Vibration sensor

A sensor and piezoelectric module technology, applied in the field of sensors to achieve the effect of improving image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

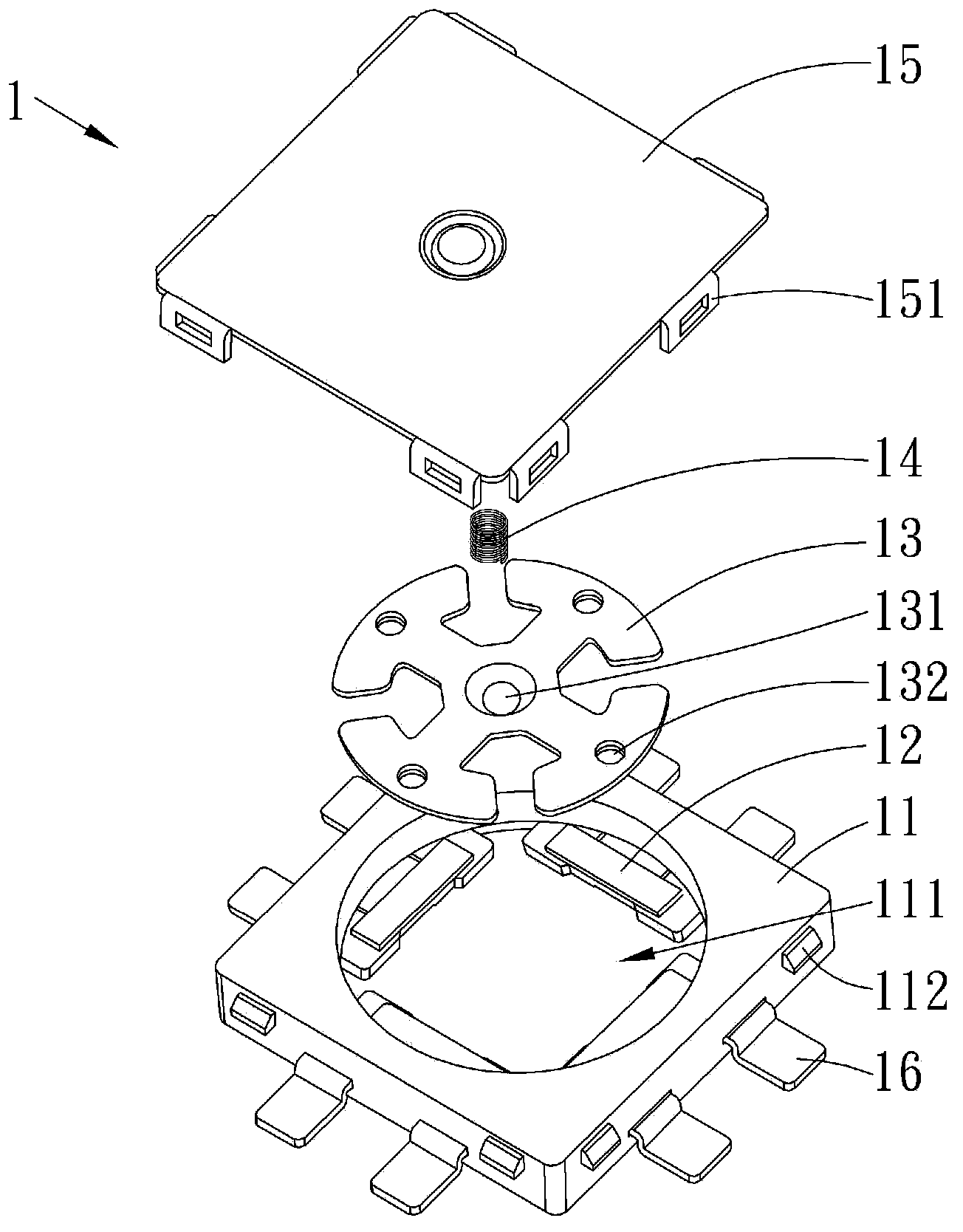

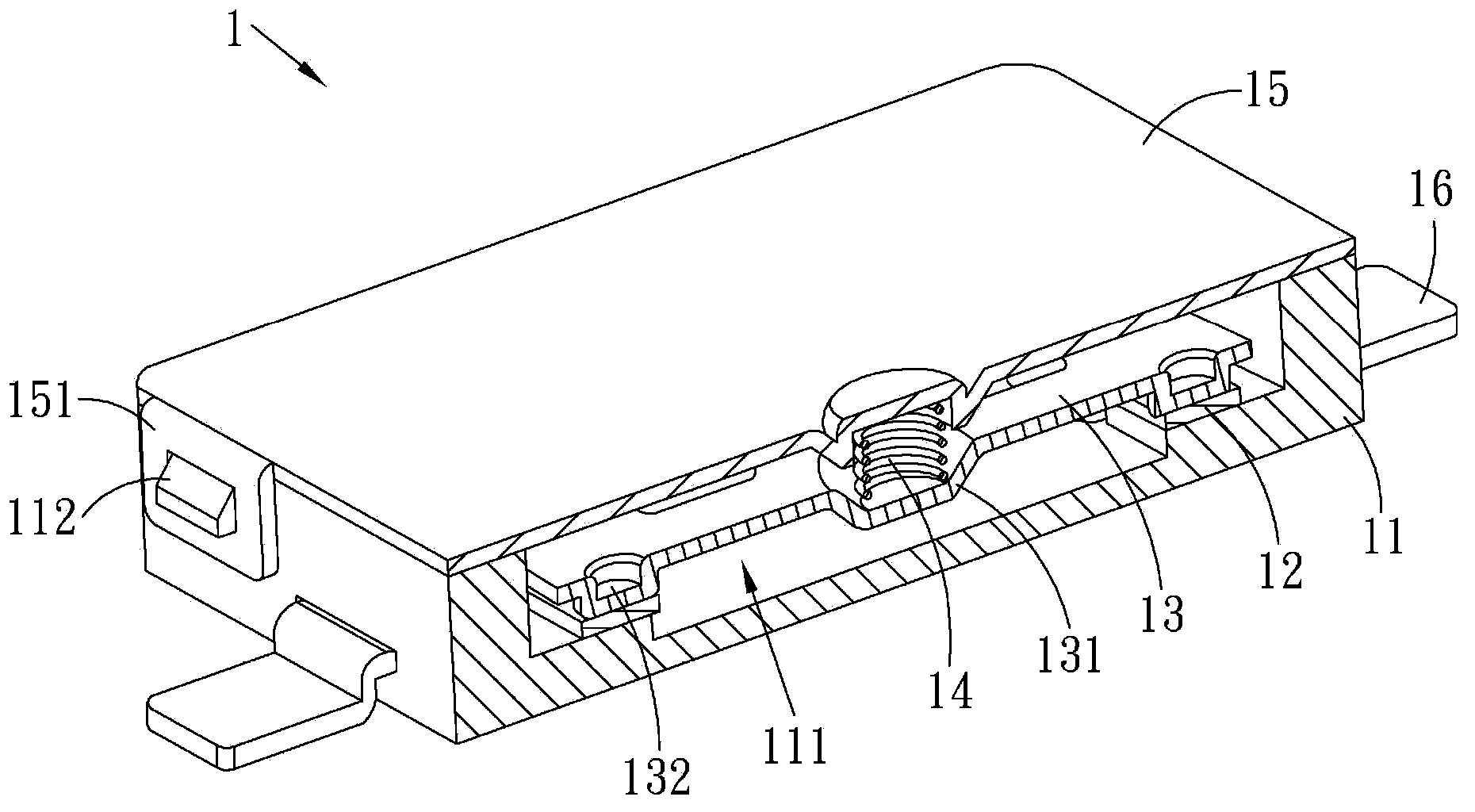

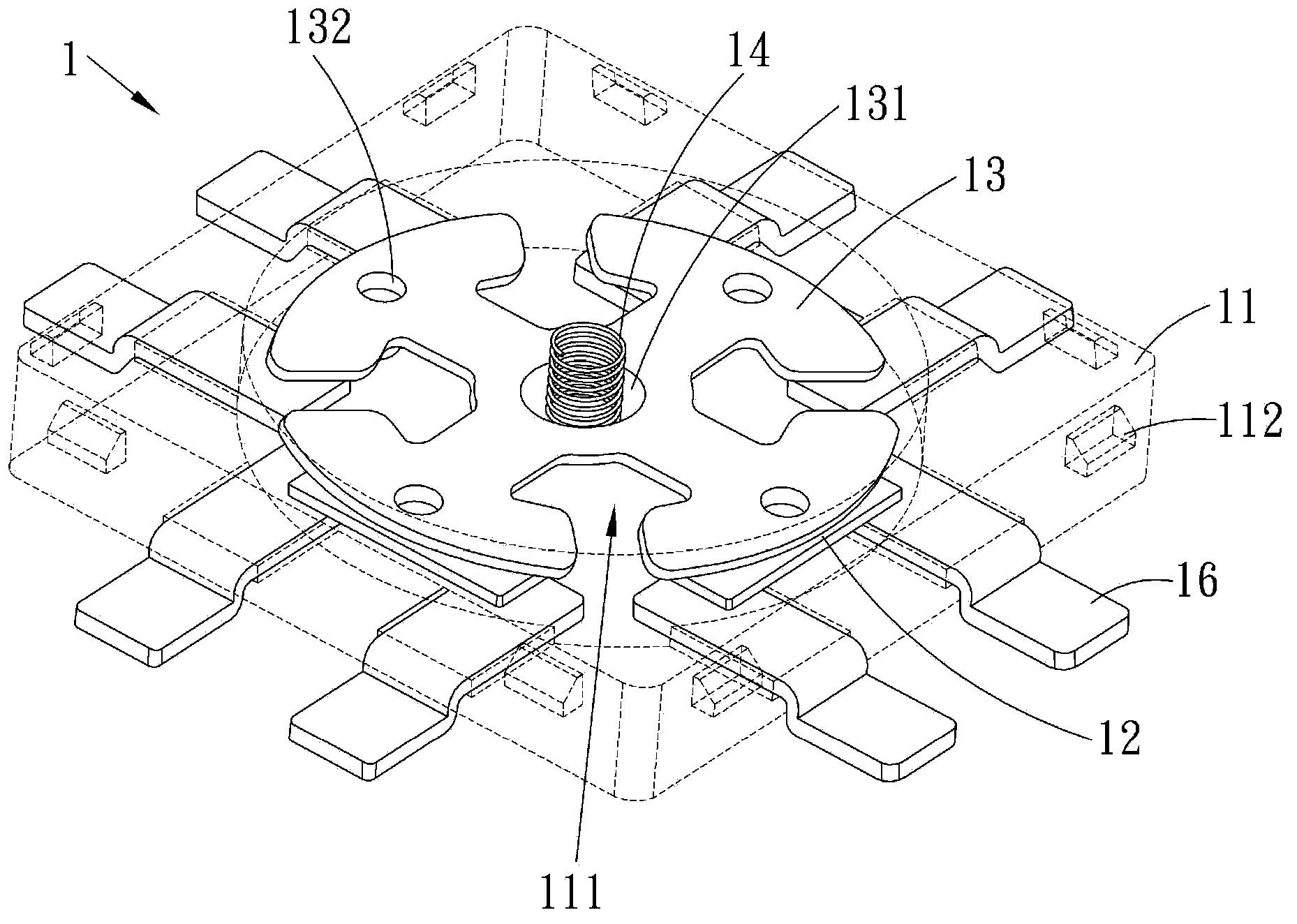

[0020] Please also refer to Figure 1 to Figure 3 , figure 1 It is an exploded view of an embodiment of the vibration sensor of the present invention, figure 2 It is a sectional view of an embodiment of the vibration sensor of the present invention, image 3 It is a perspective view of an embodiment of the vibration sensor of the present invention. As shown in the figure, the vibration sensor 1 of the present invention includes a housing 11 , a plurality of piezoelectric modules 12 , a joint module 13 , a stabilization module 14 , a plurality of sensing modules 16 and a cover 15 . The casing 11 includes a second connecting portion 112 , and an accommodating groove 111 is disposed in the casing 11 . A plurality of piezoelectric modules 12 are disposed in the accommodating groove 111 , and a geometric center of each piezoelectric module 12 corresponds to a central point of the accommodating groove 111 . The bonding modules 13 are disposed in the accommodating grooves 111 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap