Electric chuck based on bevel gear

A technology of bevel gears and bevel teeth, which is applied in the field of electric chucks, can solve problems such as high repeatability and high labor intensity, and achieve the effects of compact structure, reduced labor costs, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

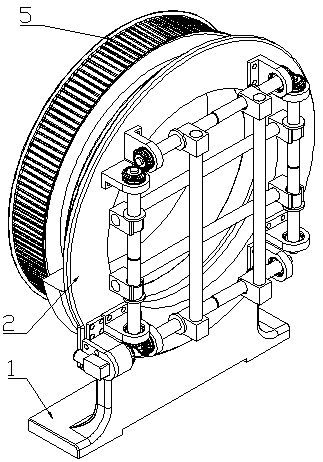

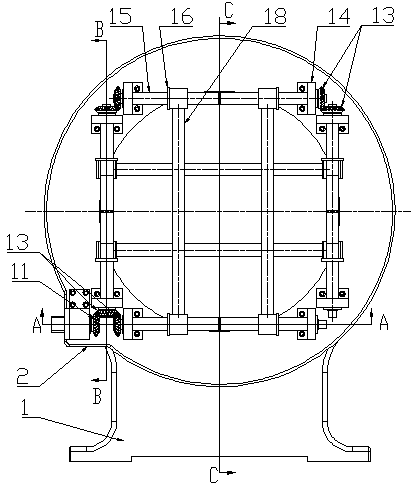

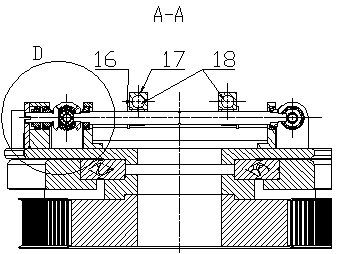

[0008] An electric chuck based on bevel gears, consisting of 1 base, 2 rotating discs, 3 crossed roller guide rails, 4 connecting discs, 5 synchronous pulleys, 6 motors, 7 end covers, 8 bearing blocks 1, 9 bearings, 10 Sleeve, 11 bevel gear shaft, 12 round nut I, 13 bevel gear, 14 bearing housing II, 15 screw shaft, 16 screw nut, 17 optical shaft seat, 18 optical axis, 19 round nut II, characterized in that : 2 Rotating discs are positioned on the inner wall of 3 cross roller guide rails and fixed on the inner wall of 3 cross roller guide rails, the outer wall of 3 cross roller guide rails is fixed in the inner hole of 1 base, 4 one side of the connecting disc is fixed on 3 cross roller guide rails On the inner wall of the guide rail, 5 synchronous pulleys are fixed on one side, 8 bearing housings I and 14 bearing housings II are fixed on 2 rotating discs, 6 motors are installed on 7 end covers, 7 end covers are fixed on 8 bearing housings I, two 9 bearings are installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com