Flexible self-centering device with high stiffness

A high-rigidity, self-centering technology, applied to gear teeth manufacturing devices, gear teeth, gear cutting machines, etc., can solve the problems of complex structure, high cost, low precision, etc., and achieve large shrinkage and expansion range, low cost, and extended The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

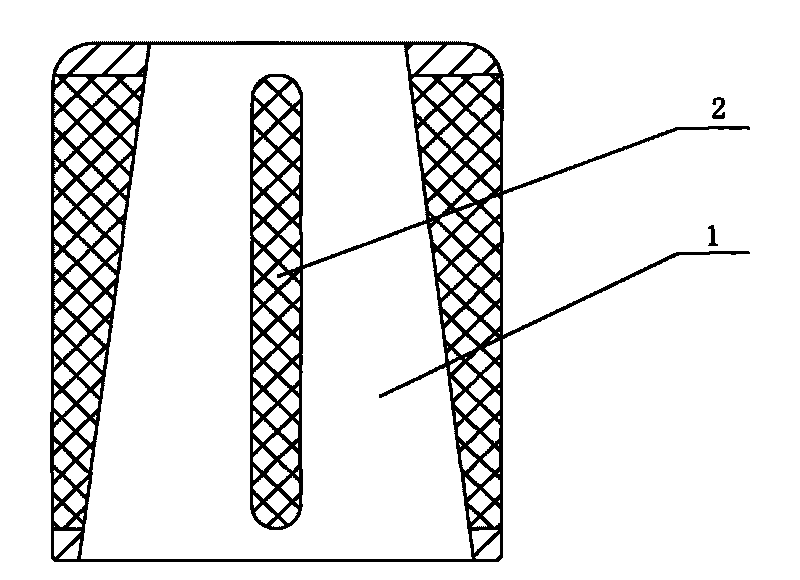

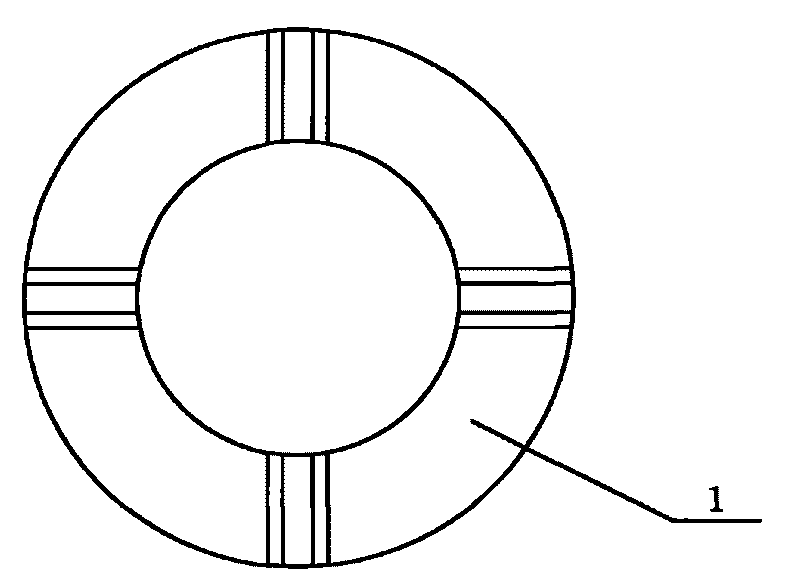

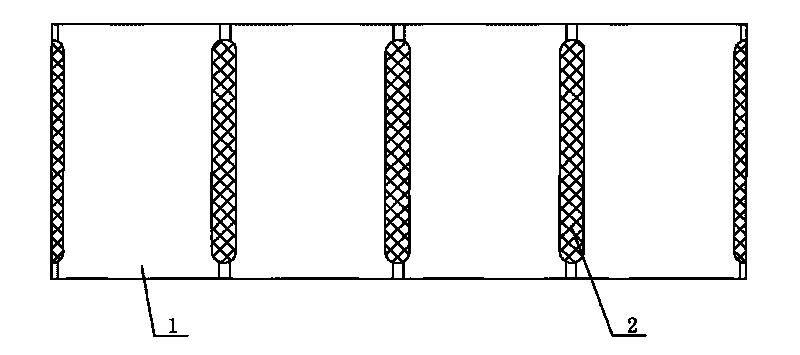

[0021] refer to Figure 1-3 , a flexible and high-rigidity self-centering device, including a plurality of positioning elements 1, and the positioning elements 1 are connected by rubber strips 2 to form an overall structure that is cylindrical on the outside and conical on the inside.

[0022] The positioning element 1 is a steel piece which has been quenched.

[0023] For the application of the present invention in gear grinding and gear hobbing fixtures, refer to Figure 4 , 5 .

[0024] The content described in the embodiments of this specification is only an enumeration of the implementation forms of the inventive concept. The protection scope of the present invention should not be regarded as limited to the specific forms stated in the embodiments. The protection scope of the present invention also extends to the field Equivalent technical means that the skilled person can think of based on the concept of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com