Patents

Literature

69results about How to "Effective reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

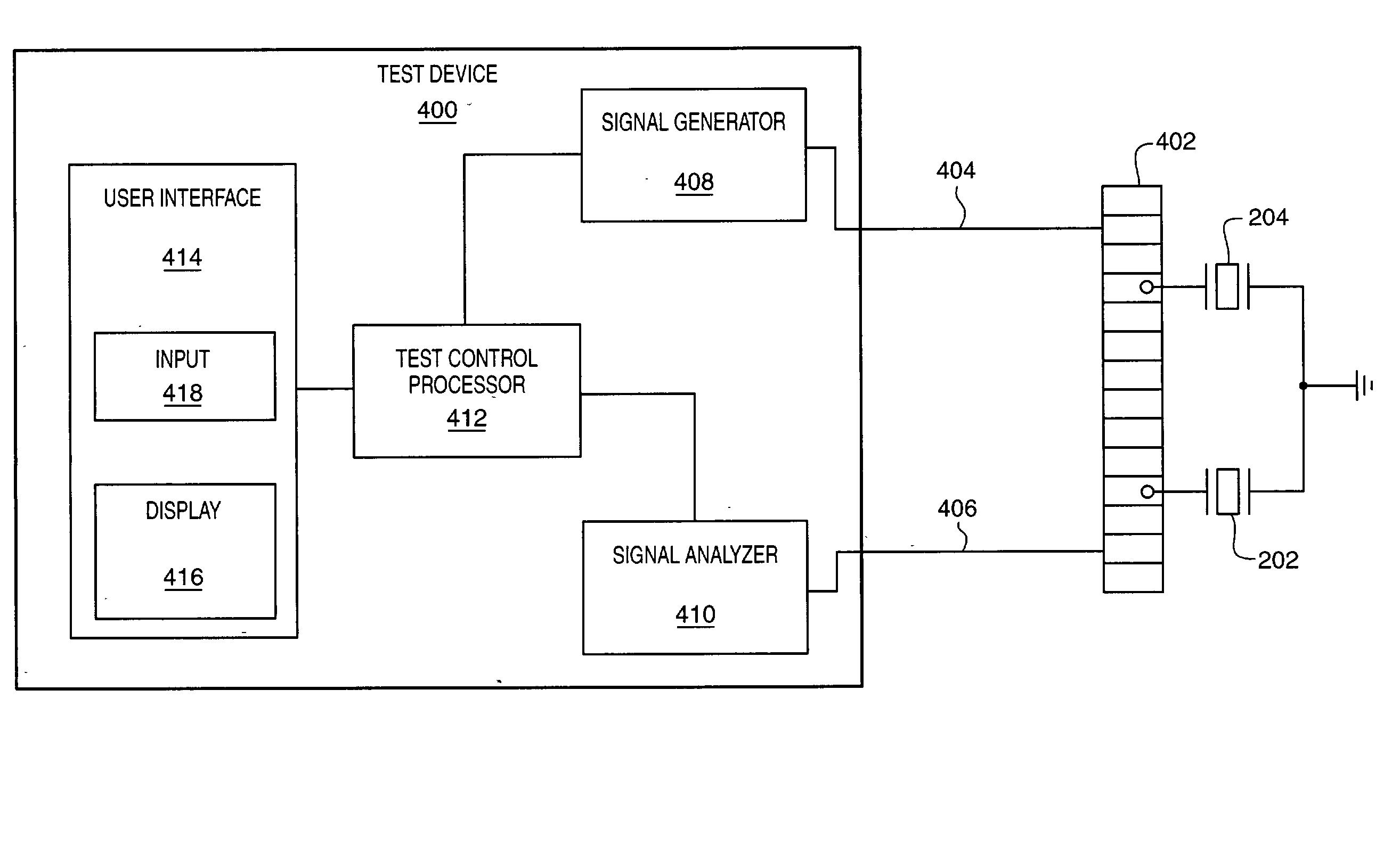

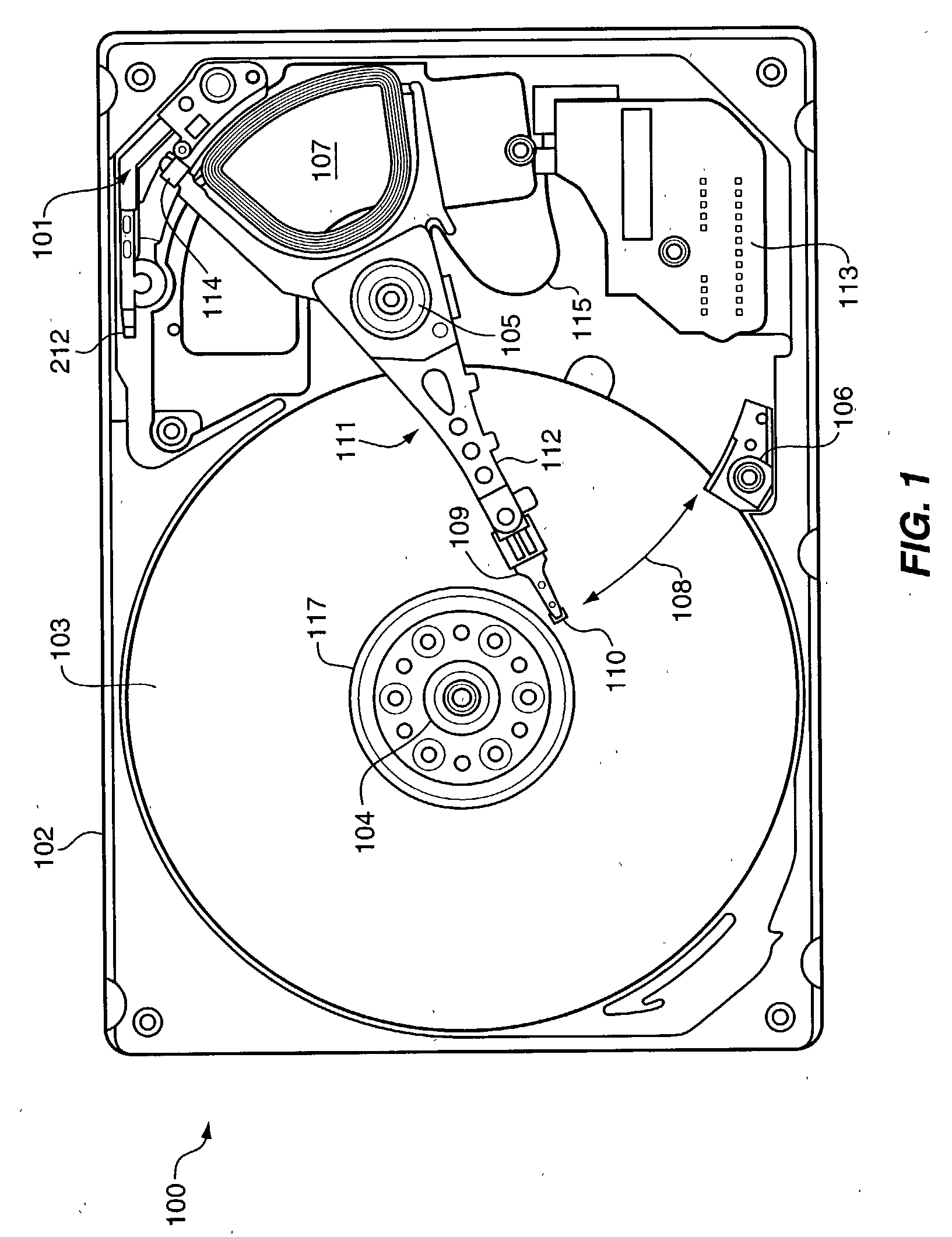

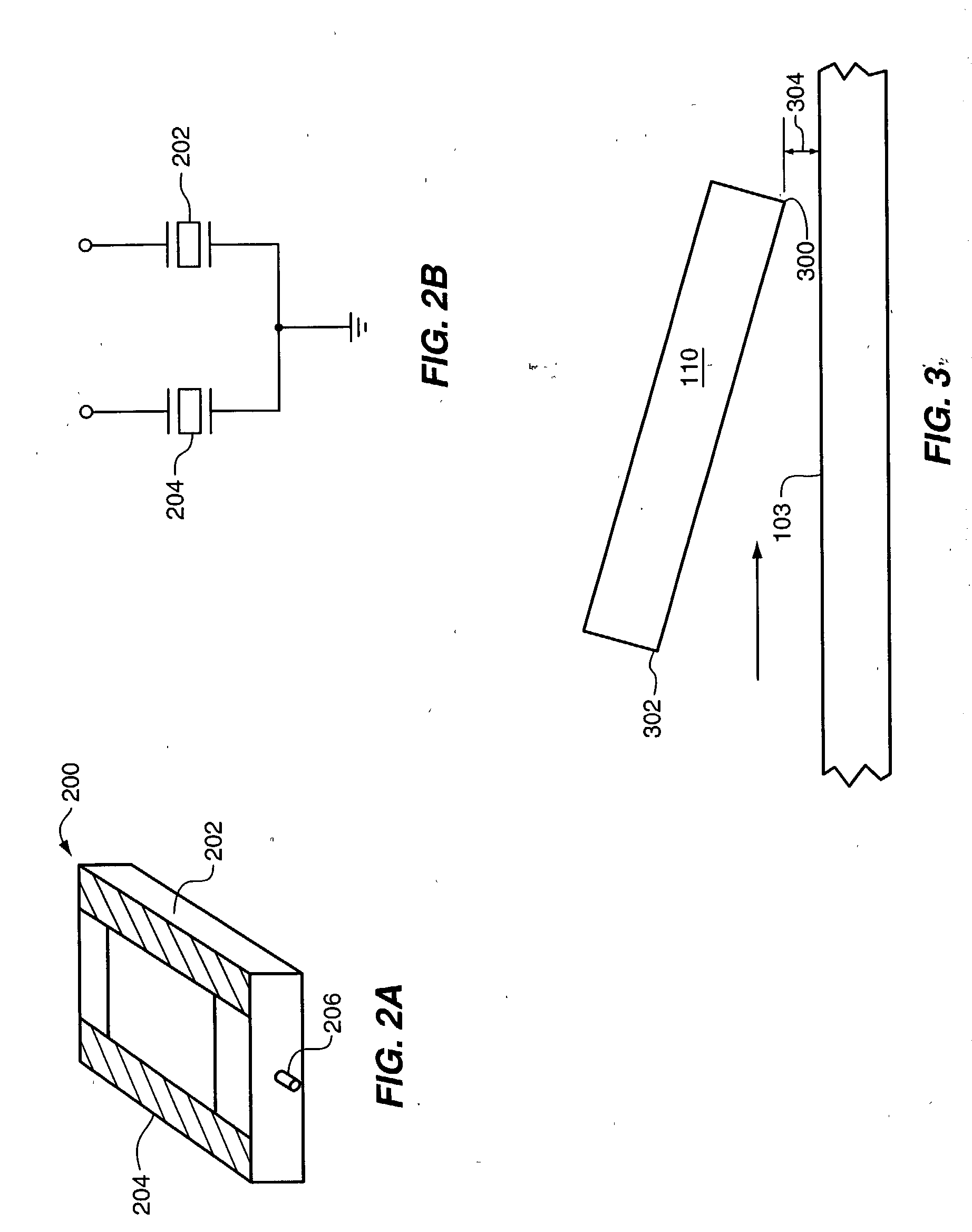

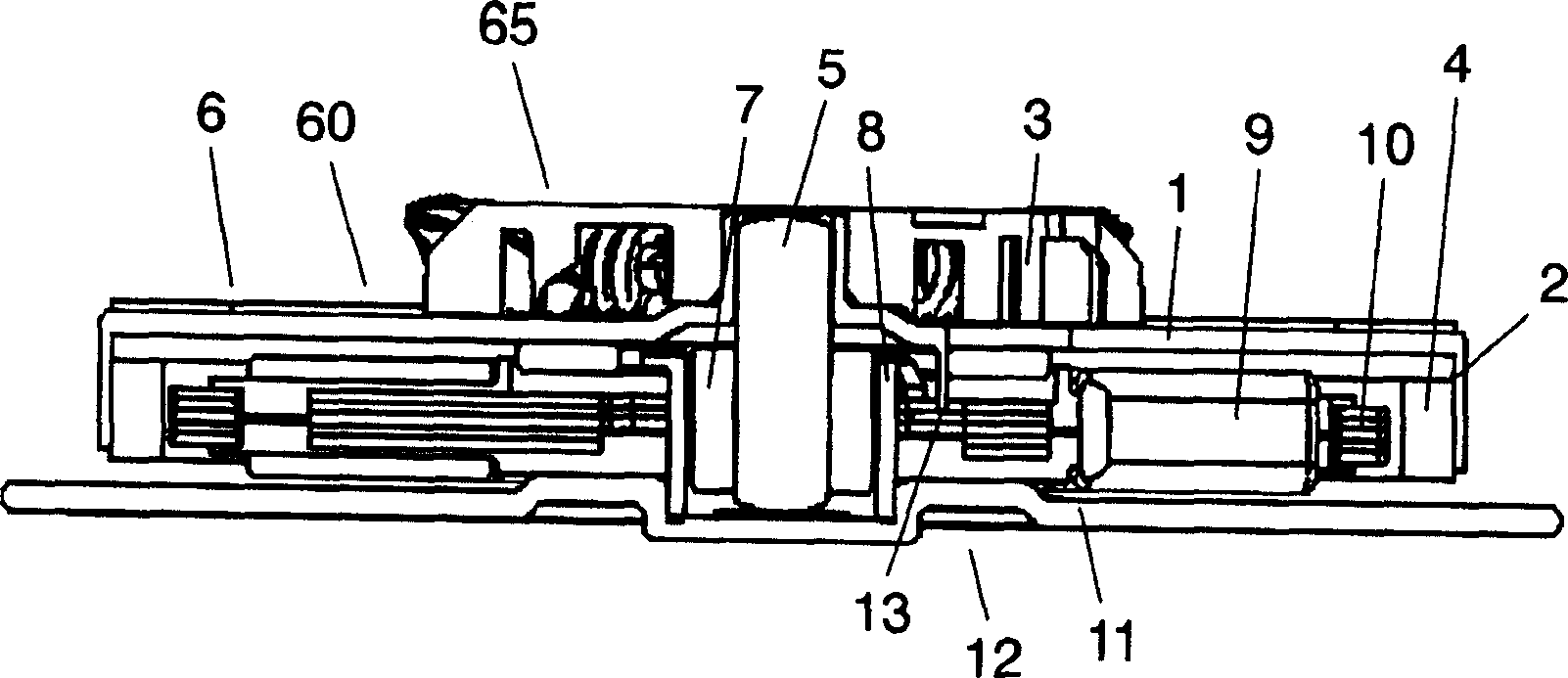

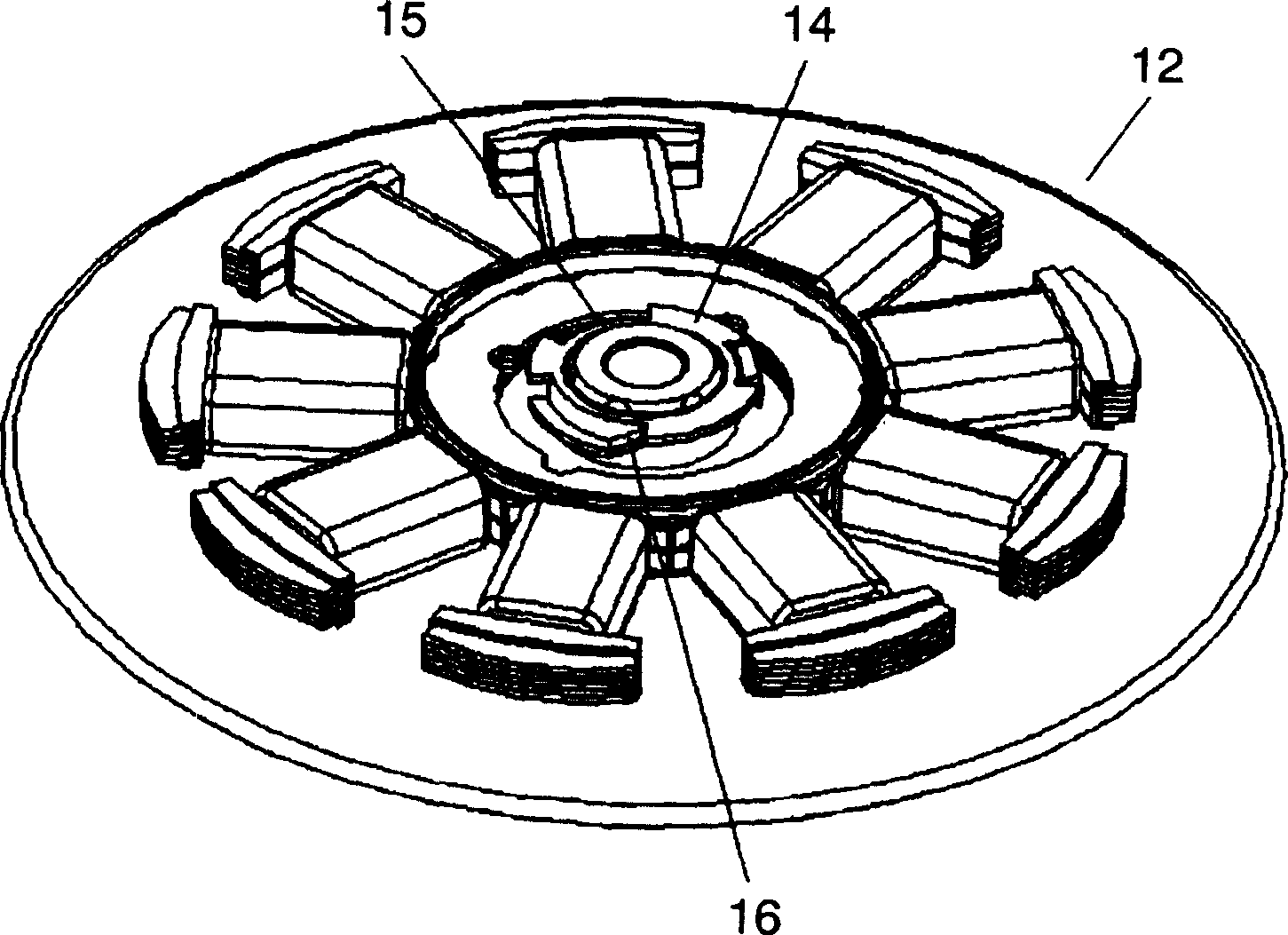

Peizoelectric microactuator and sensor failure detection in disk drives

InactiveUS20030076121A1Improve efficiencyEffective reliabilityDisc-shaped record carriersElectronic circuit testingPiezoelectric microactuatorSignal analyzer

A test device and method for testing one of a disk drive microactuator and a disk drive sensor that includes two piezoelectric elements. The test device includes a signal generator, signal analyzer, and a user interface. The test device is operational to provide a reference signal (e.g. an electrical signal) to one of the piezoelectric elements in the microactuator and obtain a test measure from the other one of the piezoelectric elements. The test measure is then utilized to assess a performance parameter for the microactuator. The test measure is generated by the other one of the piezoelectric elements in response to the reference signal provided to the first one of the piezoelectric elements. In one embodiment of the invention, the test measure is a signal generated in response to the reference signal that may be compared to a known response signal of an operational microactuator to determine operational characteristics of a subject microactuator such as circuitry operation and / or damage to the microactuator.

Owner:GUO WEI +1

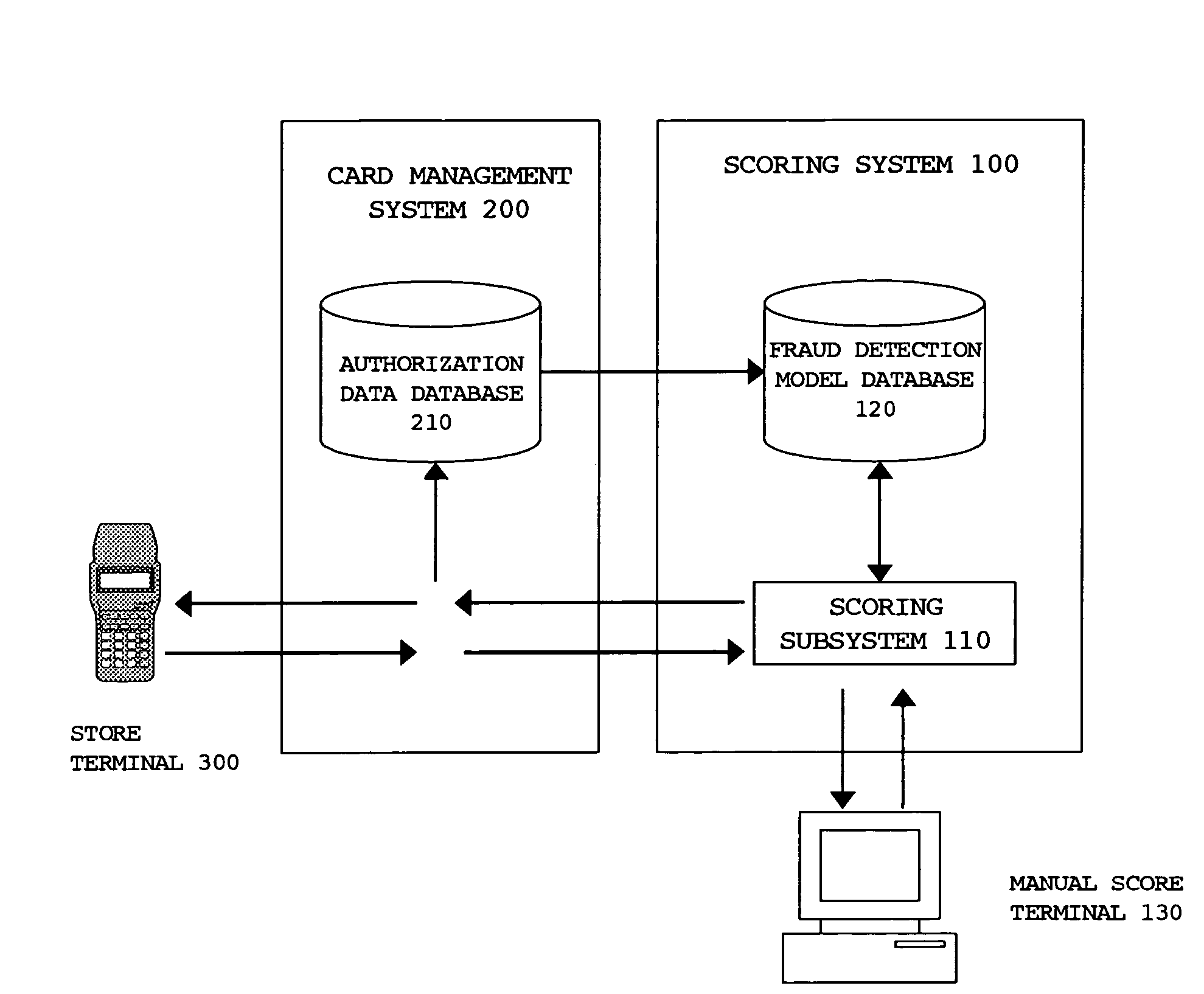

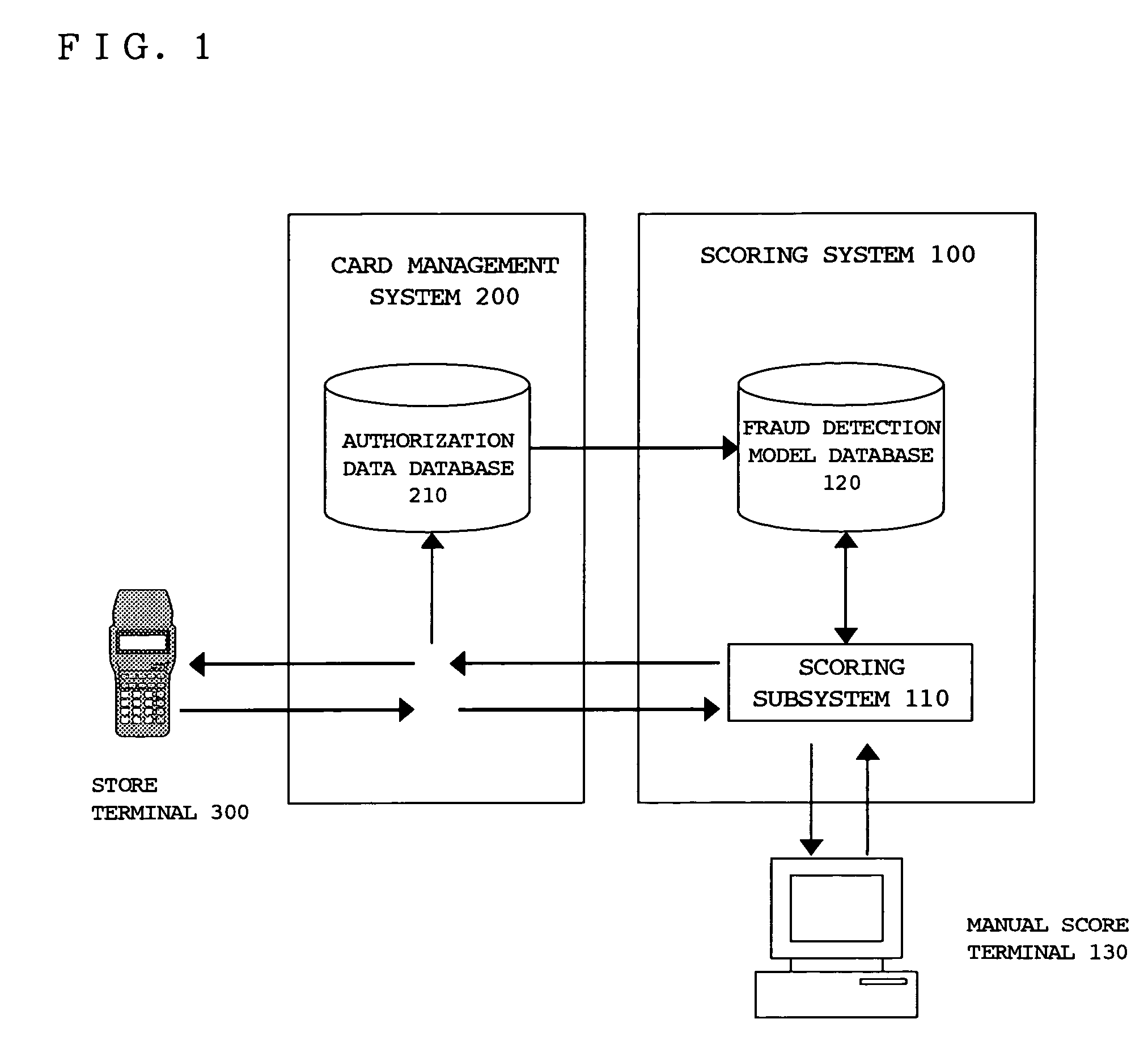

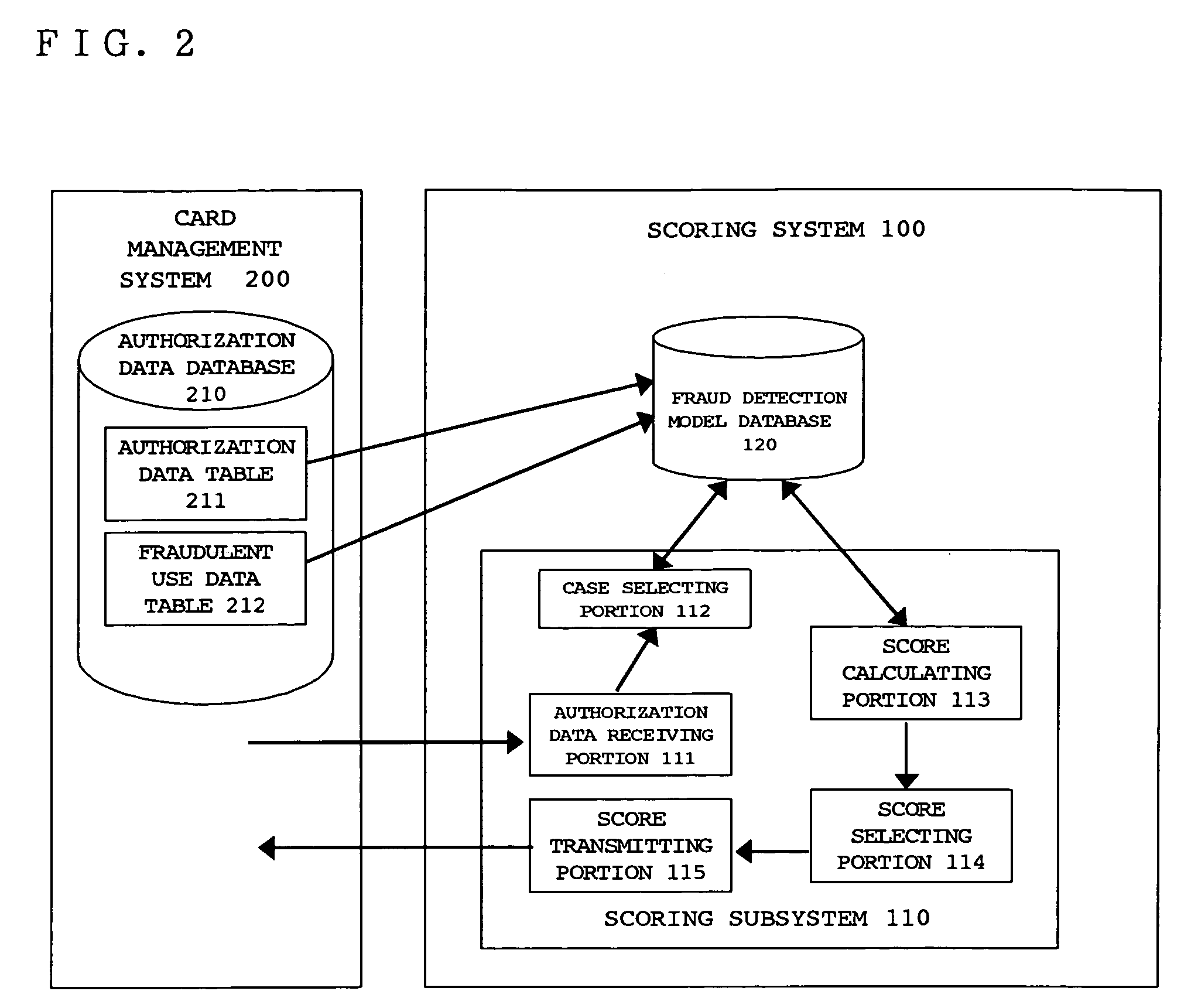

Fraud score calculating program, method of calculating fraud score, and fraud score calculating system for credit cards

A fraud score calculating program primarily for use in determining the possibility of credit card fraud can calculate a score reflecting the reliability of a model created based on Bayesian theory. Various factors are extracted from authorization data, and cases are selected for various combinations of the factors. A fraud score is calculated for each case, and a result of score calculation is specified using at least one of the calculated scores. The result of score calculation may be an average of a plurality of the calculated scores. When each score reflects reliability, the result of score calculation may be the largest of the calculated scores.

