Contact element for use in sliding contact

A technology for contacting elements and holding elements, applied to electrical components, connections, current collectors, etc., can solve problems that affect the performance or efficiency of electric motors or generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

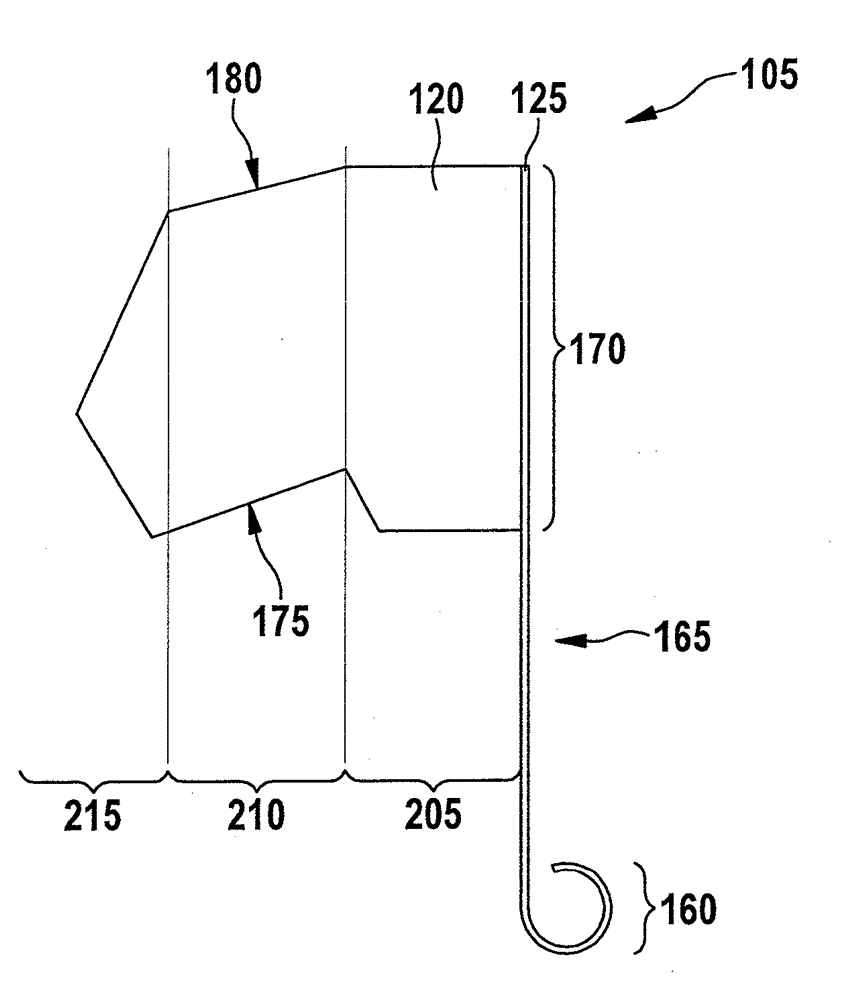

[0024] figure 1 A sliding contact 100 is shown, for example for commutating an electric motor or a generator. The sliding contact 100 includes a contact element 105 and a slideway 110 . In the illustrated embodiment, the slideway 110 is arcuate about a rotational axis 115 of the electric motor. In other embodiments, the sliding contact 100 can also be used on another device, for example a sliding contact for an antenna or a longitudinal stack. In other embodiments, the runner 110 also does not have to be curved, but can also extend, for example, in a plane.

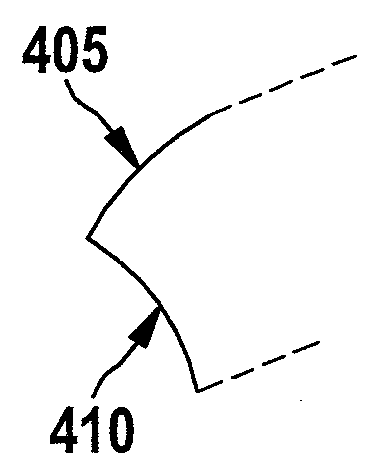

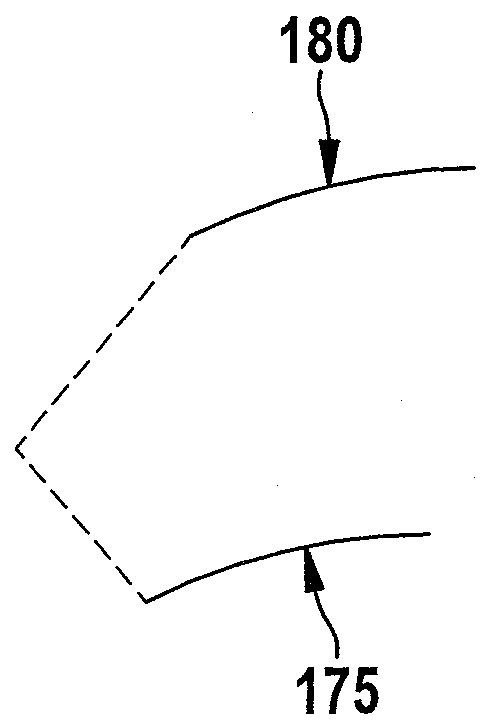

[0025] The contact element 105 includes a brush 120 , a holding element 125 and an elastic element 130 . The brushes 120 are designed to bear against the slideway 110 . The cross-section of the brush 120 is generally rectangular, but other shapes are also possible. The abutment of the brush 125 on the slideway 110 is formed by a surface 135 which has a rising edge 140 and a falling edge 145 with respect to an assumed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com