Bearing device for armature shaft of transmission drive unit and transmission drive unit

A technology of drive unit and bearing device, applied in the direction of bearing element, electromechanical device, shaft and bearing, etc., can solve problems such as consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

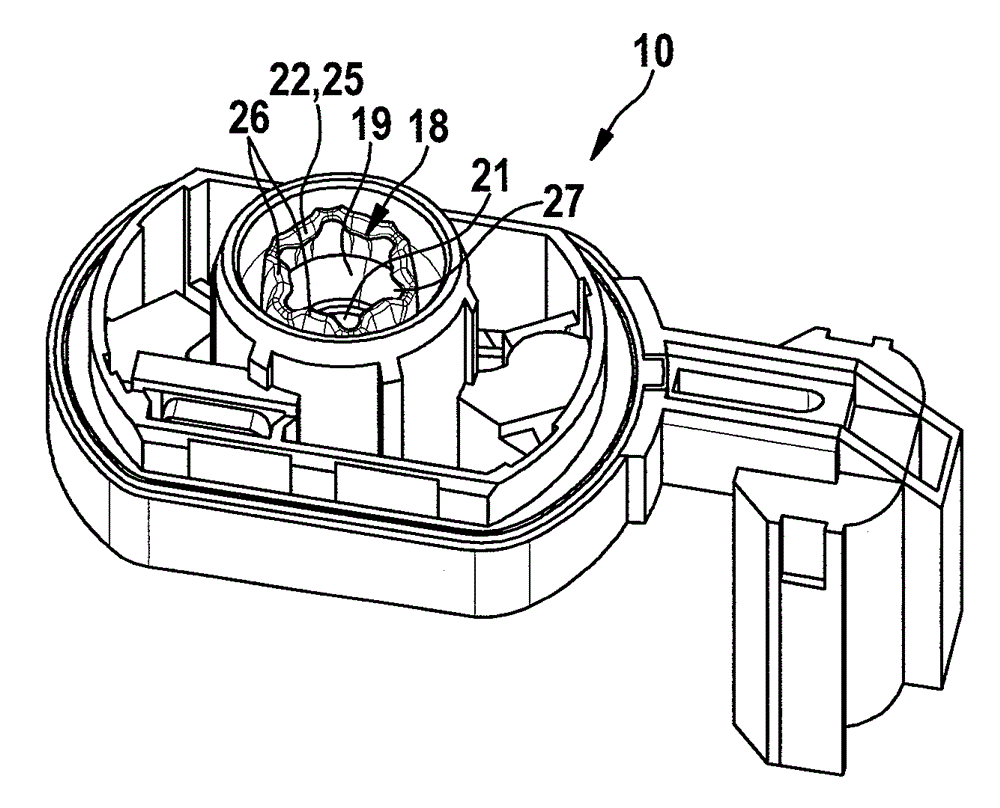

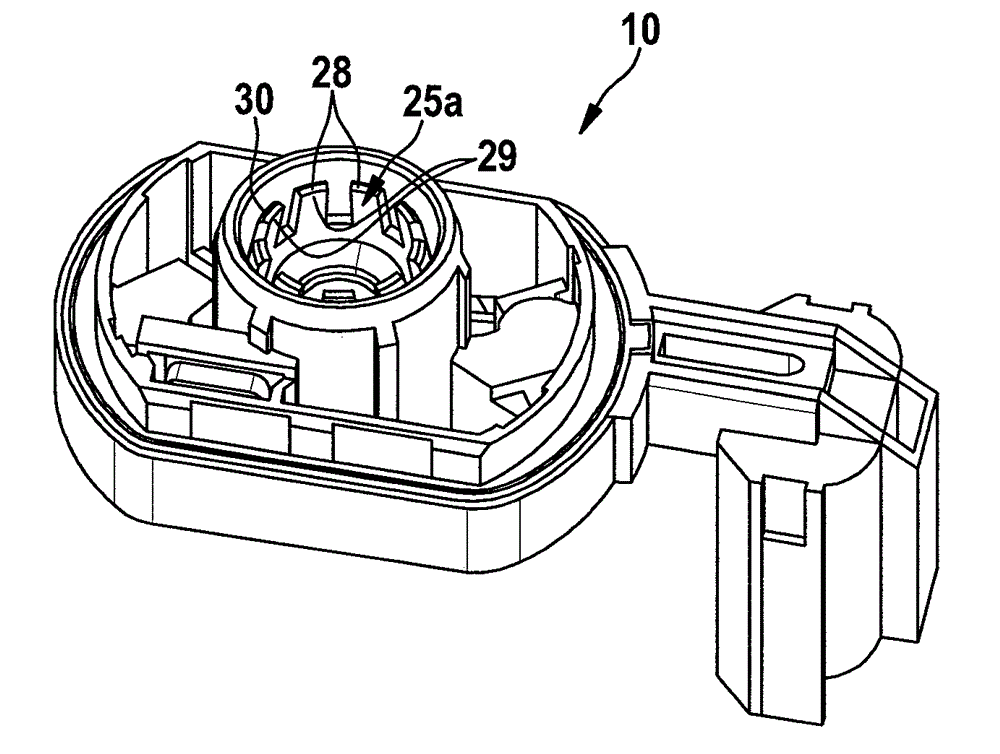

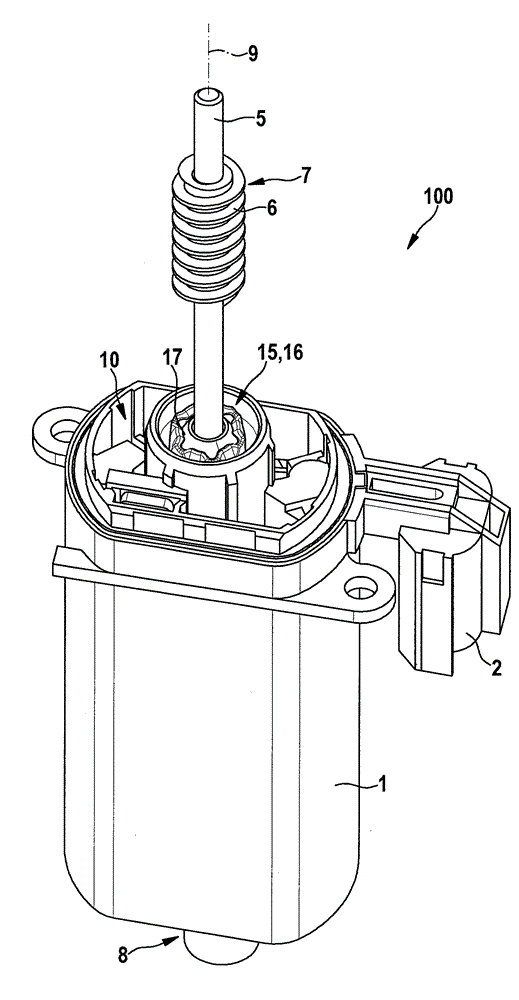

[0020] exist figure 1 A motor housing 1 is shown as a component of a transmission drive unit 100, except for the motor housing, the rest of the electric motor is not shown in the figure, the electric motor is used as a window lift drive, Seat adjustment drives and the like are used in a motor vehicle. The motor housing 1 is connected end-face to a transmission housing (not shown), in which a transmission is arranged, the driven element of which is usually designed as a driven shaft for at least indirect Adjust a component (seat, window, etc.) Arranged within the motor housing 1 are the components of the electric motor, which can be electrically connected, in particular via a plug connection 2 arranged on the motor housing 1 , to a cable harness of the motor vehicle. .

[0021] An armature shaft 5 protrudes from the end face of the motor housing 1 facing the transmission housing, which armature shaft has a drive worm 6 over part of its length, which has a helical toothing 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com