Working face equipment positioning system based on image measurement

A positioning system and image measurement technology, applied in the field of positioning systems, can solve problems such as the difficulty in accurately judging the relative position of equipment, affecting the normal production of the working face, endangering personal safety, etc., to avoid adverse effects, less intermediate links, and fast positioning accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

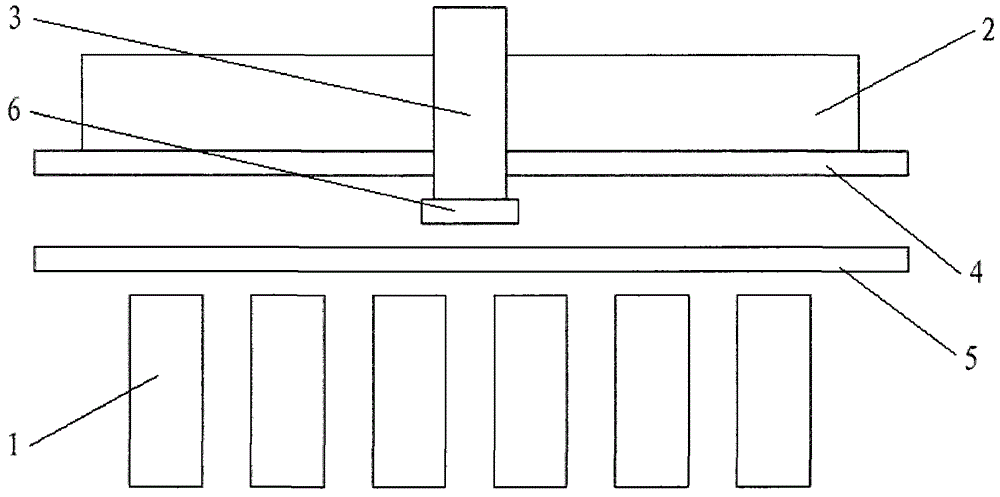

[0014] See attached figure 1 , which describes a preferred embodiment of the image measurement-based working face equipment positioning system according to the present invention. The working face equipment positioning system based on image measurement is used for positioning control of working face equipment, wherein the working face equipment mainly includes coal shearers, hydraulic support groups and scraper conveyors, and of course may also include other equipment. The working surface hydraulic support group consists of a plurality of hydraulic supports. In this embodiment, the number of hydraulic supports is 6, and a video camera is arranged on the hydraulic support. The conveyor is composed of multiple chutes, each of which is pasted with identification tapes, and each identification tape forms the first video identification belt, the second video identification belt is set on the ground in front of the hydraulic support group, and the third video identification belt is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com