ring groove rivet sleeve and the axis of a connecting hole is realized.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

A kind of aluminum alloy wheel punching process

ActiveCN104475795BReduce scrap rateAvoid the phenomenon of punching deviationThread cutting machinesChucksPunchingAlloy wheel

Owner:BAODING CITY LIZHONG WHEEL MFG

Electric chuck based on worm rod

PendingCN108044247ACompact structureImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringOptical axis

The invention discloses an electric chuck based on a worm rod. The electric chuck consists of a base, a rotating disc, a cross roller guide rail, a connecting disc, a synchronous belt wheel, a motor,an end cover, a bearing base I, a worm wheel, a worm rod ball screw shaft, a screw nut, a polish shaft base, polish shafts, a bearing, a bearing base II, a worm wheel shaft and a sleeve. The electricchuck is characterized in that the rotating disc is positioned on the inner wall of the cross roller guide rail and is fixed on the inner wall of the cross roller guide rail; the outer wall of the cross roller guide rail is fixed in an inner hole of the base; one side of the connecting disc is fixed on the inner wall of the cross roller guide rail, and the synchronous belt wheel is fixed on one side; the worm wheel is mounted on the worm wheel shaft, and is in engaged transmission with the worm rod on the worm rod ball screw shaft; a lead screw on the worm rod ball screw shaft is divided intotwo sections; the two sections of lead screw are symmetrically distributed, and are provided with left and right rotary separation areas; and the worm wheel and the worm rod ball screw shaft are in engaged transmission in three places to drive two pairs of polish shafts, across distributed up and down, to gather to the center at the same time or to move to all directions so as to realize clampingand loosening of steel pipes on the electric chuck of a laser cutting machine.

Owner:焦彬彬

Electric chuck based on bevel gear

PendingCN108015442AImprove work efficiencyWith self-centering functionLaser beam welding apparatusEngineeringBevel gear

Provided is an electric chuck based on a bevel gear. The electric chuck is composed of a base, a rotary disk, crossed roller guide rails, a connecting disk, a synchronous pulley, a motor, an end cover, a bearing seat I, bearings, a sleeve, a bevel gear shaft, a circular nut I, the bevel gear, a bearing seat II, lead screw shafts, lead screw nuts, plain shaft seats, light shafts and a circular nutII and characterized in that the rotary disk is located at the inner walls of the crossed roller guide rails and fixed at the inner walls of the crossed roller guide rails; the bevel gear of the bevelgear shaft is meshed with the bevel gear to transfer power; the lead screw shafts are locked by the bevel gear and a bearing installed in the bearing II through the circular nut I; each lead screw shaft is divided into two symmetrical sections; the rotary direction of each screw is divided into leftward-rotary direction and rightward-rotary direction; the lead screw nuts are installed on the leadscrew shafts; the plain shaft seats are mounted on the lead screw nuts; the plain shafts are installed in holes of the plain shaft seats; and a steel pipe on a laser cutting machine can be clamped tightly and loosened when the four plain shafts approach and depart.

Owner:焦彬彬

Automatic feeding and positioning device for ring groove rivet sleeve, and method

The invention relates to an automatic feeding and positioning device for a ring groove rivet sleeve, and a method. The automatic feeding and positioning device comprises a feeding device, an automaticclamping mechanism, a vertical movement mechanism, a horizontal movement mechanism and a controller, wherein the controller controls the ring groove rivet sleeve to reach a clamping position along the feeding device, the initial position of the automatic clamping mechanism is positioned at the output end of the feeding device, the ring groove rivet sleeve reaching the clamping position is automatically clamped under the control of the controller, the controller controls the vertical movement mechanism and the horizontal movement mechanism to drive the automatic clamping mechanism to transferthe ring groove rivet sleeve to the riveted position, and the consistency of the axis of the ring groove rivet sleeve and the axis of a connecting hole is realized.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Assembled dental implant

The invention relates to an assembled dental implant, and belongs to the technical field of dental implantation. The assembled dental implant is applicable to patients who suffer tooth decay, snaggletooth and periodontal disease, need to be surgically treated, and need tooth implantation after teeth are absent. The assembled dental implant comprises an implanting screw and an assembled base platform, and is assembled by the implanting screw and the assembled base platform; a conical threaded section is formed outside the implanting screw, and the end surface of a cylinder is provided with a plurality of dentiform protuberances or grooves of the implanting screw; the assembled base platform comprises a base platform body, a connecting screw and a thread bushing, the upper part of the base platform body is provided with an artificial tooth connection part, the middle part of the base platform body is provided with a transgingival part, the lower part of the base platform body is provided with an implanting screw connection part, and the assembled base platform is arranged in the implanting screw; the lower end surface of the transgingival part is provided with a plurality of dentiform grooves or protuberances of the base platform body which are matched with the dentiform protuberances or grooves of the implanting screw; and the thread bushing is matched with an internal thread of the implanting screw and is used for connecting the assembled base platform with the implanting screw.

Owner:常州百康特医疗器械有限公司

High-precision self-centering clamping mechanism applied for clamping thin-wall external member

The invention discloses a high-precision self-centering clamping mechanism applied for clamping a thin-wall external member. The high-precision self-centering clamping mechanism is mainly composed of a motion rod, conical guide sleeves, a clamping support, an expansion sleeve, compressing steel balls, a spring, a front-end mounting plate, a front-end mounting flange, a rear-end mounting flange, an O-shaped ring, and other parts. According to the clamping mechanism, the compressing steel balls are outwards extruded through the combined action of outer conical surfaces of the conical guide sleeves and a cylindrical surface in the clamping support so as to clamp the thin-wall external member. The processing precision of the compressing steel balls and the conical guide sleeves is high, and the expansion sleeve produces uniform elastic deformation in a radial direction when clamping the thin-wall external member every time, so that the clamping precision in clamping a workpiece every time is ensured; and each compressing ball can universally rotate during clamping, with the design, the mechanism can fulfill a self-centering function during a process of clamping the thin-wall external member, so that the center of the thin-wall external member and the center of the motion rod of the clamping mechanism are kept consistent.

Owner:安徽航大智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com