Owner:INTELLIGENT WAVE INC

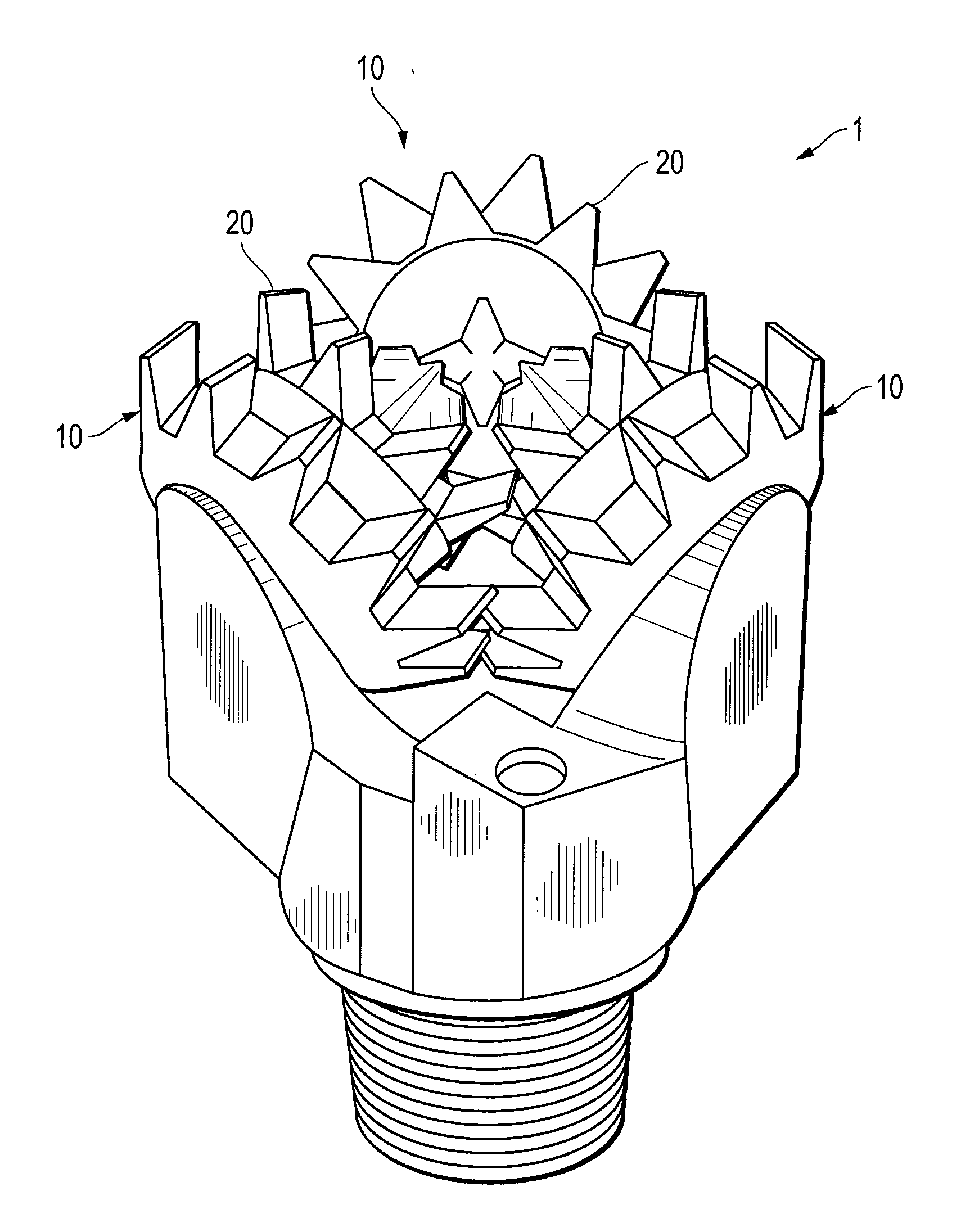

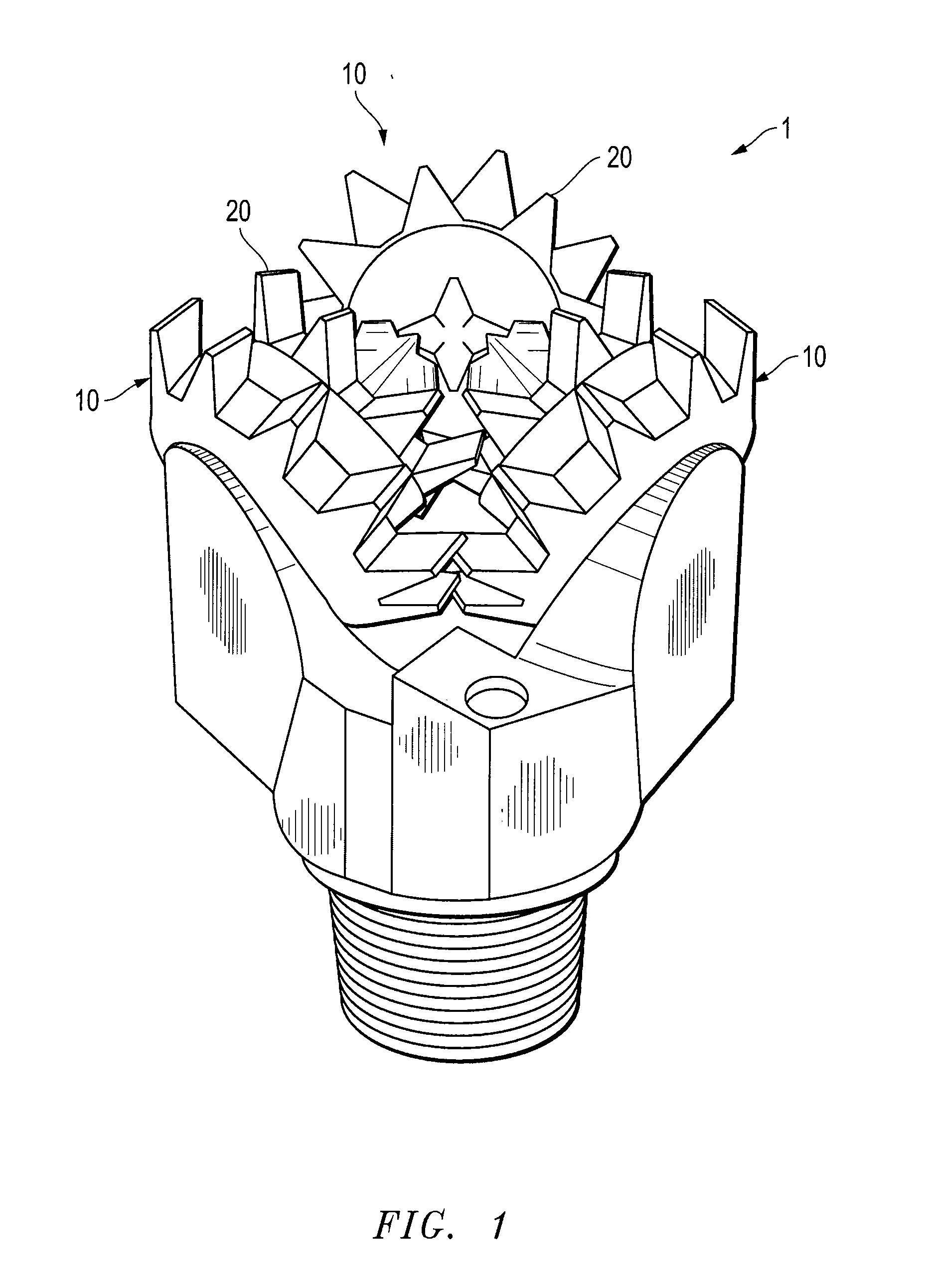

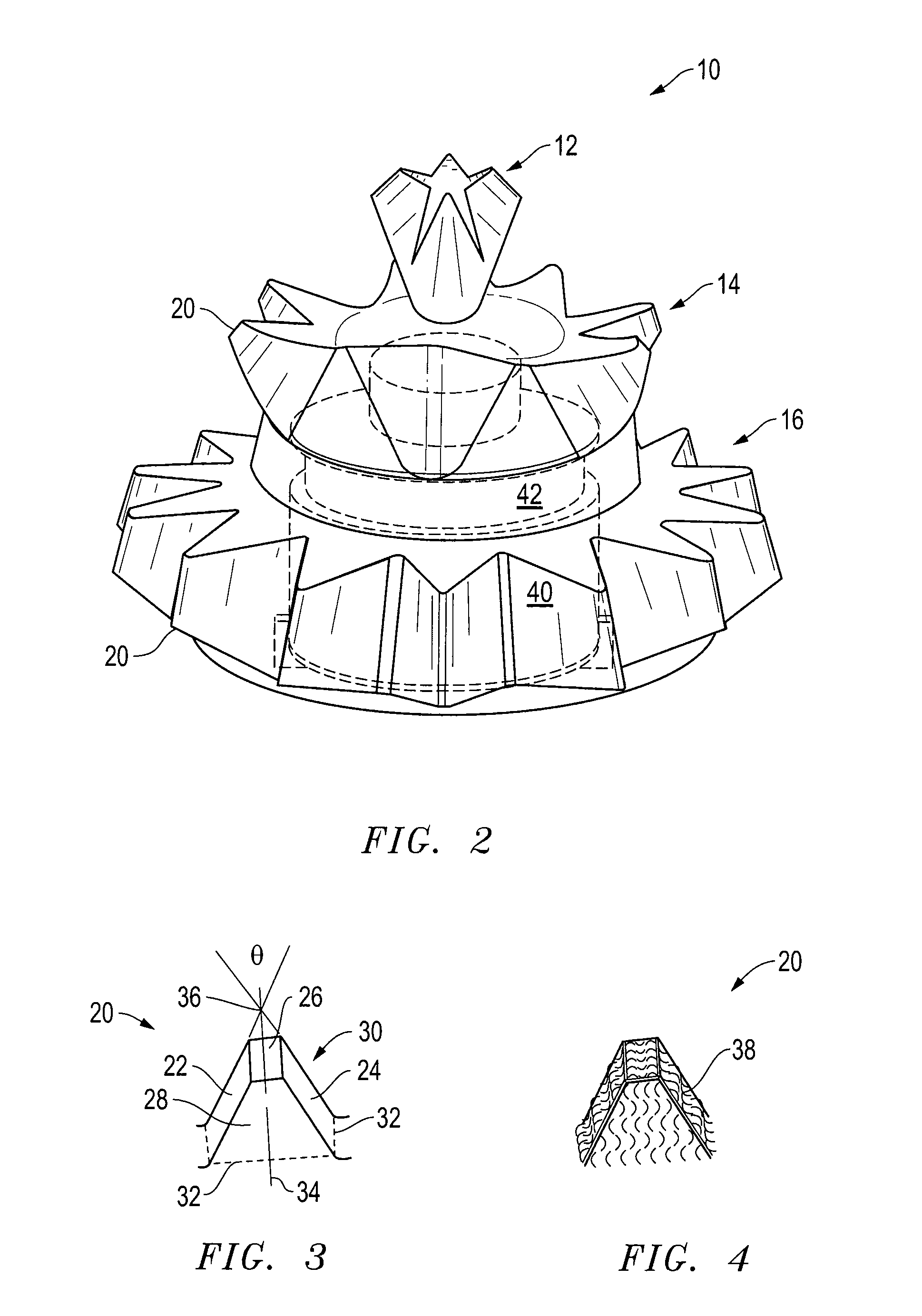

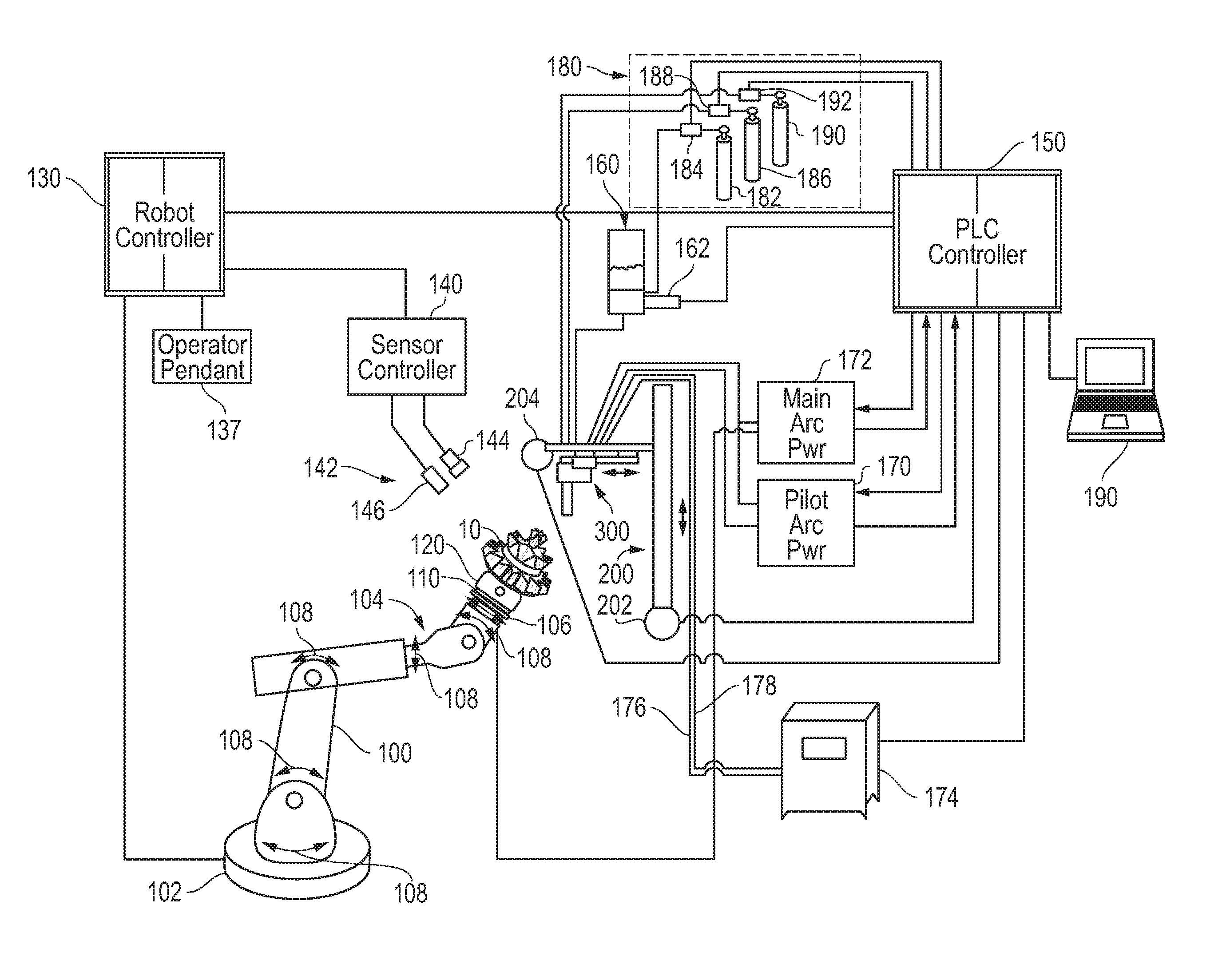

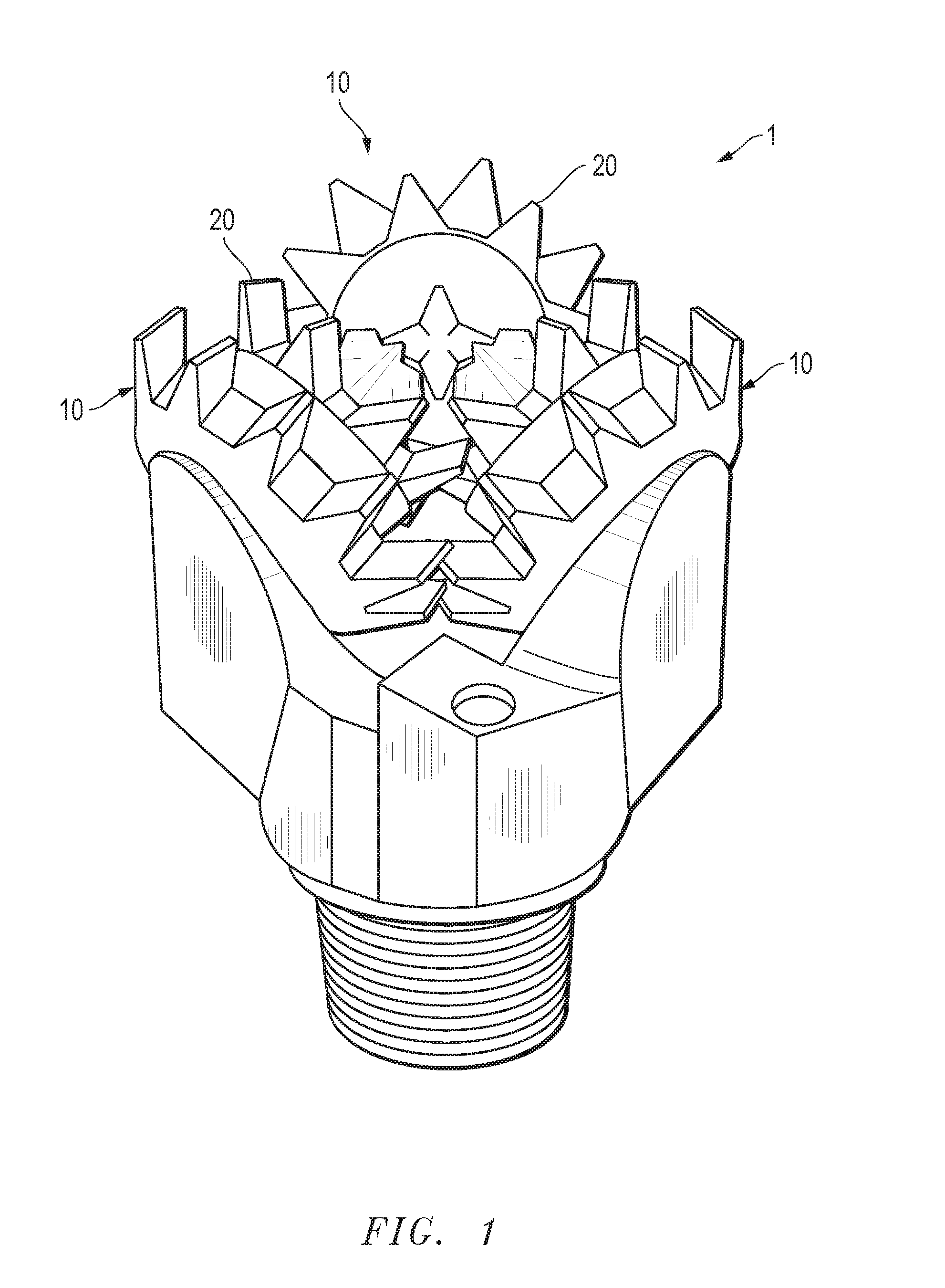

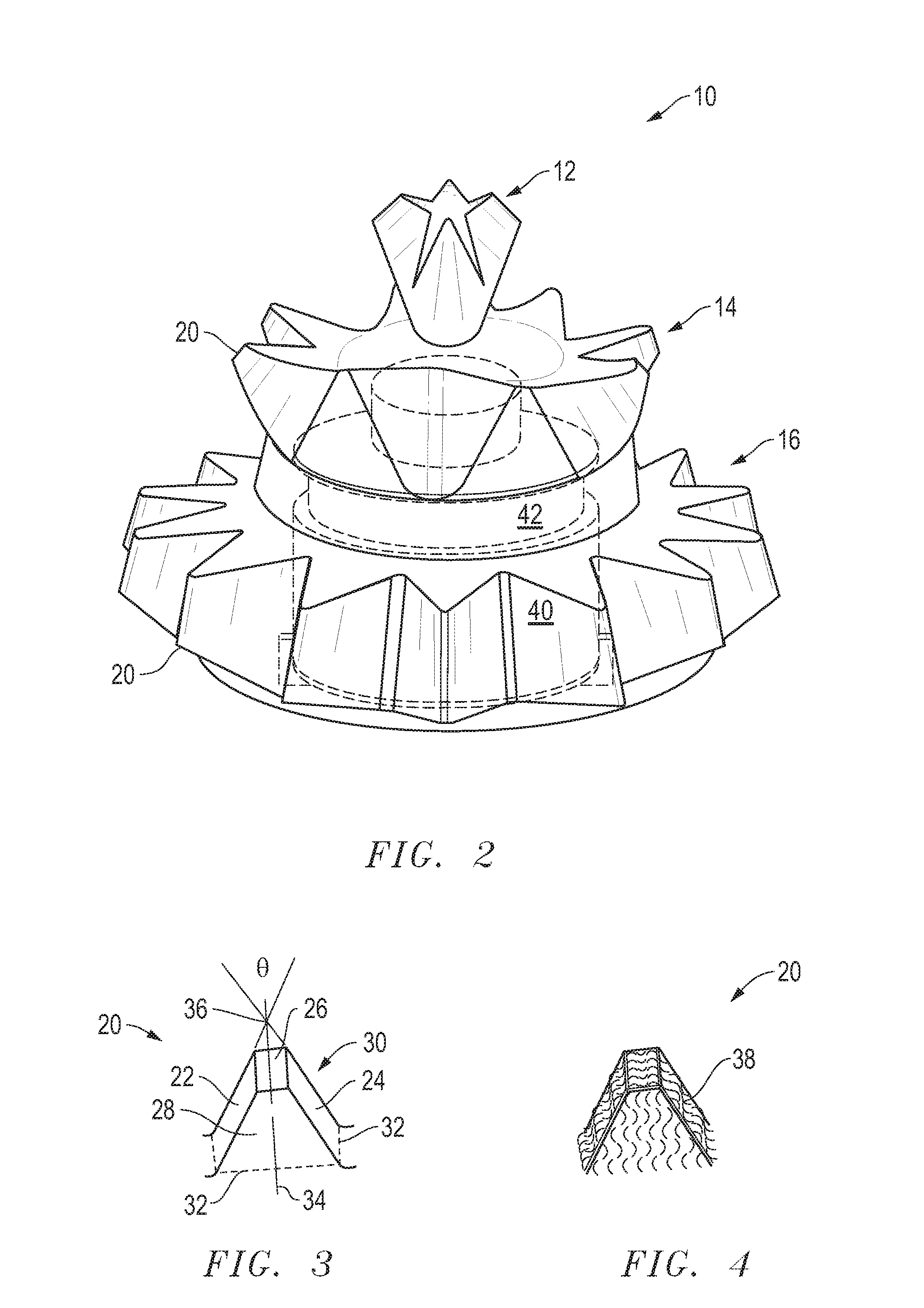

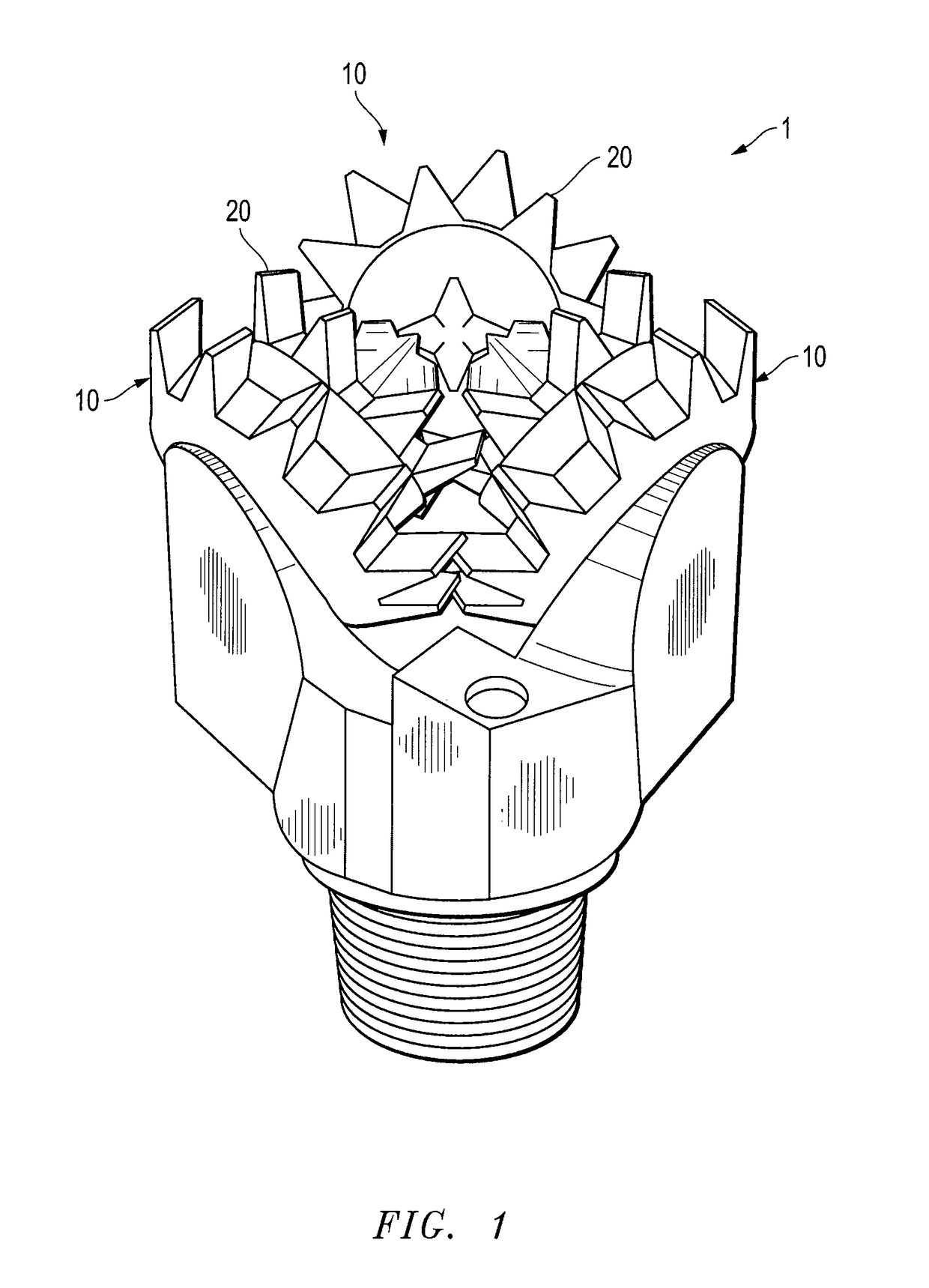

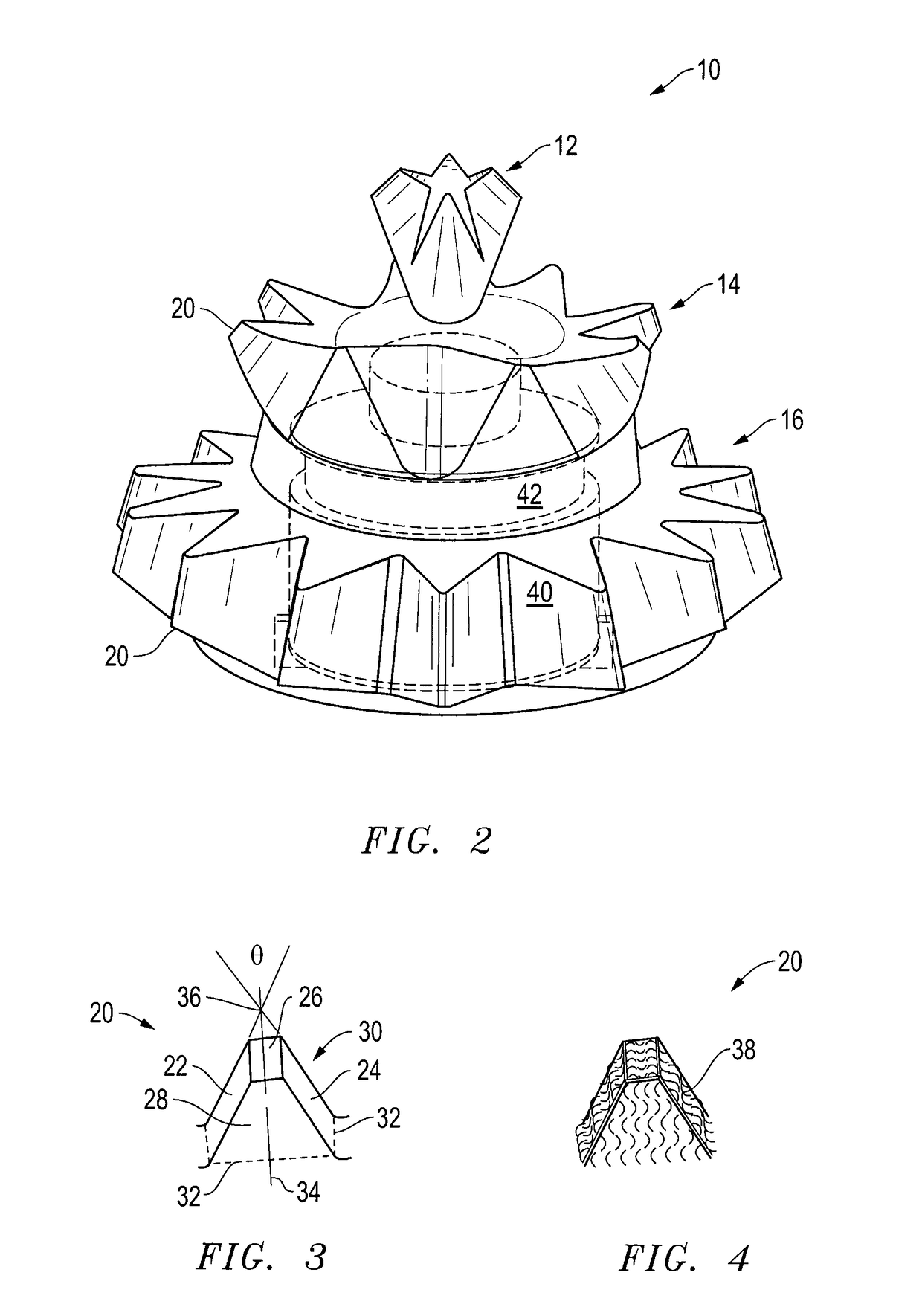

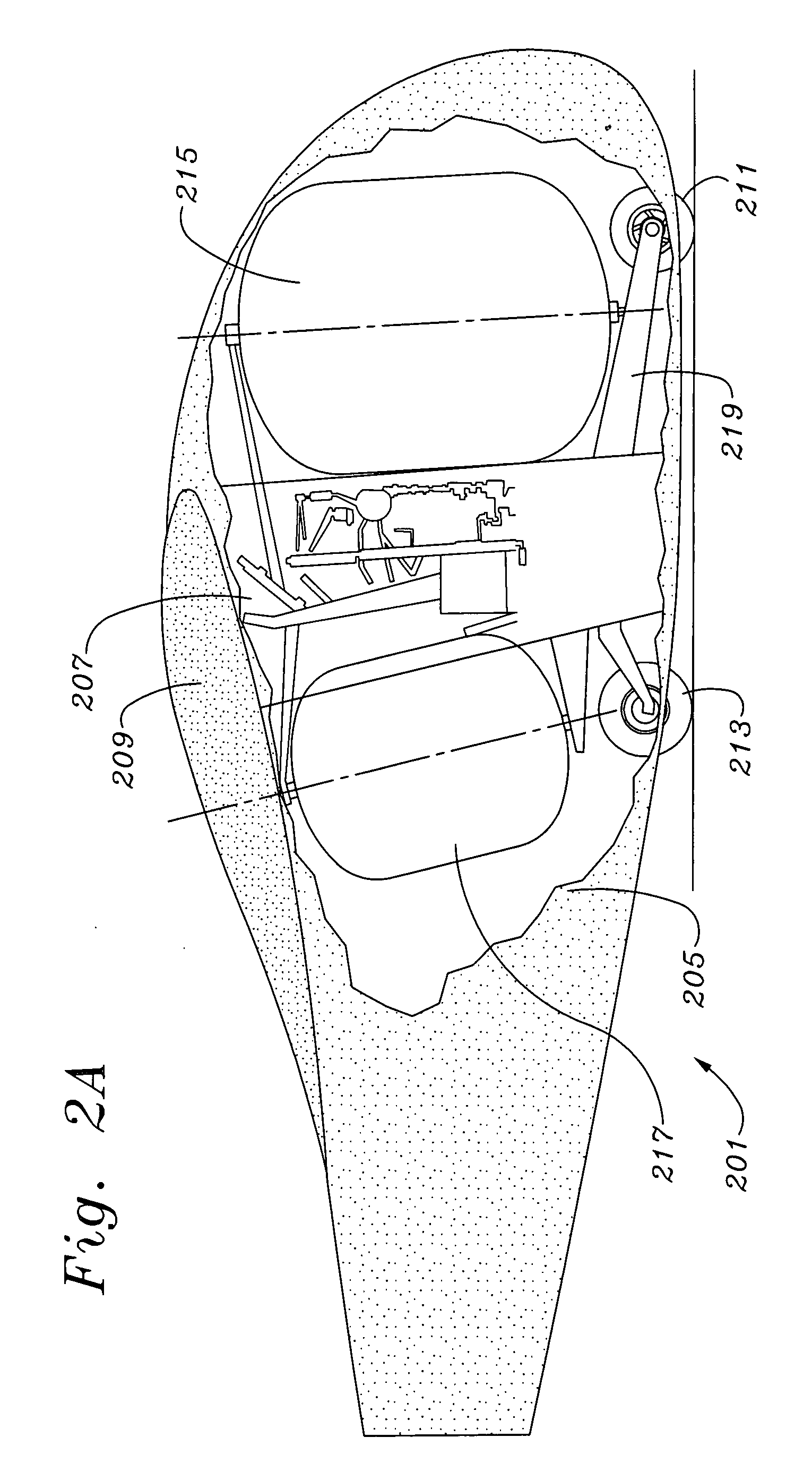

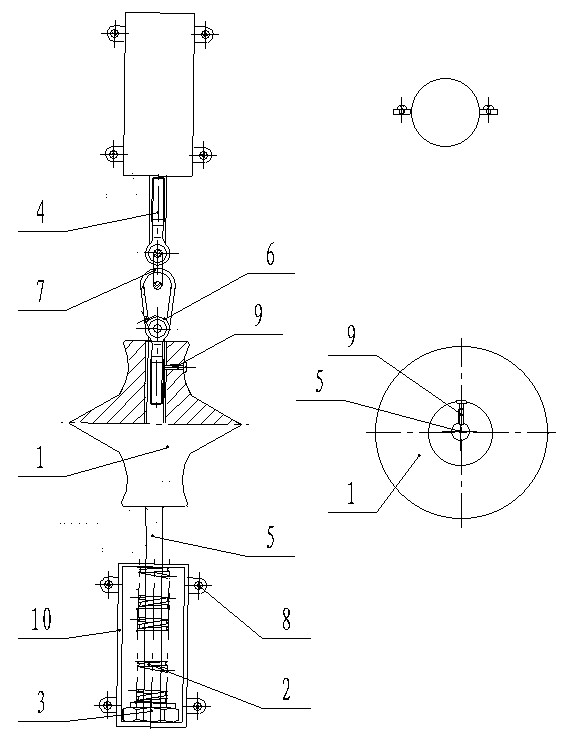

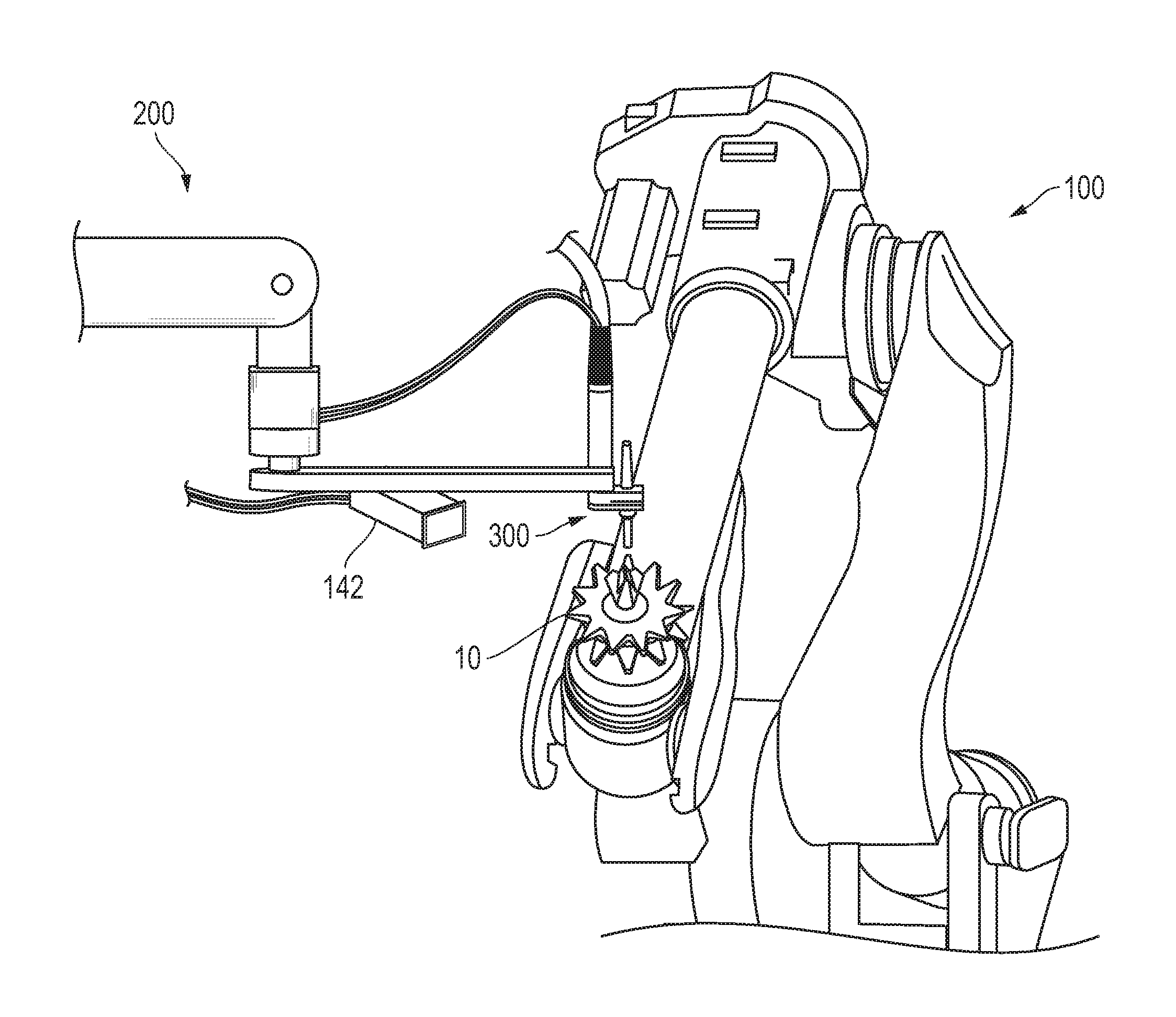

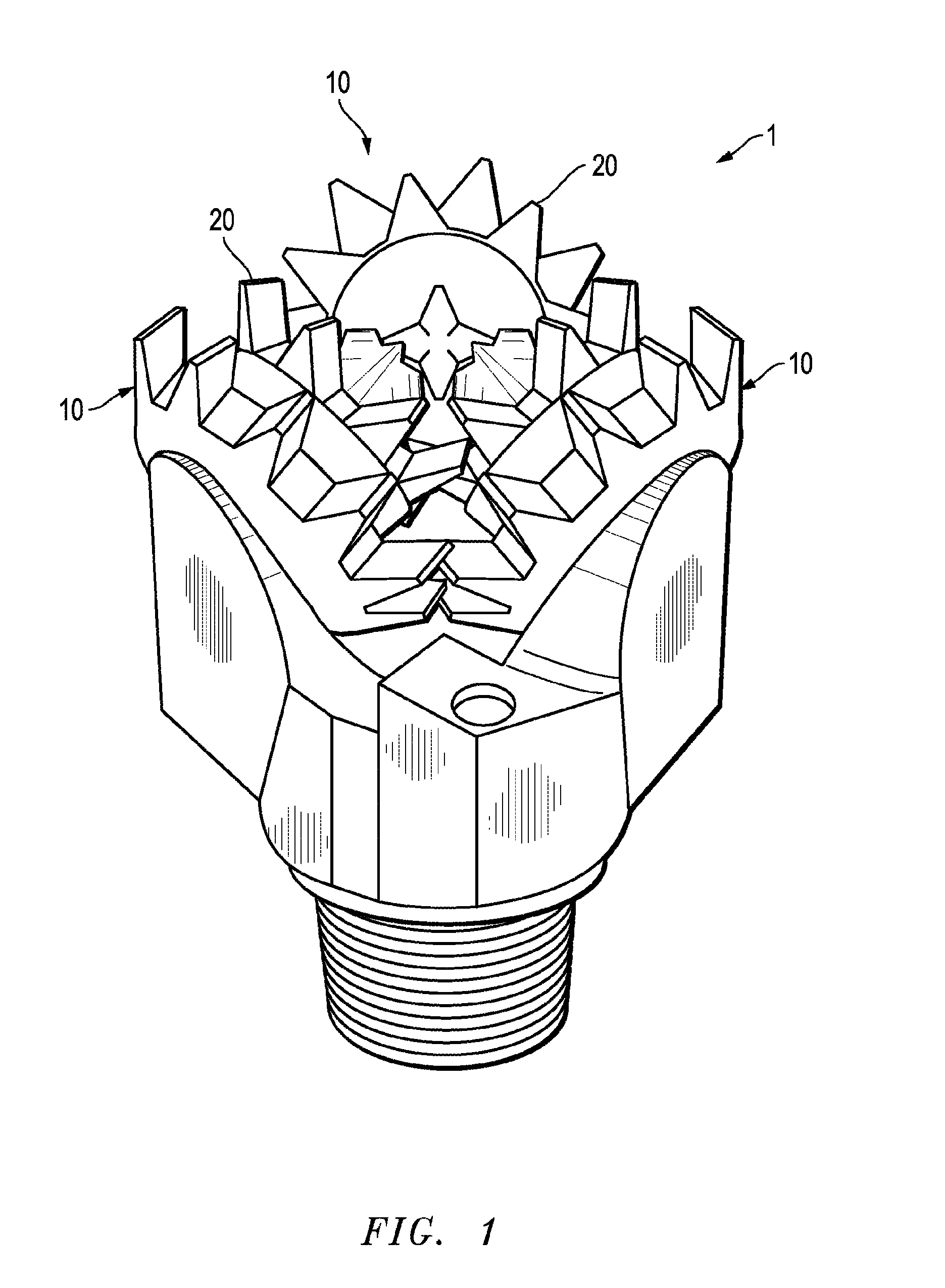

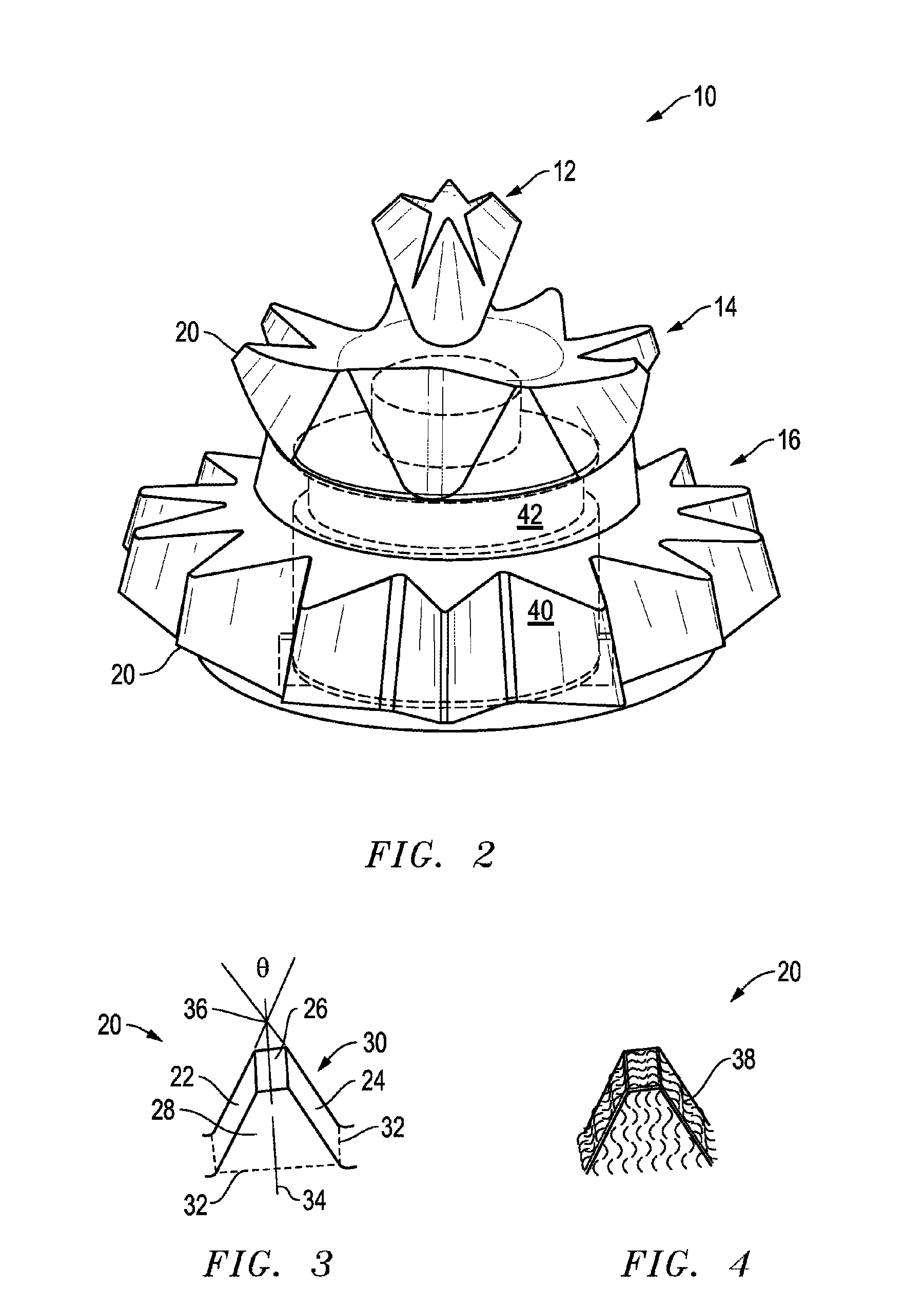

Method and apparatus for automated application of hardfacing material to rolling cutters of hybrid-type earth boring drill bits, hybrid drill bits comprising such hardfaced steel-toothed cutting elements, and methods of use thereof

