Long and thin pipe deep hole inner wall chromeplating self-centering clamping cap

A slender tube and self-centering technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of product performance degradation and the influence of the uniformity of the thickness of the chrome plating layer, etc., to achieve improved performance, high economic benefits and social value, Positioning Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

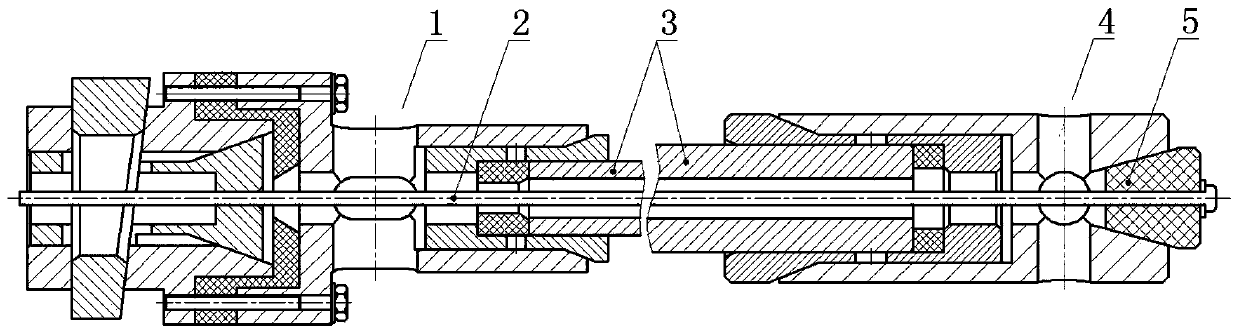

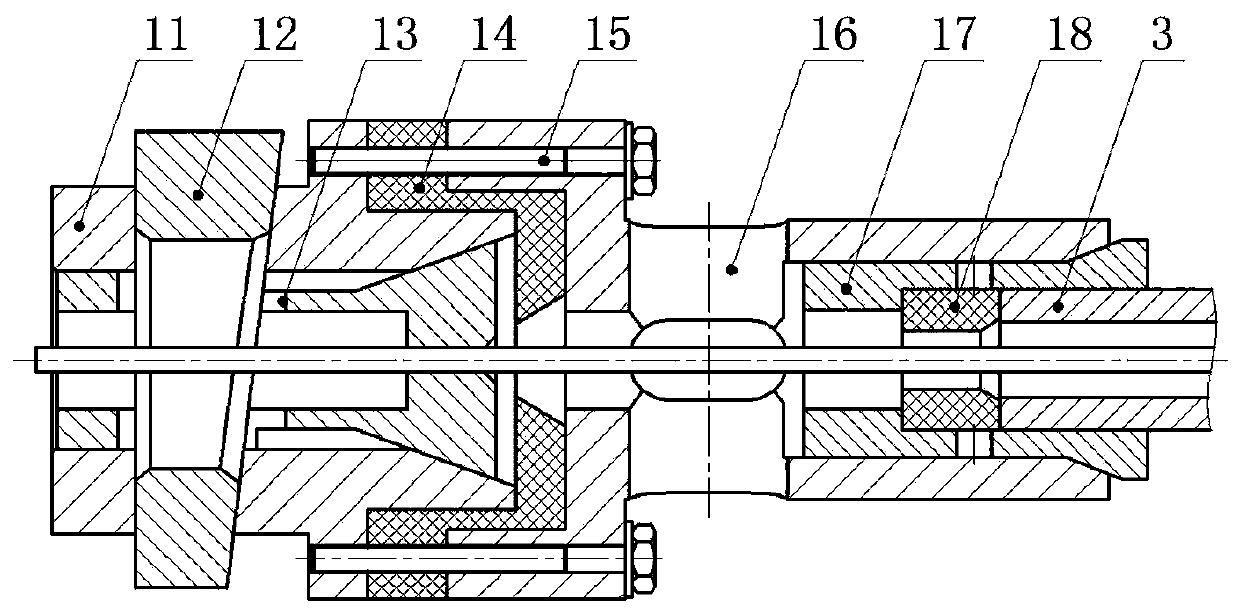

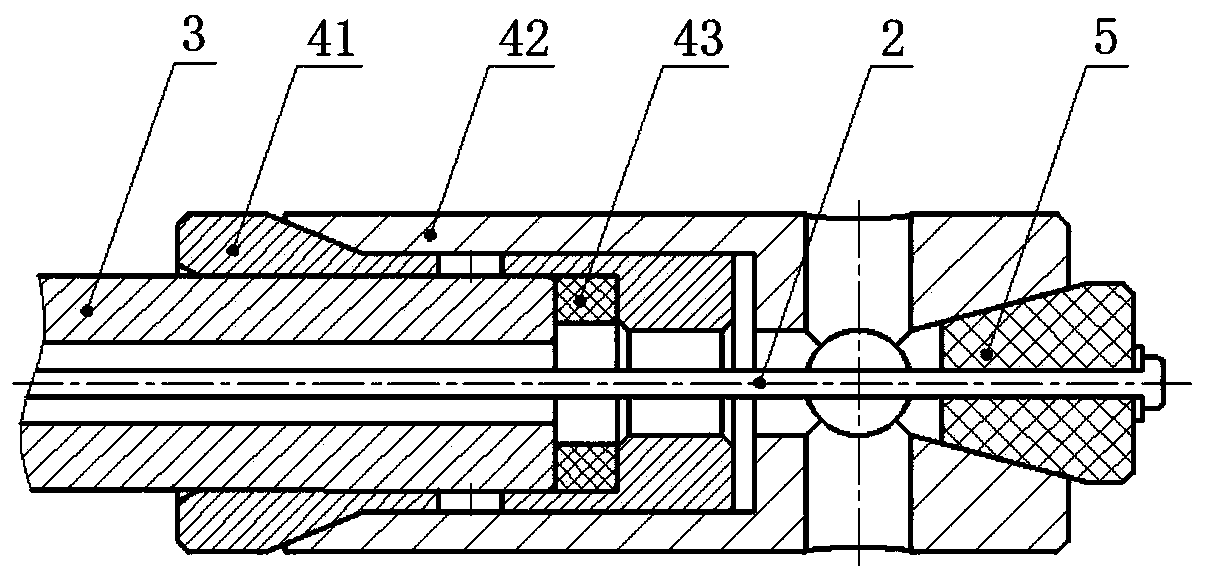

[0047] see Figure 1-Figure 11, a chrome-plated self-centering clamping cap on the inner wall of the deep hole of the slender tube. The inner wall of the deep hole of the slender tube is chrome-plated. The clamping cap includes two parts: an upper cap 1 and a lower cap 4. The main structure is a structure of revolution, the upper cap 1 and the lower cap 4 are clamped with a slender tube 3 (workpiece), the upper cap 1, the lower cap 4 and the central hole of the slender tube 3 are pierced There are anode steel wire 2, when chrome plating, the upper cap 1 and the lower cap 4 are respectively installed together with the two ends of the slender tube 3 through hole shaft cooperation, and the axis of the anode steel wire and the axis of the slender tube can be aligned on the same line through the clamping cap. On a straight line, make sure the two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com