Method for machining tooth profile of circular arc end tooth

A technology of arc-end teeth and processing methods, which is applied in the field of mechanical parts and can solve problems such as applications and not yet disclosed to the public

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

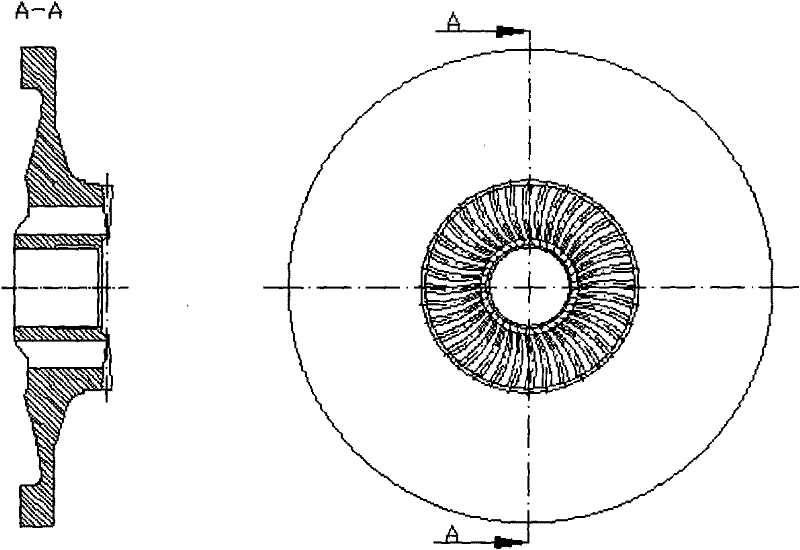

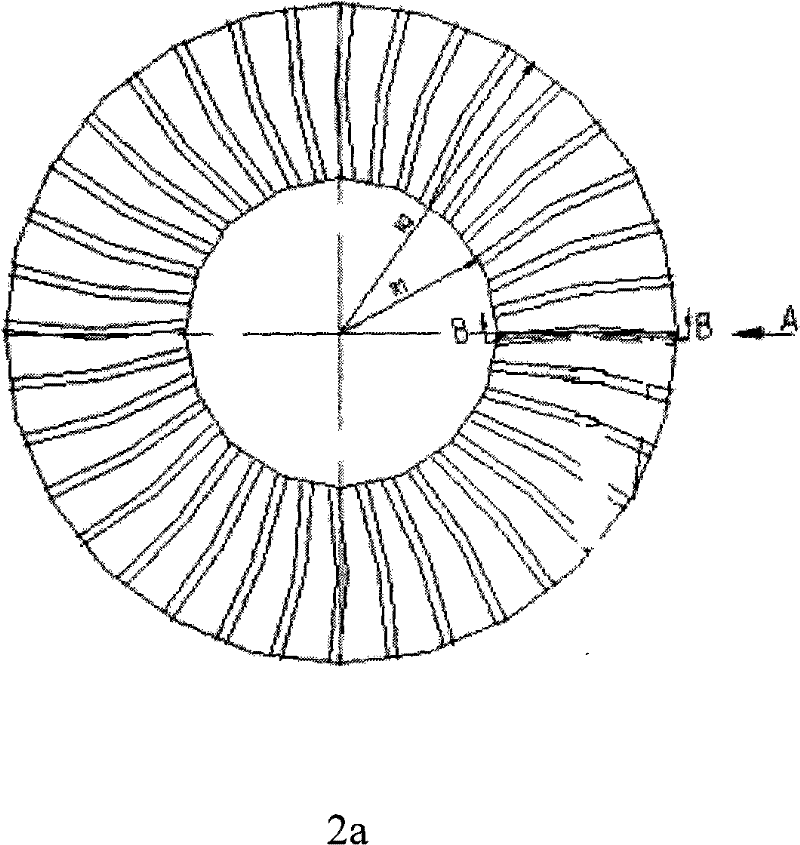

[0020] The forming method of the arc end tooth profile is mainly to determine the shape of the blank, select a reasonable tool profile angle, determine the reasonable position of the tool, and ensure the tooth profile processing of the end tooth. The tooth shape diagram of the end tooth disc is shown in the appendix figure 2 .

[0021] (1) Requirements for the rough shape of the end tooth disc

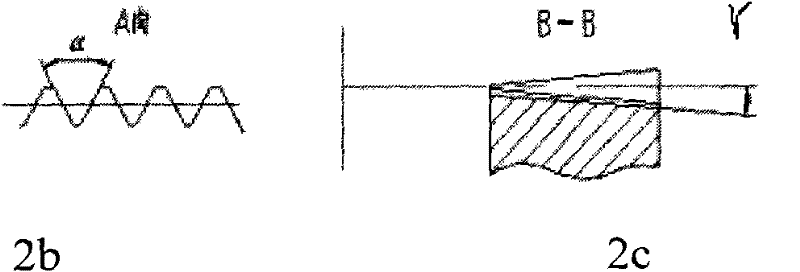

[0022] The toothed section of the end tooth disc is trapezoidal and shrinks toward the center along the arc line. The end sprocket blank 1 is in the shape of a circular tube, and the end surface needs to be processed into a conical shape, see figure 2 (c), the angle between the conical line and the horizontal line is the inclination angle γ of the tooth groove bottom.

[0023] (2) Using a formed cup wheel cutter 2 (or a formed end mill), the cutter profile angle

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com