A kind of aluminum alloy wheel punching process

A technology of aluminum alloy and wheels, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of affecting the processing accuracy, product performance, inability to ensure distribution, and affecting processing efficiency, so as to improve production efficiency and pass rate , Reduce the scrap rate of defective products and improve the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

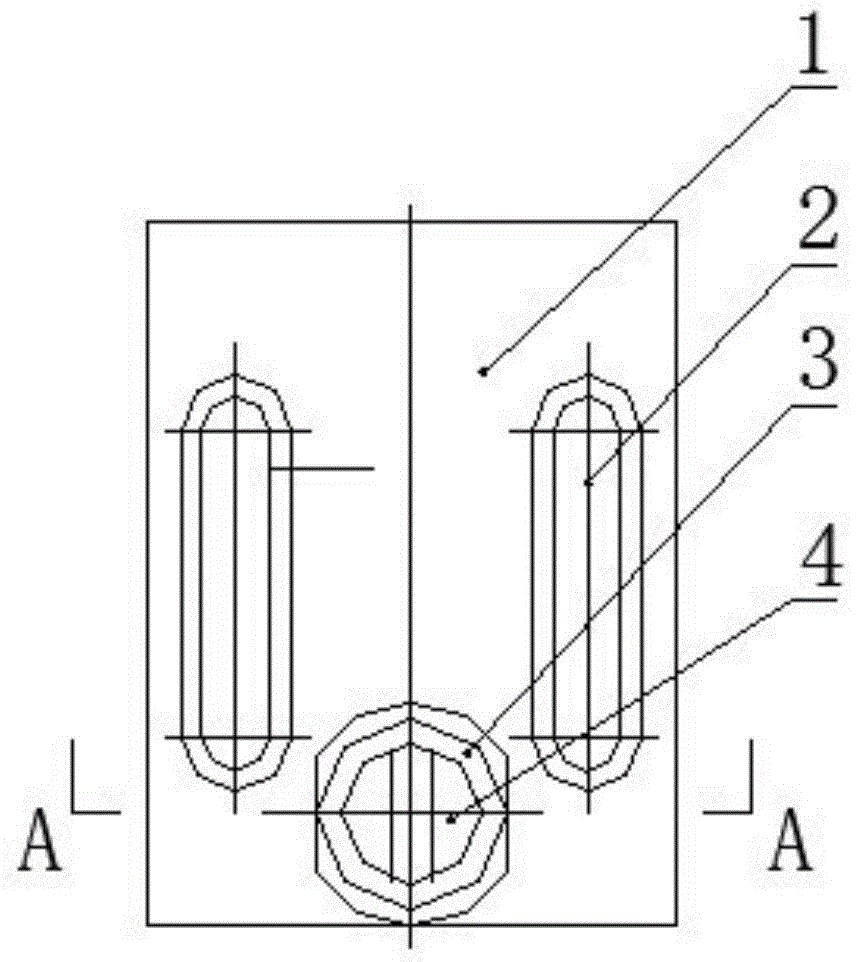

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

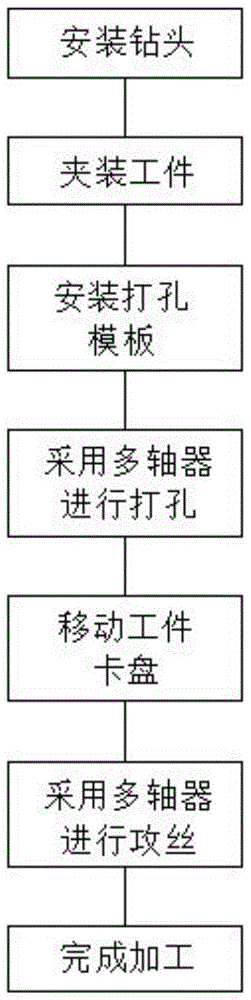

[0030] A kind of aluminum alloy wheel punching process, concrete steps are as follows:

[0031] (1) Install the drill bit, fix multiple drill bits on the multi-axis device according to the position of multiple insert holes in the workpiece window, and adjust the height difference of the drill bit according to the product size; and install the tapping drill bit on the multi-axis device for tapping ;

[0032] (2) Clamp the workpiece, fix the wheel product to be processed on the workpiece chuck, and adjust the coaxiality between the product and the fixture;

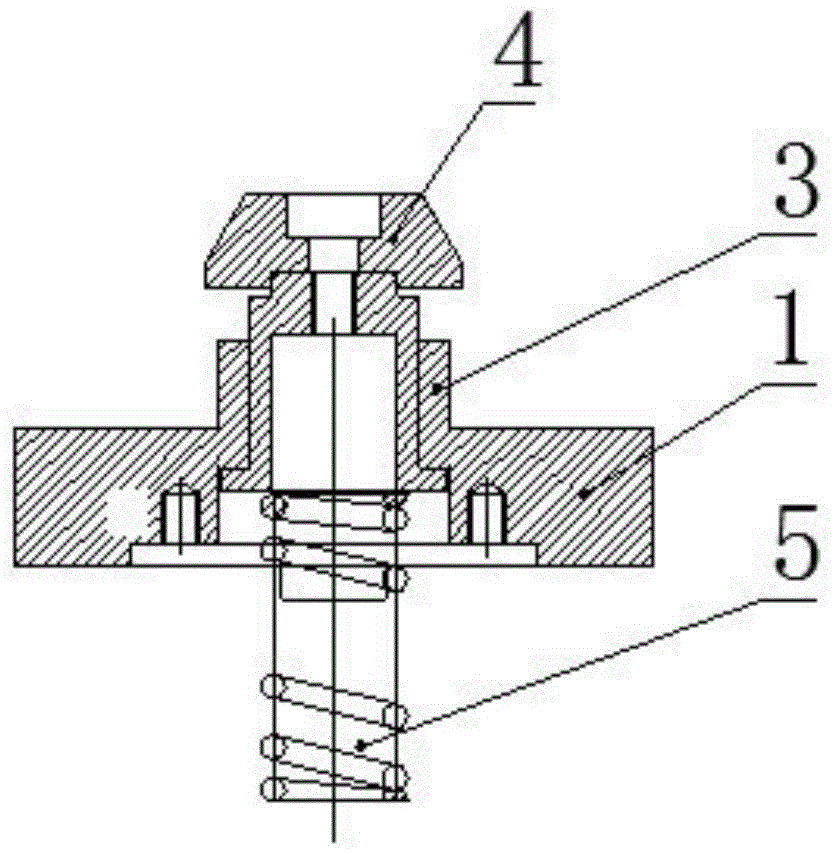

[0033] The present invention adopts a novel radial positioning structure, and three positioning structure components are radially adjusted and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com