Broach for machining inner hexagonal connecting bolt and broaching method

A corner connection and bolt technology, which is applied in the field of broach and broaching for processing inner hexagon connection bolts, can solve problems such as affecting the performance of parts, cumbersome processing technology, large batches, etc., and achieves high processing efficiency, simple operation and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

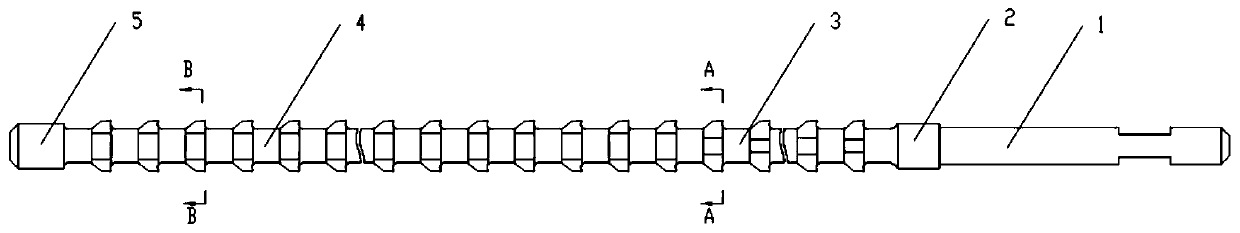

[0030] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below in conjunction with the accompanying drawings through specific implementation methods.

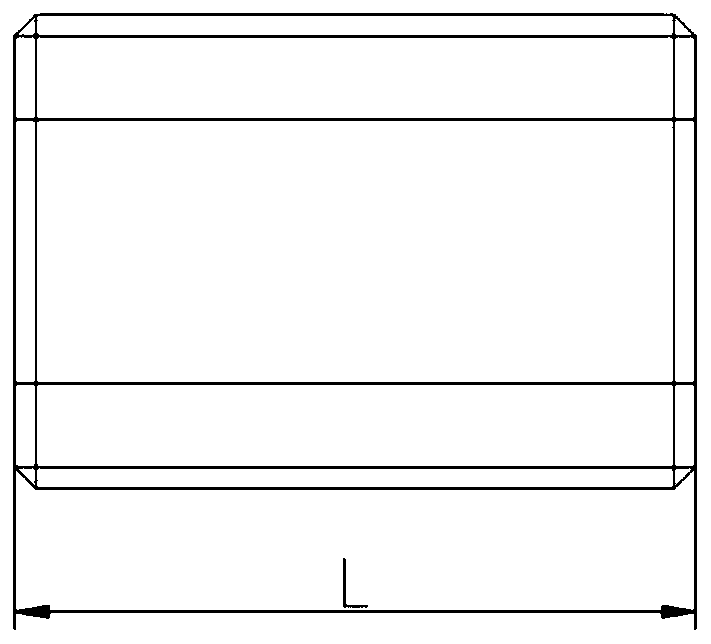

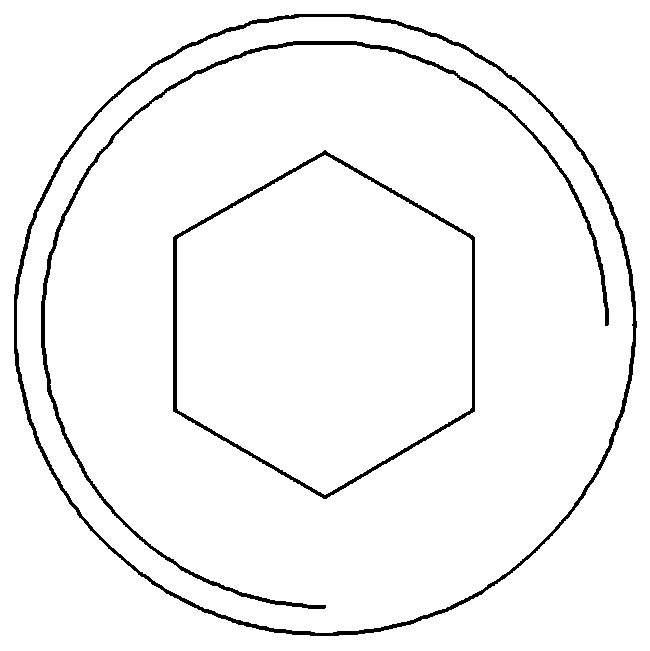

[0031] Such as Figure 3-6 As shown, a broach for machining hexagonal socket connection bolts includes a tail handle 1, a guide part and a working part. clip; the guide part is the front guide 2 and the rear guide 5, which play a role in guiding and positioning during the working process; the working part is rough cutting and shaping gradual cutting, and all the cutter teeth not only cut the allowance but also play the role of centering Function, the rough cutting part is composed of the rough cutting teeth 3 and the chip space between the two teeth; the rough cutting teeth 3 have a "V"-shaped chip breaker, and the front and rear teeth are arranged alternately. In this embodiment, the "V" shape The edge width o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com