Coil component

A technology of coil components and lead parts, which is applied in the direction of electrical components, transformers/inductor coils/windings/connections, transformers, etc., can solve the problem of insulation distance hindering the miniaturization of coil components, and achieve the increase of design freedom and the reduction of parts Number of pieces, easy effect of thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

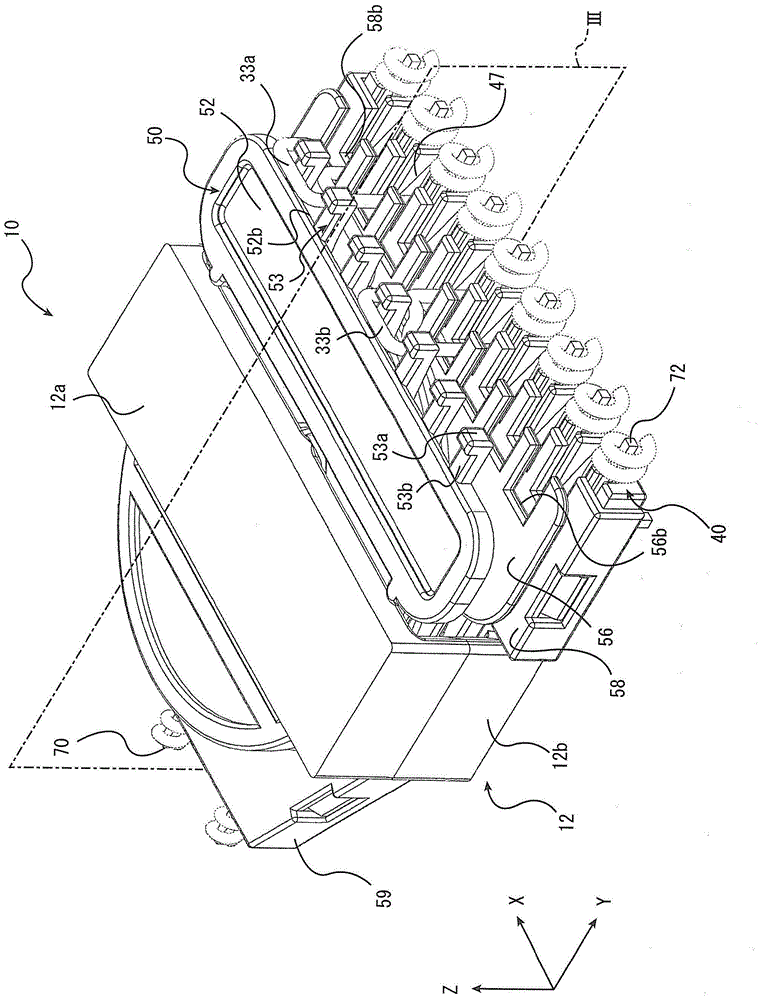

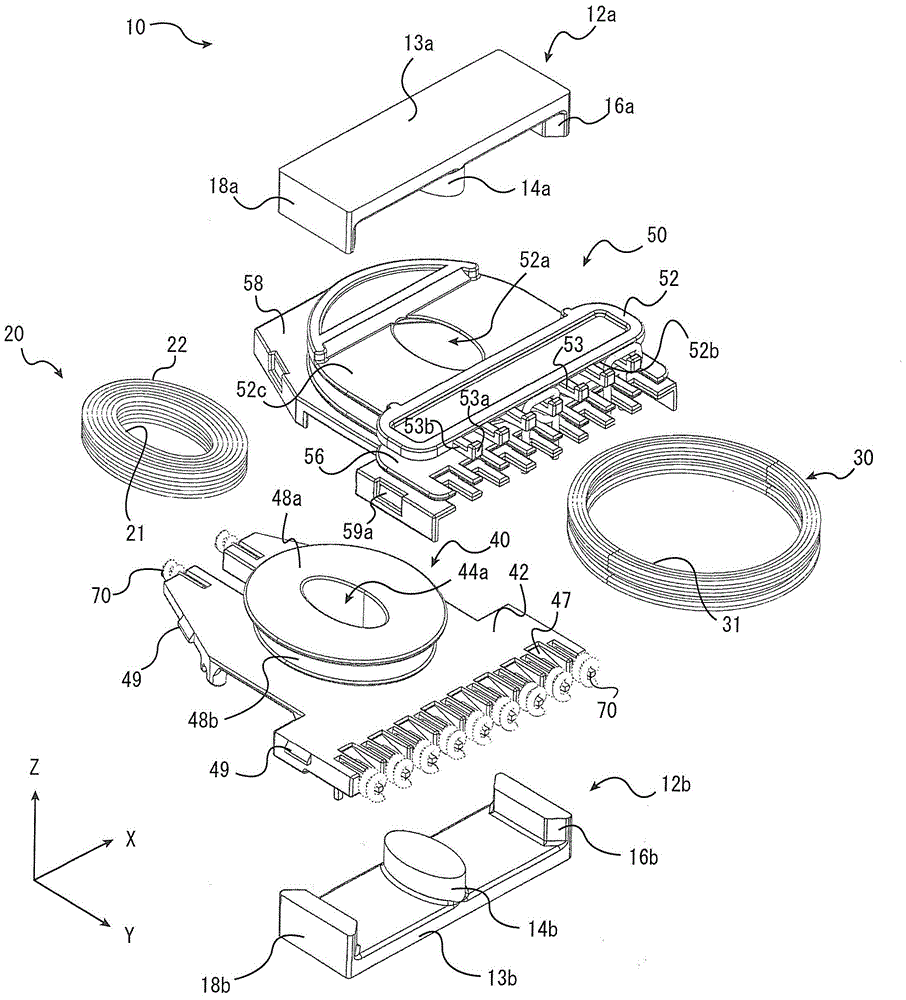

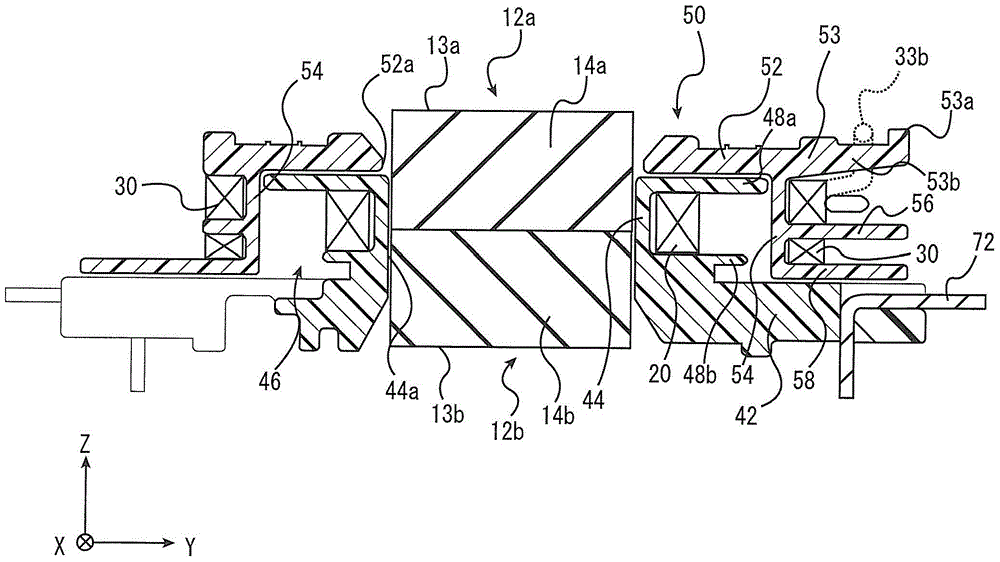

[0039] as a whole stereogram figure 1 and as an exploded perspective view figure 2 As shown, a coil component 10 according to an embodiment of the present invention has a core 12 , a bobbin 40 , a case 50 , a primary coil 20 , and a secondary coil 30 .

[0040] The core 12 of the coil component 10 is formed by forming a magnetic path through which a magnetic flux generated by a coil described later passes and assembling two separately formed members, that is, a first core 12a and a second core 12b. The first core 12 a and the second core 12 b have symmetrical shapes, and are joined to each other so as to sandwich the case 50 and the frame 40 from the vertical direction (the Z-axis direction in each figure).

[0041] like figure 1 As shown, the cores 12 each have a first core 12 a and a second core 12 b each having a substantially E-shaped longitudinal section (cross section including the X-axis and the Z-axis). like figure 2 As shown, each core 12a, 12b is composed of a ...

no. 2 Embodiment approach

[0077] Figure 5 It is a perspective view of the case 50a used for the coil component which concerns on 2nd Embodiment of this invention. The coil component according to the second embodiment is the same as the coil component 10 according to the first embodiment except that the shape of the upper flange protrusion 81 in the case 50a is different. Upper flange protrusion 81, with figure 1 The shown upper flange protrusion 53 does not have the locking portion 53a, but by appropriately securing the protruding length in the Y-axis direction, it is possible to prevent the lead wires 33a, 33b engaged with the upper flange protrusion 53 from occurring. fall off. The coil component according to the second embodiment can also obtain the same effects as those of the coil component according to the first embodiment.

no. 3 Embodiment approach

[0079] Image 6 It is a perspective view of the case 50b used for the coil component which concerns on 3rd Embodiment of this invention. The coil component according to the third embodiment is the same as the coil component 10 according to the first embodiment except that the shape of the upper flange protrusion 82 in the case 50b is different. The upper flange portion 82 has an upper groove portion 82c opened upward, and a locking portion 82a connected to the front end side of the upper groove portion 82c. Passing through the upper groove portion 82c when the lead portions 32a, 32b are engaged with the upper flange protrusion 82 prevents the lead portions 33a, 33b from falling off and stabilizes the positions of the lead portions 33a, 33b. The coil component according to the third embodiment can also obtain the same effects as those of the coil component according to the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com