InactiveUS20100181292A1Improve quality and consistencyFacilitate automatic collectionDrill bitsArc welding apparatusHybrid typeElectricity

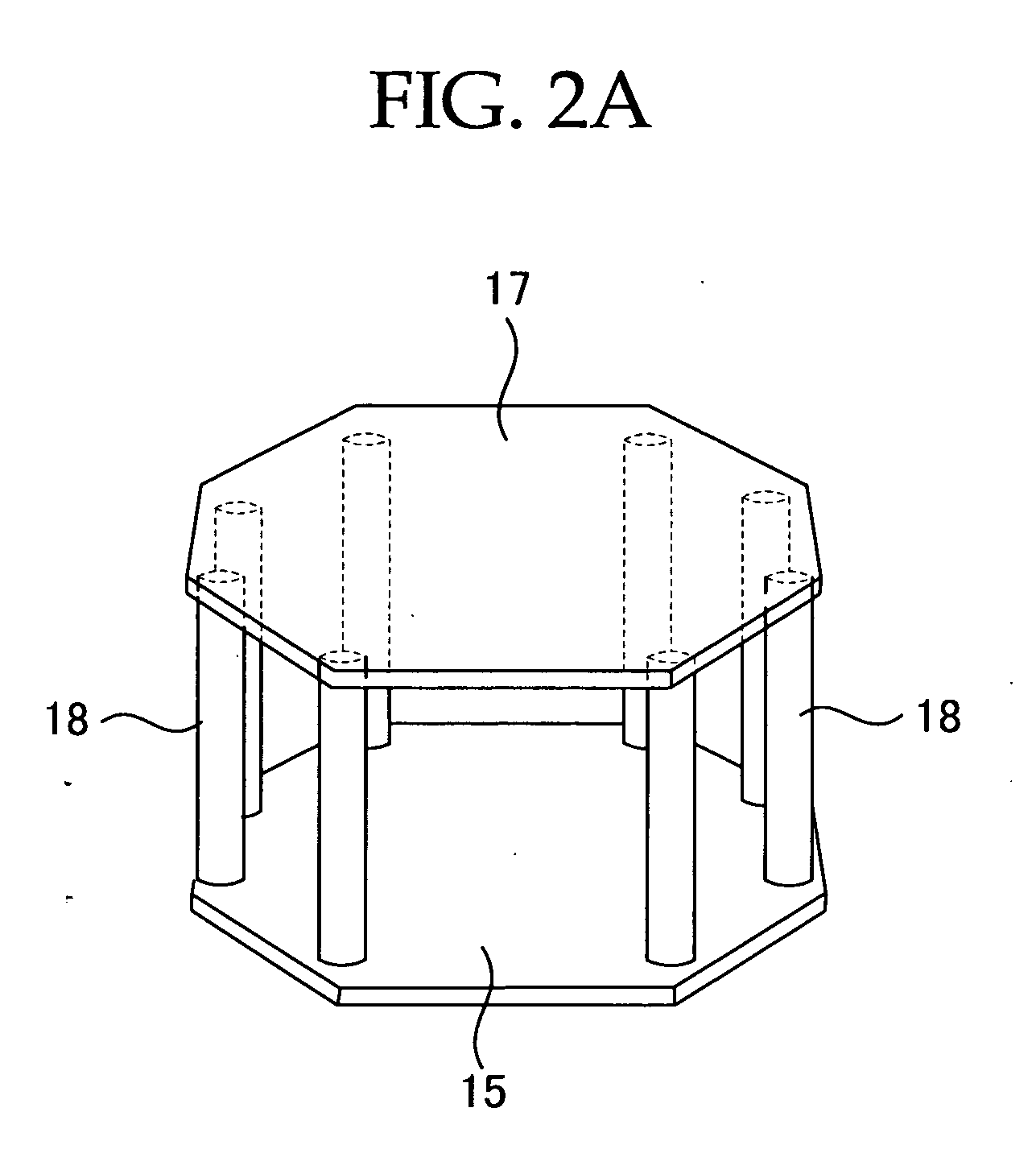

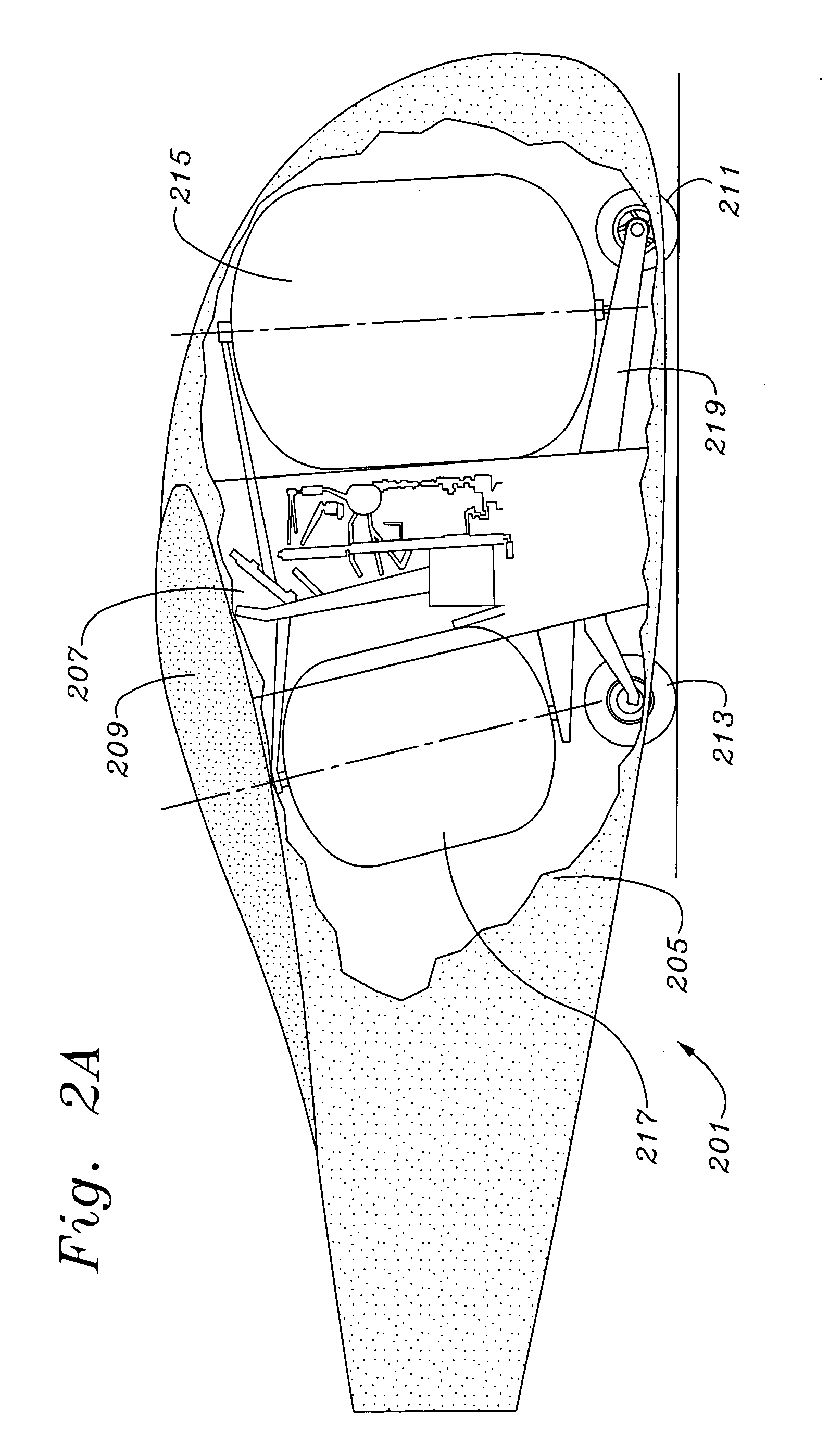

The present invention relates to a system and method for automated or “robotic” application of hardfacing to the surface of a steel-toothed cutter of a standard earth-boring rock bit or a hybrid-type rock bit. In particular, the system incorporates a grounded adapter plate and chuck mounted to a robotic arm for grasping and manipulating a rock bit cutter, particularly a hybrid rock bit cutter, beneath an electrical or photonic energy welding source, such as a plasma arc welding torch manipulated by a positioner. In this configuration, the torch is positioned substantially vertically and oscillated along a horizontal axis as the cutter is manipulated relative along a target path for the distribution of hardfacing. Moving the cutter beneath the torch allows more areas of more teeth to be overlayed, and allows superior placement for operational feedback, such as automatic positioning and parameter correction. In the preferred embodiment, sensors provide data to the control system for identification, positioning, welding program selection, and welding program correction. The control system, aided by data from the sensors, manipulates the robotically held cutter while controlling the operation and oscillation of the torch. These systems and methods can be applied to hardfacing steel teeth of the rolling cutters of both standard tri-cone or di-cone type rolling cone bits, as well as to hybrid-type earth boring drill bits.

Owner:BAKER HUGHES INC

Method and Apparatus for the Automated Application of Hardfacing Material to Rolling Cutters of Earth-Boring Drill Bits

ActiveUS20100065337A1Improve quality and consistencyFacilitate automatic collectionDrill bitsMetal-working drilling toolsRobotic armControl system

The present invention relates to a system and method for automated or “robotic” application of hardfacing to the surface of a steel-toothed cutter of a rock bit. In particular, the system incorporates a grounded adapter plate and chuck mounted to a robotic arm for grasping and manipulating a rock bit cutter beneath an electrical or photonic energy welding source, such as a plasma arc welding torch manipulated by a positioner. In this configuration, the torch is positioned substantially vertically and oscillated along a horizontal axis as the cutter is manipulated relative along a target path for the distribution of hardfacing. Moving the cutter beneath the torch allows more areas of more teeth to be overlayed, and allows superior placement for operational feedback, such as automatic positioning and parameter correction. In the preferred embodiment, sensors provide data to the control system for identification, positioning, welding program selection, and welding program correction. The control system, aided by data from the sensors, manipulates the robotically held cutter while controlling the operation and oscillation of the torch.

Owner:BAKER HUGHES INC

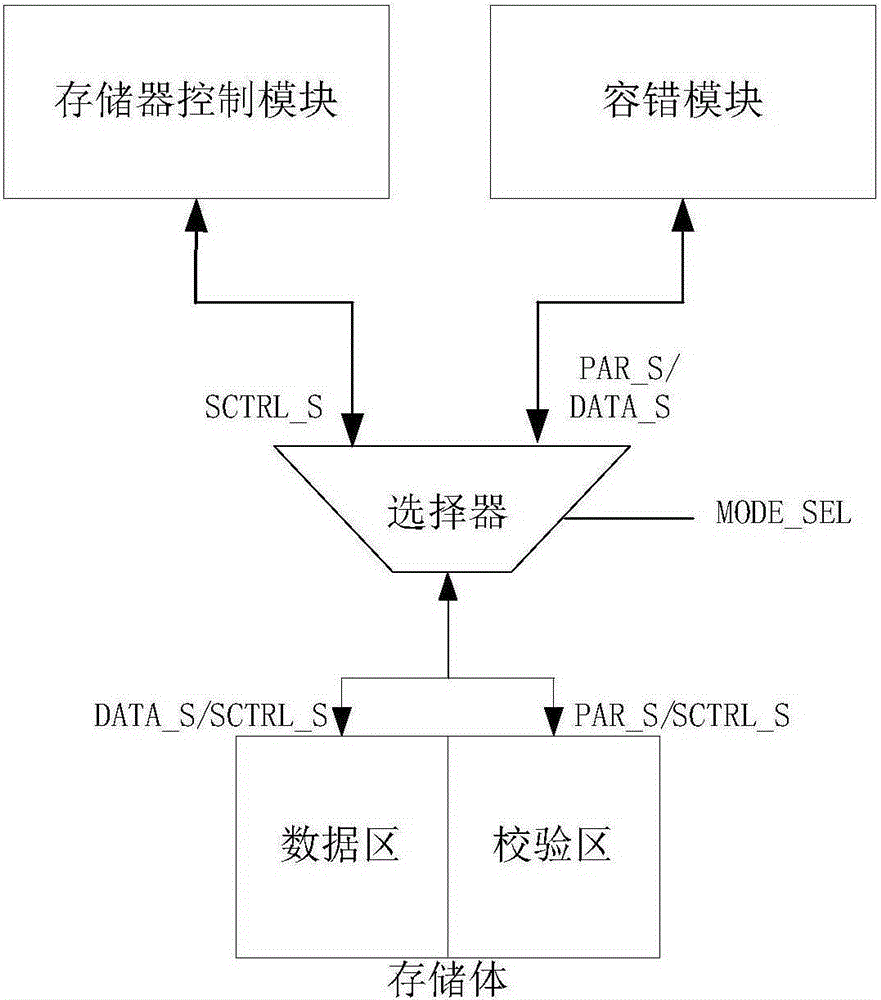

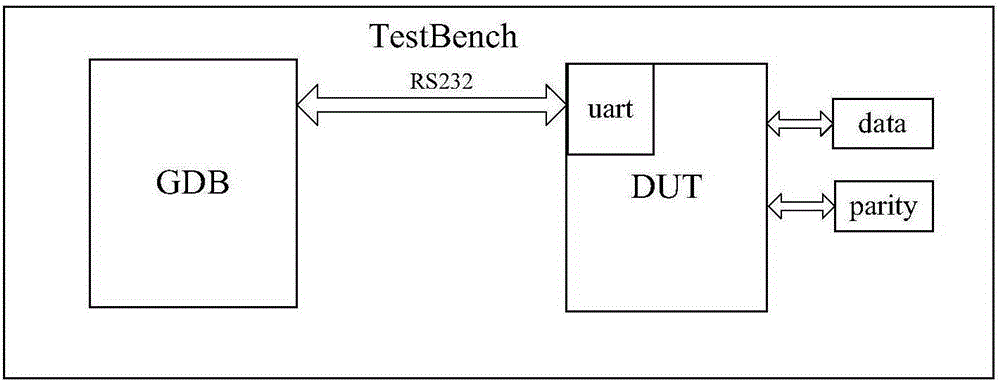

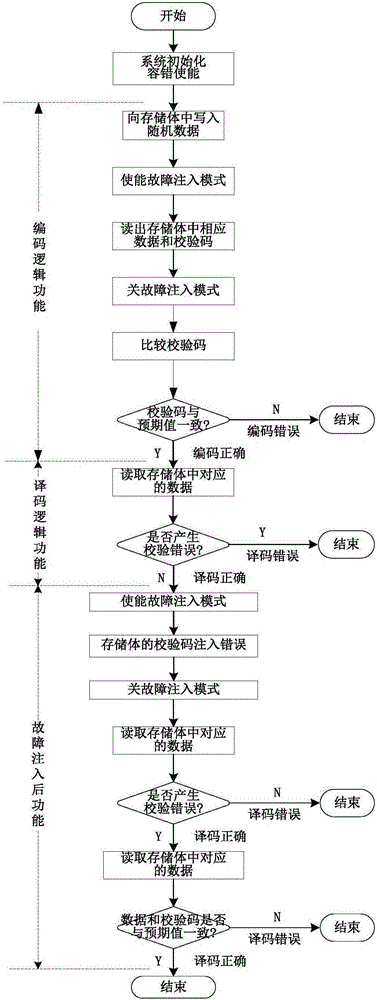

Automatic verification platform and method for on-chip memory management unit fault-tolerant structure

ActiveCN105185413AAchieve correctnessAchieve reliabilityStatic storageSpecial data processing applicationsComputer architectureStacking fault

The invention provides an automatic verification platform and method for an on-chip memory management unit fault-tolerant structure. The automatic verification platform and method can conduct random fault injection verification on the fault-tolerant structure and are high in verification coverage rate. The platform comprises a debugging host and a to-be-tested host connected through a serial port. The debugging host is used for flow control verification, encoding result checking, fault injection, decoding result checking in the verification process, and monitoring and debugging of a processor. The on-chip memory stack fault-tolerant structure is integrated in the to-be-tested host and used for generation of check codes, decoding verification after decoding logic and fault injection and loading of an automatic verification program for the memory stack fault-tolerant structure. The memory stack fault-tolerant structure comprises a memorizer control module, a fault-tolerant module, a selector and a memory stack. The memorizer control module and the fault-tolerant module conduct read-write control over the memory stack through the selector to control the working mode and the failure mode of the on-chip memory stack fault-tolerant structure.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

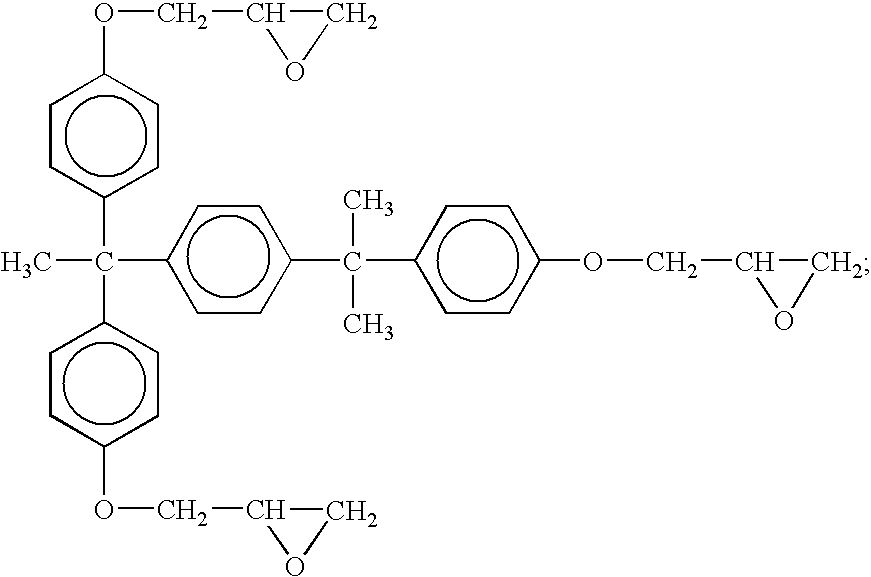

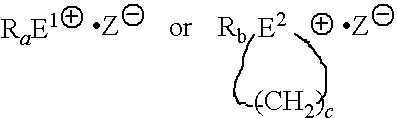

Epoxy resin composition using latent curing agent and curable by photo and heat in combination

InactiveUS20090076180A1Sufficient curabilityEffective reliabilityImpression capsOrganic chemistryEpoxyAdduct

The present invention is to provide a latent curing type epoxy resin composition which comprises(A) 100 parts by weight of an epoxy resin,(B) 5 to 25 parts by weight of a cation polymerization photo initiator, and(C) 5 to 35 parts by weight of at least one heatset anion curing agent selected from the group consisting of an epoxy adduct with an amine compound, a urea adduct with an amine compound and a compound in which an isocyanate compound is added to a hydroxyl group of an epoxy adduct with an amine compound.

Owner:NAMICS CORPORATION

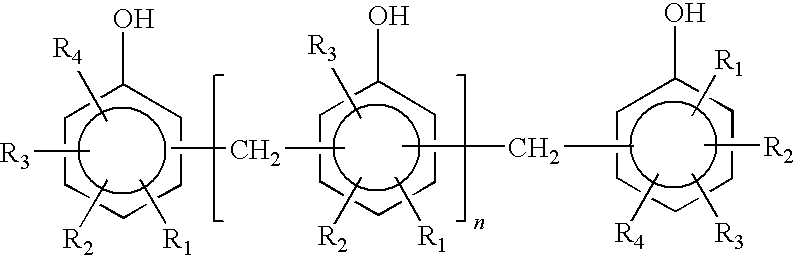

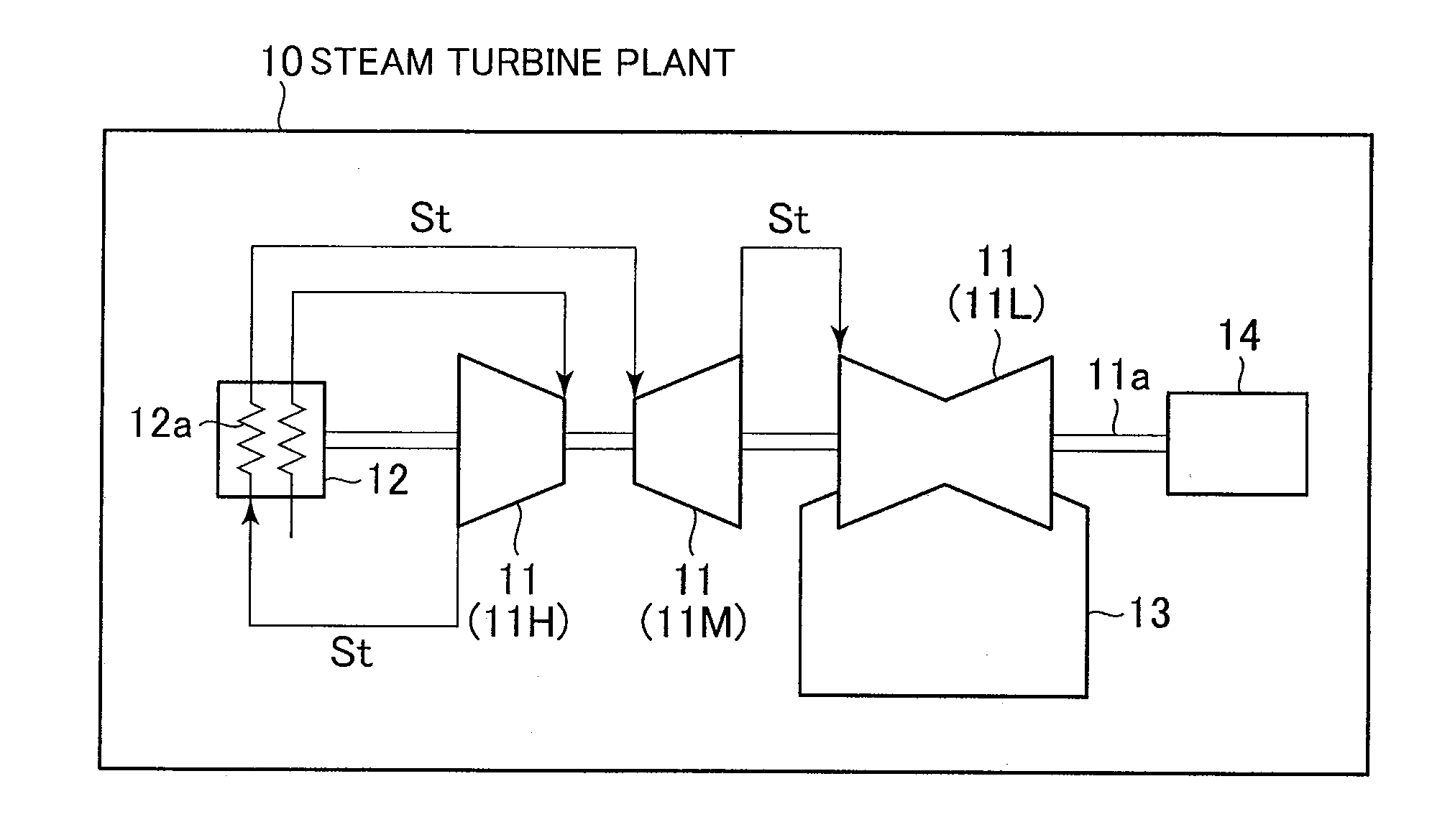

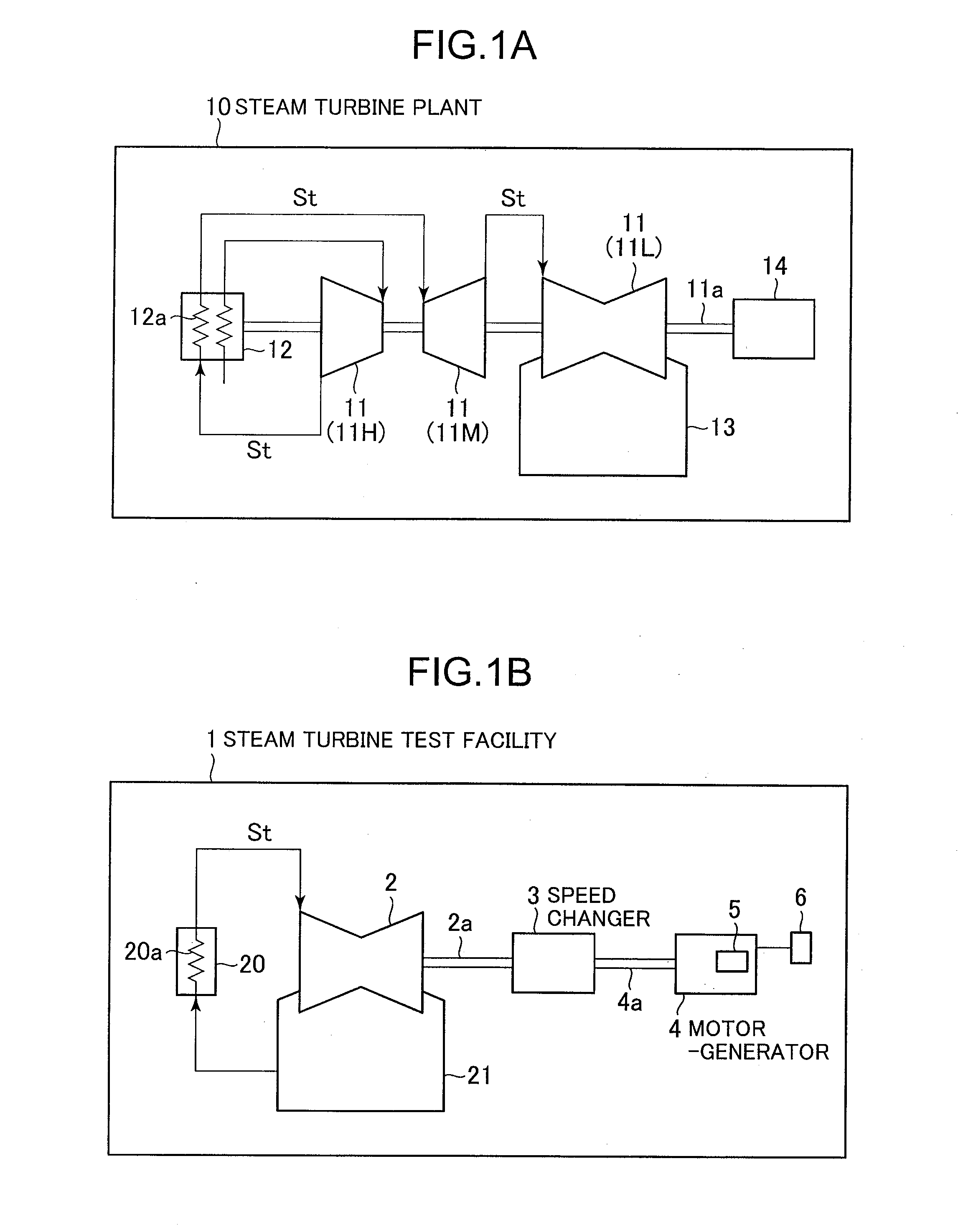

Steam turbine test facility, low-load test method, and load dump test method

ActiveUS20100162802A1Improve efficiencyImprove performanceGas-turbine engine testingJet-propulsion engine testingTime profileLow load

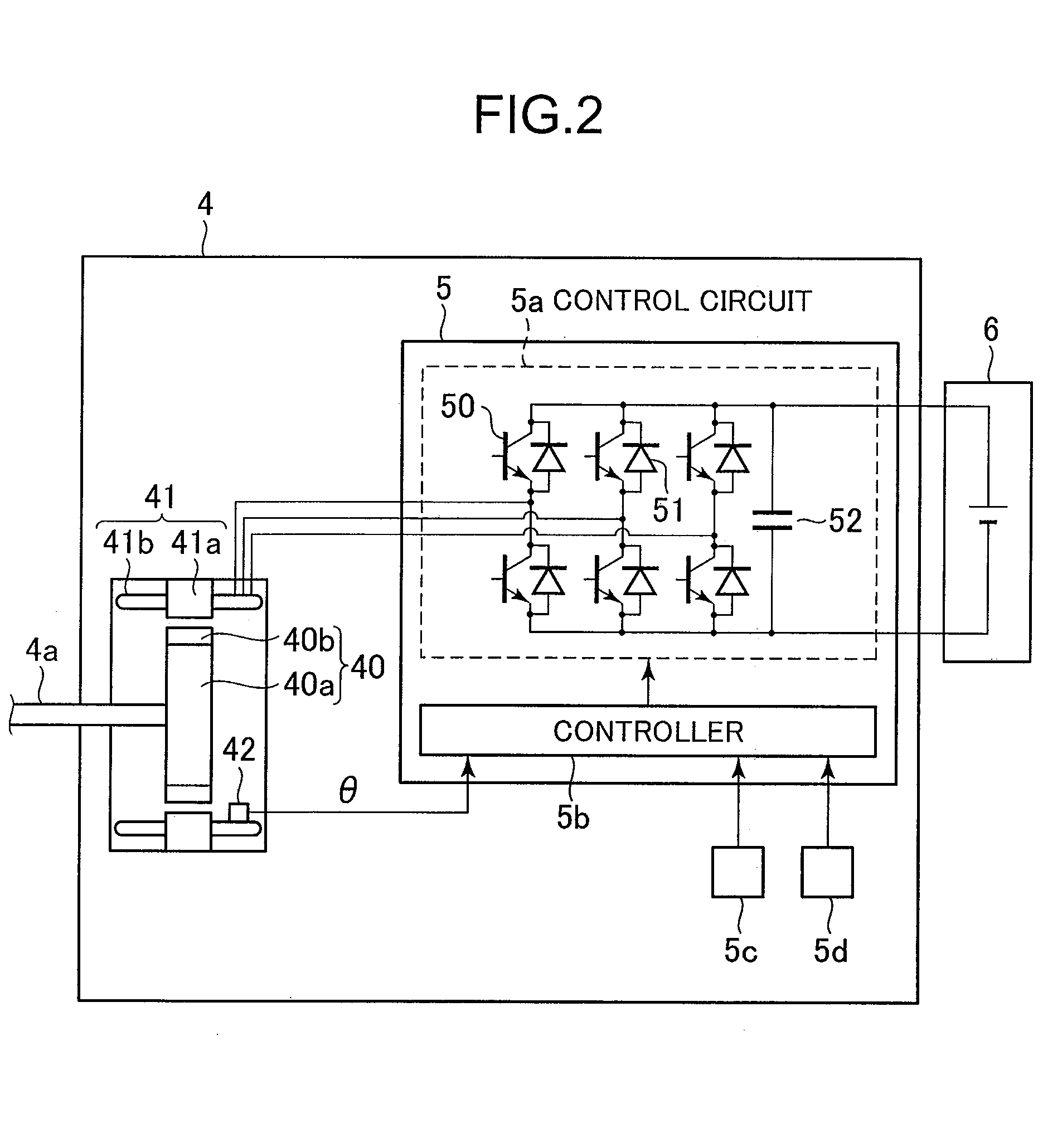

It is an object of the present invention to provide a steam turbine test facility including a test steam turbine, in which the behavior of an actual steam turbine can be precisely simulated and the efficiency of performance test can be improved. A steam turbine test facility 1 includes a test steam turbine 2 which simulates the behavior of a real steam turbines 11 included in the steam turbine plant 10, and a motor-generator 4 connected to the test steam turbine 2. A control unit 5 included in the motor-generator 4 controls the motor-generator 4 to change the rotational speed of the test steam turbine 2 based on an arbitrarily set speed change pattern. The speed change pattern is set such that the test steam turbine 2 in the load disconnection state simulates a time-profile of the rotational speed of the steam turbines 11 with the load disconnected.

Owner:MITSUBISHI POWER LTD

Method and apparatus for automated application of hardfacing material to rolling cutters of hybrid-type earth boring drill bits, hybrid drill bits comprising such hardfaced steel-toothed cutting elements, and methods of use thereof

InactiveUS8471182B2Improve quality and consistencyFacilitate automatic collectionDrill bitsArc welding apparatusHybrid typeElectricity

The present invention relates to a system and method for automated or “robotic” application of hardfacing to the surface of a steel-toothed cutter of a standard earth-boring rock bit or a hybrid-type rock bit. In particular, the system incorporates a grounded adapter plate and chuck mounted to a robotic arm for grasping and manipulating a rock bit cutter, particularly a hybrid rock bit cutter, beneath an electrical or photonic energy welding source, such as a plasma arc welding torch manipulated by a positioner. In this configuration, the torch is positioned substantially vertically and oscillated along a horizontal axis as the cutter is manipulated relative along a target path for the distribution of hardfacing. Moving the cutter beneath the torch allows more areas of more teeth to be overlayed, and allows superior placement for operational feedback, such as automatic positioning and parameter correction. In the preferred embodiment, sensors provide data to the control system for identification, positioning, welding program selection, and welding program correction. The control system, aided by data from the sensors, manipulates the robotically held cutter while controlling the operation and oscillation of the torch. These systems and methods can be applied to hardfacing steel teeth of the rolling cutters of both standard tri-cone or di-cone type rolling cone bits, as well as to hybrid-type earth boring drill bits.

Owner:BAKER HUGHES HLDG LLC

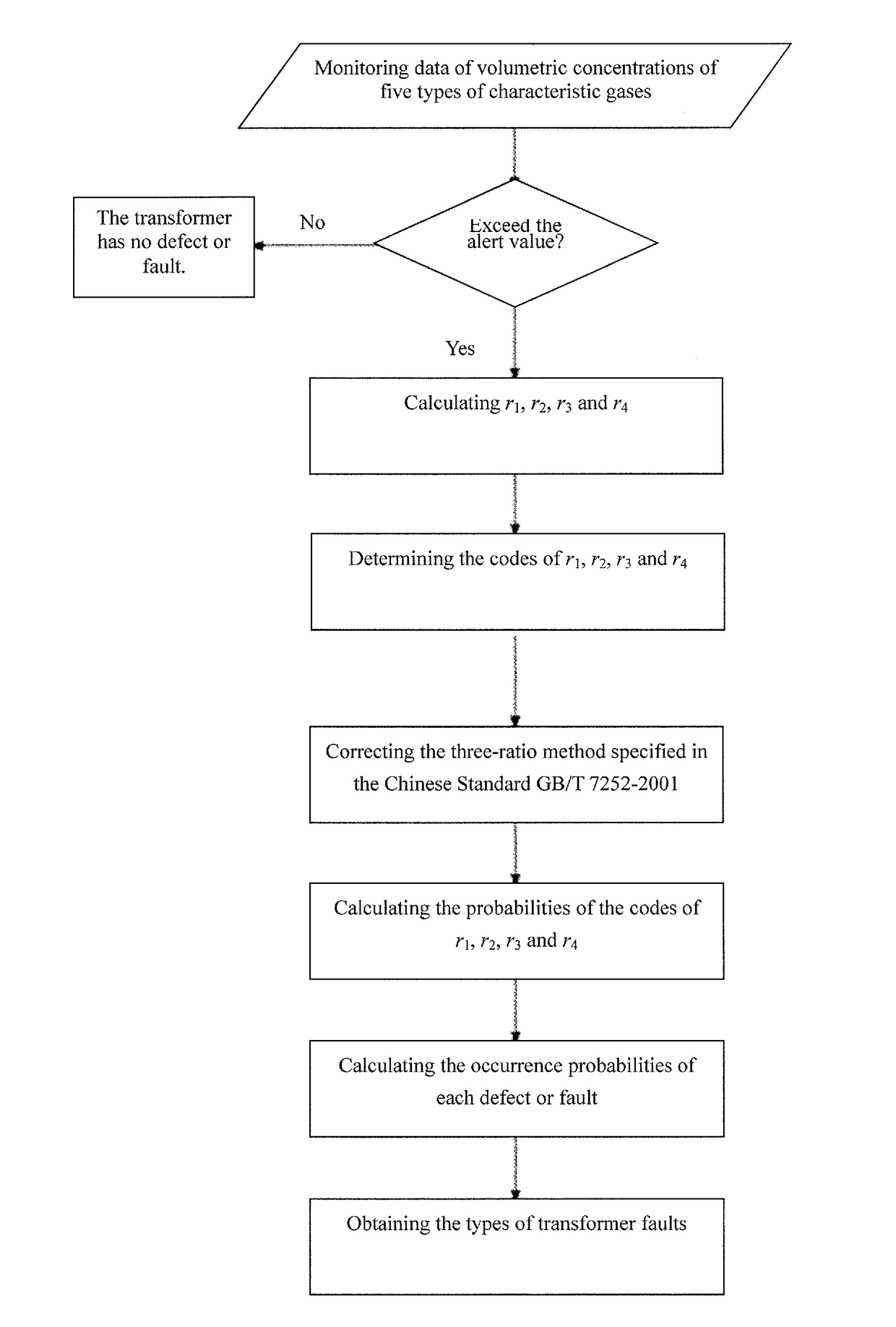

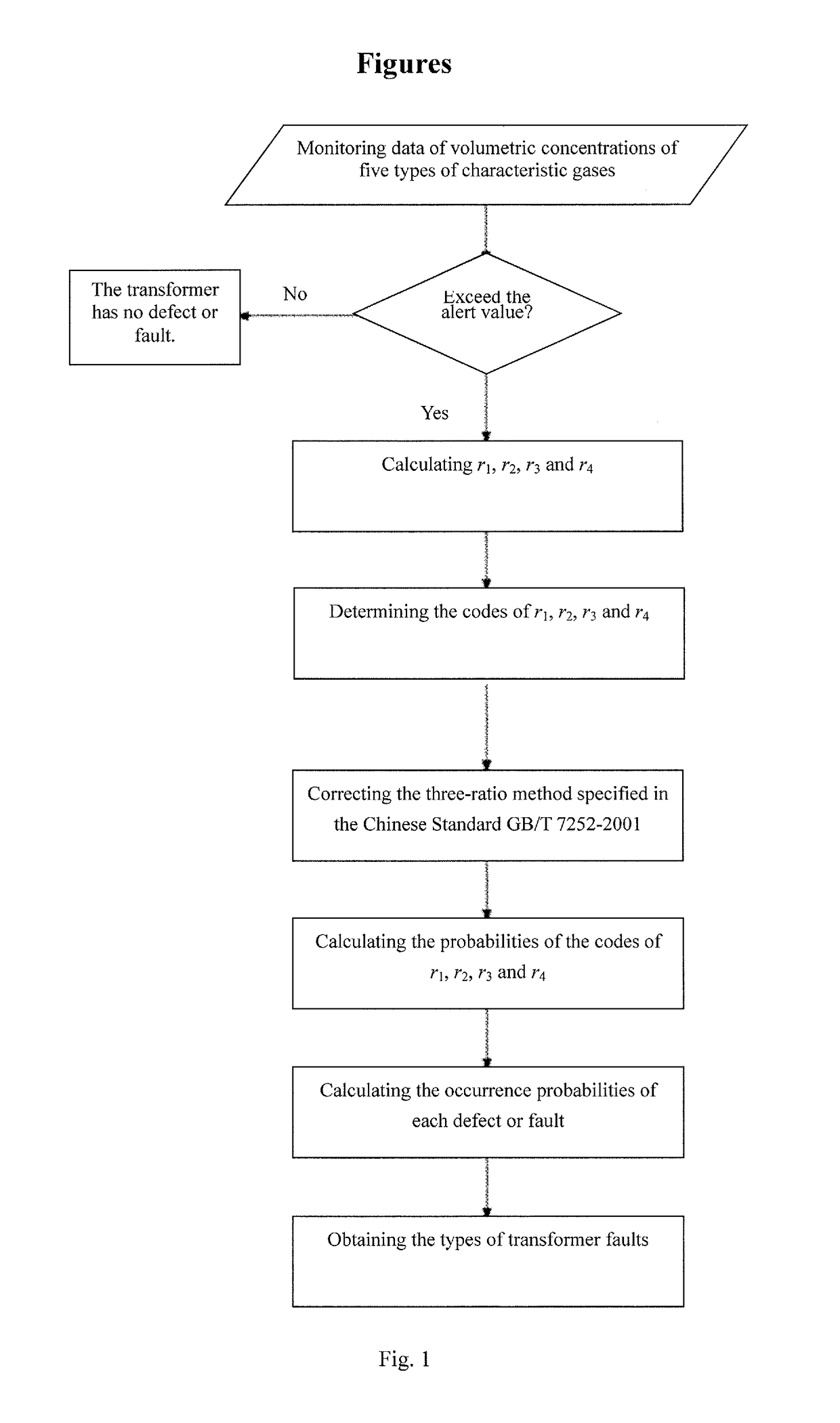

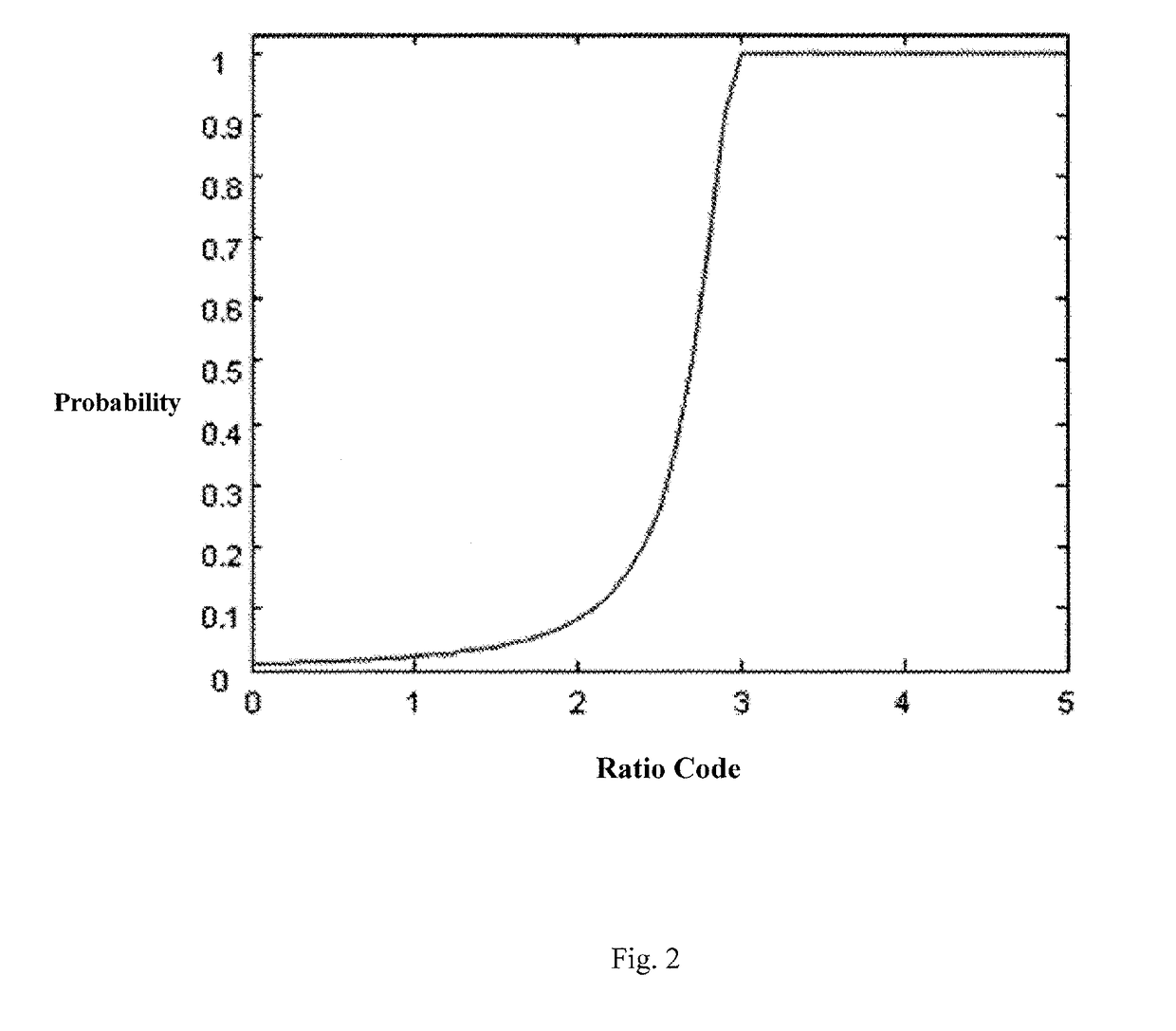

Internal transformer composite-defect fuzzy diagnostic method based on gas dissolved in oil

InactiveUS20170336461A1Improve effectivelyImprove reliabilityTesting/calibration apparatusTransformers testingTransformerMonitoring system

A transformer internal composite defect fuzzy diagnosis method based on gas dissolved in oil, comprising: a step of acquiring monitoring data of volume concentrations of five types of monitored feature gas; a step of determining ratio codes; a step of modifying a three-ratio method; a step of fuzzifying a boundary range; a step of calculating probabilities of the ratio codes; a step of calculating a probability of occurrence of each defect fault; and finally obtaining a fault type of a transformer. The method has the beneficial effects that: the method is simple and easy to achieve, and particularly suitable for being applied to an on-line transformer state monitoring system; based on a concept of fuzzy logic, diagnosis of composite defects of the transformer under a complicated state and evaluation of the degree of severity can be achieved, and the problem of sudden change caused by criterion boundary absolutisation can be effectively avoided; and multi-feature information such as an attention value and a ratio of the gas dissolved in the oil are merged and analysed, thereby effectively improving the diagnosis reliability.

Owner:STATE GRID CORP OF CHINA +2

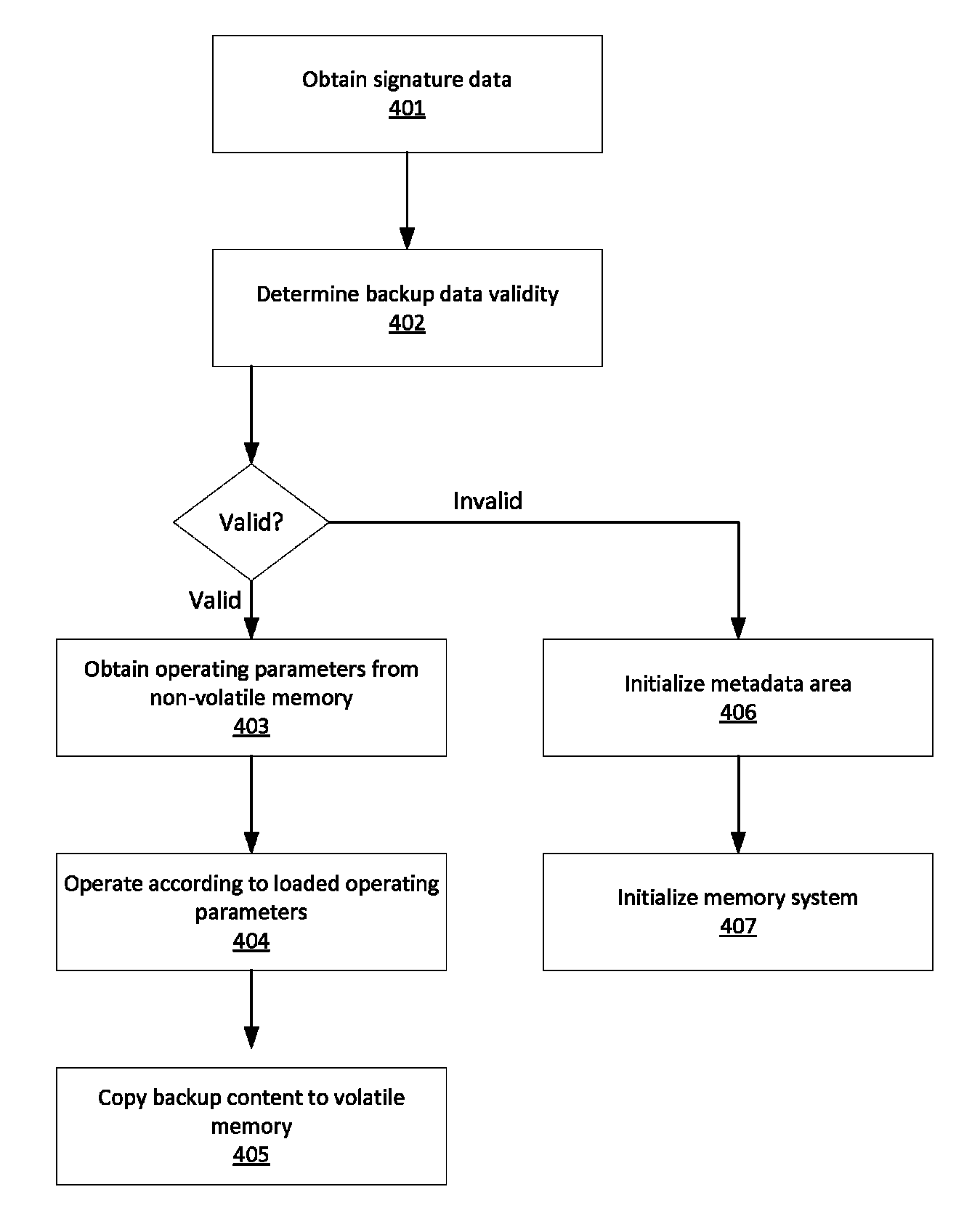

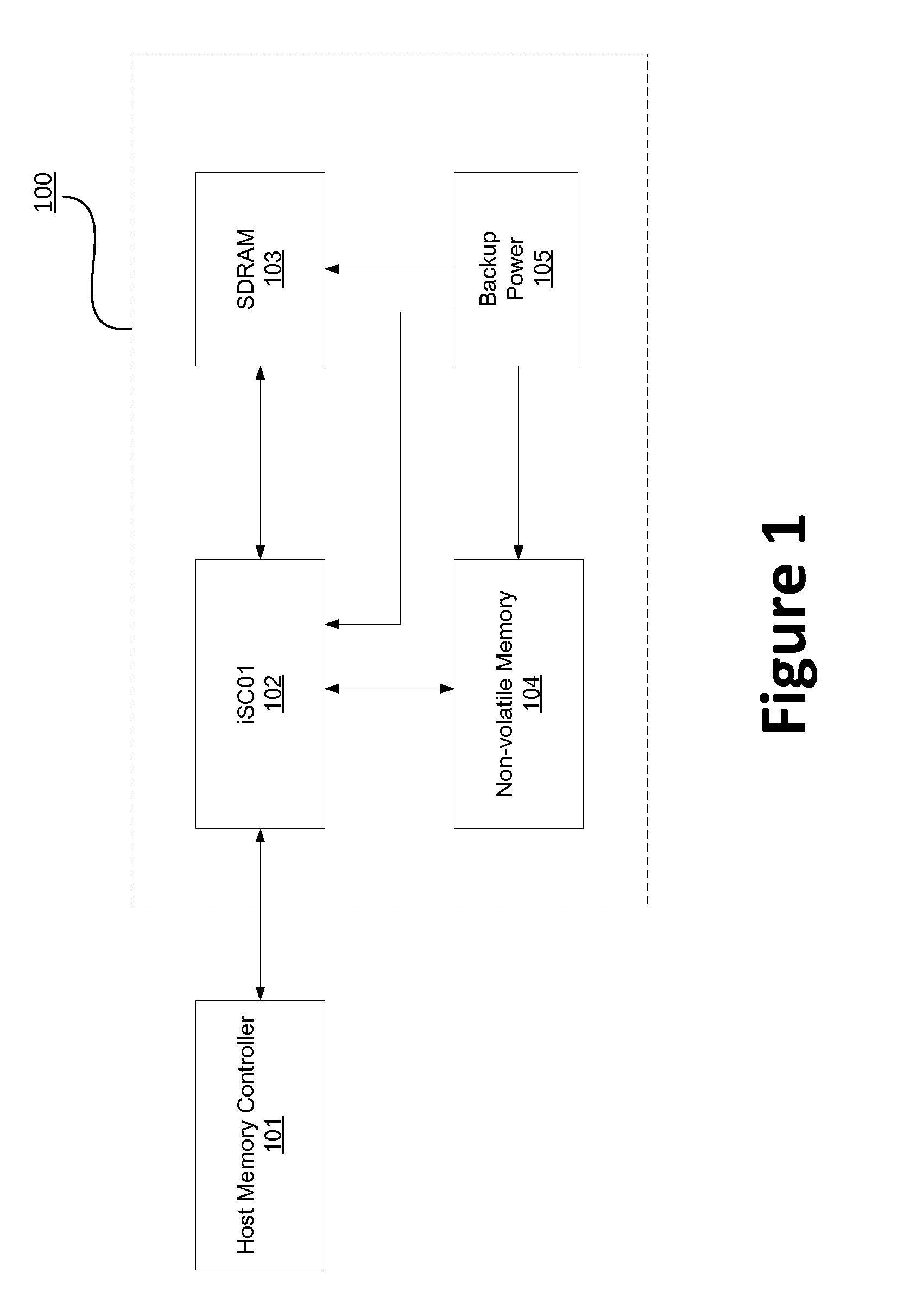

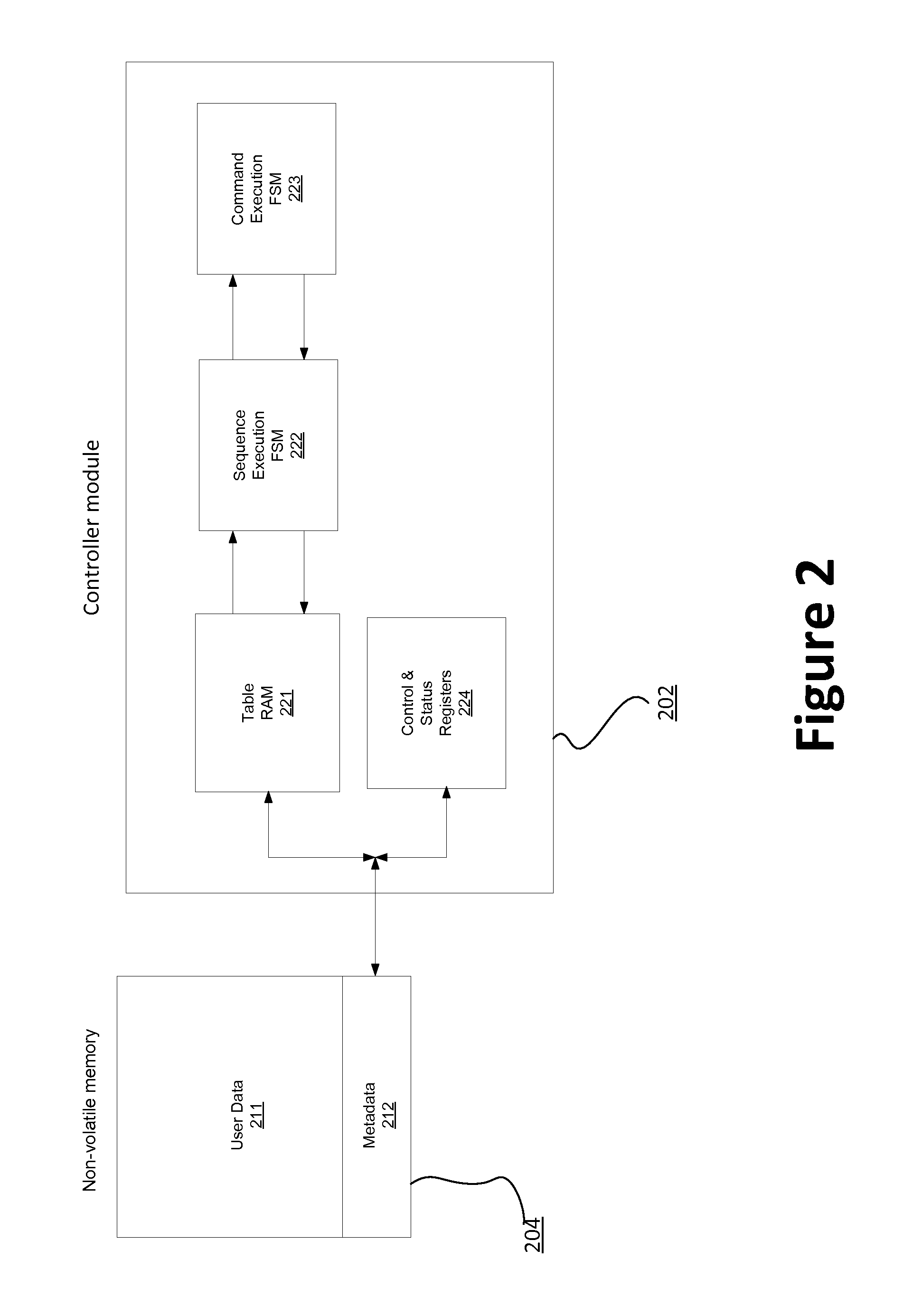

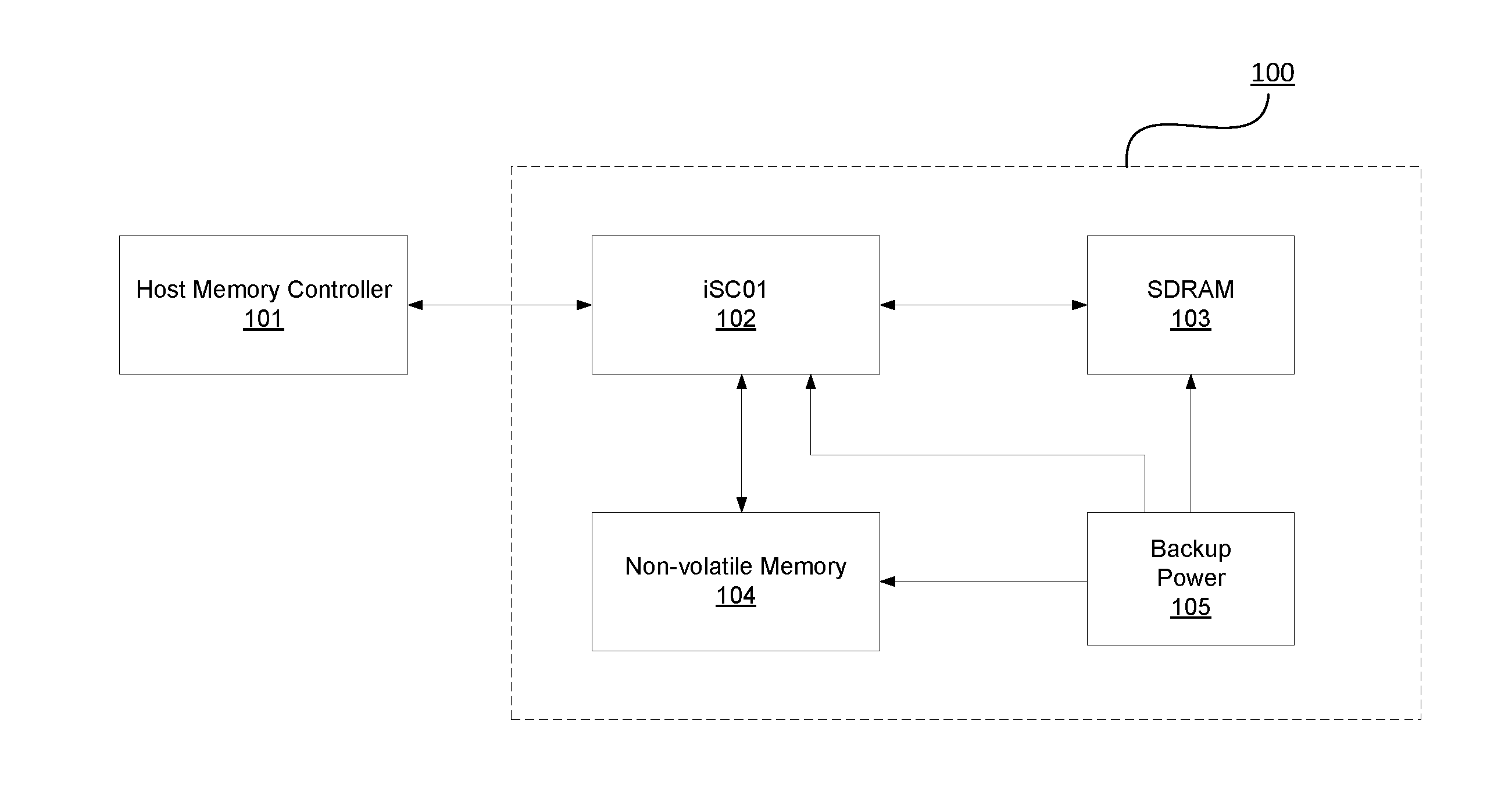

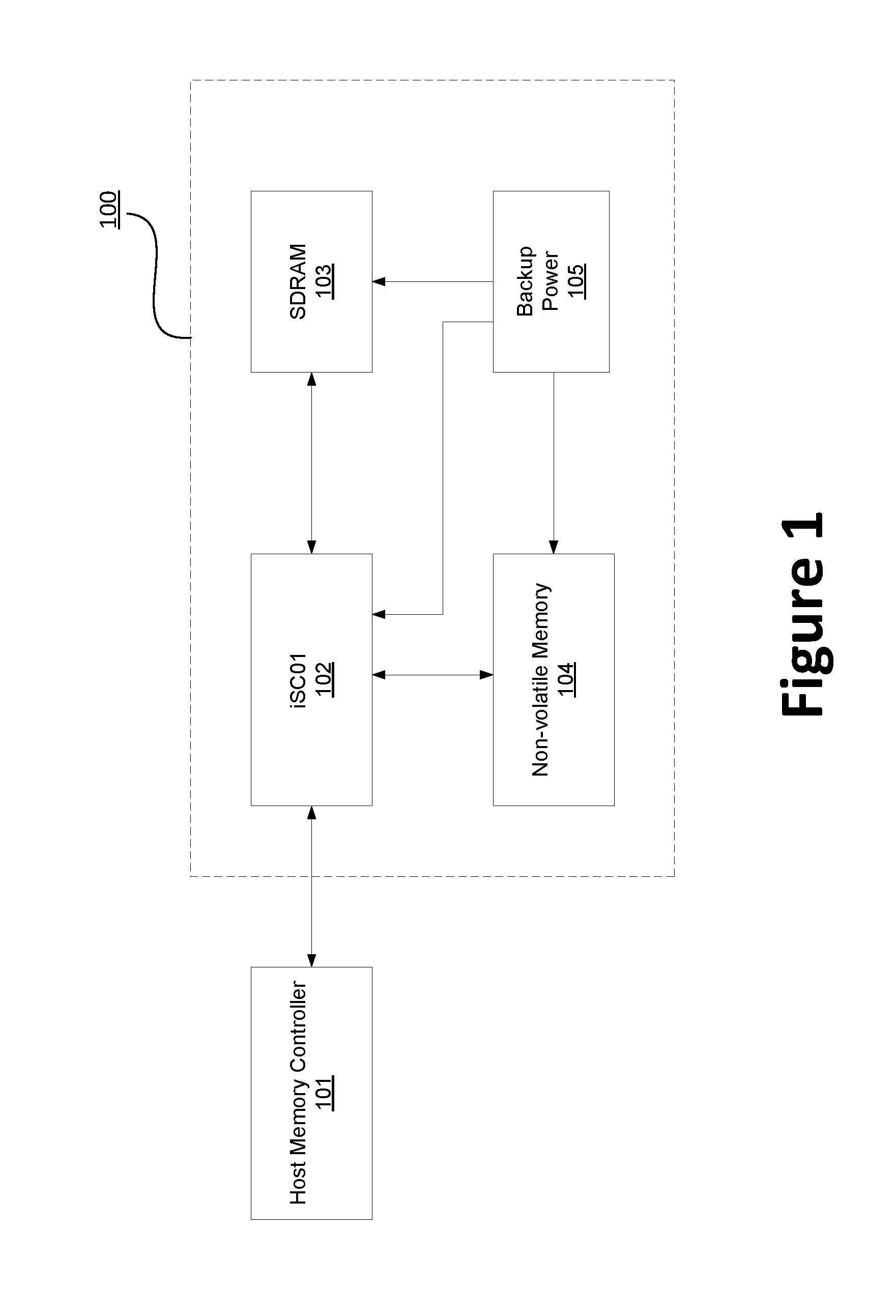

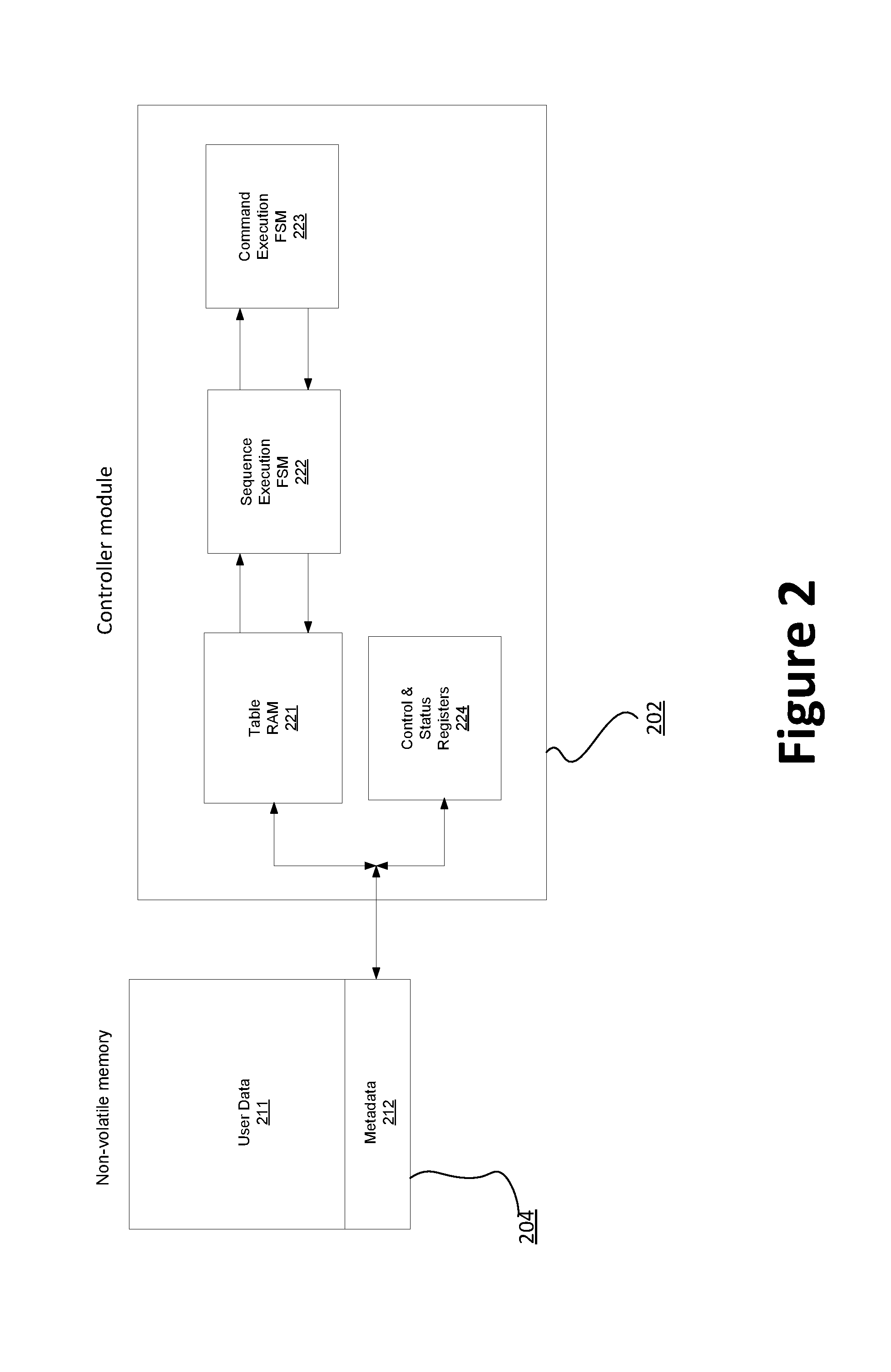

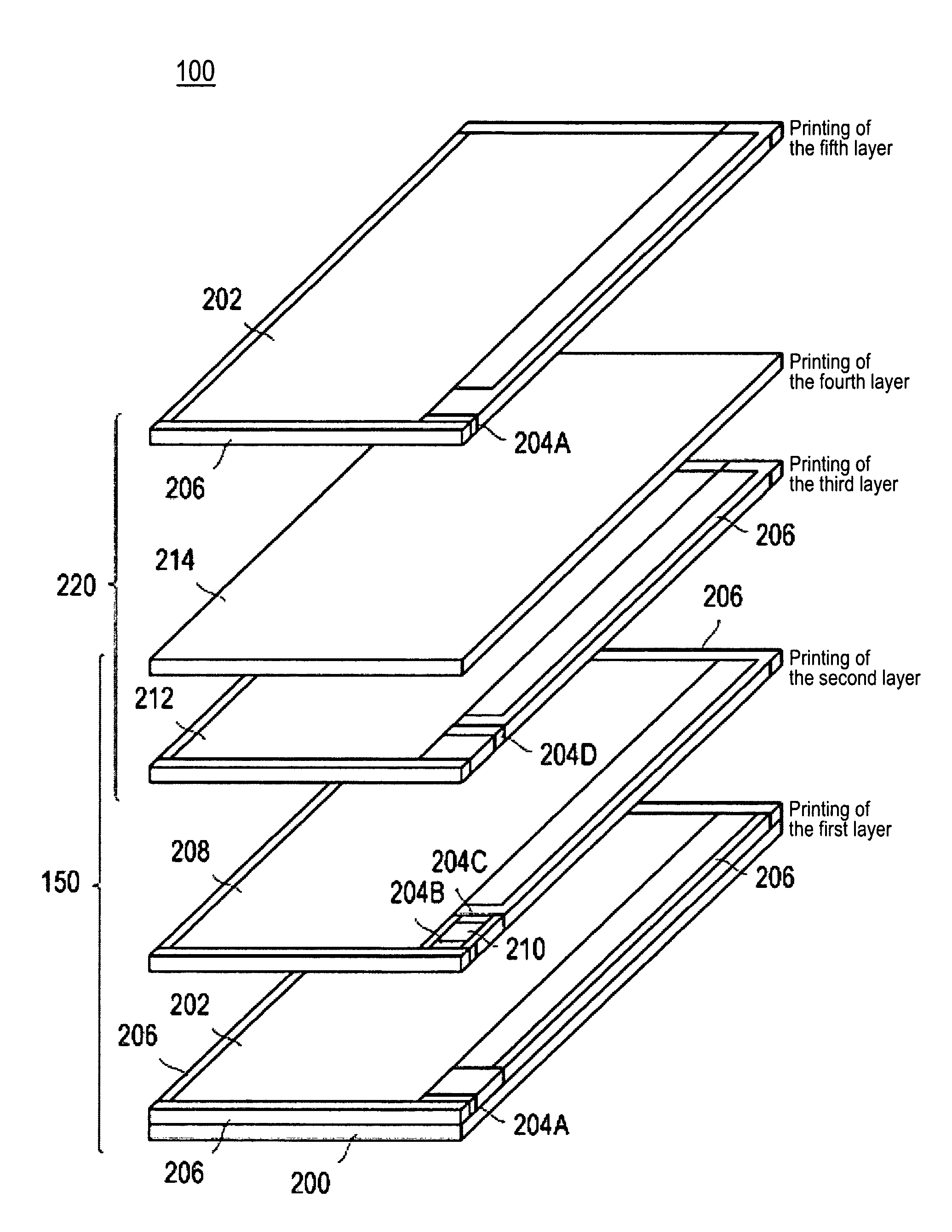

Memory controller system with non-volatile backup storage

ActiveUS9348705B1Easy to useEffective reliabilityMemory architecture accessing/allocationMemory adressing/allocation/relocationSystem recoveryControl system

The present invention is directed to computer storage systems and methods thereof. More specifically, embodiments of the present invention provide an isolated storage control system that includes both a non-volatile memory and a volatile memory. The non-volatile memory comprises a data area and a metadata area. In power failure or similar situations, content of the volatile memory is copied to the data area of the non-volatile memory, and various system parameters are stored at the metadata area. When the system restores its operation, the information at the metadata area is processed, and the content stored at the data area of the non-volatile memory is copied to the volatile memory. There are other embodiments as well.

Owner:RAMBUS INC

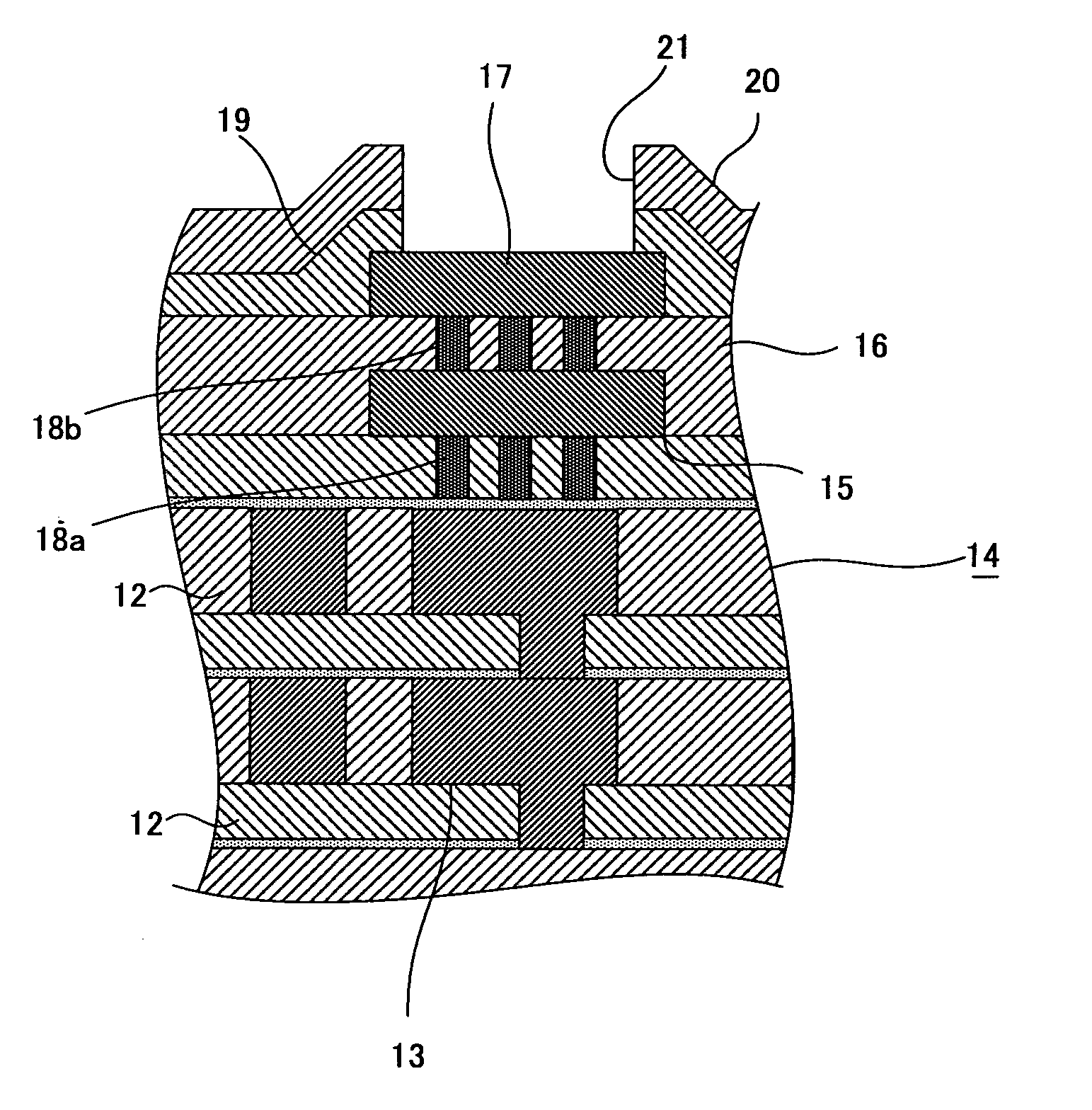

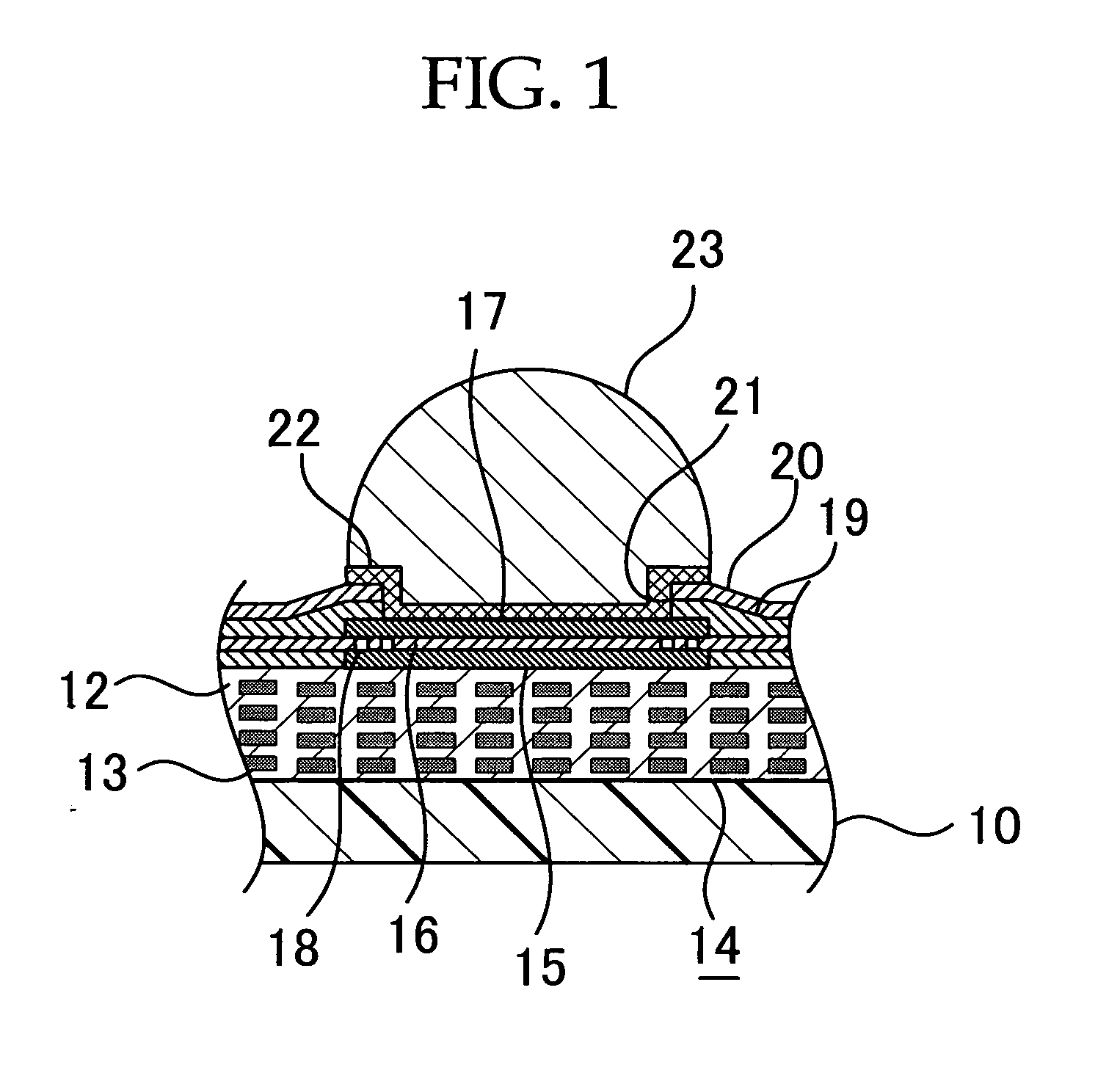

Semiconductor device and method for manufacturing the same

InactiveUS20070232056A1Great strengthHigh performance and reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

It is an object of the present invention to provide a semiconductor device with high performance and reliability, in which peeling off of interconnection layers or conductive layers due to thermal stress developed during packaging of a semiconductor substrate is suppressed, and thus electrical break down is prevented and an efficient method for manufacturing the semiconductor device. The semiconductor device of the present invention is characterized by having a semiconductor substrate, an interconnection layer 12, a first conductive layer 15, an interlayer insulating film 16 and a second conductive layer 17. The method for manufacturing the semiconductor device of the present invention is characterized by containing at least forming an interconnection layer, forming a first conductive layer, forming an interlayer insulating film and forming a second conductive layer so as to be electrically connected to the first conductive layer.

Owner:FUJITSU LTD

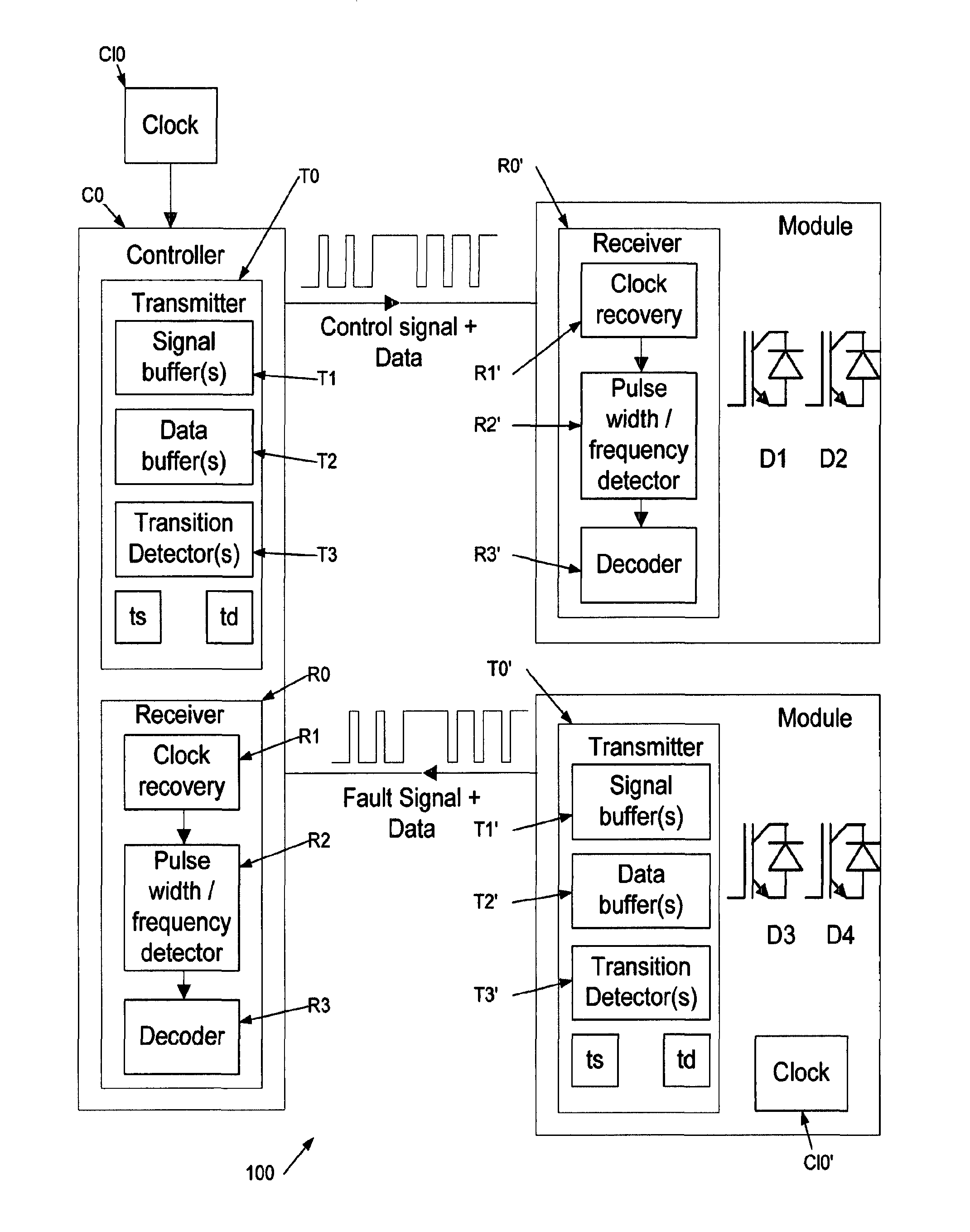

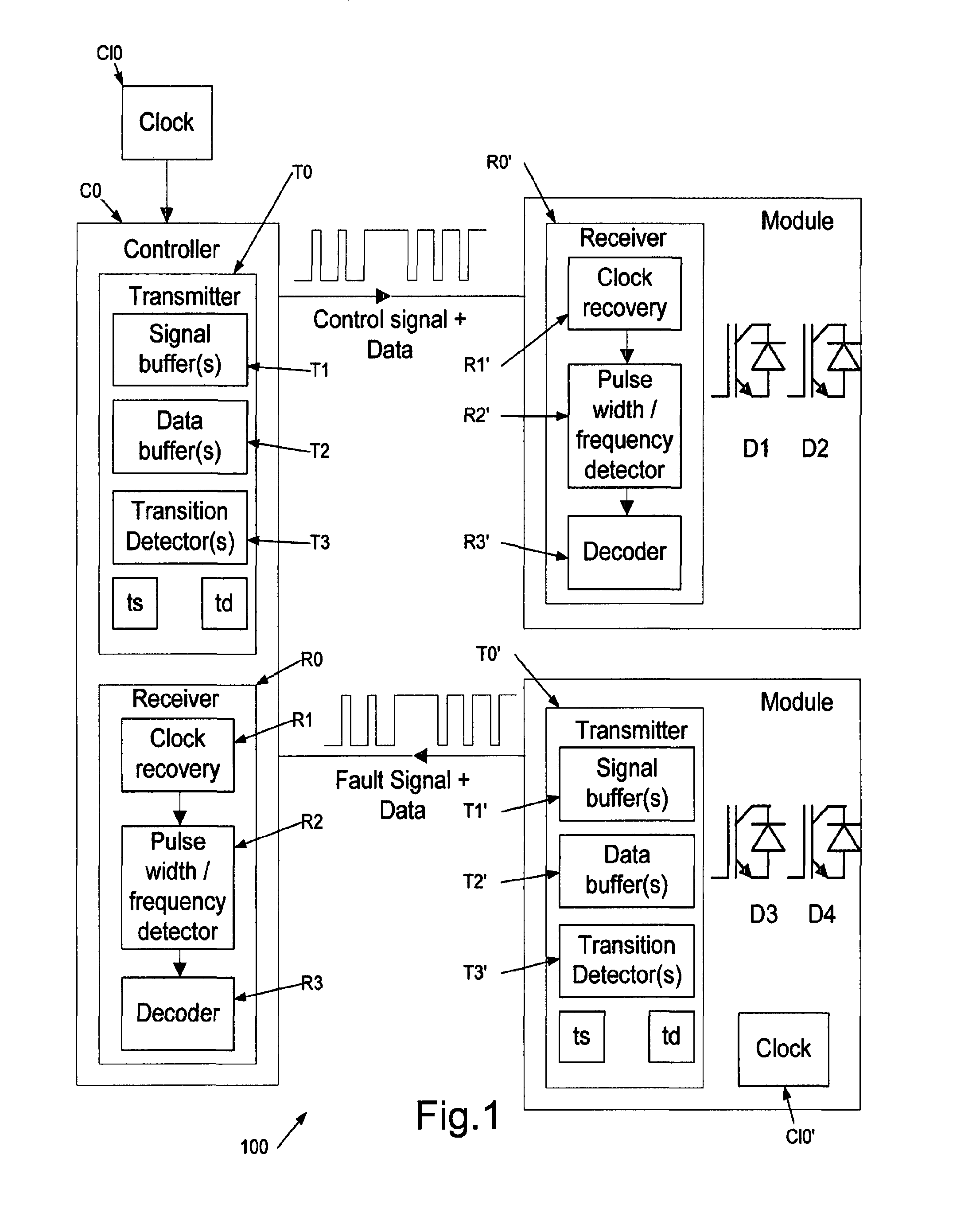

Low-skew communication system

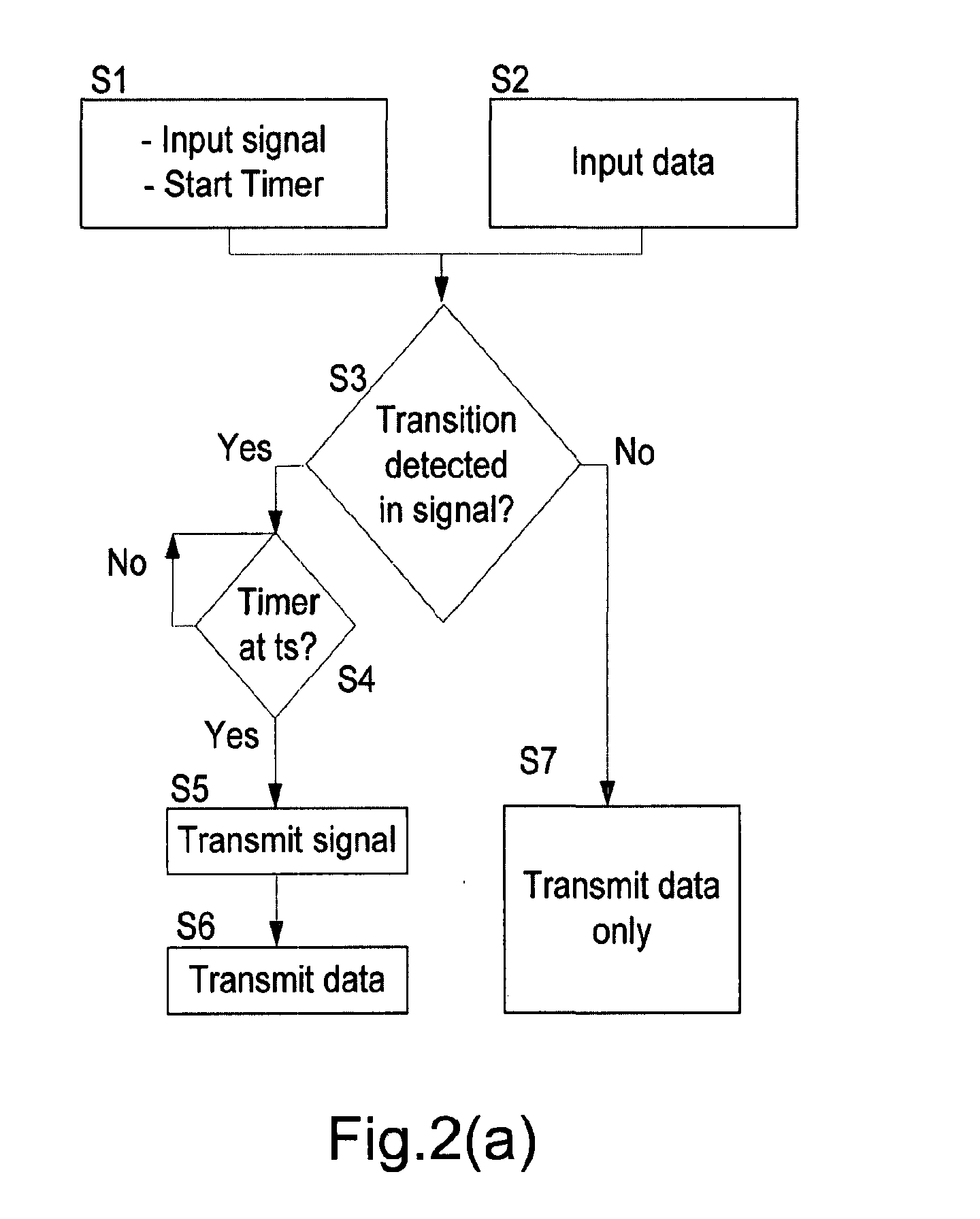

ActiveUS20160197560A1Reduce offsetRelieve pressureComputer controlAc-dc conversionTelecommunications linkCommunications system

The invention generally relates to power converters, and more particularly to a communications method for controlling at least one power switching device of a power converter, a communications system for a power converter, and a power converter comprising the communications system. For example there is provided a communications method for controlling at least one power switching device of a power converter, the method comprising: inputting a signal to a transmit end of a communications link; inputting data to the transmit end of the communications link; determining whether the signal comprises a transition; when said determination indicates that the signal comprises a transition, transmitting the signal comprising the transition into a communications channel of the communications link, wherein the transmitted signal is delayed by a predetermined time delay relative to the inputted signal, said predetermined time delay to allow said determining; transmitting the data on the communications channel, wherein when said determination indicates that the signal comprises a transition the transmitting the data is delayed until after said transmitting the signal; and if the signal has been transmitted, receiving the transmitted signal at the receive end of the communications link and controlling at least one said power switching device dependent on said received signal.

Owner:MASCHFAB REINHAUSEN GEBR SCHEUBECK GMBH & CO KG

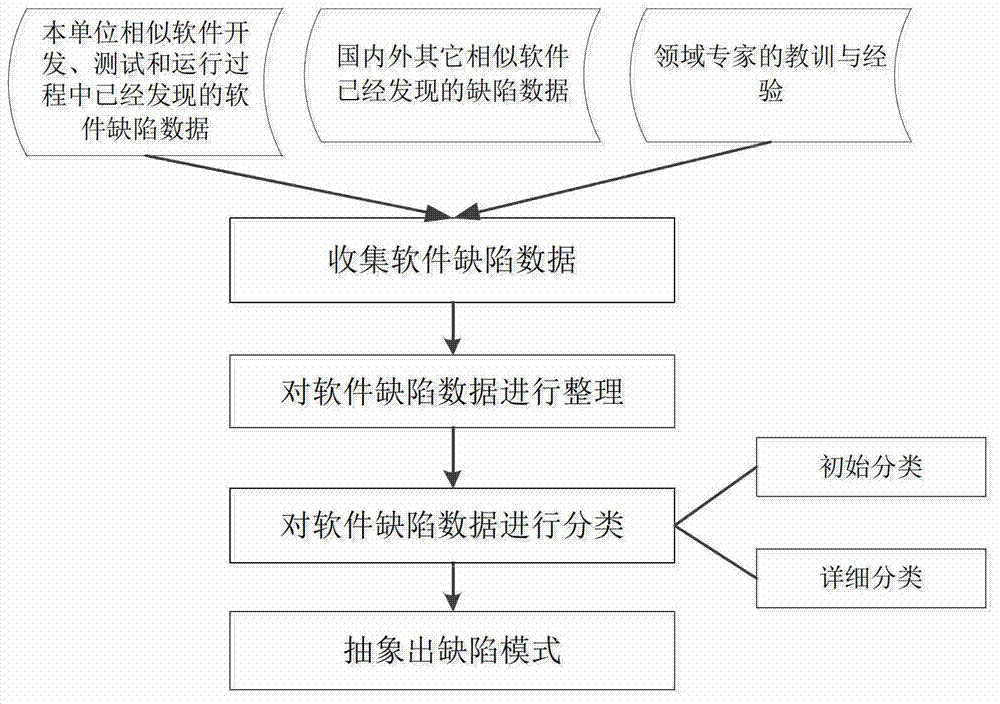

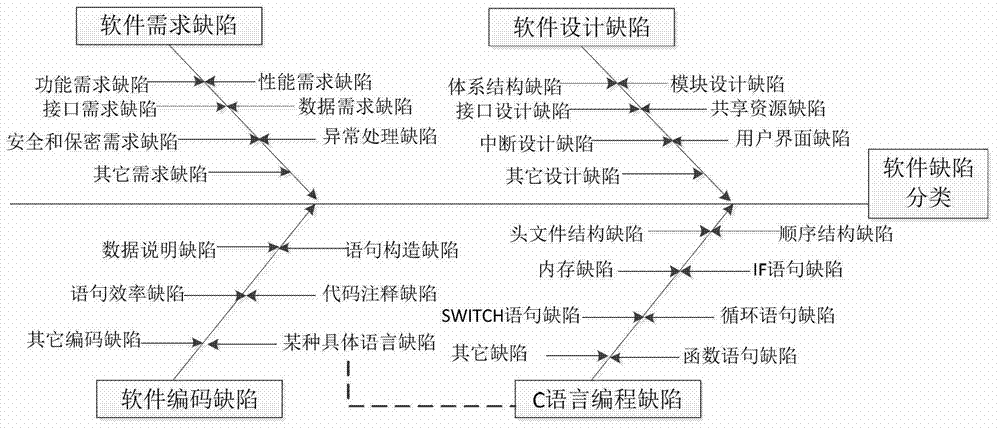

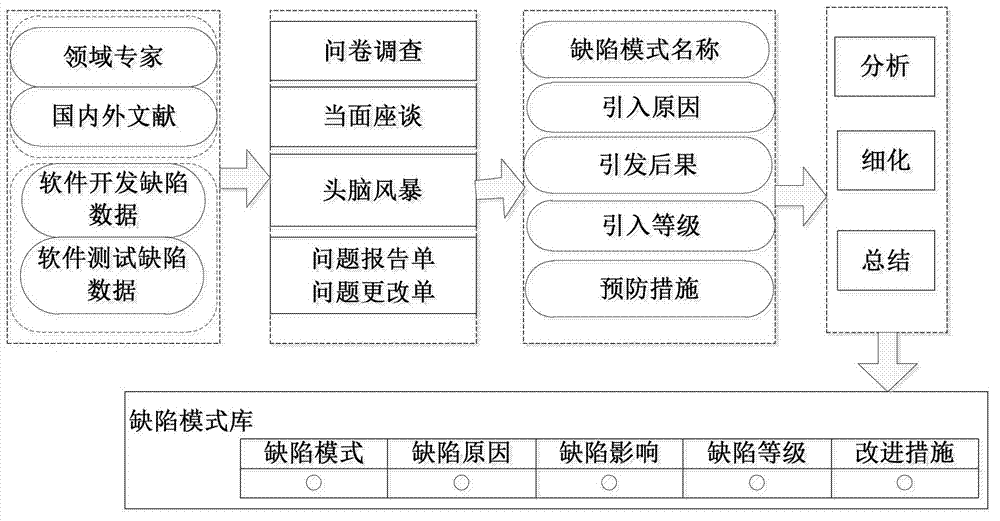

Software reliability designing method driven by defects

InactiveCN102819489AEffective reliabilityStrong targetingSoftware testing/debuggingDependabilityReliability design

The invention discloses a software reliability designing method driven by defects. According to the method, defect data of similar software are collected for recognizing potential defects in the software, make defect classification standards and establish a software detect model bank. On the basis of the detect model bank, causes of defects are perfected through software fault tree analysis (SFTA), and improvement measures are made according to the causes of defects, so that the implementation of a software reliability design technology is guided. According to the method disclosed by the invention, the implementation blindness of the software reliability design technology is overcome, the pertinence of a software reliability design is improved, the software reliability design can be carried out more effectively, defects can be prevented to the greatest extent and avoided as early as possible, the follow-up test and repair cost is greatly reduced, and the reliability of the software is improved more effectively.

Owner:BEIHANG UNIV

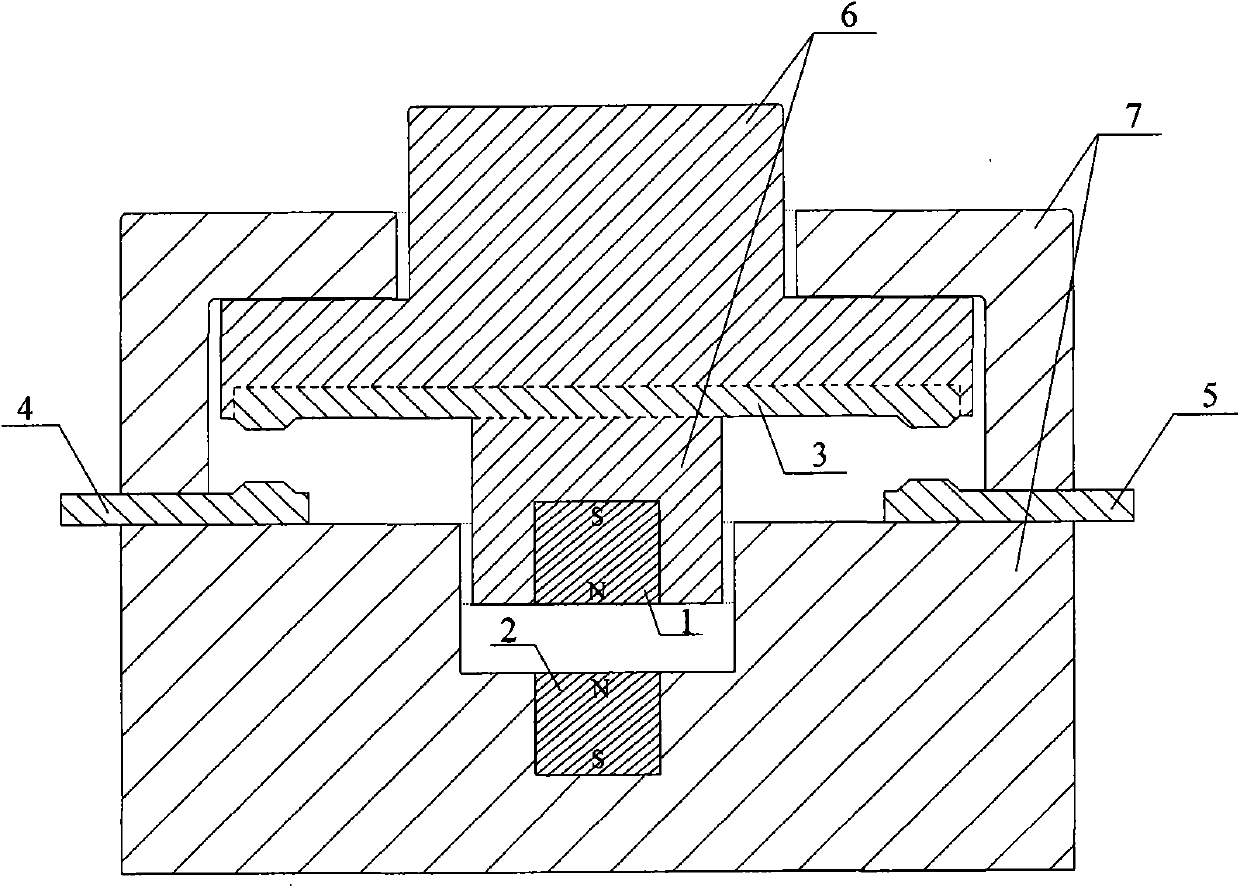

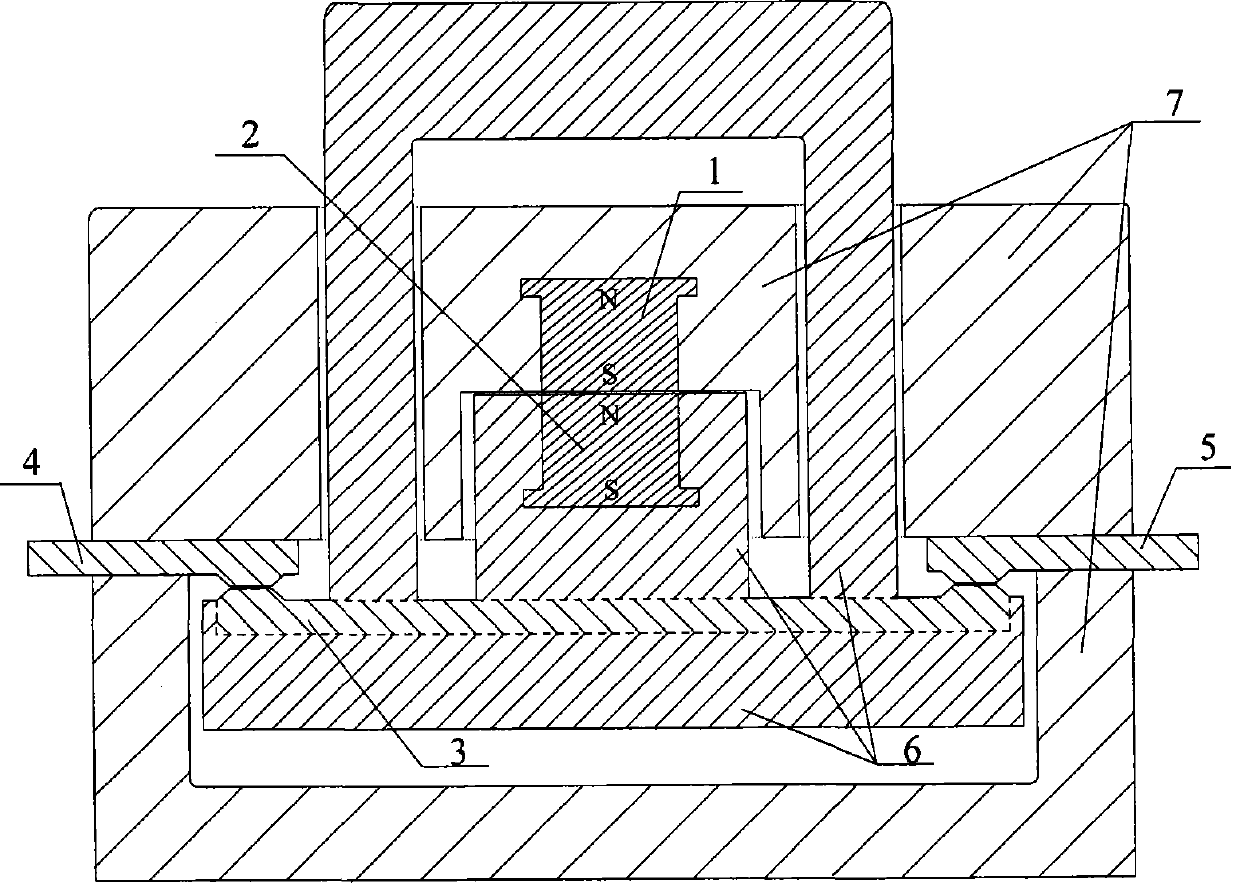

Magnetic button

InactiveCN103474291AEffective reliabilityAchieve thinningMagnetic/electric field switchesUltrasound attenuationEngineering

The invention provides a magnetic button which can achieve structural simplification and integral attenuation. Two permanent magnets are embedded in an outer shell and a touch column respectively, a movable contact is fixed to the touch column, a fixed contact is fixed to the outer shell, and under the mutual action of the two permanent magnets and the action of pressing the button externally, the touch column drives the movable contact to be connected or disconnected with the fixed contact in an outer shell moving chamber. The connection and the disconnection of a switch are controlled by pressing the button, and when the button is released, the switch is reset immediately through the action of force generated by the repellent of the same poles or the attraction of the opposite poles between the two permanent magnets. According to the relation of the force of the repellent of the same poles and the force of the attraction of the opposite poles between the two permanent magnets and a distance, the shorter the distance is, the larger the force is, and the longer the distance is, the smaller the force is. The magnetic touch switch can be connected by gradually increasing the force of pressing the button when the magnetic touch switch is dynamically connected, the force of pressing the button needs to overcome larger force at the very start so that the switch can be dynamically disconnected, and therefore the effective reliability of dynamically connecting and disconnecting the switch can be guaranteed.

Owner:北京威凯龙科技发展股份有限公司

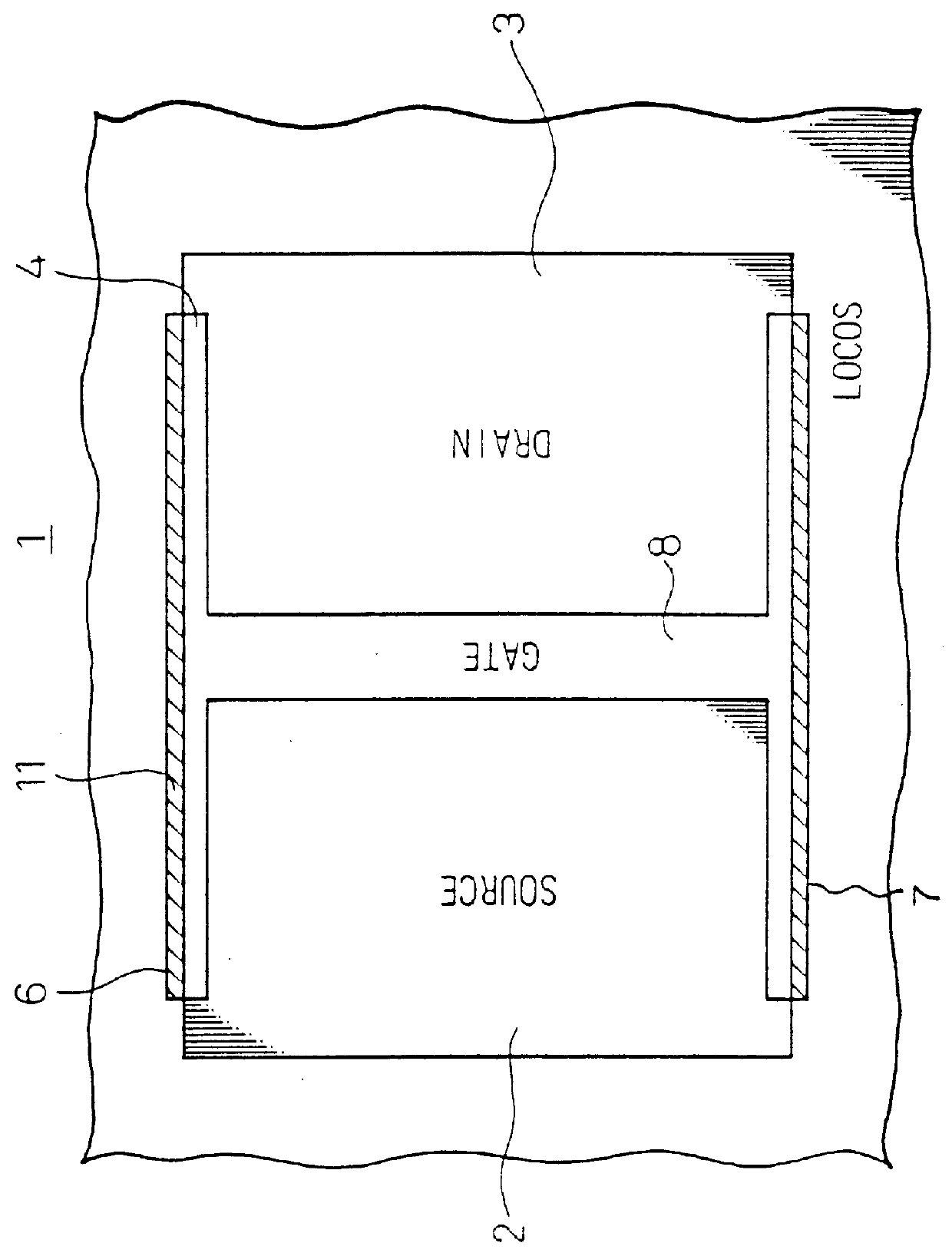

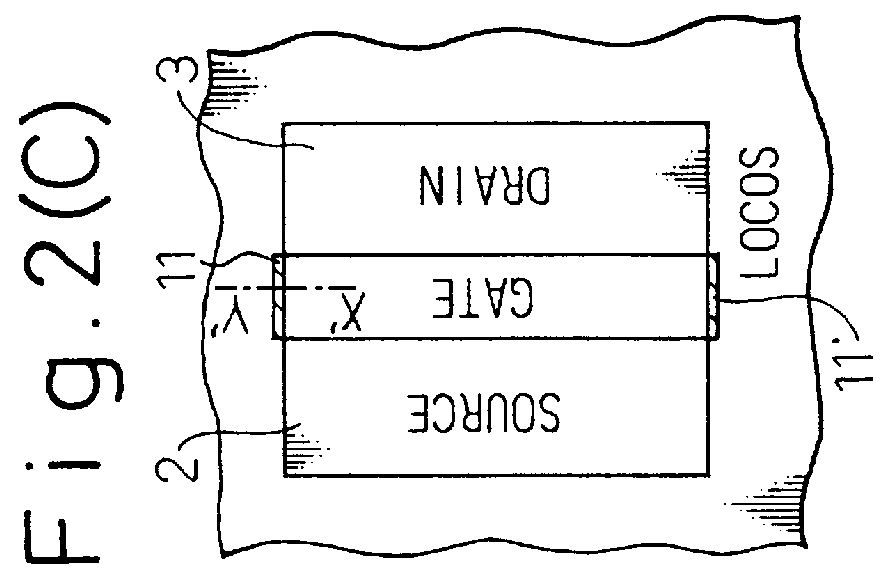

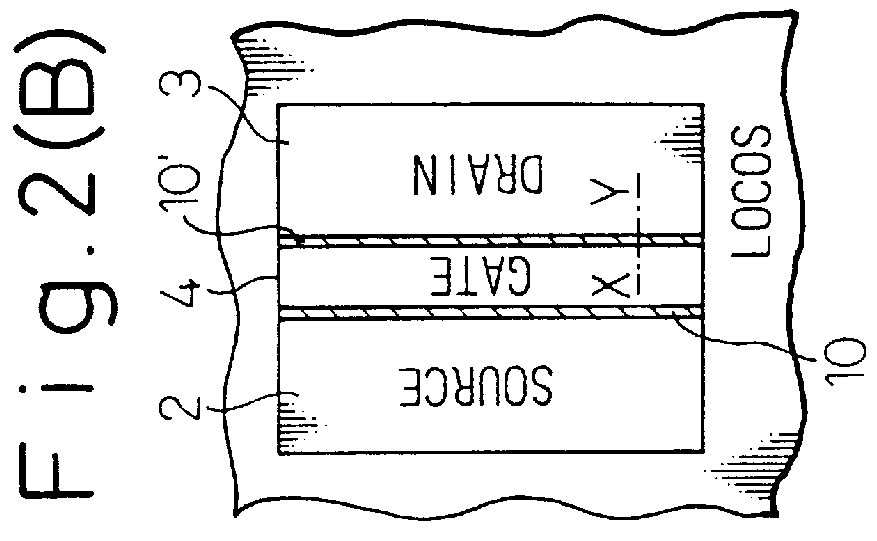

Method of producing semiconductor devices and method of evaluating the same

InactiveUS6031246AEffective reliabilityImprove defectsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsBeak shapeDevice material

A simulation method capable of efficiently evaluating reliability of gate oxide films formed on the elements within short periods of time to evaluate characteristics of a semiconductor device made up of elements of any size and any number. In a semiconductor device having transistors formed thereon, a pattern for evaluating characteristics of a semiconductor device characterized in that gate area portions, gate bird's-beak portions and LOCOS bird's-beak portions, are factors affecting the insulation breakdown of the gate oxide film, are rendered to be variable, so that the shapes of these portions can be handled as independent parameters.

Owner:FUJITSU LTD

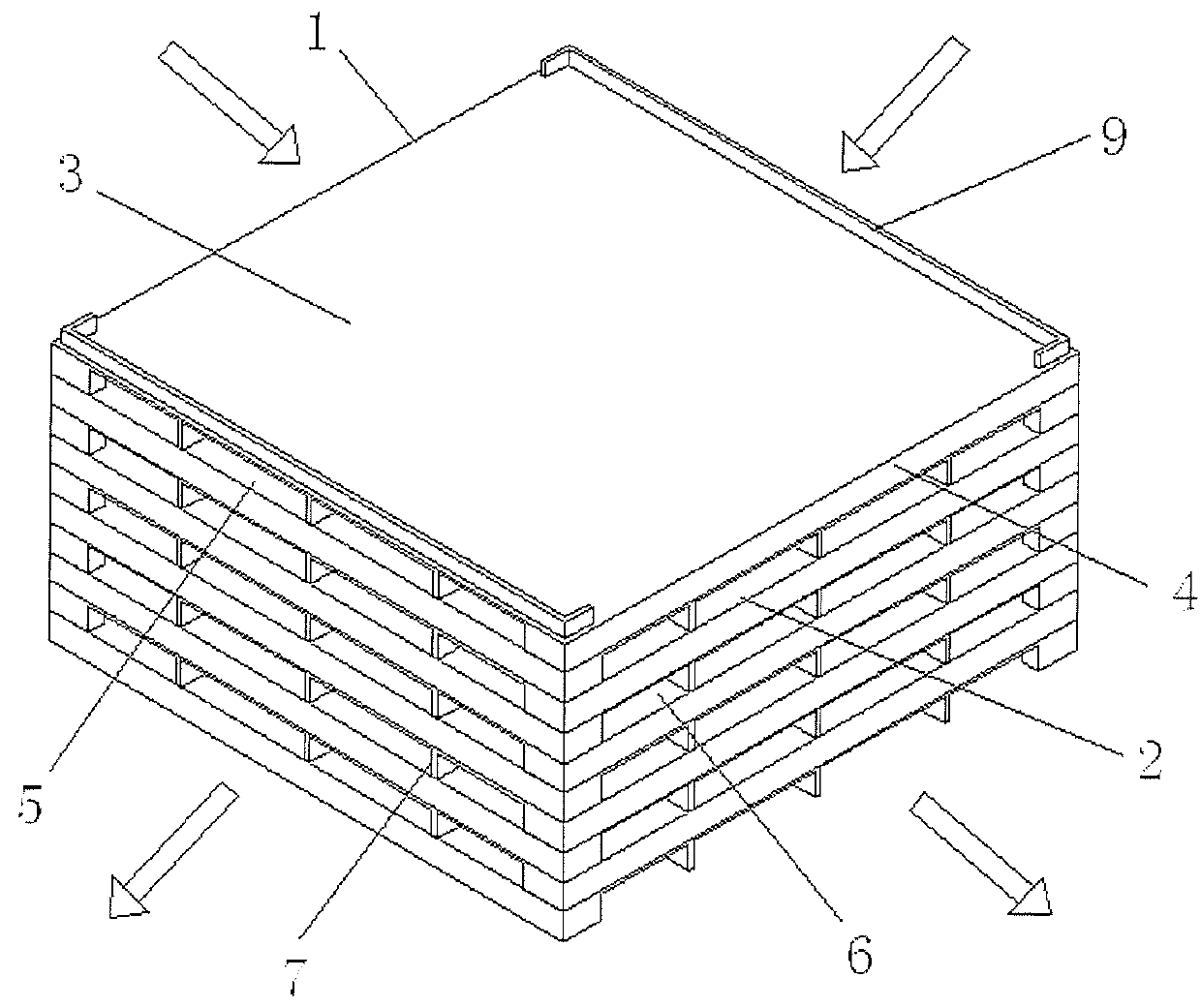

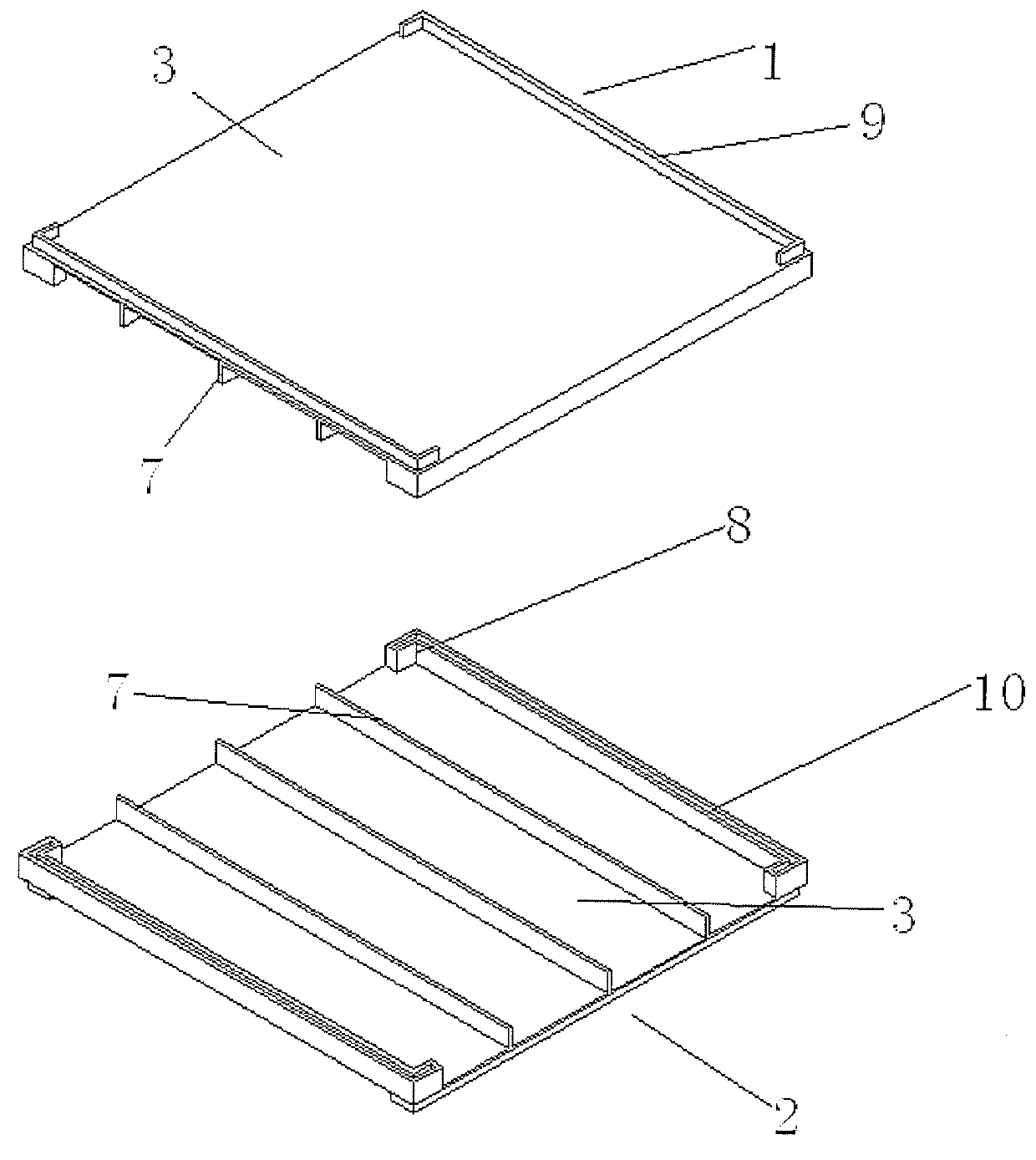

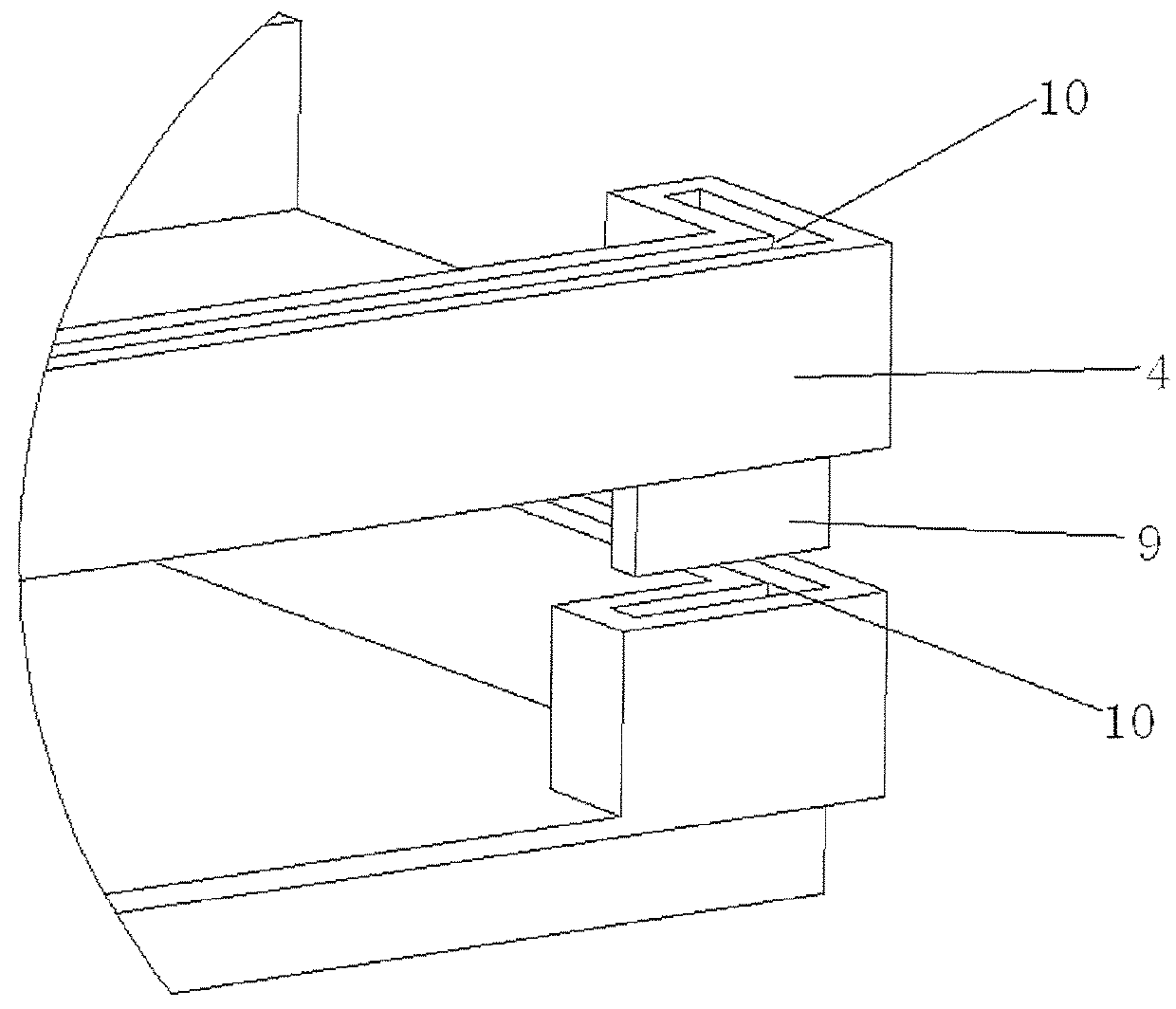

Stacked Plate Heat Exchanger With Form Fitting Connection Of The Plates

ActiveUS20180266774A1Improve stabilityEffective reliabilityHeat recovery systemsHeat exchanger fasteningPlate heat exchangerEngineering

The present invention provides a heat exchanger, comprising a plurality of first heat exchange plates (1) and second heat exchange plates (2) that are connected sequentially and at an interval; the first heat exchange plates (1) and the second heat exchange plates (2) each comprise a heat exchange sheet (3) and a heat exchange frame (4) disposed on side ends of the heat exchange sheet (3); the side ends of the heat exchange sheet (3) are formed with a snap projection (9) in a direction away from the heat exchange frame (4); the heat exchange frame (4) is formed with a snap groove (10); the first heat exchange plates (1) and the second heat exchange plates (2) are in interference connection through the engagement between the snap projection (9) and the snap groove (10); an air channel (5, 6) is formed between a first heat exchange plate (1) and an adjacent second heat exchange plate (2), the air inlet of the first heat exchange plate (1) and the air inlet of the second heat exchange plate (2) have different directions, and the air outlet of the first heat exchange plate (1) and the air outlet of the second heat exchange plate (2) have different directions. The present invention puts the first heat exchange plate (1) and the second heat exchange plate (2) in interference connection through the engagement between the snap projection (9) and the snap groove (10), which effectively ensures stability and reliability of the connection, and ensures the airtightness of the connection.

Owner:ZEHNDER VERKAUFS UND VERW

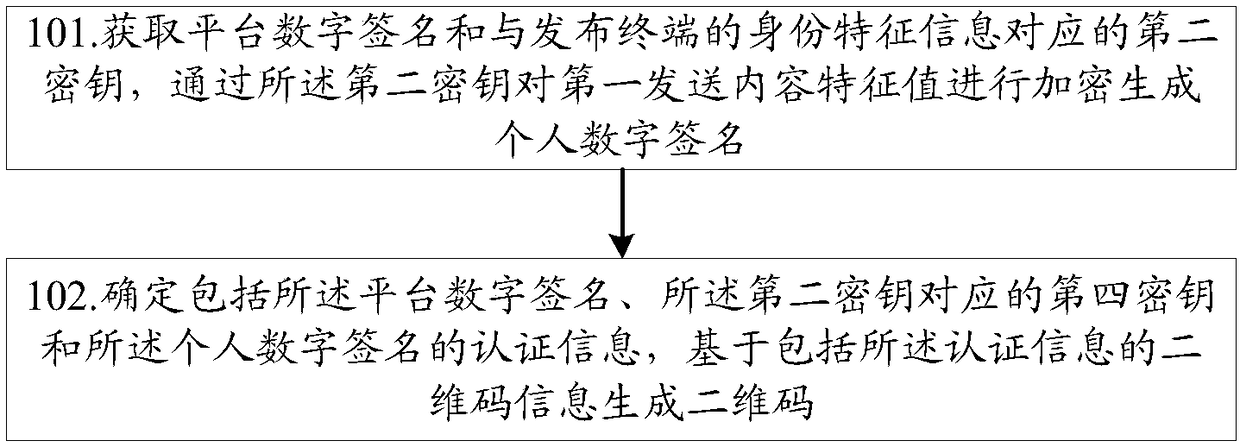

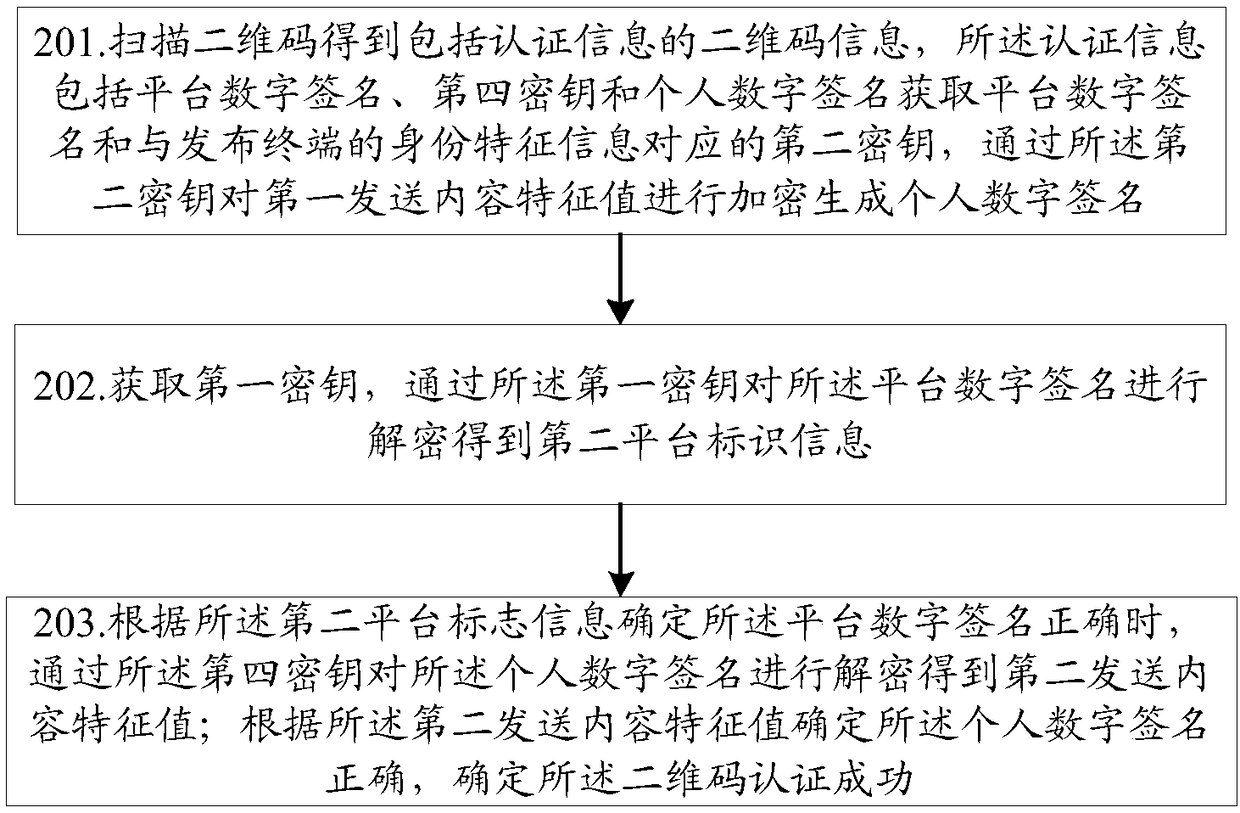

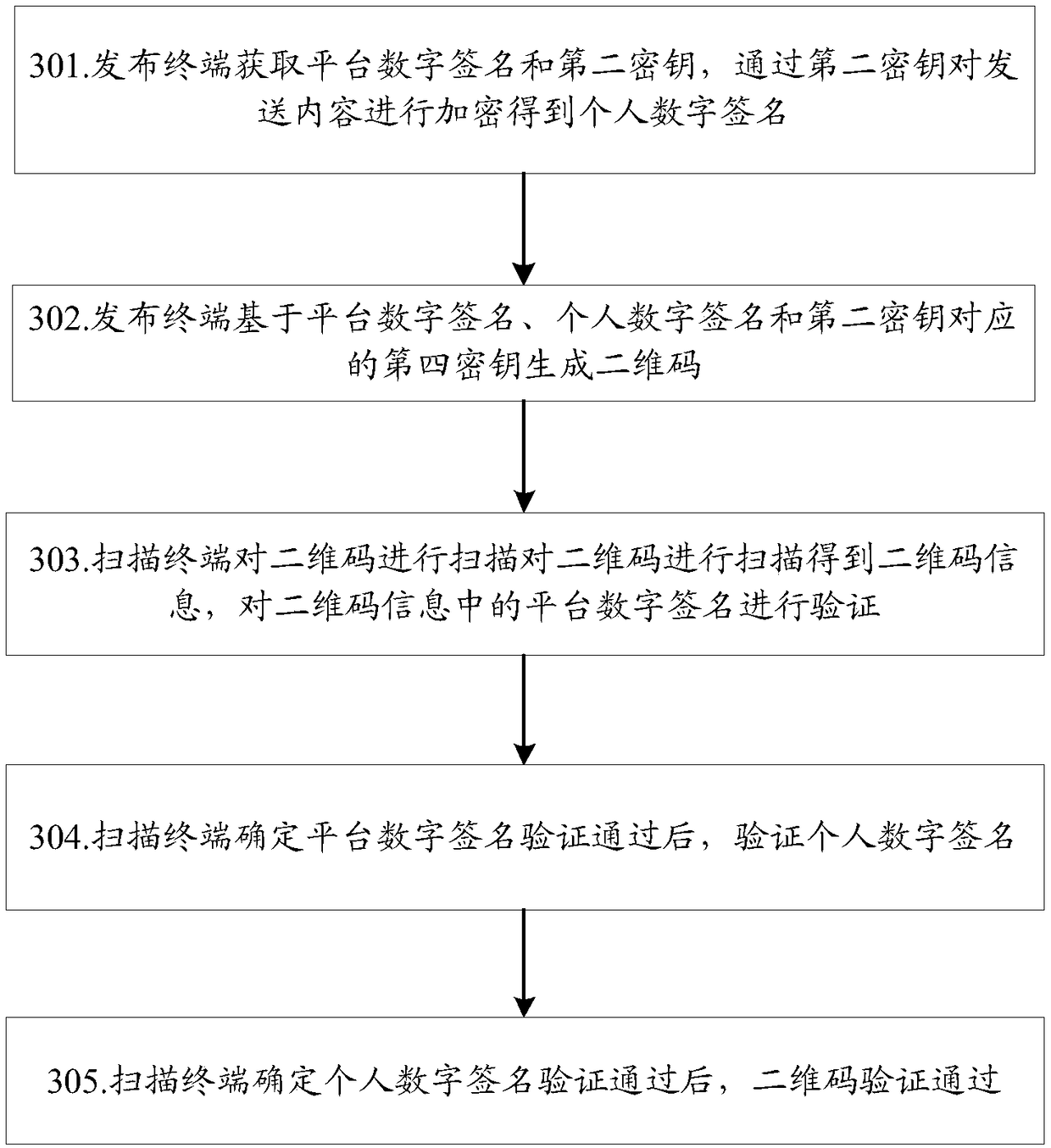

QR code authentication method and device, and computer readable storage medium

ActiveCN109495268AEffective reliabilityEffective securityKey distribution for secure communicationUser identity/authority verificationDigital signatureComputer terminal

The invention discloses a QR code authentication method. The method comprises the following steps: acquiring a platform digital signature and a second key corresponding to identity feature informationof a release platform; encrypting the first sending content feature value through a second key to generate personal digital signature, wherein the platform digital signature is obtained by encryptingthe first platform identification information through the first key; determining authentication information including the platform digital signature, a fourth key corresponding to the second key andthe personal digital signature, and generating a QR code based on the QR code information including the authentication information. The invention further discloses a QR code authentication device anda computer readable storage medium.

Owner:CHINA MOBILE COMM GRP CO LTD +1

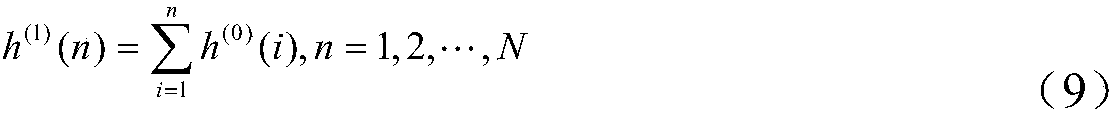

Method for forecasting trend of health degree with intelligent electric meter based on GM (1,1)

ActiveCN109358306AEffective reliabilityEffective guidanceElectrical measurementsTrend predictionReliability engineering

The invention relates to a method for forecasting trend of health with intelligent electric meter based on GM(1,1), specifically comprising the following steps of: step (1): carrying out evaluation onthe health degree of the intelligent electric meter, and obtaining the health degree indicator data of the intelligent electric meter; step (2): establishing a model for forecasting trend of health degree with intelligent electric meter based on GM(1,1) using the intelligent electric meter indicator data; step (3): carrying out trend prediction on the health degree of the intelligent electric meter. The method for forecasting trend of health degree with intelligent electric meter based on GM (1,1) obtains the overall health degree of the intelligent electric meter through the health degree comprehensive evaluation index of the intelligent electric meter, and provides effective suggestions and reliable guidance for the pre-judgment of the intelligent electric meter in the regional scope.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

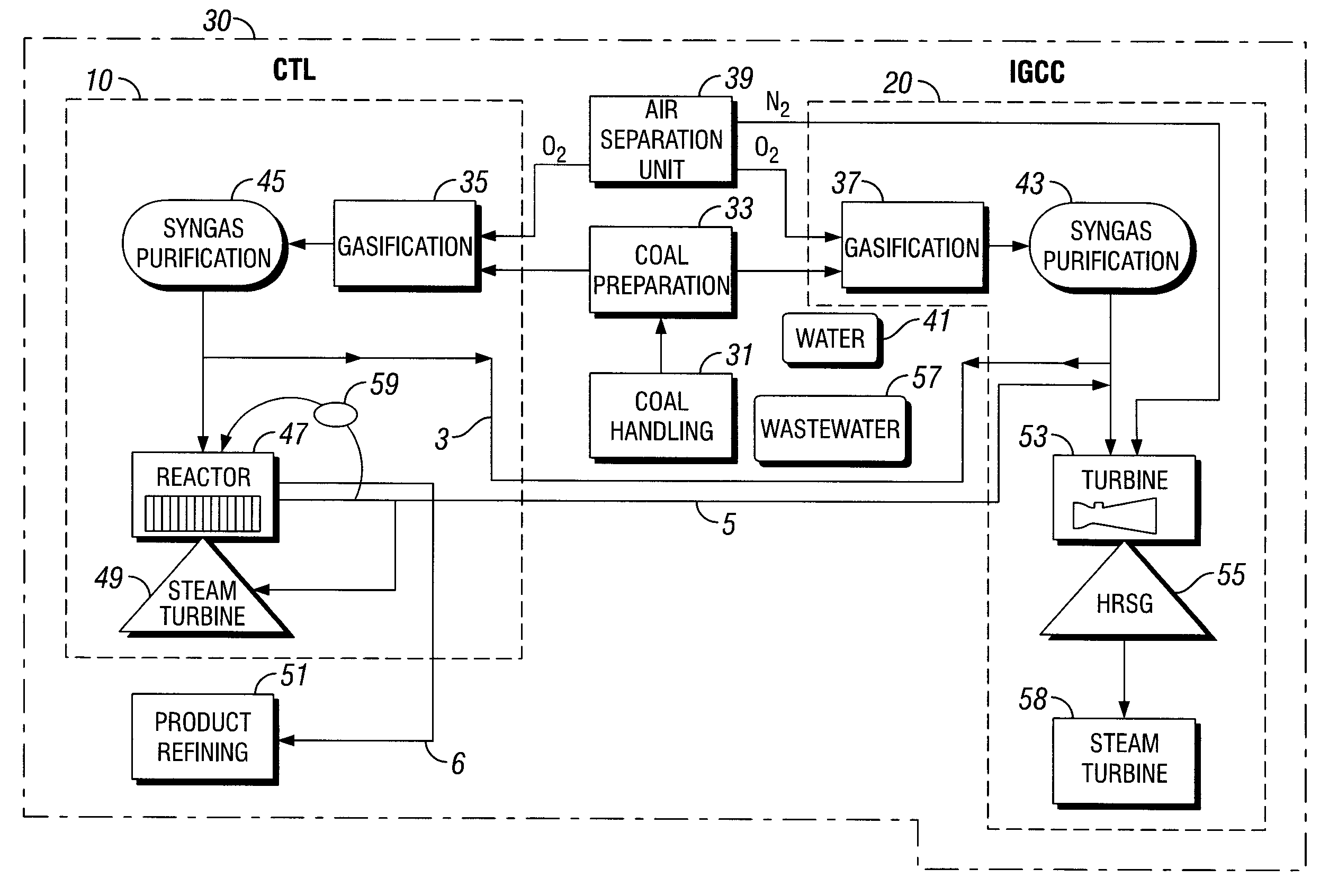

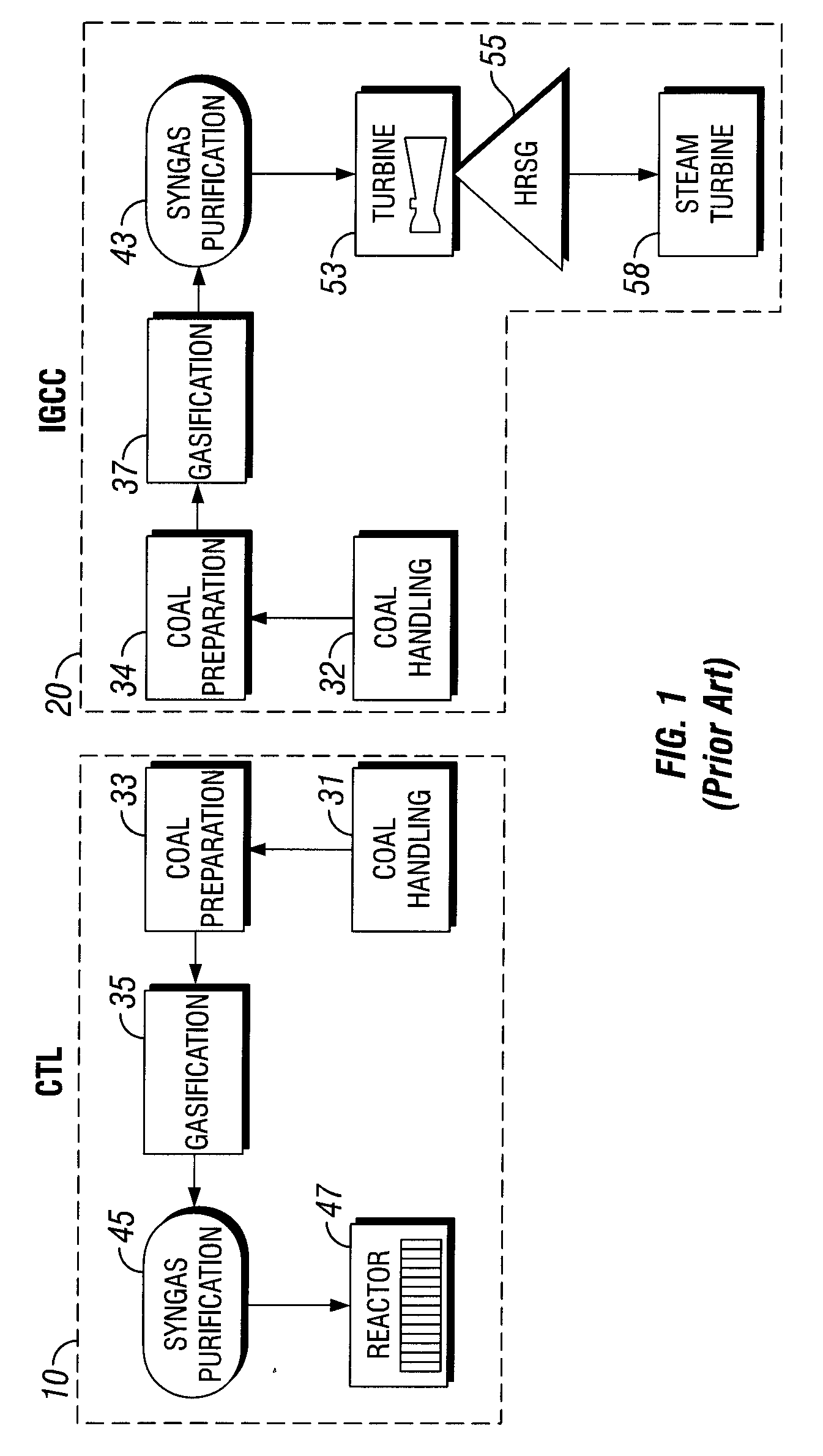

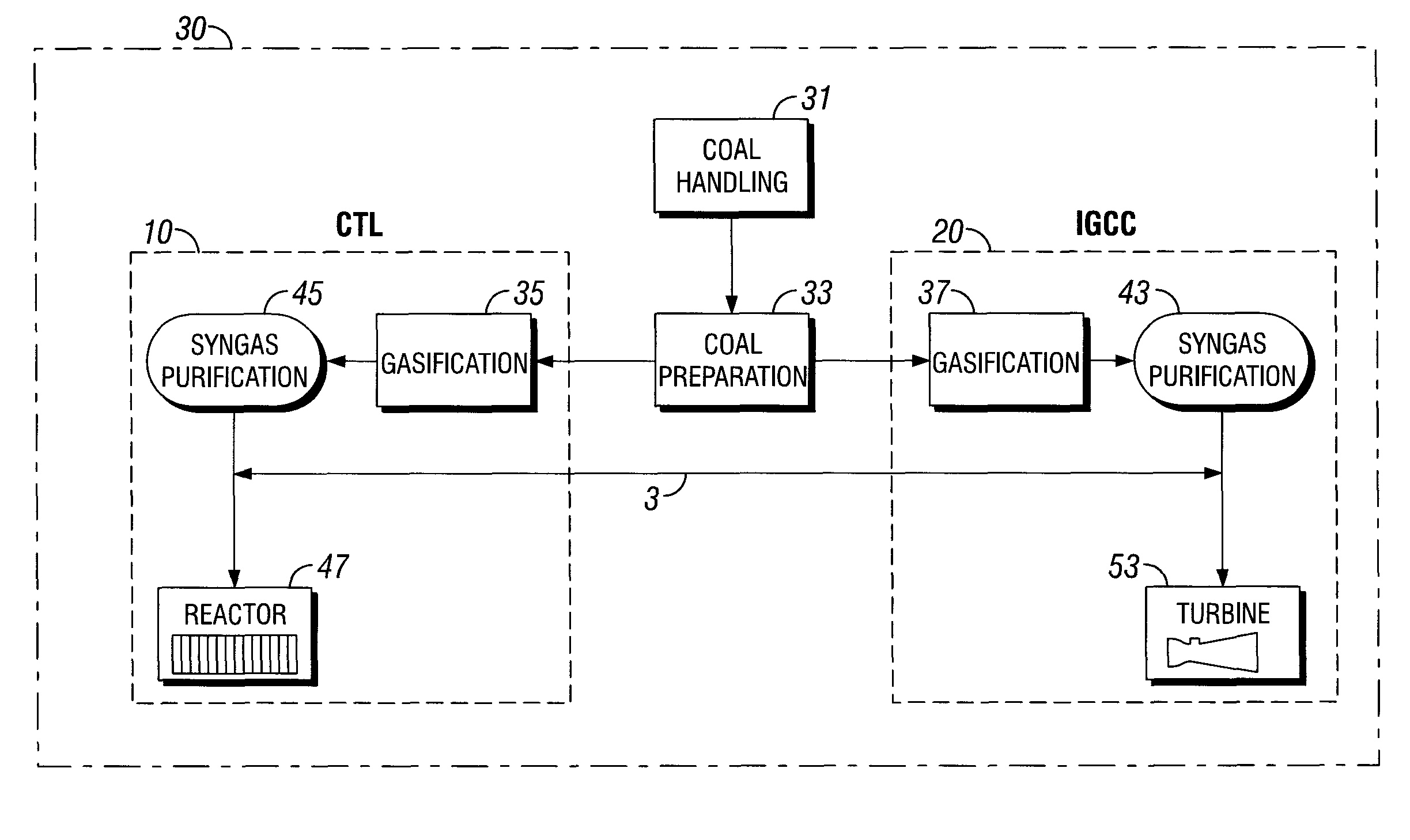

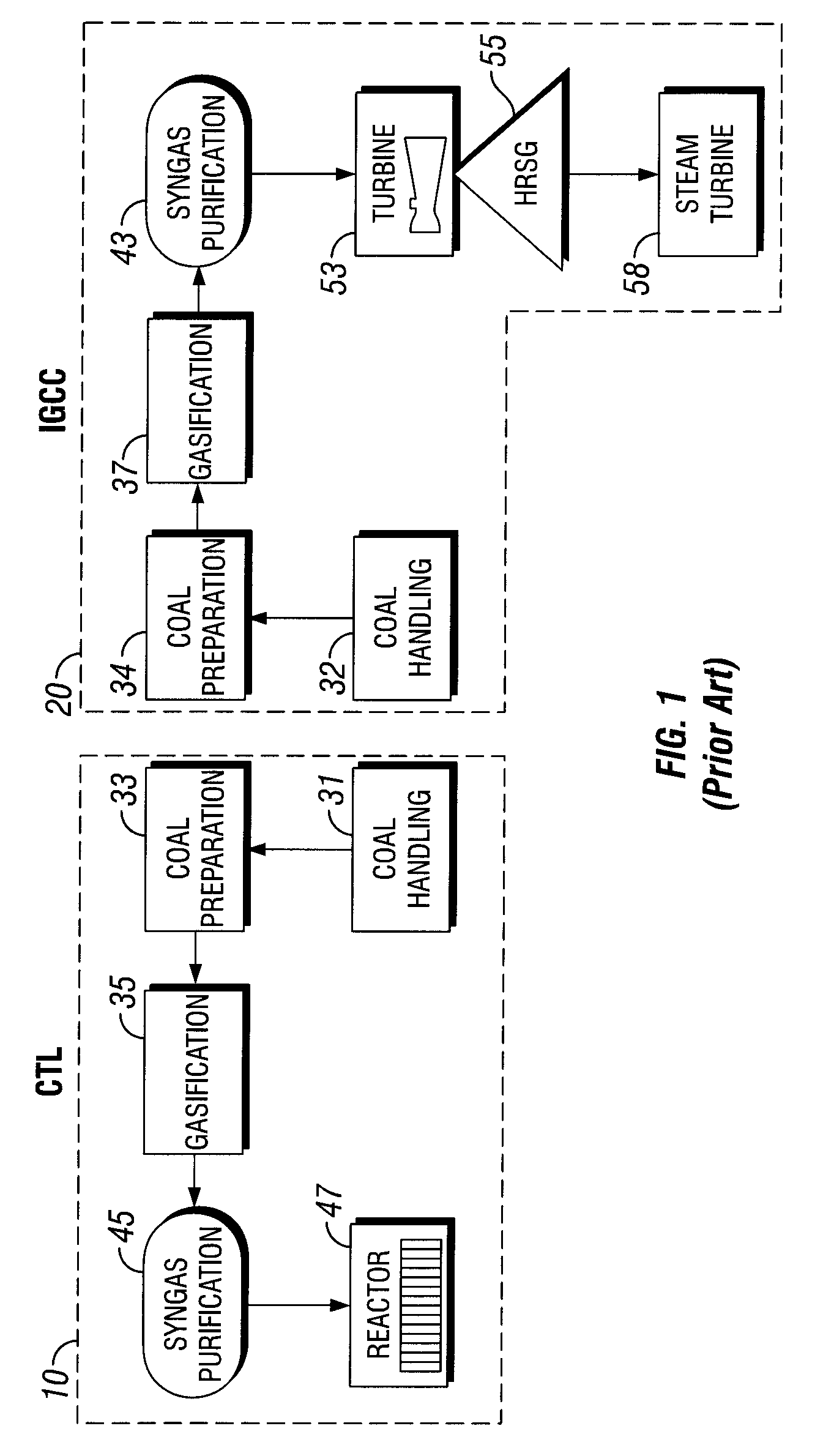

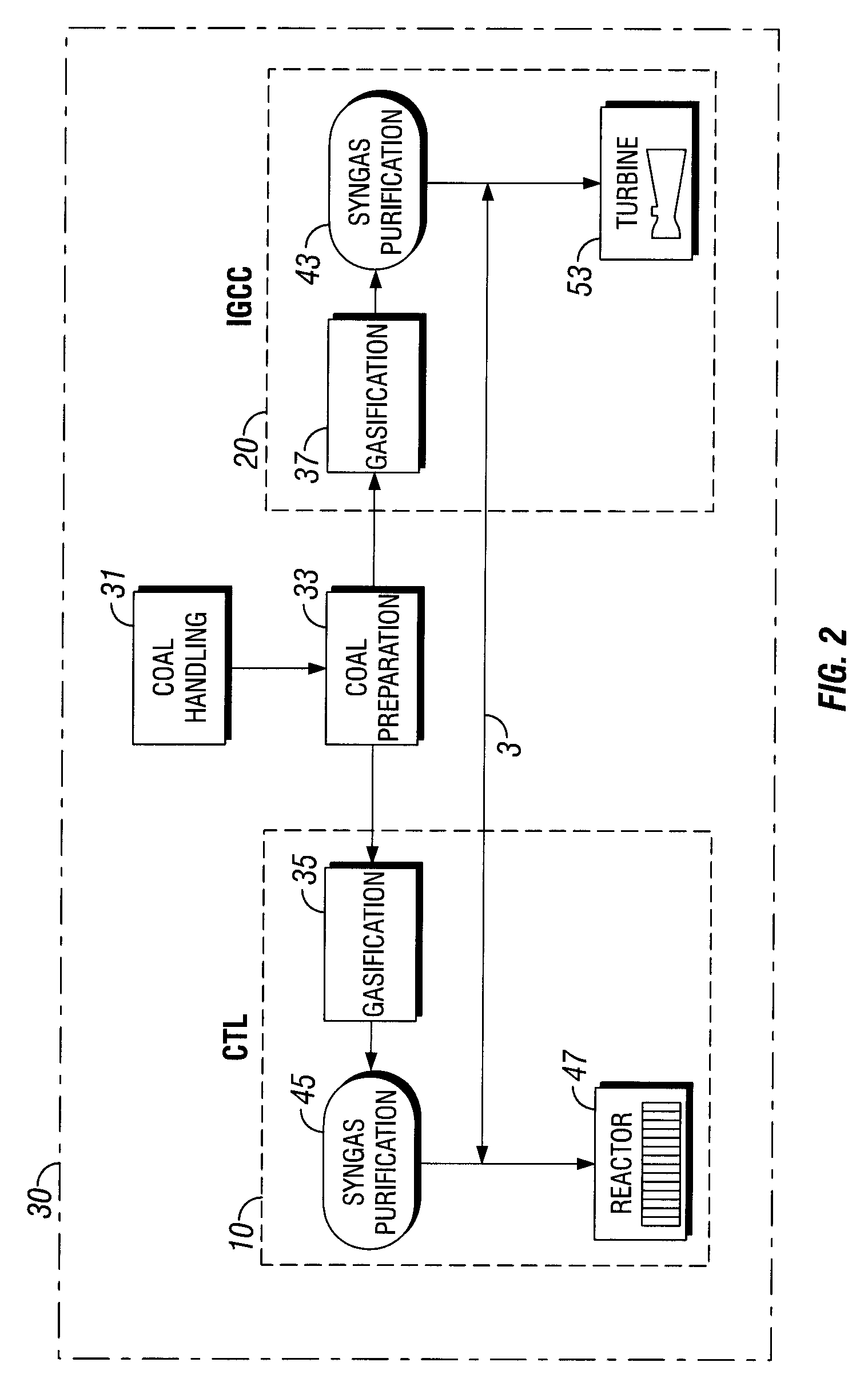

Integration of an integrated gasification combined cycle power plant and coal to liquid facility

InactiveUS20090090057A1Advantage in of operational flexibilityAdvantage in of scalabilityGas modification by gas mixingCombustion enginesPower stationElectrical devices

A novel method of combining the CTL fuel plant and IGCC electrical plant by sharing the systems of coal intake, coal preparation, gas separation, and water units is described herein. This configuration allows for the combined facility to offer advantages in efficiencies of production, operational flexibility, scalability, and reliability by a multi-path integration of the processing units.

Owner:RES USA LLC

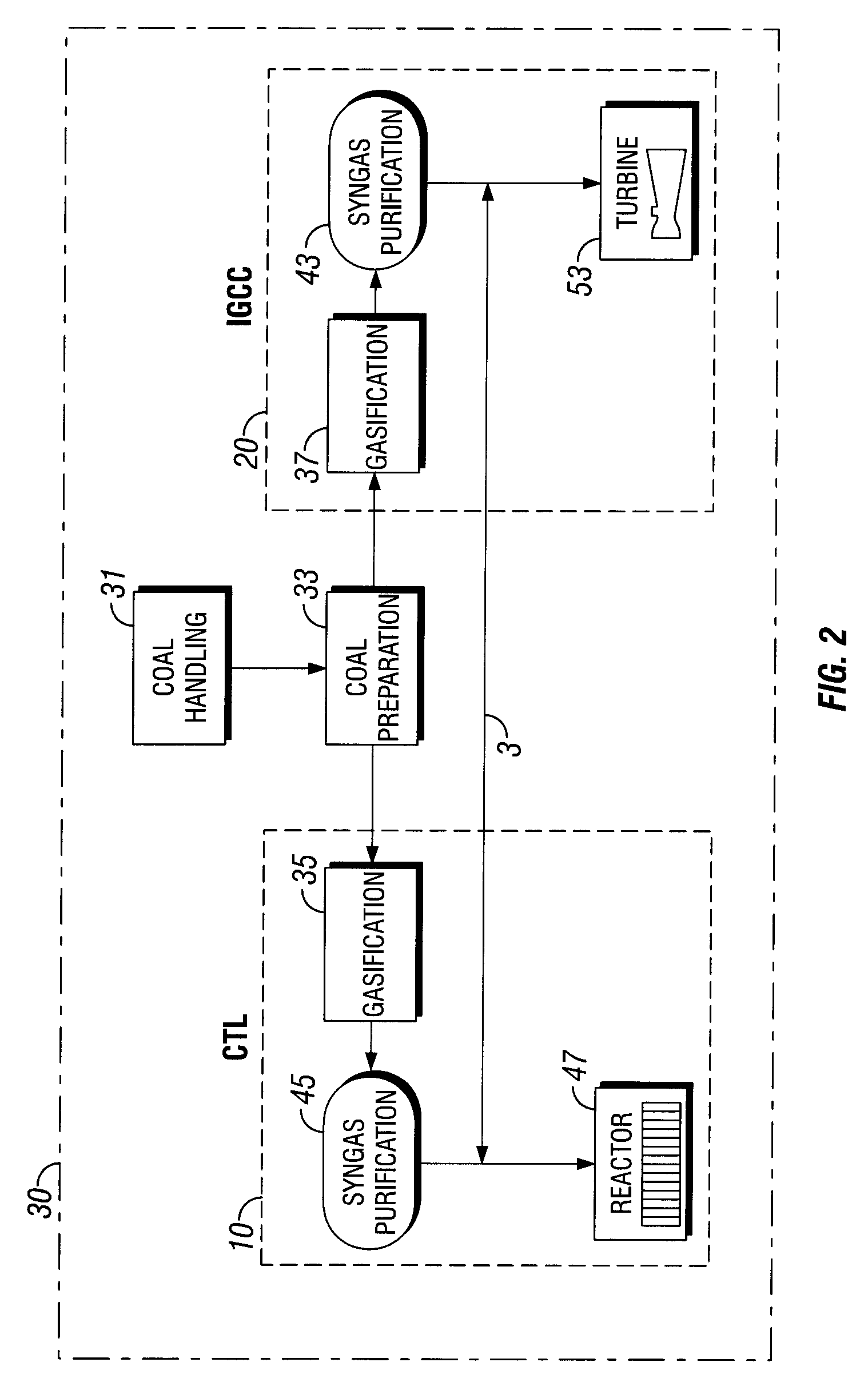

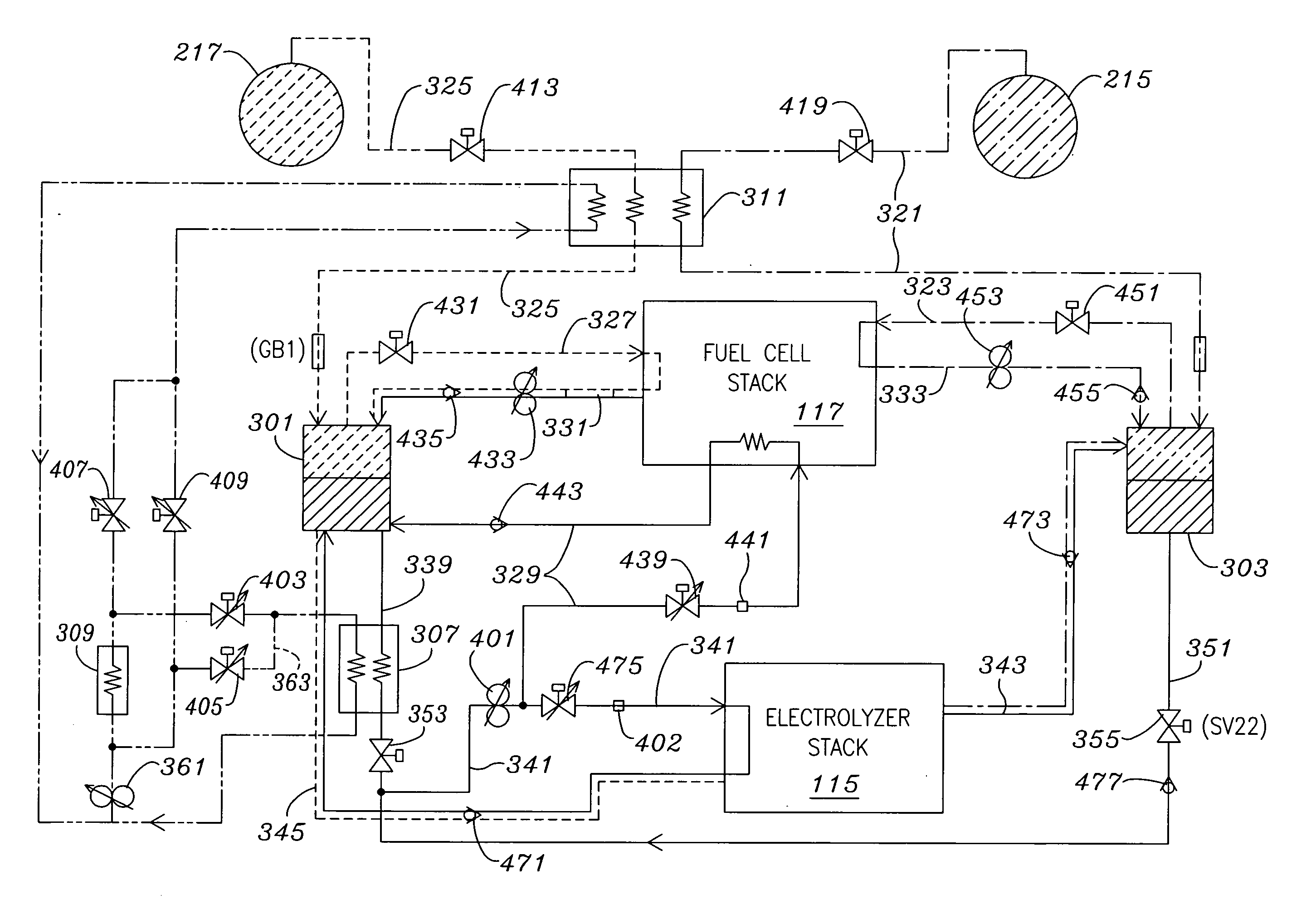

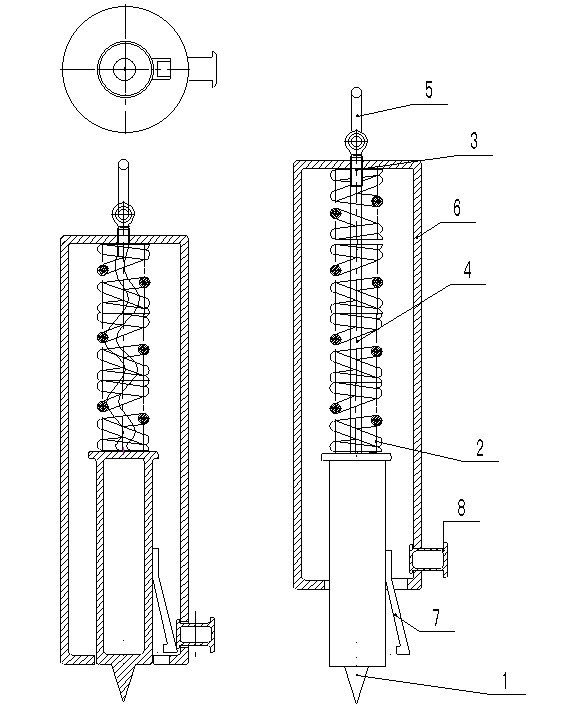

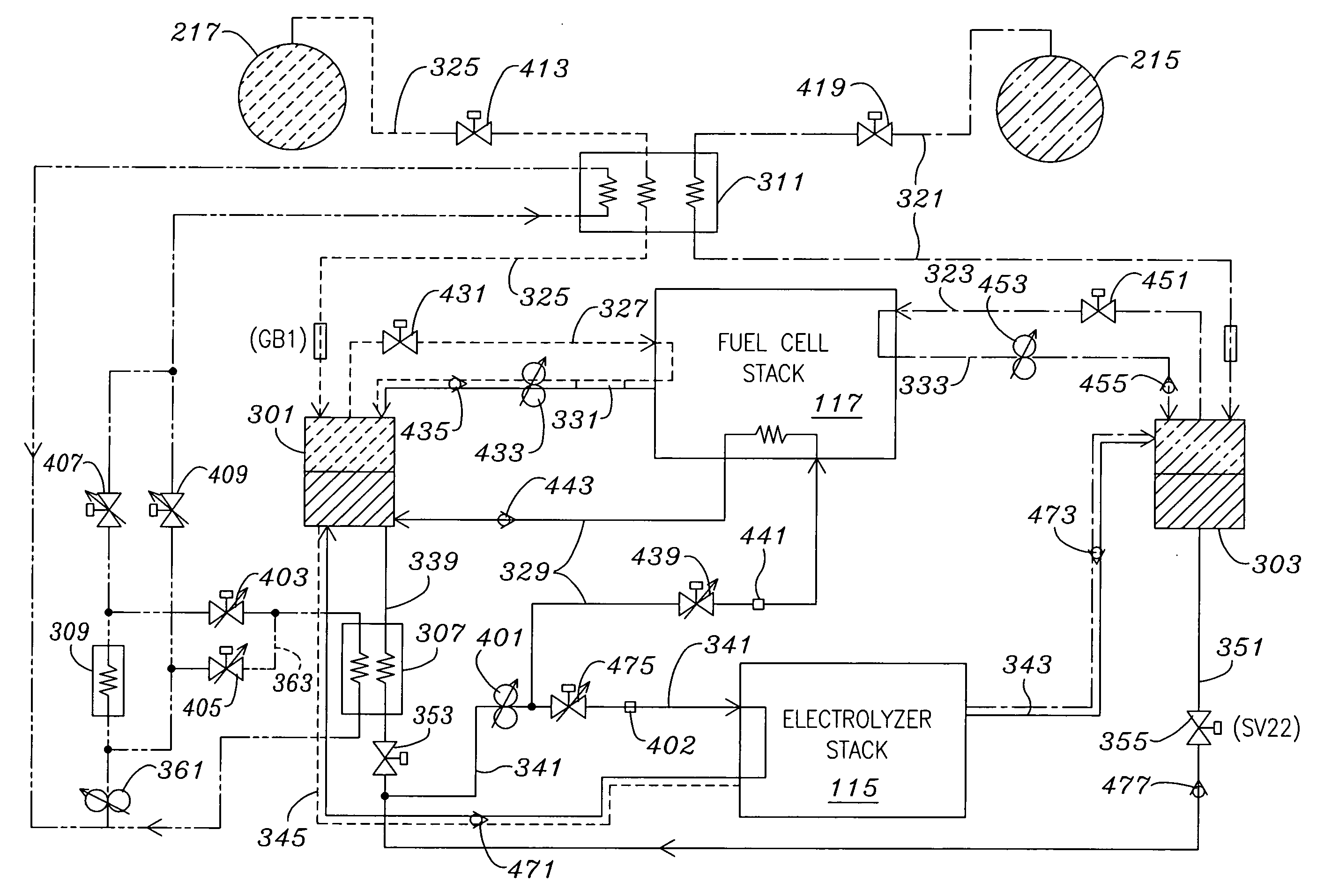

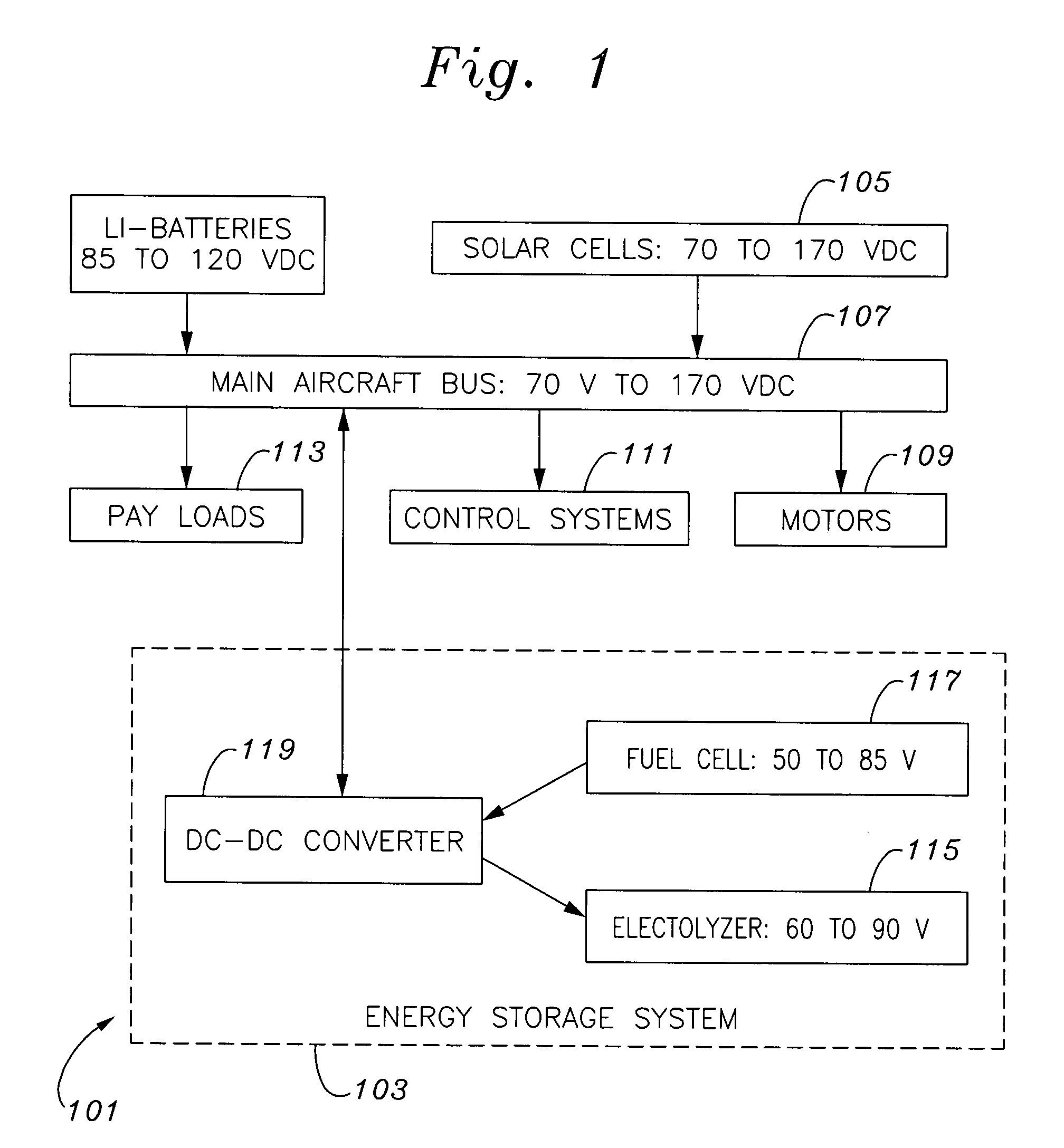

Energy storage system

InactiveUS20080166613A1Improve performanceReduce weightElectrolysis componentsFuel cells groupingOxygen tankFreeze-drying

A closed loop energy storage system configured with a hydrogen tank, an oxygen tank, a fuel cell stack and an electrolyzer. A heat exchanger freeze-dries the hydrogen and oxygen prior to their storage in their respective tanks. The heat exchanger also uses excess fuel cell heat to preheat streams of hydrogen and oxygen coming from the tanks. Phase separators serve both to separate water from hydrogen and oxygen, and to store the water. A thermal management system encloses all the system components except the tanks. An airfoil-shaped shell covers the system, and the larger of the two tanks extends substantially across the shell at its point of greatest camber thickness. The tanks are composed of polymer liners integral with composite shells.

Owner:AEROVIRONMENT INC

Memory controller system with non-volatile backup storage

ActiveUS20160239240A1Easy to useEffective reliabilityMemory architecture accessing/allocationInput/output to record carriersControl systemSystem recovery

