Sleeve spool valve structure featuring rigid cutting-off

A technology for sleeve valves and spools, applied in sliding valves, valve devices, engine components, etc., can solve the problem that the working temperature cannot be strictly cut off, and achieve the effect of reducing fluid noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

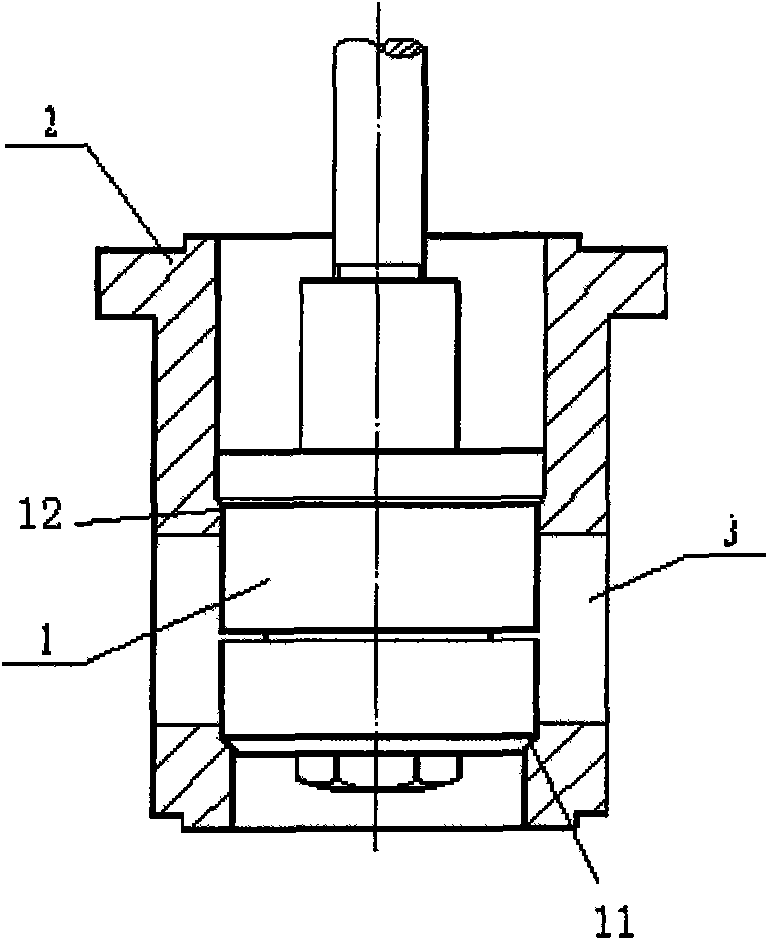

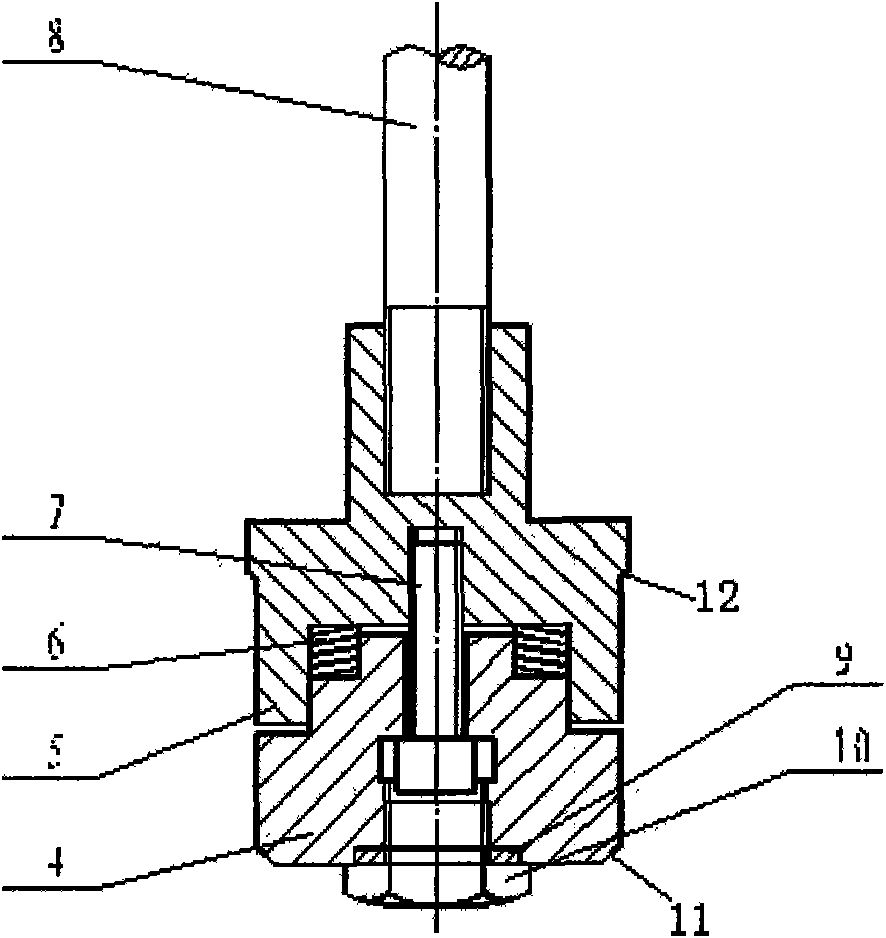

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0013] Such as figure 1 , Shown in 2, the sleeve valve structure of the tight shutoff of the present invention, it is made up of spool assembly 1, sleeve 2. The spool assembly 1 includes a lower spool 4 , an upper spool 5 , a disc spring set 6 , a screw 7 , a valve stem 8 , a sealing gasket 9 and a sealing bolt 10 .

[0014] The 60° to 90° sealing tapered surface of the lower valve core 4 and the 60° to 90° conical valve seat at the bottom of the sleeve 2 form a lower seat seal. The 60° to 90° sealing cone surface 12 of the upper valve core 5 and the 60° to 90° conical valve seat on the top of the sleeve 2 form an upper valve seat seal. The disc spring group 6 is clamped between the lower spool 4 and the upper spool 5, and its elastic deformation can eliminate the gap between the upper and lower valve seat seals due to factors such as temperature changes, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com