A shielded water-cooled permanent magnet high-speed well pump motor

A water-cooled, pump motor technology, used in electromechanical devices, electrical components, electric components, etc., can solve the problems of complex structure, less than ideal, slow flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

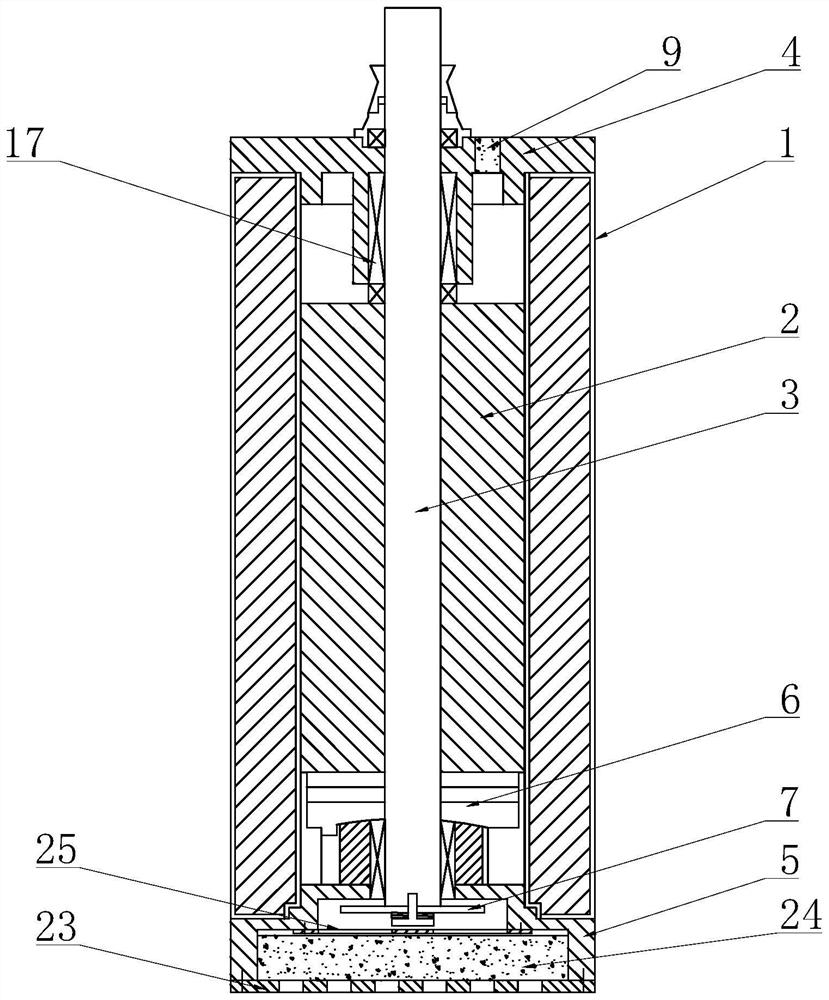

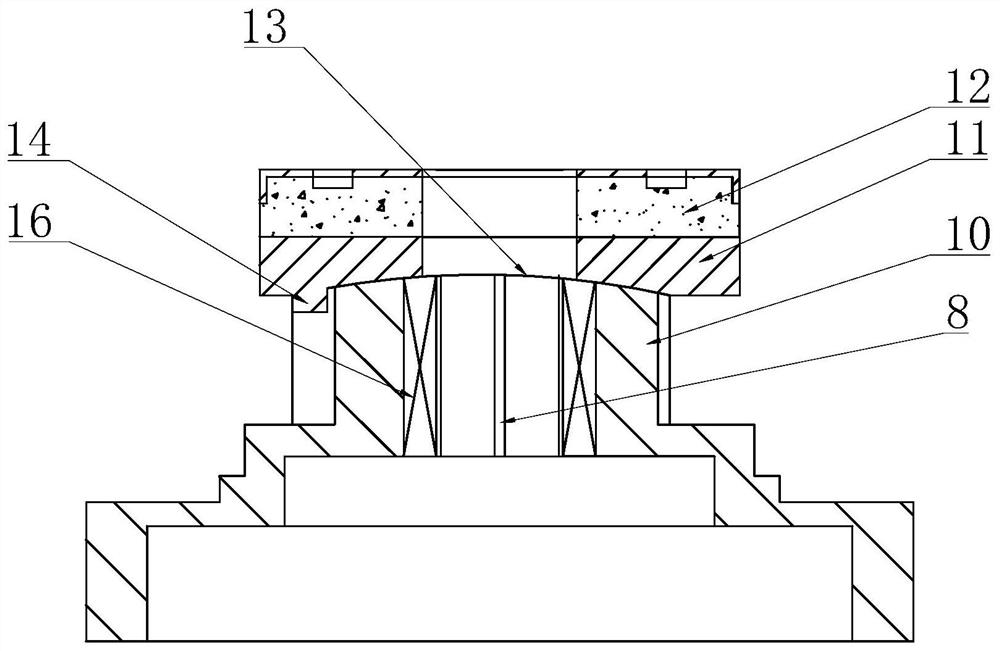

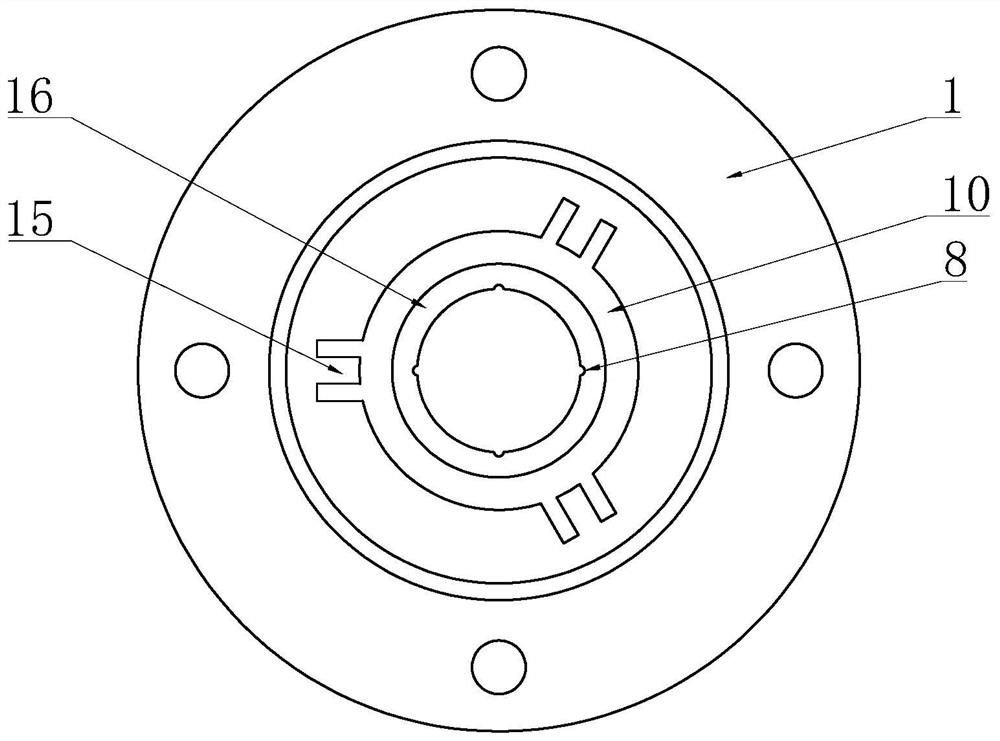

[0055] A shielded water-cooled permanent magnet high-speed well pump motor, including a casing 1, a stator, a rotor 2 and a rotating shaft 3, the rotor 2 is fixed on the rotating shaft 3, and the two ends of the casing 1 are respectively provided with an upper end cover 4 and a lower end cover 5. The upper end cover 4 is provided with an upper shaft hole adapted to the rotating shaft 3, and the lower end cover 5 is provided with a lower shaft hole adapted to the rotating shaft 3. It is characterized in that: the casing 1 is an inner and outer double-layer structure. A shielding chamber is formed between the layers of casings 1, the stator is installed in the shielding chamber, and the shielding chamber is filled with resin, an axial thrust assembly 6 is provided between the lower end of the rotor 2 and the lower end cover 5, and the lower end of the rotating shaft 3 is also provided with There is a pumping impeller 7 located on the outside of the lower end cover 5, a flow guide...

Embodiment 2

[0066] Compared with Embodiment 1, the difference is that the structure of the filter assembly is different, and it can automatically perform blockage removal and anti-blockage control. The specific content is as follows:

[0067] The filter assembly includes an outer frame 100 and a gear box 101 installed in the outer frame 100. The upper transmission shaft 102 and the lower transmission shaft 103 are respectively connected to the gear box 101, and there is also a gear box for connecting the upper transmission shaft 102 and the lower transmission shaft. The reduction gear set of the transmission shaft 103, the upper transmission shaft 102 and the rotating shaft 3 are connected by a floating coupling 104, and the bottom end of the rotating shaft 3 is provided with a shaft for controlling the axial conflict or separation between the floating coupling 104 and the rotating shaft 3 The first clutch device, the lower section of the outer frame 100 is a filter area, the periphery of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com