Exhaust structure of rotary piston type internal combustion engine

A technology of rotary piston and internal combustion engine, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problems of large space, special structure, difficulties, etc., and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

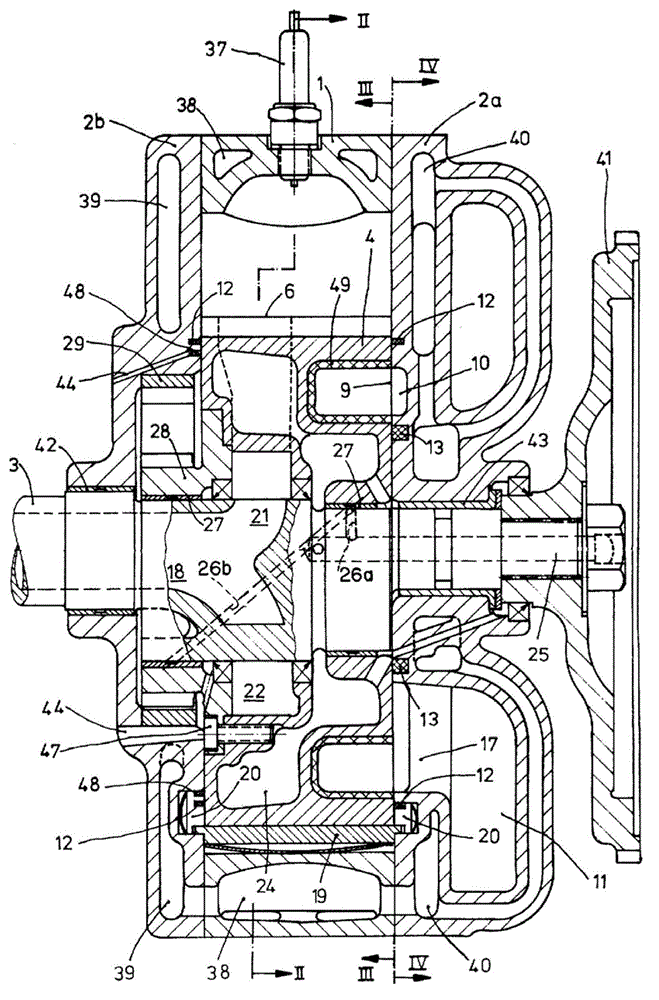

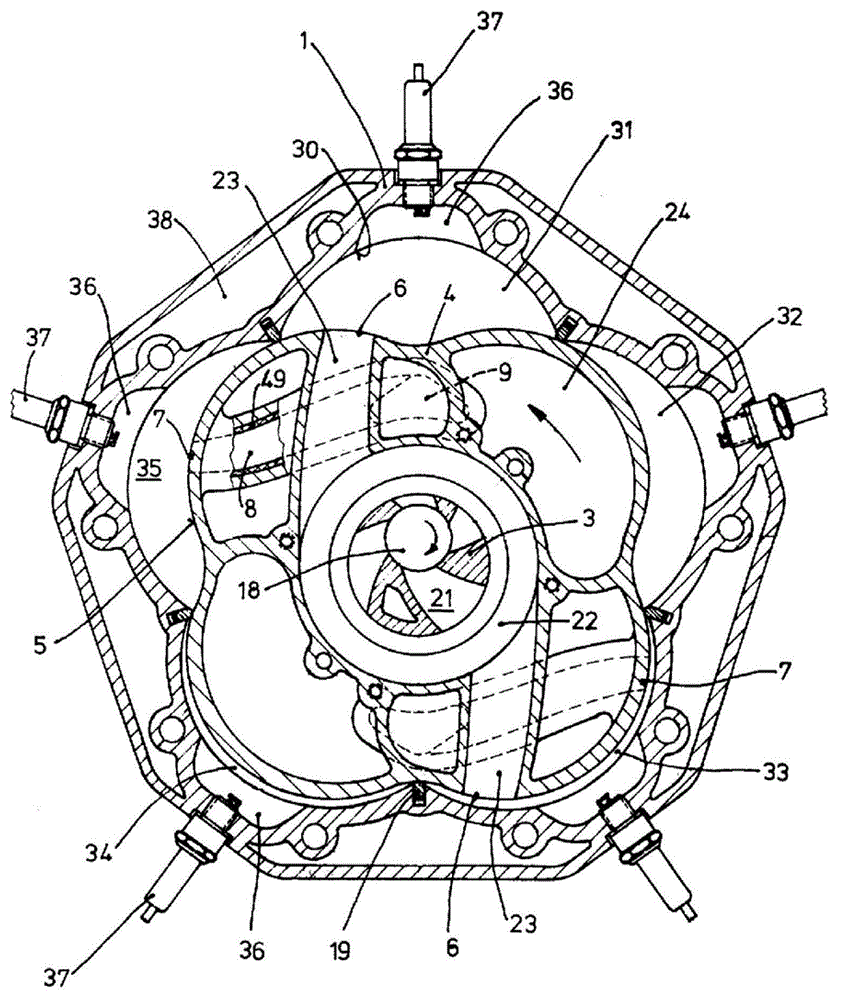

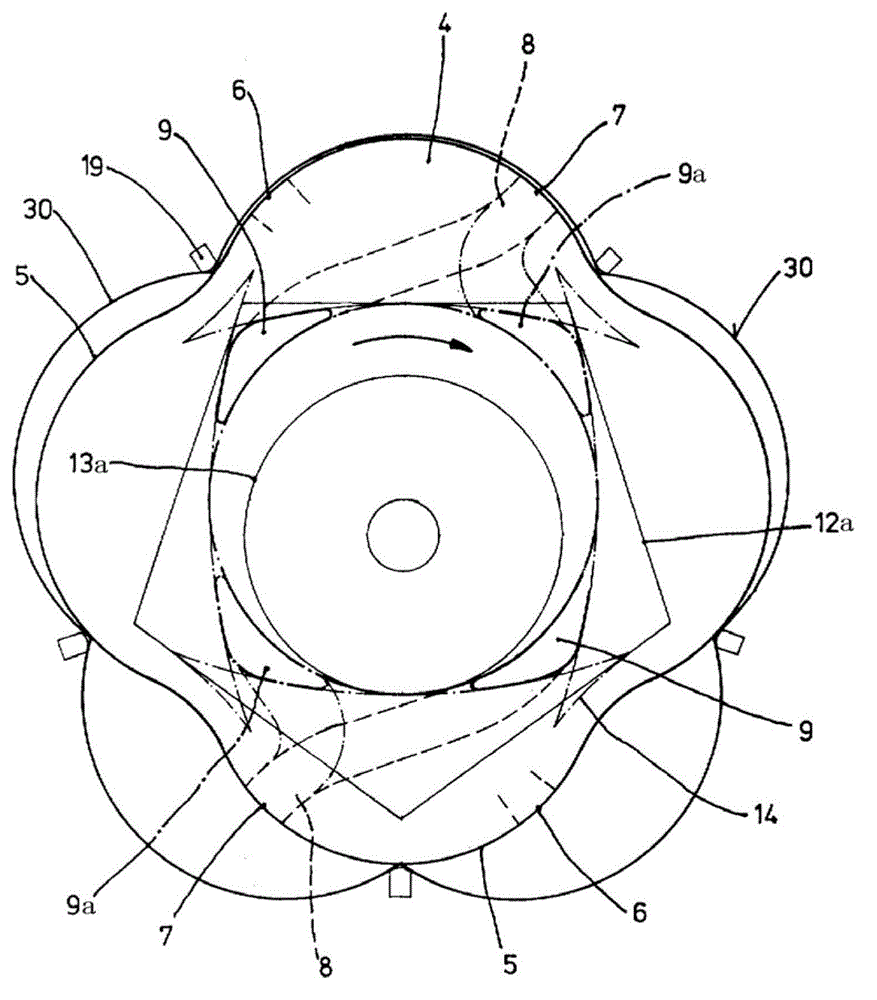

[0019] Such as figure 1 with 2 Shown is an exhaust structure of a rotary piston internal combustion engine of the present invention, comprising a box body and an eccentric shaft 3 composed of a first mechanism 2a, a second mechanism 2b and an intermediate mechanism 1, and the intermediate mechanism 1 is arranged on the first mechanism 2a and the second mechanism Between the two mechanisms 2b, the eccentric shaft 3 runs through the entire box and is connected to the flywheel 41 at its driving end. The eccentric shaft 3 is radially installed on the first mechanism 2a and the second mechanism of the box through the first bearing bush 42 and the second bearing bush 43. On part 2b, the intermediate mechanism 1 is provided with a piston device 4, and the piston device 4 is fixed on the box body by bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com