Reducing roll riveting mounting tool for knuckle bearing

A technology for riveting installation tools and joint bearings, which is applied in the field of variable-diameter rolling riveting installation tools for joint bearings, and can solve the problems of high cost, high production and processing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

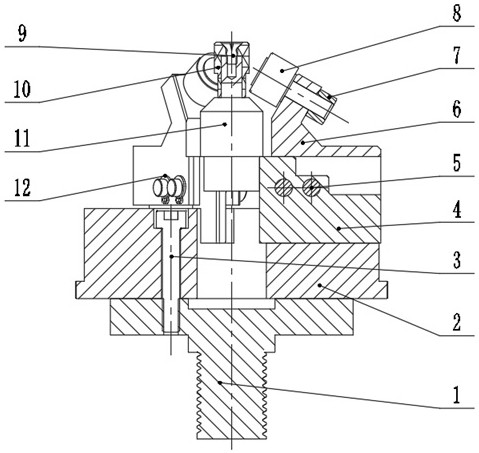

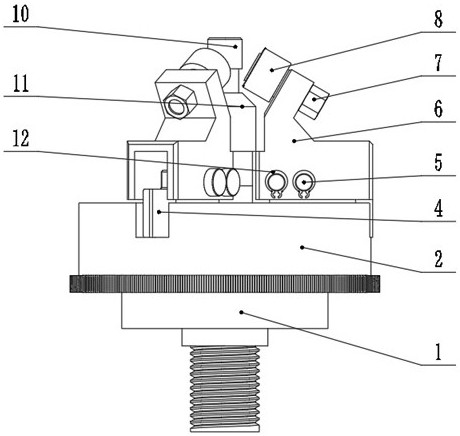

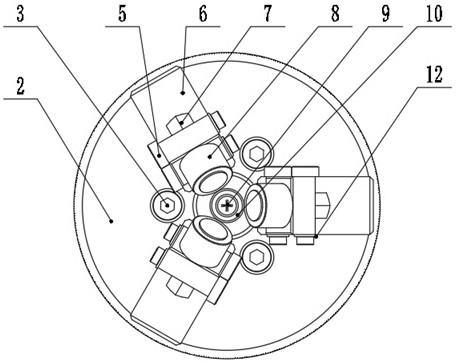

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

[0023] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, this embodiment is the structure of the rolling riveting installation tool for variable diameter joint bearings, including a connecting screw handle 1, a supporting plate body 2, three connecting handle mounting screws 3, three moving bodies 4, a fixed pin shaft 5, a fixed Mandrel circlip 12, three roller brackets 6, three rollers 8, three fixing nuts 7, positioning mandrel 11, lubricating sleeve 10, lubricating sleeve mounting screw 9, one end of connecting screw handle 1 is provided with external thread and equipment The main shaft is connected, and the other end of the connecting screw handle 1 is provided with a seam structure. After the connecting screw handle 1 and the support plate body 2 are positioned through the seam, three connecting handle mounting screws 3 are used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com