Owner:RAMBUS INC

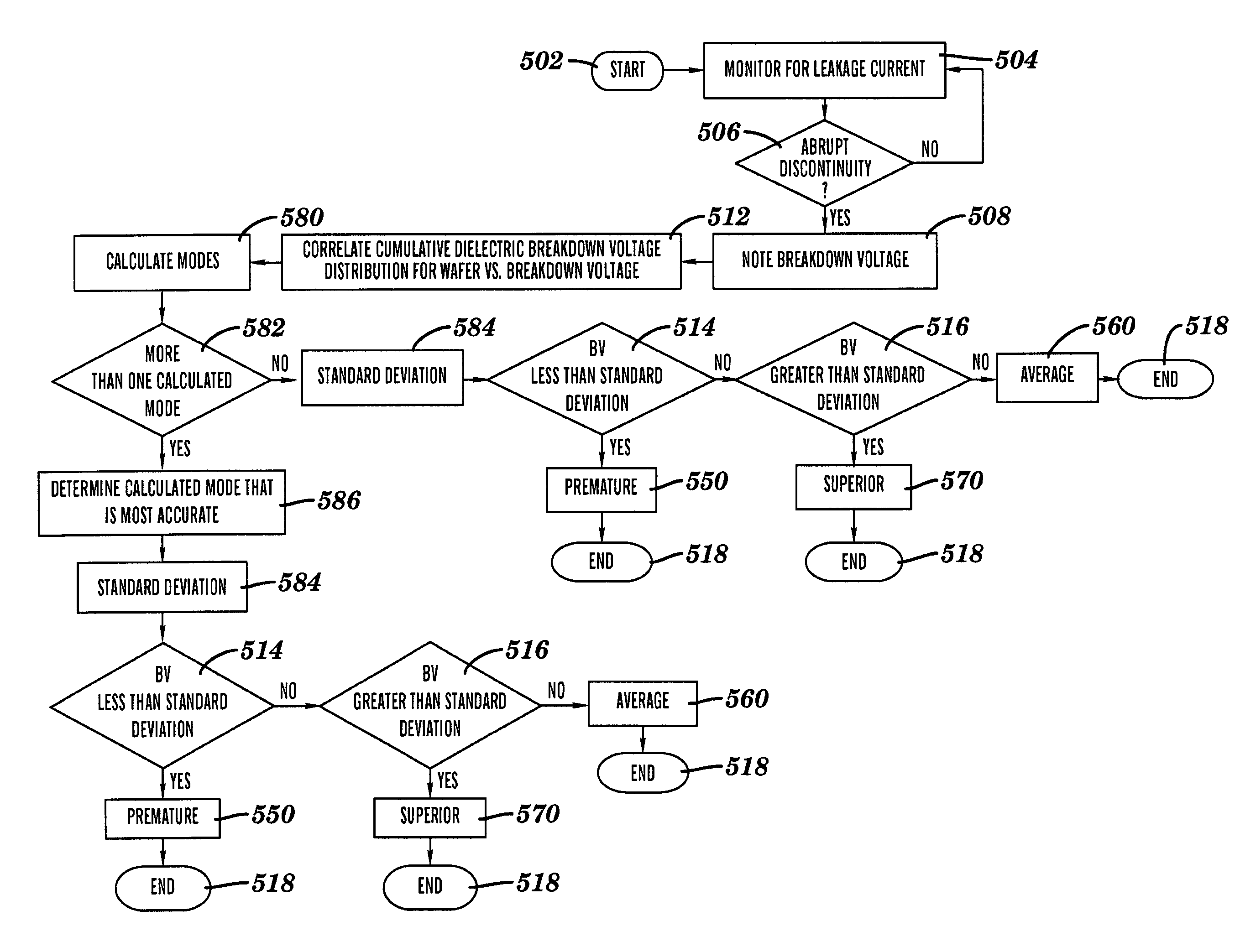

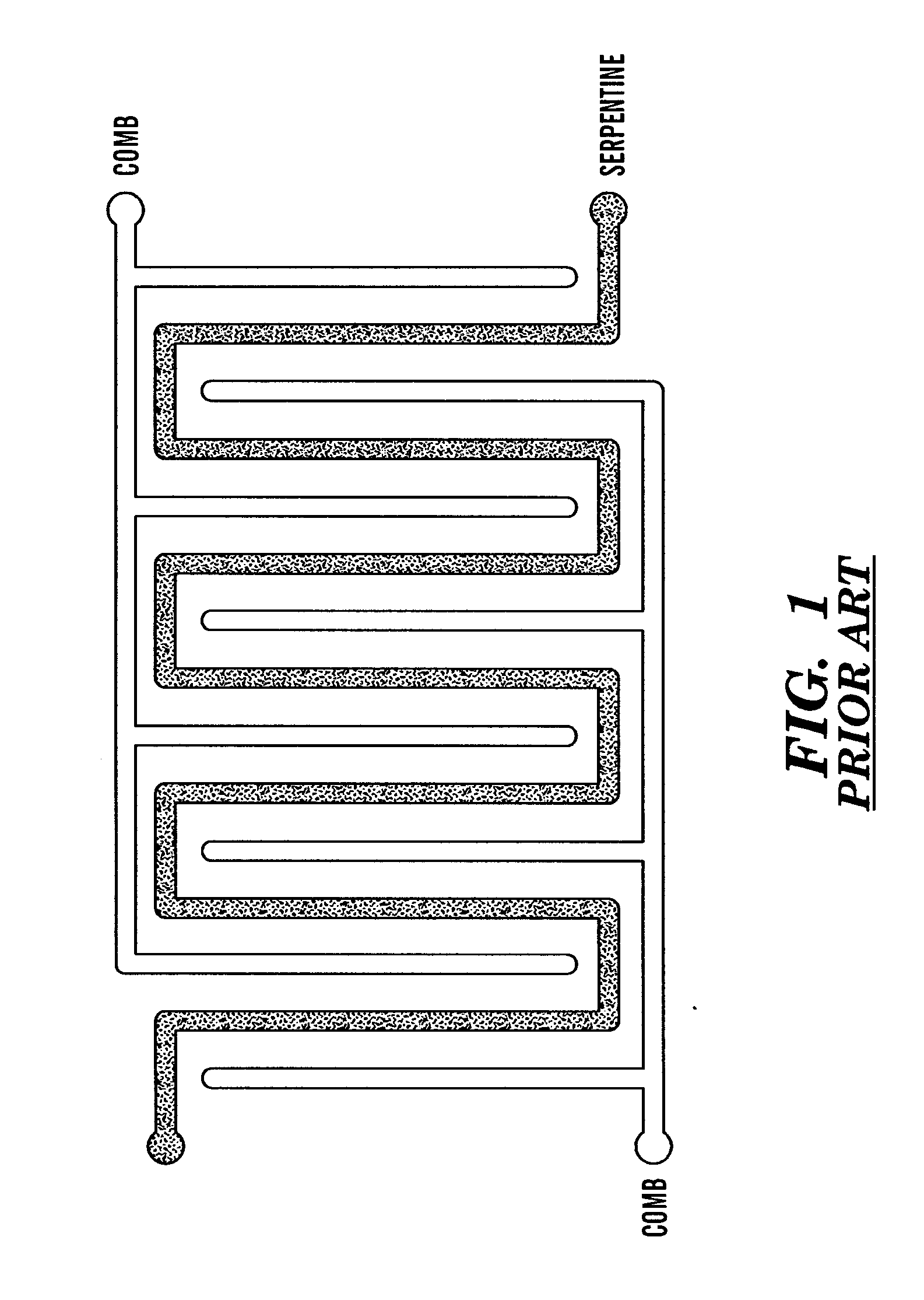

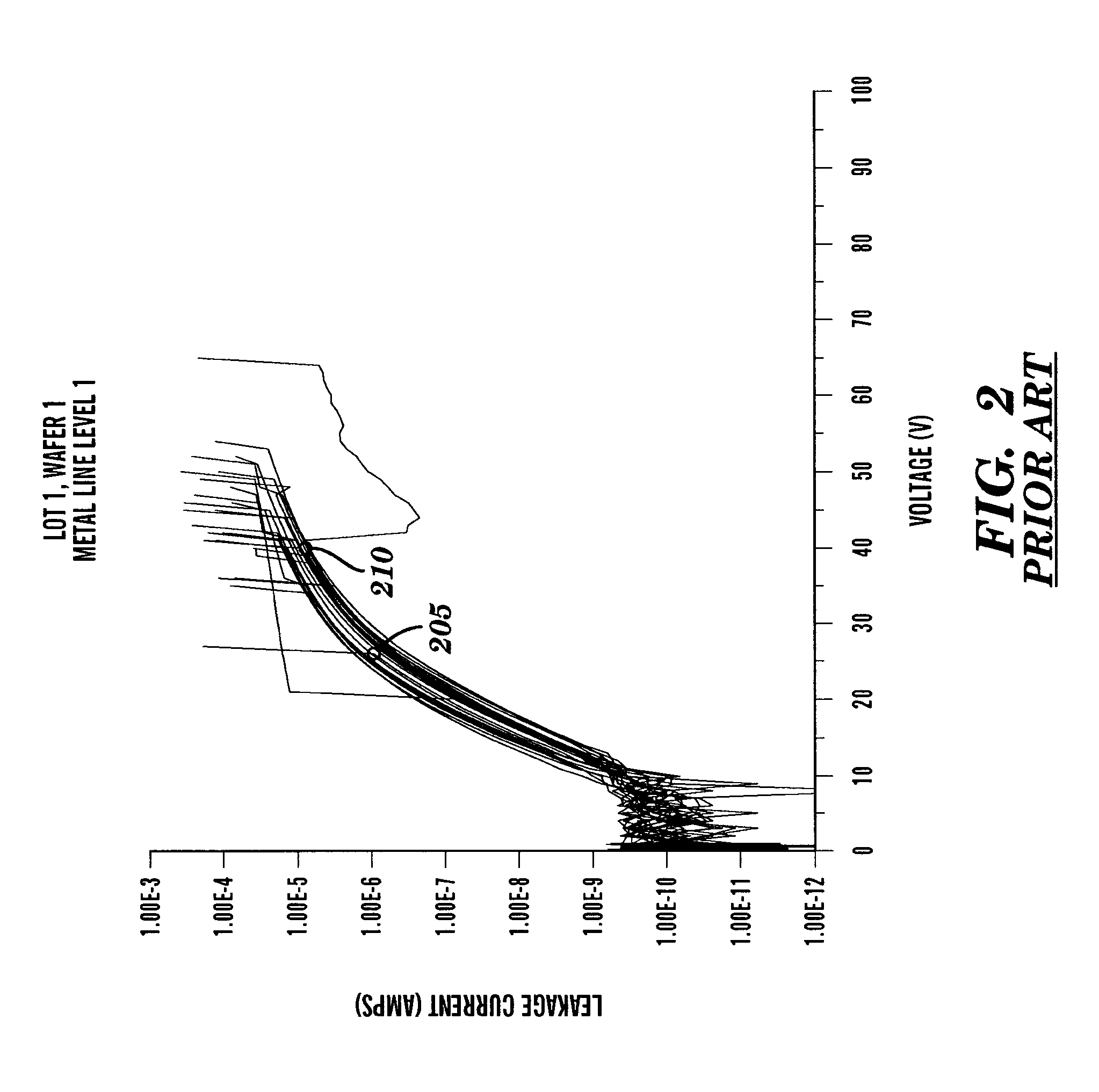

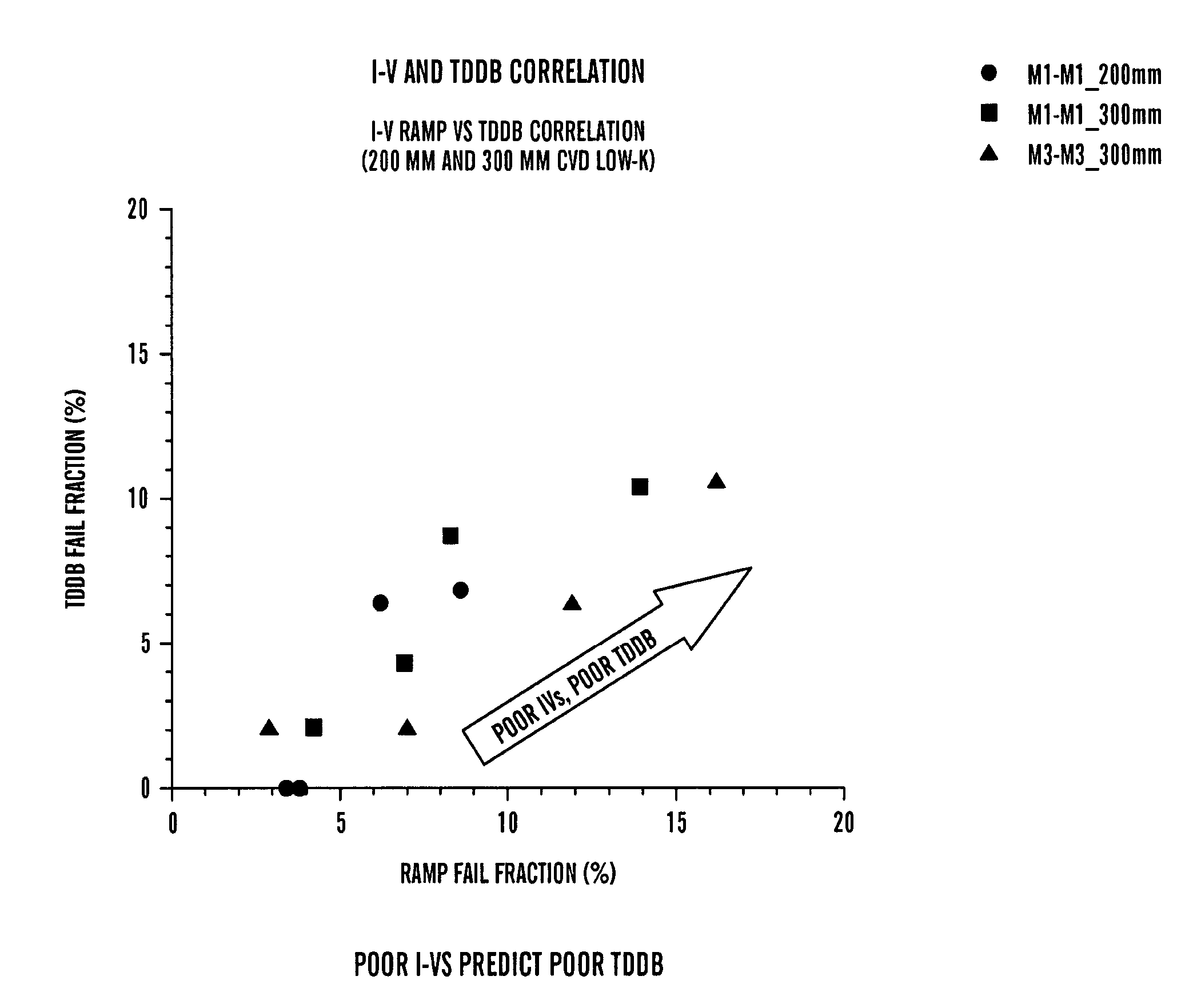

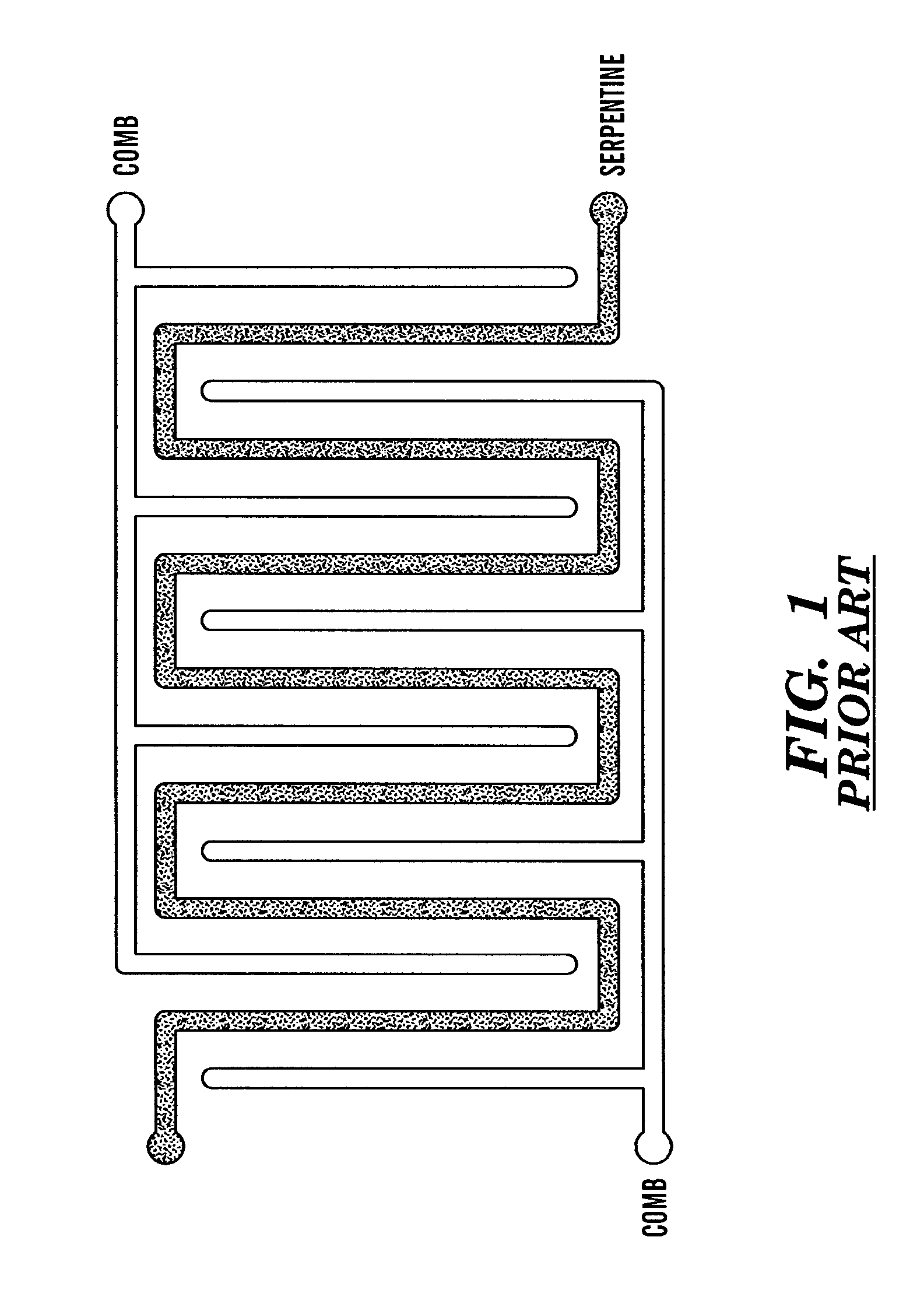

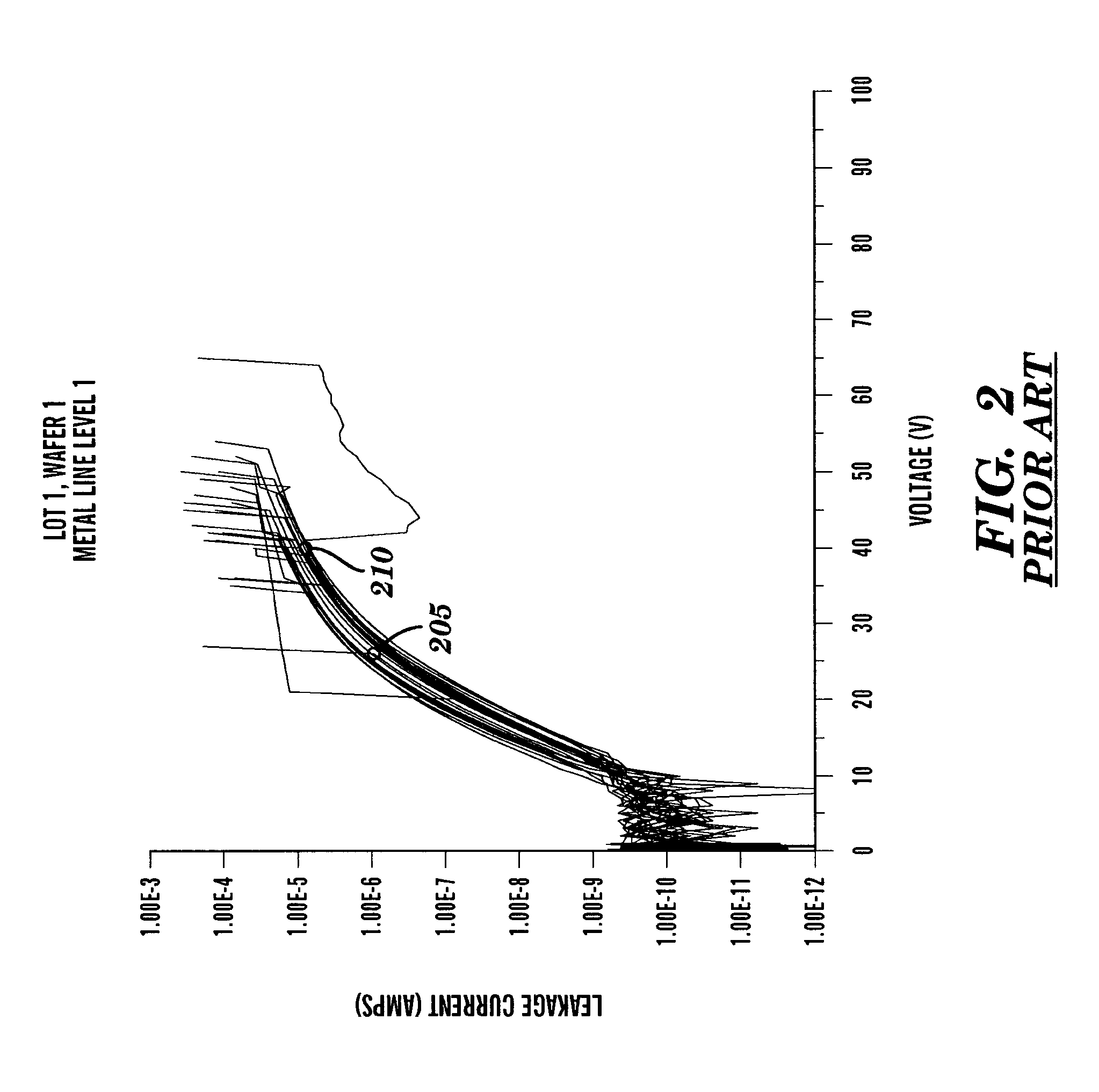

Method for prediction of premature dielectric breakdown in a semiconductor

InactiveUS20080174334A1SalvagingReduce overall man-hoursSemiconductor/solid-state device testing/measurementDetecting faulty computer hardwareDielectricElectricity

The invention predicts premature dielectric breakdown in a semiconductor. At least one dielectric breakdown mode is calculated for the semiconductor wafer. If a one mode is calculated, premature dielectric breakdown will be associated with any semiconductor with a breakdown voltage less than a predetermined standard deviation of a plurality of breakdown voltages within said calculated mode. If multiple modes are calculated, the mode that most accurately represents dielectric breakdown for the semiconductor wafer is determined and premature dielectric breakdown will be associated with any semiconductor with a breakdown voltage less than a predetermined standard of the calculated mode that most accurately represents dielectric breakdown for the semiconductor wafer.

Owner:GLOBALFOUNDRIES INC

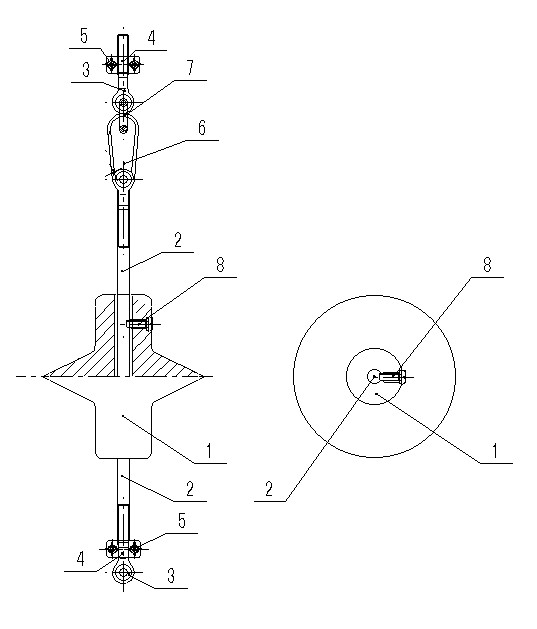

Method and device for assisting in beating

InactiveCN102009631AWill not affect trafficLarge escape spacePedestrian/occupant safety arrangementEngineeringPhysical property

The invention discloses a method and a device for beating. The method is a work method replacing labor force by elastic potential energy according to physical properties of an elastic object. The device consists of fixed pieces and an operating piece, wherein the fixed pieces are formed by respectively arranging locking heads (3) on two sides of a window frame by screws (5) and pressure plates (4); the operating piece is formed by connecting an elastic object (2) with a hanging hook (6); the elastic object (2) penetrates through a beating body (1) and is fixed by positioning screws (8); and the other end of the elastic object (2) is connected with the fixed pieces. By using the method and the device, the elastic object can be compressed or stretched by people with little force and the beating body is driven by elastic force to smash glass. The integral attractiveness of an original object cannot be damaged by adopting the invisible installation; by using elastic potential energy as power and the device to repeatedly operate, people are farther from the glass so as to avoid the injury and the fearful psychology caused by the damage of glass; and by adopting a combined structure, the beating body can beat any position of safety glass.

Owner:潘锟海

Energy storage system

InactiveUS20080187809A1Reduce weightSimple systemElectrolysis componentsFuel cells groupingOxygen tankFreeze-drying

A closed loop energy storage system configured with a hydrogen tank, an oxygen tank, a fuel cell stack and an electrolyzer. A heat exchanger freeze-dries the hydrogen and oxygen prior to their storage in their respective tanks. The heat exchanger also uses excess fuel cell heat to preheat streams of hydrogen and oxygen coming from the tanks. Phase separators serve both to separate water from hydrogen and oxygen, and to store the water. A thermal management system encloses all the system components except the tanks. An airfoil-shaped shell covers the system, and the larger of the two tanks extends substantially across the shell at its point of greatest camber thickness. The tanks are composed of polymer liners integral with composite shells.

Owner:AEROVIRONMENT INC

Method for prediction of premature dielectric breakdown in a semiconductor

InactiveUS8053257B2Effective reliabilityFast reliabilitySemiconductor/solid-state device testing/measurementDetecting faulty computer hardwareDielectricEngineering

The invention predicts premature dielectric breakdown in a semiconductor. At least one dielectric breakdown mode is calculated for a layer within chips comprising a semiconductor wafer lot. If only one mode is calculated, that is the best calculated mode. If multiple modes can be calculated, a best mode that most accurately represents dielectric breakdown for the semiconductor wafer lot is determined. Premature dielectric breakdown will be associated with any semiconductor with a breakdown voltage less than a predetermined standard deviation from the best calculated mode.

Owner:GLOBALFOUNDRIES INC

Method and apparatus for the automated application of hardfacing material to rolling cutters of earth-boring drill bits

ActiveUS8698038B2Improve quality and consistencyFacilitate automatic collectionDrill bitsMetal-working drilling toolsRobotic armControl system

The present invention relates to a system and method for automated or “robotic” application of hardfacing to the surface of a steel-toothed cutter of a rock bit. In particular, the system incorporates a grounded adapter plate and chuck mounted to a robotic arm for grasping and manipulating a rock bit cutter beneath an electrical or photonic energy welding source, such as a plasma arc welding torch manipulated by a positioner. In this configuration, the torch is positioned substantially vertically and oscillated along a horizontal axis as the cutter is manipulated relative along a target path for the distribution of hardfacing. Moving the cutter beneath the torch allows more areas of more teeth to be overlayed, and allows superior placement for operational feedback, such as automatic positioning and parameter correction. In the preferred embodiment, sensors provide data to the control system for identification, positioning, welding program selection, and welding program correction. The control system, aided by data from the sensors, manipulates the robotically held cutter while controlling the operation and oscillation of the torch.

Owner:BAKER HUGHES HLDG LLC

Bipolar battery cell and assembled battery for a vehicle

ActiveUS7989106B2Improve reliabilityEfficient manufacturingBatteries circuit arrangementsFinal product manufactureBattery cellElectrolyte

The invention relates to a bipolar battery cell having a built-in discharge circuit that can automatically balance the charged conditions. The bipolar battery cell includes a plurality of bipolar electrodes, each including a collector having a positive-electrode layer on one surface and a negative-electrode layer on another surface. The bipolar battery cell further includes a plurality of electrolyte layers that exchange ions between the bipolar electrodes; and a discharge circuit that electrically conducts adjacent bipolar electrodes. The discharge circuit is provided on the same surface of at least one layer of the positive-electrode layers, the negative-electrode layers, or the electrolyte layers. Multiple bipolar battery cells are combined to form an assembled battery for vehicular applications.

Owner:NISSAN MOTOR CO LTD

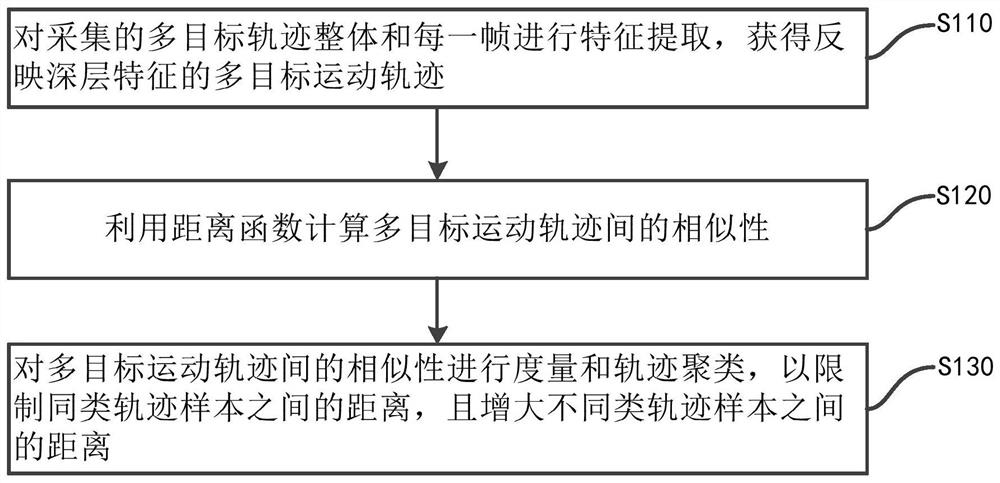

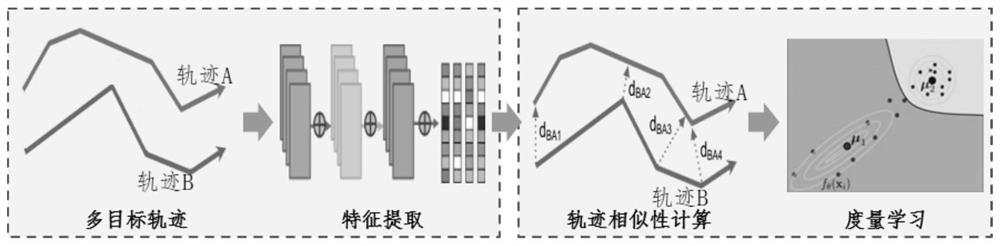

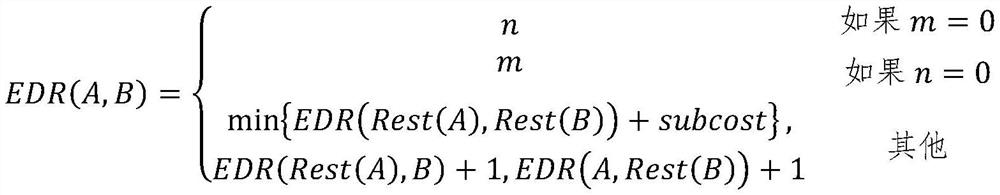

Multi-target tracking repositioning method based on trajectory similarity measurement learning

PendingCN112561960AValid informationEffective reliabilityImage analysisFeature extractionMulti target tracking

The invention discloses a multi-target tracking repositioning method based on trajectory similarity measurement learning. The method comprises the steps: carrying out feature extraction on the whole collected multi-target trajectory and each frame, and obtaining a multi-target motion trajectory reflecting deep features; calculating the similarity among the multi-target movement tracks by utilizinga distance function; and performing measurement and trajectory clustering on the similarity between the multi-target motion trajectories to limit the distance between similar trajectory samples and increase the distance between different types of trajectory samples. By utilizing the method, the problems of target loss and error tracking caused by factors such as shielding and overlapping among multiple targets can be solved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Integration of an integrated gasification combined cycle power plant and coal to liquid facility

InactiveUS8105403B2Efficiency advantageEffective reliabilityCombustion enginesGas modification by gas mixingPower stationElectrical devices

A novel method of combining the CTL fuel plant and IGCC electrical plant by sharing the systems of coal intake, coal preparation, gas separation, and water units is described herein. This configuration allows for the combined facility to offer advantages in efficiencies of production, operational flexibility, scalability, and reliability by a multi-path integration of the processing units.

Owner:RES USA LLC

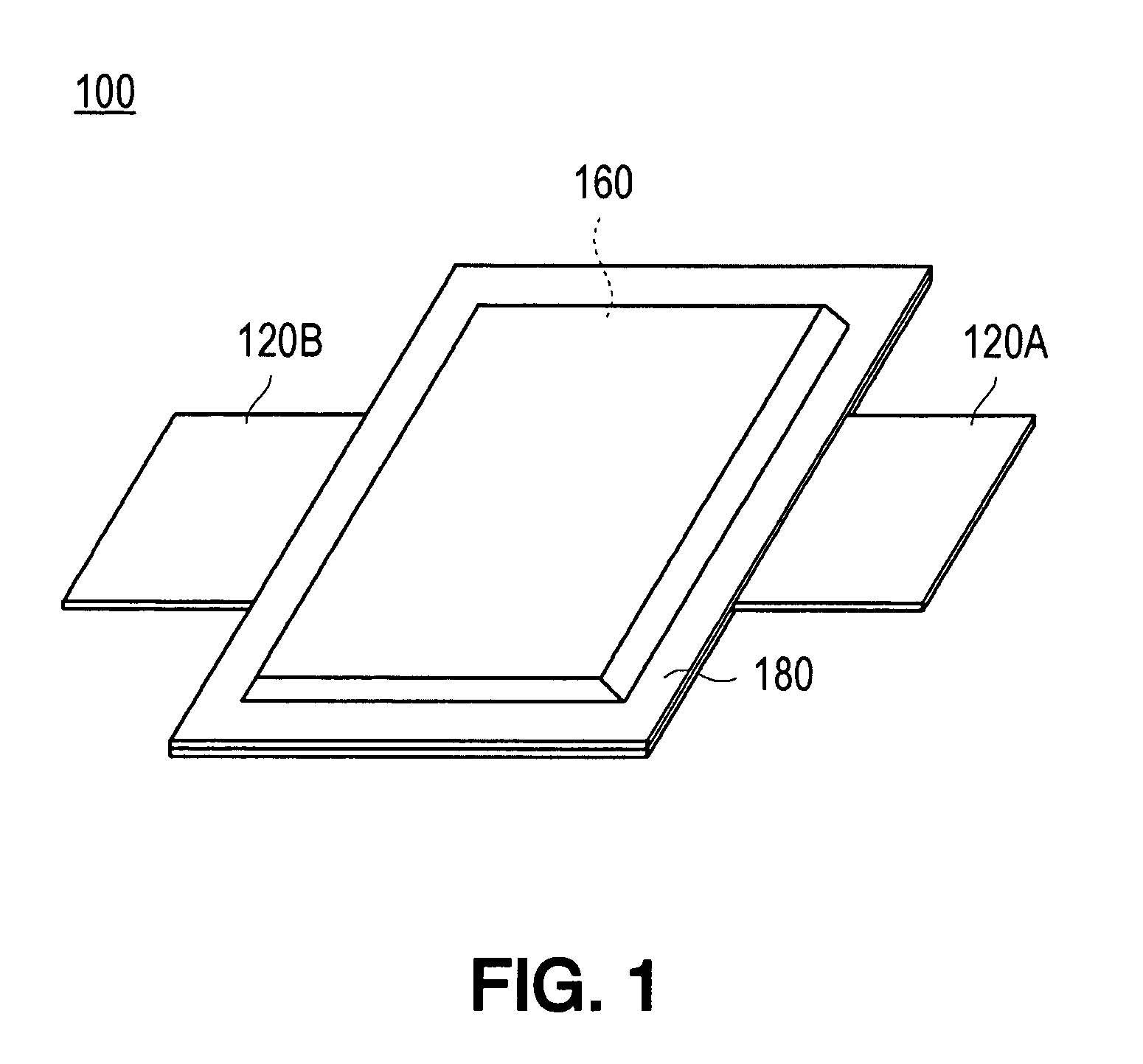

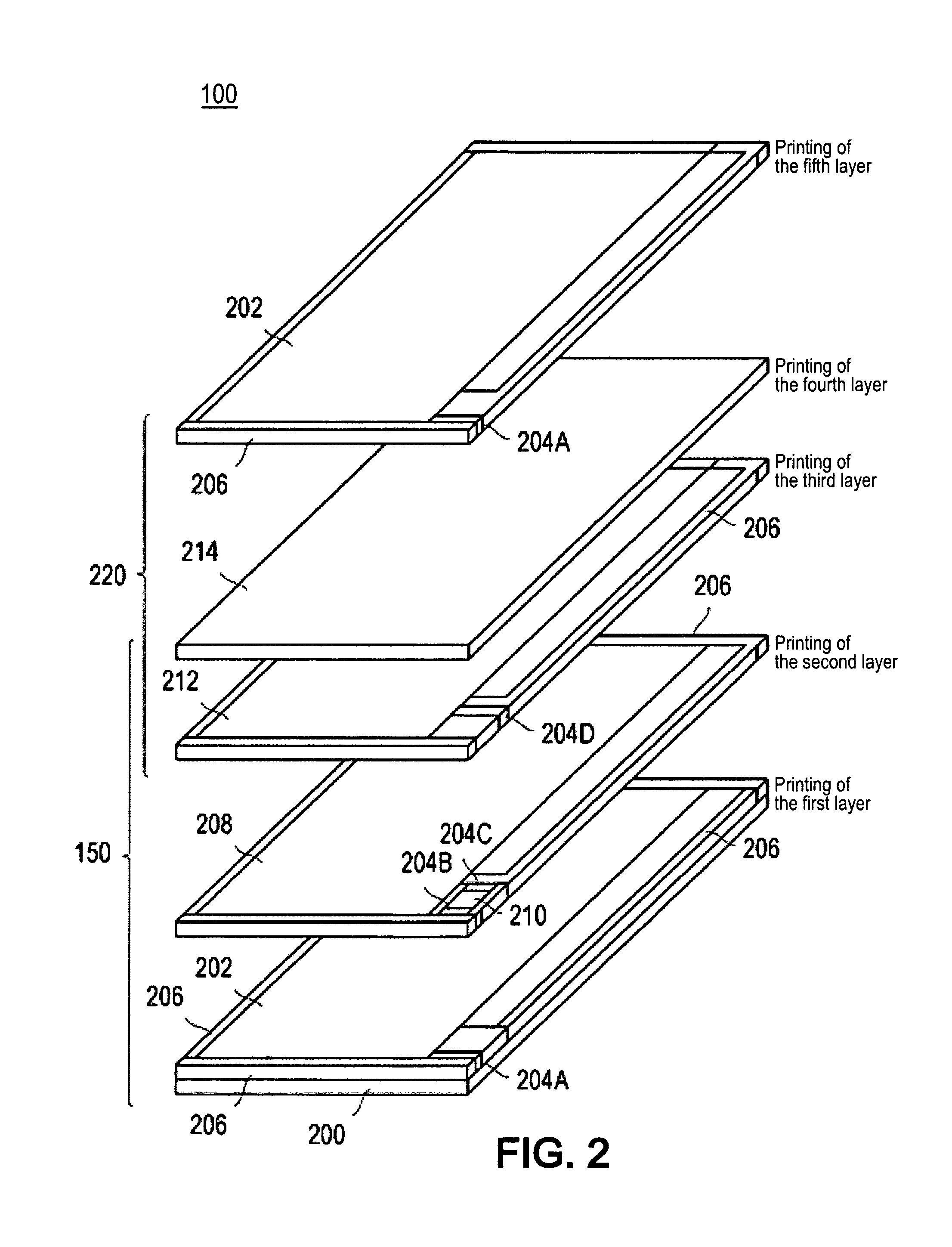

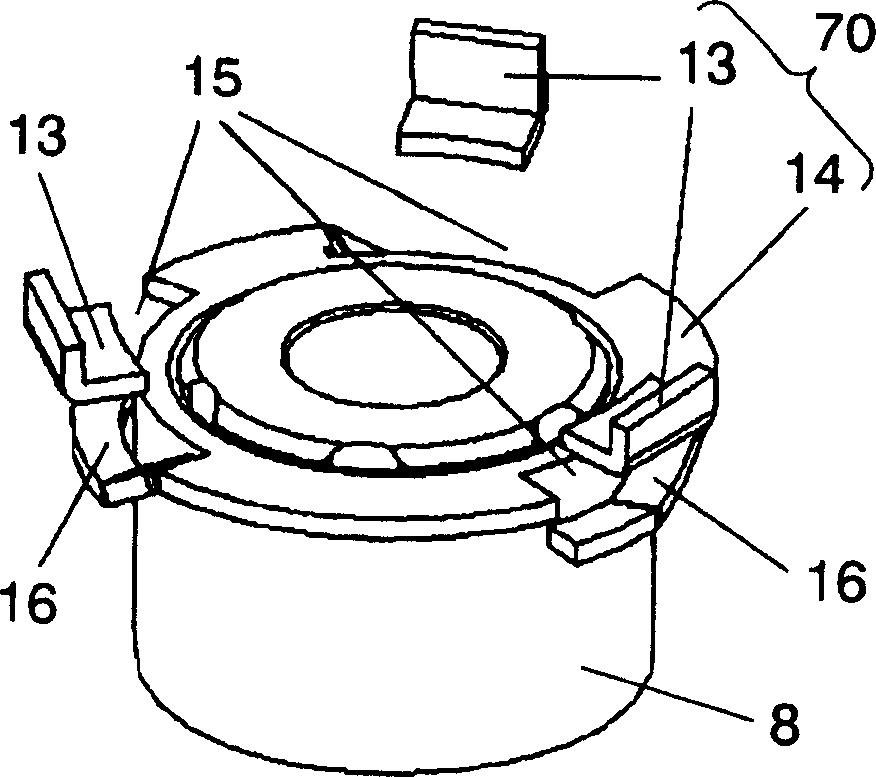

Disc driving unit and disc equipment using the same

InactiveCN1866371AImprove rigidityEffective reliabilityRecord information storageRecording on magnetic disksComing outEquipment use

The disc-driving unit is formed of a rotor having a turntable on which a disc is mounted, a stator having a bearing housing, and a drop-guard mechanism for protecting the rotor from coming out of the stator. On the turntable, a plurality of engaging sections are integrally formed, while on the bearing housing, an engaged section is integrally formed. The engaged section has a plurality of recesses each of which has an opening width wide enough for passing through each of the engaging sections and a plurality of guides for helically guiding the engaging sections into the recesses. A helical engagement of the engaging sections and the engaged section completes the drop-guard mechanism.

Owner:MINEBEA MOTOR MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com