Piston-cylinder assembly

A technology of pistons and equipment, applied in the field of shift transmissions, can solve problems such as structural space limitations of transmission regulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

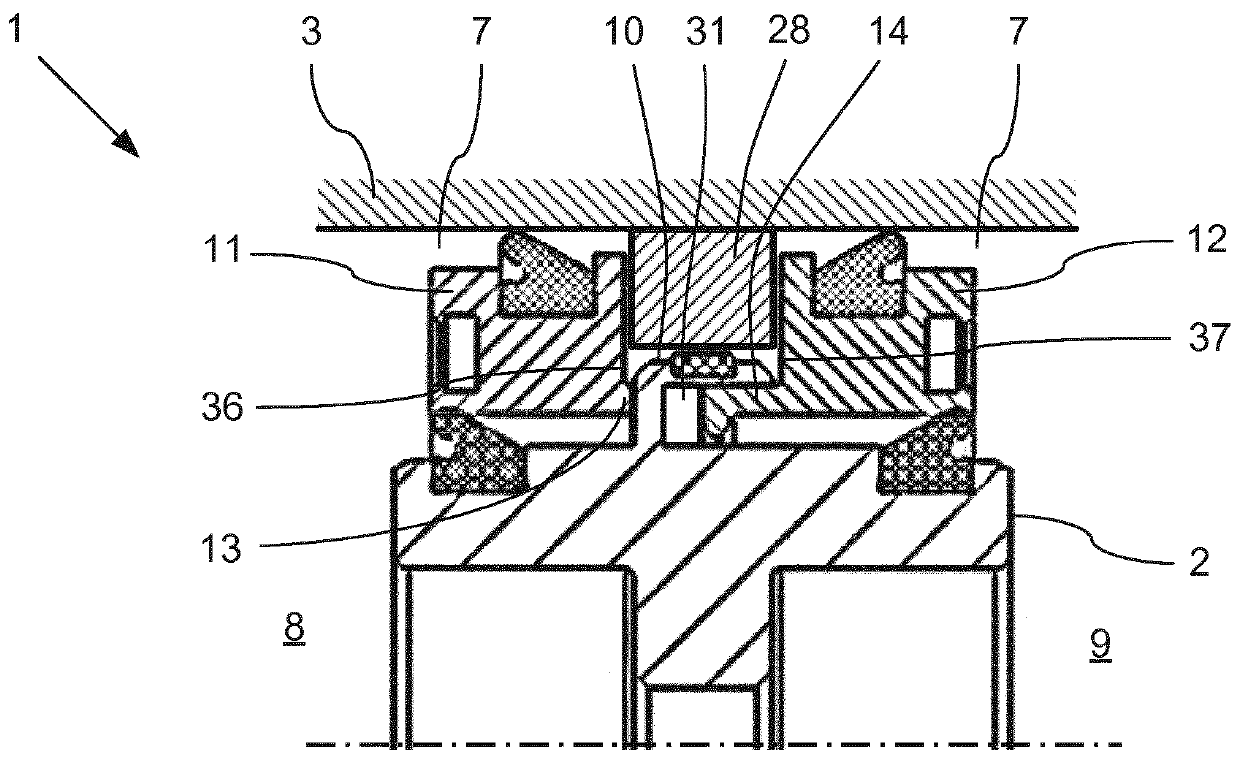

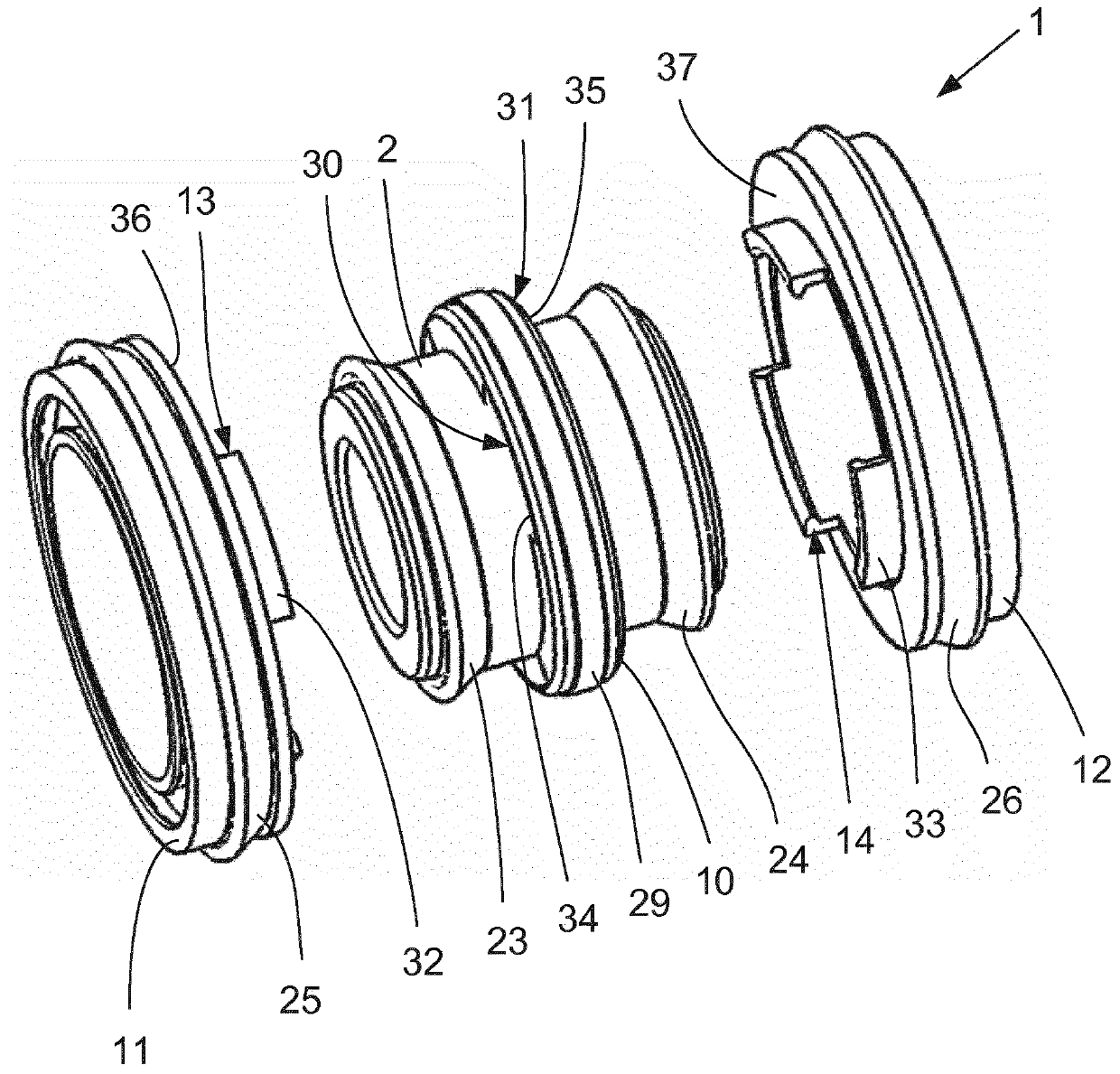

[0036] exist Figure 4 The piston-cylinder arrangement 1 .1 already explained above is illustrated in FIG. 1 , which is known from the prior art. In contrast, in figure 1 and figure 2 The piston-cylinder arrangement 1 according to the invention illustrated in , has a main piston 2 and two traction pistons 11 , 12 in a space-saving arrangement. For this purpose, a circular piston land 10 is formed on the main piston 2 , which has two circular axial depressions 30 , 31 facing away from each other. The first recess 30 is open towards the first traction piston 11 and the second recess 31 is open towards the second traction piston 12 . On the two traction pistons 11 , 12 are respectively formed two circular pushing sections 13 , 14 , which are adapted in terms of their geometry and dimensions to the two recesses 30 , 31 in the main piston 2 . The first traction piston 11 therefore has a first push section 13 which is aligned with the first depression 30 of the piston land 10 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com